Model overview

Let's analyze the most popular modifications of a diesel generator (DGU) with auto start.

DGS 5 kW

The models are intended for personal use. Compared to industrial ones, they cannot function for days, but the motor power is enough for a steady supply of electricity for up to 10 hours.

They can be used both in a private house and on construction sites.

DGS 6 kW

These units are of high build quality and economy. They are used as sources of power supply of an autonomous type in trade kiosks, private houses, and workshops.

The stations make it possible to protect expensive electrical equipment from breakdowns in case of power supply problems. They support the work of various organizations in a normal mode during a power outage.

DGS 7 kW

They can supply several consumers in parallel or one, but with significant inrush currents. You can connect electric tools, garden equipment, power plants. The equipment is practiced both permanently and for work outside the territory, for example, in the construction business, when carrying out road repairs, and so on.

DGS 15 kW

Optimal generator for its power. It is quite comfortable, since it has a small size and is practical for using it as a spare power source. In places where a cold start is required, this unit is simply irreplaceable. DGS can be both mobile and stationary.

DGS 10 kW

It is a reliable and inexpensive power source capable of withstanding continuous load and continuous operation.

Suitable for uninterrupted supply of electricity to a cottage, house, small warehouse or shop. Compact and reliable in operation, the unit with a different list of possibilities stands out for ease of maintenance, low noise level and good productivity.

DGS 20 kW

It is a compact and reliable unit that combines high productivity, reasonable cost and versatility. The station generates and conducts a current of 220/240 V with a frequency of 50 Hz to power equipment, devices and installations of various types and purposes. The unit is practiced as a backup source of electricity, as well as as a key power supply for electrical appliances in offices, cottages, houses, on not very large industrial and construction sites.

DPP 30 kW

It is practiced as an electrical substation that supplies electricity to autonomous facilities. The unit uses advanced technologies, it has ideal technical capabilities. Through the transmission shaft, the torque from the internal combustion engine is sent to the rotor. There, an electric current is generated in the stator windings.

DGS 100 kW

Produces current for users who need energy either permanently or temporarily. In the structure of the structure of the power plant there is an electromagnet-rotor, which is driven by the internal combustion engine. The installation is not only simple, reliable, but also characterized by a relatively inexpensive cost of electricity.

250 kWt

A unit for supplying a large number of consumers with electricity without interruptions. Energy is generated in the internal combustion engine when the fuel is ignited. Then, by means of the transmission shaft, it is sent to the rotor magnet. Rotating in the stator, it contributes to the appearance of the load current.

Device

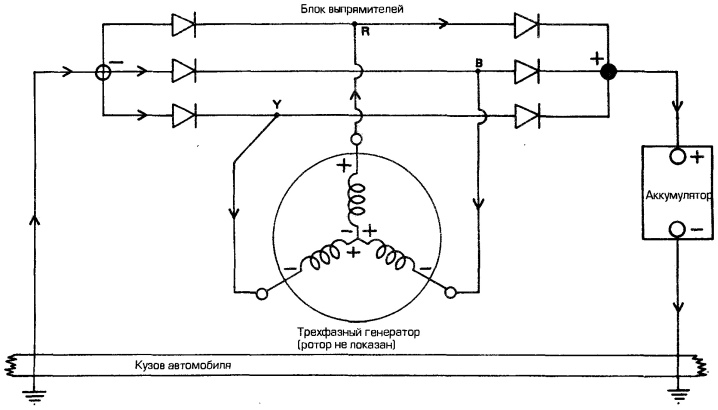

The purpose of an electric generator is to convert mechanical energy into electrical energy. It consists of 2 main parts - a moving rotor and a fixed stator.

- The rotor is mounted on bearings. On the one hand, a drive from an external source of motion is connected to it, and on the other, an impeller for cooling.

- The stator is a fixed element. It contains the mounting feet of the unit, cooling fins and output terminals. And also a plate with technical characteristics.

Other components.

- Rotor sliding contact. It is necessary to power its windings or to drain the generated electricity. Most models do not have it.

- Indicator and control means.

- Side covers.

- Oilers for supplying grease to bearings and other equally important elements.

Now you need to understand the method of obtaining electricity.

Connection diagrams

The main task when connecting to the existing power grid is to prevent the "meeting" of the generated current and that coming from the power plant. Otherwise, the consequences will be dire.

To solve this problem, there are several methods for connecting the generator to the mains.

Through an outlet

The easiest method. Consumers are connected directly to the generator. But there are serious disadvantages:

- complete absence of protective devices;

- you need to buy a special 4-pole outlet, designed for high current.

This method is strongly discouraged. We wrote about him only because he exists.

Through the distributor machine

This is a more convenient method as it does not require any changes to the existing electrical network. It has proven itself especially well in private homes.

Follow the steps below to connect.

- Switch off the input circuit breaker of the centralized power distribution system. Simply put, de-energize the house.

- Install a new 4-pole circuit breaker in the dashboard. Connect its output contacts to the home network.

- Carefully connect the generator cable to the new machine. All wires are connected to the corresponding terminals.

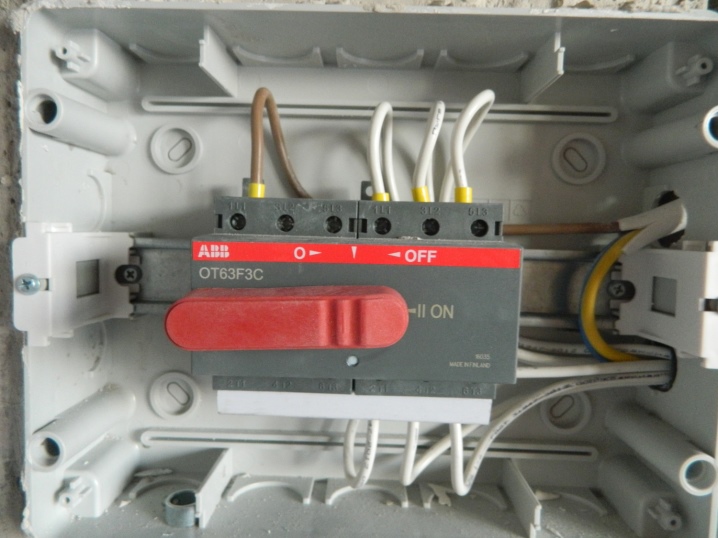

Through the switch

The main disadvantage of the previous scheme is the possibility of mains voltage entering the generator. This can happen if the switches are not used carefully. To prevent this from happening, the generator can be connected through a switch.

Such a connection completely eliminates the possibility of a short circuit. The switch has 3 contacts:

- the first - power supply of consumers from a centralized network;

- third - power supply from the generator;

- central - the network is completely de-energized.

Consumers are connected to the central contact.

After the switch, fuses, RCDs and other protective equipment must be installed.

In this way, the main generators are connected.

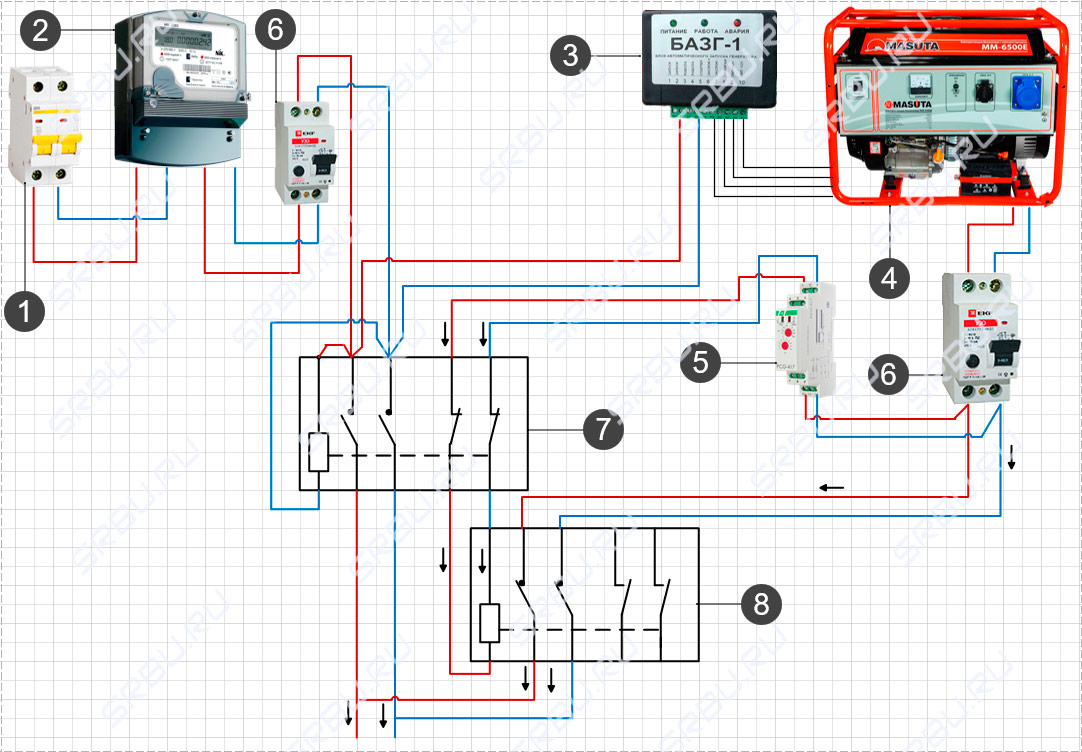

Automatic activation system

The main disadvantage of all these methods is manual control. And sometimes it is necessary for the generator to start automatically (especially in emergency situations). In these cases, an automatic activation system is used.

It includes 2 cross starters and a control module. In the event of a power outage, they disconnect consumers from the centralized system and connect to a generator.

Regardless of the connection method, never forget to ground the generator frame. And most importantly: switching devices, switches and fuses must not be placed in the ground wire. This will prevent accidents and guarantee the safe operation of the device.

About which generator to buy: single-phase or three-phase, see below.

Gasoline generator ТСС SGG 5000 EH

Check out these articles as well

-

Drill storage

-

High-quality and reliable furniture for arranging your own home

-

Porcelain stoneware for floors and walls

-

Features of the use of vibratory ramming soil

Single-phase gasoline generator TCC SGG 5000 EH with electronic start equipped with a wheel set and handles for ease of movement. It is absolutely indispensable for many situations where an inexpensive, mobile, unpretentious and easy-to-use source of independent power supply is required.

A gas generator with a maximum power of 5.5 kW will not only perfectly cope with the creation of a backup power supply in cases of power outages, but also guarantee stable operation as the main power source. The electric generator runs on AI-92 gasoline.Recommended SAE 10W30 oil.

Photo of gasoline generator ТСС SGG 5000 EH

Technical characteristics of the gas generator TCC SGG 5000 EH

| Specifications | Parameter |

| Inverter | No |

| Welding function | No |

| Frequency | 50 Hz |

| Engine model | Wester EM420 |

| Fuel consumption | 2.77 l / h |

| Fuel type | Petrol |

| Automatic regulation of AVR output voltage | there is |

| Produced by | China |

| Overall dimensions, mm) | 825 x 540 x 580 |

| Operating time without refueling | 9 o'clock |

| Oil tank capacity (l) | 1.1 |

| Engine power | 16 l. with. |

| Fuel tank capacity (l) | 25L |

| Maximum power | 5.5kw |

| Noise level (dB) | 72 |

| Voltmeter | there is |

| Engine displacement (cc) | 420cc |

| Power, kWt) | 5kw |

| Weight, kg) | 89 |

| Voltage (V) | 220 V |

| Number of cylinders (pcs) | 1 PC |

| Start type | electric starter |

| Wheels and handles | Yes |

| Guarantee | 3 years |

Fubag TI 2600

One of the best inverter gasoline generators in its class, with an operating power of 2.3 kW (maximum 2.6 kW), the unit weighs only 26 kg. Lightweight, mobile and productive, the option is quite economical and easy to operate. The only constructive disadvantage is that a separate drain for oil is not provided in the oil sump, therefore, to replace it, the device must be tilted 90 degrees in order to drain it through the filler neck.

The device is distinguished by a competent execution: high-quality assembly, a reliable 4-stroke engine, an economical mode of operation and an oil level sensor are provided. The volume of the fuel tank in the gasoline generator is small - 4.6 liters, but at a flow rate of 1.1 liters / hour, this is enough for 4 hours of autonomous operation, in addition, this reduces the total weight of the unit. The generator can be connected to two electrical appliances with a voltage of up to 230 V at the same time, plus there is a 12 V output for charging the battery. In addition to all the advantages, the TI 2600 is one of the quietest gasoline generators, with a noise level of only 60 dB.

Advantages:

- low weight with good performance

- inverter voltage control

- oil level indicator

- two 220 V sockets

- low noise level

Disadvantages:

- small volume of gas tank

- complicated oil change process

How to connect?

As important as the characteristics of a diesel generator set are in themselves, they mean nothing without a mains connection. The wiring diagram is simple and allows you to change almost nothing in the home wiring. First, turn off the 380 V input circuit breaker, thereby turning off all devices. Then they put an updated four-pole machine in the dashboard. The terminals of its outputs are connected to the taps for all the necessary devices.

Then they work with a cable that has 4 cores. It is brought to a new machine, and each core is connected to the corresponding terminal. If the circuit also includes an RCD, then the switching must take into account the peculiarities of the wiring of the conductors. But the connection via an additional automatic distribution machine does not suit everyone.

In this case, the busbars are connected to one, the high-voltage supply conductors to the other set of poles. The main contact assembly of the circuit breaker is the one from which the conductors are brought directly to the load. The switch is thrown to the input from the high-voltage line or from the generator. If the switch is in the middle, the electrical circuit is broken. But manual selection of a power source is not always convenient.

Automatic load transfer always activates the control unit and a pair of contactors. The starters are cross-connected. One unit is made on the basis of a microprocessor or a transistor assembly. He is able to recognize the loss of power supply in the main network, disconnection of the consumer from it. The contactor will also work out the situation with switching devices to the generator outlet.

The following video demonstrates testing a 6 kW three-phase generator.

Peculiarities

It should be said right away that diesel three-phase generators can be used both for domestic needs and for small industrial enterprises.As such, they are even preferable, because they provide more power than gasoline counterparts. And therefore, the high price of diesel vehicles is fully justified.

The main specificity of diesel generators with 3 working phases is also:

-

the use of relatively inexpensive fuel;

-

increased efficiency;

-

the ability to connect to several energy consumers at once;

-

resistance to significant loads and even drops in the network;

-

mandatory presence of a bundle with a three-phase network;

-

commissioning only by people with special permission.

Varieties of diesel generators

Diesel generators designed for 10 kW are small in size. They are conventionally classified into two types according to the execution format: frame and bonnet. The former have an open design. They are used indoors or outdoors in good weather.

The second ones are reliably protected by a metal box. It resembles a locker with hinged doors allowing easy access for station maintenance. The presence of special insulation in the structure helps to reduce the noise level. Such a design is relevant in places where a significant noise load is not allowed, there is a risk of dust, moisture, etc. penetrating the unit. The stations differ in their rated current and the number of phases. There are single-phase and three-phase modifications. The choice depends on the type of connected consumers.

In addition, diesel generators may differ in power, cooling method (air, radiator (water-air) and double-circuit (another name for water-water), as well as the ability to move (stationary or mobile).

Gas-petrol electric generator Daewoo Power Products GDA 3500DFE (2800 W)

- power - from 2800 to 3500 W;

- work from gas and gasoline;

- 2 sockets for 220 V, 1 for 12 V;

- economical.

The gas-petrol model can operate on AI-92 fuel or bottled gas. Active power - 2800 W, maximum - 3200 W, full - 4 kW. The current strength is 8.3 A. The unit is equipped with a DAEWOO DF-series 210 engine with a volume of 208 cc. Its capacity is 7.5 liters. with. The motor is 1-cylinder, 4-stroke, air-cooled. The volume of the tank is 18 liters, the generator can work on one filling for 15 hours.

Starting is possible either from an electric starter or from a manual starting device. The generator is equipped with a muffler, overload protection, voltmeter, hour meter. Working resource - 1500 hours. Automatically turns off when the engine oil level is low. You can buy for 28,000-30,000 rubles.

Average dimensions - 605x430x425 mm, weight - 45 kg. Installed on a frame with handles, it is quite easy for two to carry. There are 2 sockets for 220 V and one for 12 V. The device is designed for continuous operation with a load of 50% for 15 hours. The peculiarity is that it can only be started on gasoline; after warming up, it is possible to switch to gas. Noise level - 74 dB - in a private house it is better to install it in a garage or soundproof room.

The model is suitable for power supply of a private house, shop, small organization. Can be used for welding, charging mobile gadgets, for garage, powering car devices with 12V voltage.

The generator, according to reviews, is good. One of the few models that run on gas without any complaints. I like efficiency, reliability, long service life, protection against short circuit and lack of lubrication. There are complaints about the inconveniently located neck of the oil filling container. You can start only with gasoline.

Pros:

- runs on gas;

- 15 hours of work with one gas station;

- economical, consumption - 1.2 l / h;

- increased working resource;

- overload protection, lack of oil;

- 2 sockets for 220 V, 1 for 12 V;

- good power.

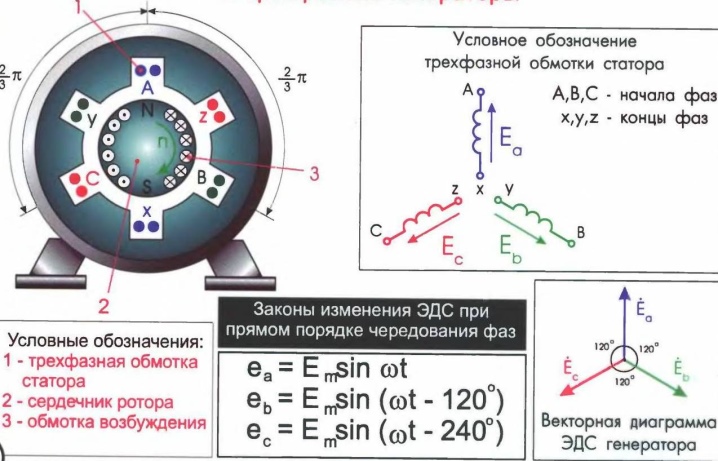

Principle of operation

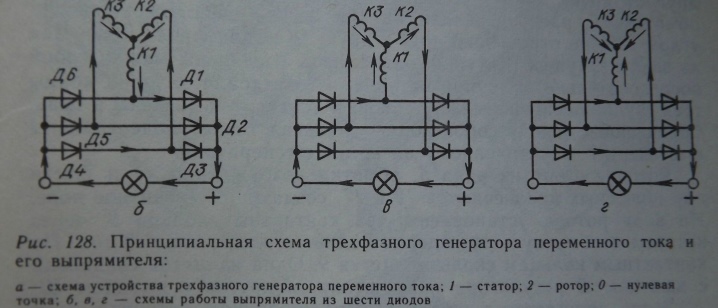

The principle of operation of three-phase generators is based on the law of electromagnetic induction. It reads: an electromotive force (EMF) will be induced at the ends of a metal frame placed in a rotating magnetic field.In this case, both the frame itself and the magnets can rotate.

This is how demo models work. In real generators, instead of a frame, a coil of thin copper wire with conductors isolated from each other is used. This is done to increase the efficiency of the installation.

In modern models of 3-phase generators, the rotor acts as a magnet. In this case, the magnet can be permanent or electric. In the latter case, a sliding contact with graphite brushes is used to power the rotor. To start such a device, a separate source of electricity is needed.

The power winding is located in the stator. This removes the need to transfer large currents through the sliding contact and increases operational reliability.