4) Selection of the power plant version and complete set with heaters

Diesel power plants can be made in an open form (open on the frame), under the hood, in a noise-absorbing casing and also in an insulated block container.

From practice, gasoline and diesel power plants of low power are portable (portable) with a small fuel tank in the upper part, and diesel power plants of higher power (more than 10 kW) usually come out on a frame with a large-capacity tank already integrated in it.

BUT it should be noted that for power plants of large capacities (more than 500 kW), an integrated fuel tank may not be performed, since high vibrations and sound effects during long-term operation can break its tightness, therefore, for such power plants, we recommend using an external fuel tank separately from the power plant by connecting them with a fuel pumping system. The power plant can be installed under the hood, which will protect the power plant from precipitation and dust. To operate the power plant, it is necessary to open or remove the doors through which ventilation of the power plant and access to its control panel is provided.

The sound-absorbing casing has additional advantages over the version in a weatherproof hood. The soundproofing of the casing allows the power plant to be used in close proximity to consumers. As a rule, with such a design of the power plant, it is not required to open any hatches or doors of the casing for its operation; the control panel (ШУЭ) of the power plant is also freely accessible from the outside of the casing from the outside.

However, it should be remembered that neither the version in the hood, nor the version in a sound-absorbing casing can provide the power plant with any kind of thermal insulation for operation at temperatures below zero.

In any case of using an open-type diesel power plant, in a weatherproof hood or noise-absorbing casing at low temperatures, we recommend using both standard and optional preheaters (electric heater or flare heater for air in the intake manifold, electric oil heater and / or fuel heater for coolant).

To use a diesel generator as a backup power source, (that is, performed in 2 degrees of automation) and automatically reliably start and quickly take the load in the event of a failure of this network, it is necessary that the diesel generator is in a "warm" ready state, which is ensured by the standard electric heater for coolant coolant. For our Russian climatic conditions during operation in winter at low temperatures, in this case, it is necessary that the diesel power plant is in a heated room or in a thermal protective block container. Our company can also offer you the version in a thermal protective block container.

The station under a weatherproof hood, in a soundproof casing and in a block container can be installed on a tractor or car chassis, which gives her the opportunity be as mobile as possible. If no special requirements are imposed on the speed of movement, we recommend that you order a tractor trailer, as it is simpler and cheaper, with maximum travel speed by tugboat 25-40 km / h (depending on the type of trailer).

Rent

Renting a 100 kW diesel generator is the best option for providing the facility with a powerful power source at minimal cost. The rental price depends on the period of use of the unit and the number of machine-hours worked by it.Its amount for the year is one third of the purchase price of a new device.

Today there are two rental options on the domestic market:

- No service. The customer receives the generator for temporary use and uses his own resources to ensure its correct operation. Monitors the level of fuel and lubricants, and also carries out a competent load distribution.

- With service. The client is provided with fuel tanks of the required volume and the services of a diesel operator who will manage the installation. The customer's task includes only the supply of diesel fuel.

Quality level, manufacturer

All existing models of 100 kW diesel generators can be conventionally divided into several categories in terms of quality level and place of assembly:

1. Reliable European manufacturers

Well-known European factories are known to everyone and there are not so many of them. the main manufacturers of 100 kW generators in Europe are: SDMO (France), GESAN (Spain), CTM (Italy), Pramac (Italy), AtlasCopco (Belgium). These manufacturers make their generators of the mentioned power on European engines JohnDeere, Volvo, Iveco,

2. Generators of the middle price category

Turkish manufacturers (AKSA, TEKSAN, DALGAKIRAN), assembling their generators, mainly on Korean Doosan engines, should be attributed to the middle price category. In addition to them, here you can also mention some companies that have long transferred most of their production to China - FG Wilson, CATARPILLAR, Cummins. Such generators will nominally have a "European passport" with "Chinese roots".

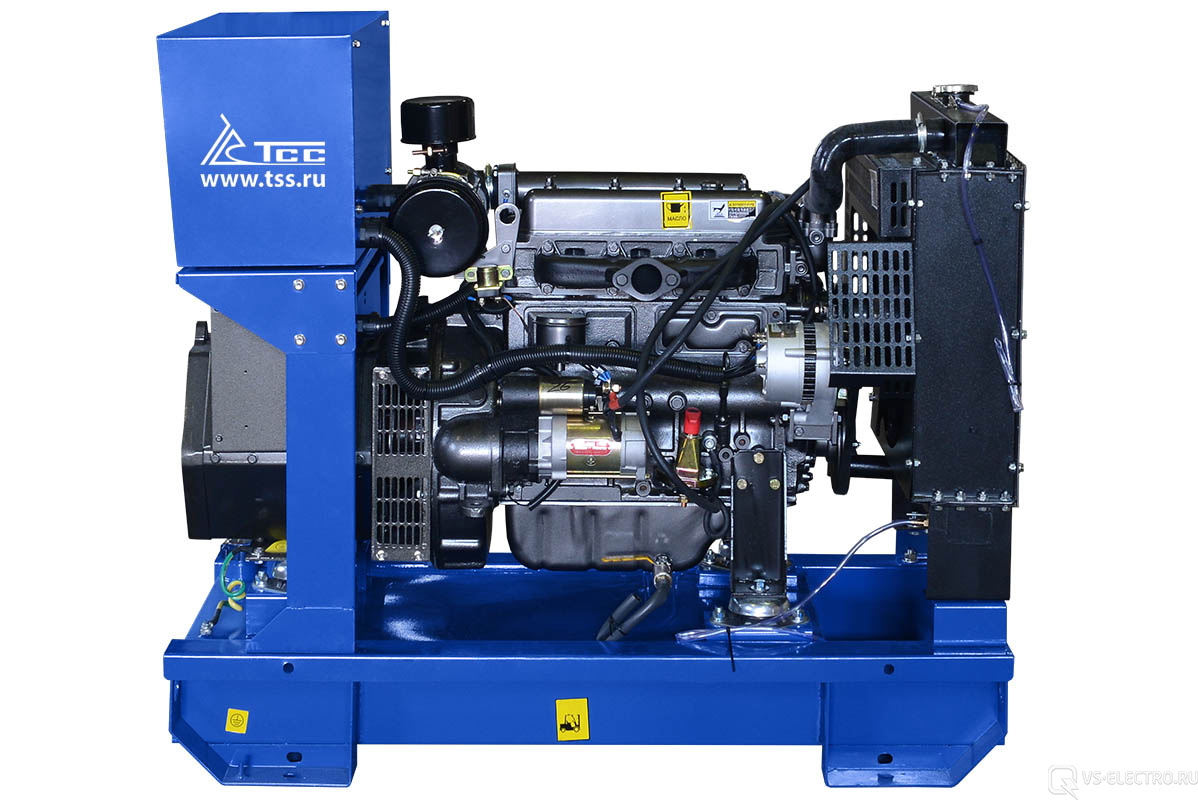

3. Domestic diesel generators with a capacity of 100 kW.

It should be clearly understood that 100% of domestic generators are assembled only on YaMZ and KAMAZ engines. If you see a supposedly domestic generator on any other engine, this means that with 90% probability the seller is hiding the real manufacturer, and most likely it has Chinese roots.

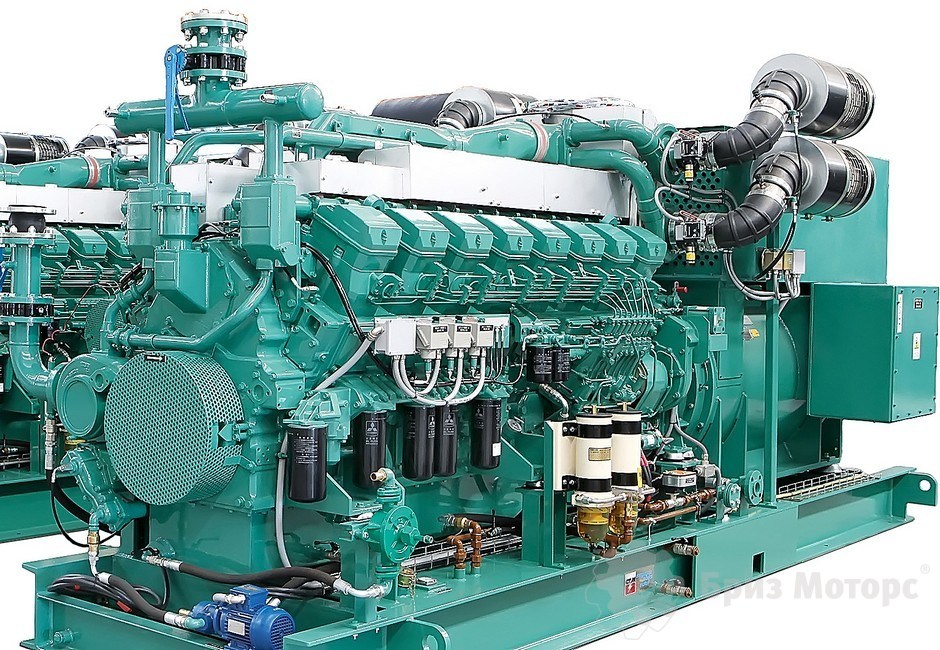

4. Budgetary Chinese and "pseudo-Chinese" generators

Such a generator can be Chinese, or Russian, but assembled in China. Quite often, an "assembly kit" comes from a Chinese plant, which turns into a Russian generator by sticking a nameplate. It is worth mentioning such brands and trademarks as AmperHouse, TSS, Rikardo, Bearford, Azimut, CTG and many, many others. Unfortunately, sometimes the equipment supplier does everything possible to hide the true origin of the equipment.

Gasoline, diesel or multi-fuel generators

It would seem that what a gas generator should work on primarily depends on the cost of fuel and its availability in a particular region. At first glance, everything is logical - diesel fuel is cheaper than gasoline, and gas, in turn, has an additional advantage besides the lowest price - it can also be supplied through the gas main (and interruptions in gas supply are an order of magnitude less frequent).

But the fact that manufacturers offer devices that operate on all types of fuel indicates that each of them has its own undeniable advantages, which must be taken into account when choosing.

Pros and cons of gasoline generators

For a number of reasons, gasoline engines are the most common in household stand-alone generators, which are used for household needs or provide the operation of electrical equipment on small construction sites - for example, when building a summer cottage. The advantages of using them are as follows:

+ Pros

- Relatively low cost, which is much lower than that of diesel counterparts with similar characteristics.

- Smaller overall dimensions and weight of the device as a whole.

- Easy start of the engine at subzero temperatures - the principle of operation of the engine makes it possible to start it without any particular difficulties at temperatures down to -20, and in some cases even lower.

- Quiet operation of the motor - the sound volume is within 70 dB, which is comparable to the hum of a vacuum cleaner not at the highest speeds.

- Ability to idle - with minimal load.

- Minuses

- Gasoline engines have a relatively low service life - few models can go beyond the 5000 operating hours mark.

- The design of the engine assumes regular maintenance - without preventive maintenance, the likelihood of its failure increases significantly.

- High requirements for fuel quality.

- The maximum generator power does not exceed 15 kW.

The permissible errors for the output voltage and frequency of the electric current are 10 and 4%, respectively, of those declared in the device's passport.

Advantages and Disadvantages of Diesel Generators

Diesel stand-alone power generators are more common in industries where power and reliability are paramount. They have the following positive and negative sides:

+ Pros

- Power significantly exceeds gasoline counterparts with similar characteristics. If for the latter the limitation is 15 kW, then household diesel engines can deliver power up to 25, and stationary ones - over 40 kW.

- Diesel engines are characterized by smoother operation.

- The design of a diesel engine makes it possible to operate it without major repairs much longer than a gasoline engine - high-quality models have a motor resource of 40 thousand hours.

- The principle of operation of a diesel engine makes it more resistant to fuel detonation, and also increases the fire safety of the entire device as a whole.

- General fuel quality requirements are lower than those of gasoline engines.

- Minuses

- The high cost of the engine itself.

- Since the ignition of the fuel mixture occurs from compression, a cold engine at subzero temperatures does not start well even at -5 C and below.

- If less than 40% of the load (of the nominal) is connected to the generator, the diesel can stall.

When using a diesel engine, the error from the voltage and frequency declared in the passport is 1 and 2.5%, respectively.

Gas (multi-fuel) autonomous electricity generators

In fact, these are the same gasoline engines on which LPG is installed, which allows you to switch between operating modes - petrol / gas. Such a universal (by type of fuel) engine retains all the pros and cons of a gasoline engine, but acquires several more advantages:

- Reduced cost per kilowatt-hour, as the price of gas is the lowest of all fuels.

- Longer service life as less carbon deposits are generated in the cylinders when the gas is burned.

- The ability to work from the gas main - in this case, the period of uninterrupted operation depends only on the capabilities of the engine.

- The reducer allows using several types of gas as fuel: natural (from the gas main), liquefied (sold in cylinders), coke oven, pyrolysis, biogas and others used in industry.

Although motorists note that the installation of HBO somewhat reduces the engine power, but since there is no need to frequently change the load modes during generator operation, this difference is not felt in any way.

Gas generators for 1 kW

The power and weight of these devices imply their use exclusively as a mobile source of electricity for one or more low-power consumers.

| Hammer GNR2200 А | Briggs & Stratton 1800A | |

| Launch type | manual | manual |

| Number of phases | 1 (220 volts) | 1 (220 volts) |

| Cooling | aerial | aerial |

| Active power, W | 2000 | 1700 |

| Tank volume, l | 15 | 1.8 |

| Battery life, h | 12 | 2 |

| Noise level, dB | 68 | 70 |

| Dimensions (WxHxD), mm | 593x432x440 | 550x380x390 |

| Weight, kg | 50 | 35 |

Gasoline generator Hammer GNR2200 А

Gasoline single-phase generator with a capacity of 1.6 kW. Powered by a four-stroke internal combustion engine volume of 196 cm³, issuing 3600 rpm.

+ Pluses of Hammer GNR2200 А

- The successful cooling design allows the generator to be used without shutting down for 10 hours - until the tank runs out of gasoline.

- The exhaust of the internal combustion engine is conducted through a muffler, which achieves a fairly quiet operation of the entire device as a whole - the passport 68 dB is about the sound of a working vacuum cleaner, and not at the highest power.

- General reliability of the design - users note the unpretentiousness of the device and the ability to find components for it, if you still need to carry out repairs.

- Good layout and assembly minimizes vibration during operation.

- High enough power for its class - according to user reviews, it is enough even for the operation of submersible pumps, which, after a break in operation, are already started under load.

- Cons of Hammer GNR2200 A

- The weight of the generator is 45 kg - if you do not put the platform on the wheels, then it will be difficult to move it alone.

- Air cooling will not cope with its duties when installing the generator in the sun - it is imperative to arrange at least a canopy.

Briggs & Stratton 1800A Gasoline Generator

Gasoline single-phase generator of frame type weighing 31 kg with manual start. The brushless generator delivers 1.7 kW of nominal power and 1.8 kW of maximum power. The engine with a displacement of 127 cm³ is air-cooled.

+ Pros of Briggs & Stratton 1800A

- Easy engine start in frosty weather - according to user reviews, problems are not observed even at -25 ° C.

- Relatively low fuel consumption - according to the passport, a full 1.8 liter tank is enough for 2 hours of operation, and users note that with a load of no more than 1 kW, gasoline is enough for 3 hours.

- Brushless Generator - Simplifies design and improves reliability.

- The weight of the device allows you to move it alone if necessary.

- Multilevel engine and generator protection. Oil and fuel sensors.

- Cons of Briggs & Stratton 1800A

- More often than not, you have to look for detailed instructions for assembly and operation on the Internet.

- When buying a generator, you immediately need to purchase oil for filling into the crankcase - it is not available in the factory configuration.

- A small number of service centers in the regions - although users note the reliability of the device, but before buying, you need to find out where you can take it for repair nearby.

Generator models

The following generator models are very popular for summer cottages and private houses:

- Kipor 5kva. Single-phase gas, with a rated power of 4.5 kW. Equipped with auto start, self-control system and voltage stabilizer. Price 111 thousand rubles.

- KraftDele KWD-6500. German diesel three-phase generator with a rated power of 6.5 (maximum 7.5 kW) and a resource of 100 thousand hours. Equipped with a self-monitoring system, voltage stabilizer and auto start. Price 85 thousand rubles.

- FORTE FGD6500EW. German welding diesel generator, giving out voltage of 12, 380 and 230 V. Rated power 6.5 kW, maximum 7.5 kW. Equipped with a stabilizer, auto start, and self-control system. Price 81 thousand rubles.

- Honda EG 5500CXS. Gasoline single-phase generator, 5.5 kW. Equipped with the AVR function, it costs 124 thousand rubles.

- WERK WPG6500. Chinese single-phase gasoline generator, 5.5 kW (max 6.5 kW). It produces alternating current of direct conversion, it is not equipped with automatic equipment. Price 74 thousand rubles.

- Lifan LF5GF-4ES BF. Chinese single-phase gasoline and, with a rated power of 5 kW. It is equipped with AVR, autostart, and the built-in digital panel gives parameters about the output voltage, load current, frequency of the generated current, total load power and engine hours from the moment of the first start. Price 75 thousand rubles.

- Dalgakiran DJ 4000 DG-EC. Diesel Turkish mini alternator of synchronous type with auto start, short circuit and overload protection, rated power 3.3 kW. The single-cylinder engine of the device is equipped with an air cooling system. Price 91 thousand rubles.

We offer to look at the review of this generator

Mini generators

At home or in a summer cottage, the large power of the generator in most cases remains unclaimed, and then efficiency, small dimensions and weight, and a low price of the device come to the fore.

Inverter and mini-generators have positive feedback from consumers, as they meet most of the requirements for them:

Let's start our acquaintance with mini-generators with a model from FoxWeld

- FoxWeld G950 mini. Single-phase two-stroke gasoline generator, 750 W (maximum 850 W). Ghtlecvjnhtyf overload protection, 220/12 V socket. The engine is air-cooled. Price 10 thousand rubles.

- Briggs & Stratton ProMax 10 3500А. Gasoline single-phase mini-generator of the Italian company, with a rated power of 2.7 kW (max. 3.4 kW), with auto start. Has a built-in voltage stabilizer and alternator (alternator). Price RUB 49,000

- Brigadier BG 2500. Chinese single-cylinder four-stroke synchronous petrol generator with a capacity of 2.5 kW. Has an automatic regulator of output voltage. Price 38 thousand rubles.

The last generator and its start is shown in the video.

When choosing an electric generator, you need to decide on the power of the connected devices, the type and duration of the load, on the operating conditions, and take into account the positive reviews of the people who used the device.

If it is necessary to turn it on for a short time and to have a small load, it is recommended to purchase a gasoline or gas electric generator. If you plan to connect powerful devices in the form of pumps, welding, concrete mixers, or use the device for a long time, diesel generators will be the most reliable, since they have a longer service life, less power loss, are more economical and adapted to long-term operation.

2) Choice between 1-phase (230V) and 3-phase (400V) power plant:

A very common common misconception: it is better to take a three-phase power plant (400V), because it is "universal" (it has an output of both 400V and 230V).

Our recommendations: if you do not plan to connect three-phase consumers or a sufficient number of single-phase consumers to different phases of a diesel generator, and in such a way as to prevent significant power imbalance in phases, you should give preference to a 1-phase power plant. Indeed, for a 3-phase power plant of the same power to connect a 1-phase consumer to one phase, this phase can provide only a third of the load, and this is not enough for work such as a powerful grinder or a hammer drill at a construction site.

You should not be confused by the fact that the entrance to the house has 3 phases, and the power plant is single-phase. Switching is carried out by the installed automation unit or by manual switching of inputs.

If you plan to connect powerful electric motors with 3-7 times starting currents or such a difficult load for the operation of a diesel generator as electric welding, then it is better to consult with our specialists in advance.

When choosing a 3-phase power plant, you should pay attention to the uniformity of the load planned for connection in phases. Uneven distribution of loads across phases will cause premature failure generator

For example, we do not recommend connecting a single-phase welding machine to a three-phase generator.

The asymmetry of the load in phases should not exceed 25% of the nominal value, while the current of any phase should not exceed the nominal current of the power plant.

The lineup

The range of 100 kW diesel generators most popular on the Russian market includes the following models: SST YaMZ-100, AD 100 S-T400-1RM2 and Cummins C150 D5.

SST YAMZ-100

Diesel generator YaMZ 100 kW is a rather expensive unit with a high level of power and reliability.The unit is equipped with an eight-cylinder engine with a speed of 1500 rpm. Its fuel consumption reaches 22 l / h. A three-phase generator is responsible for generating electric current. At the output, it gives out a voltage of 230 and 400 V.

The unit has a volumetric fuel tank of 200 liters. The operating weight of the generator is 2.76 tons. In their reviews, consumers note that the installation has a low vibration level and a low noise level, but for this protective covers must be used.

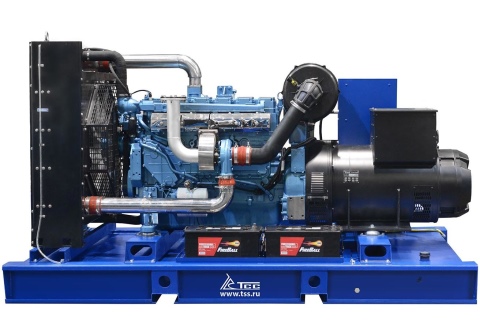

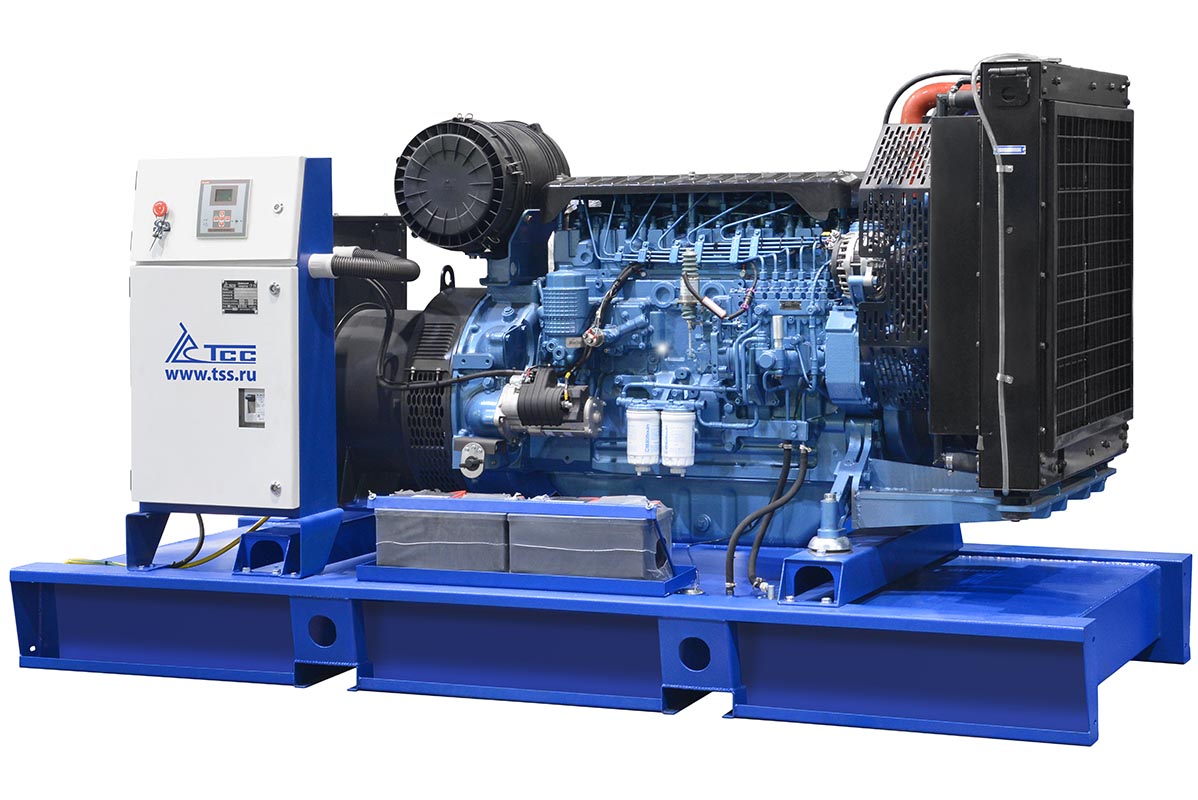

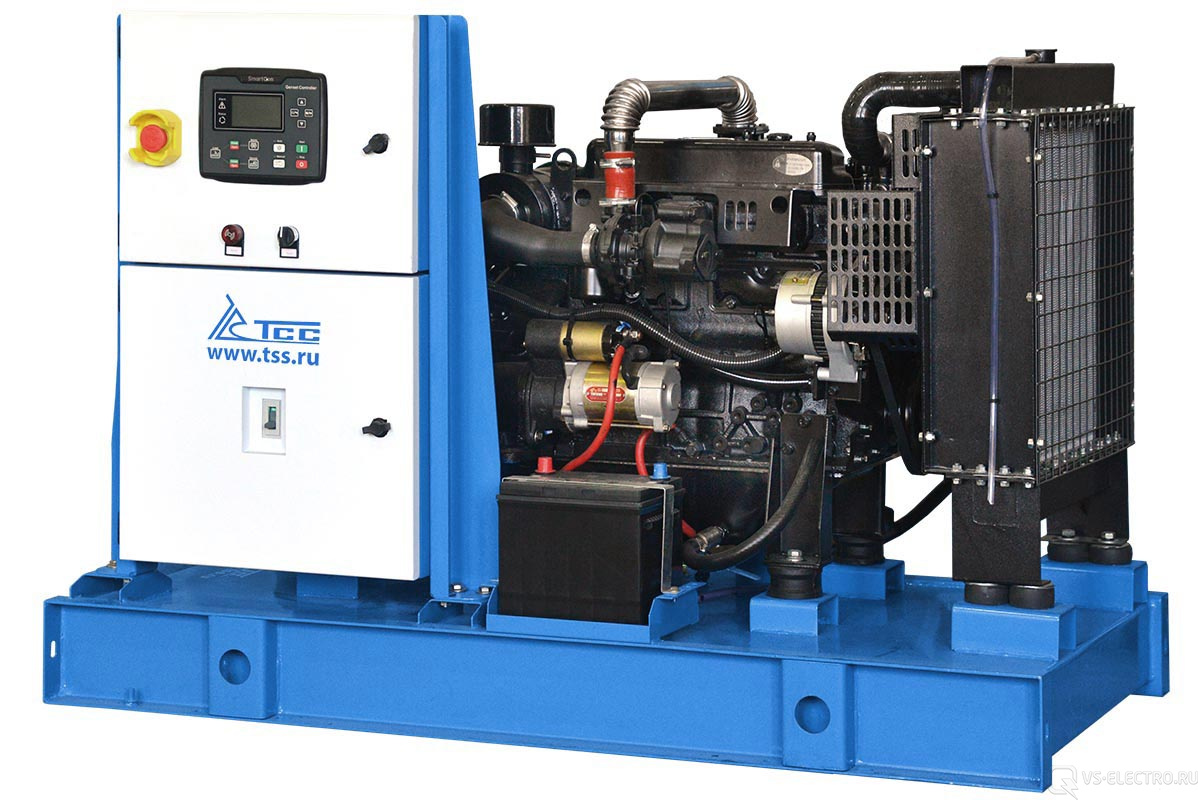

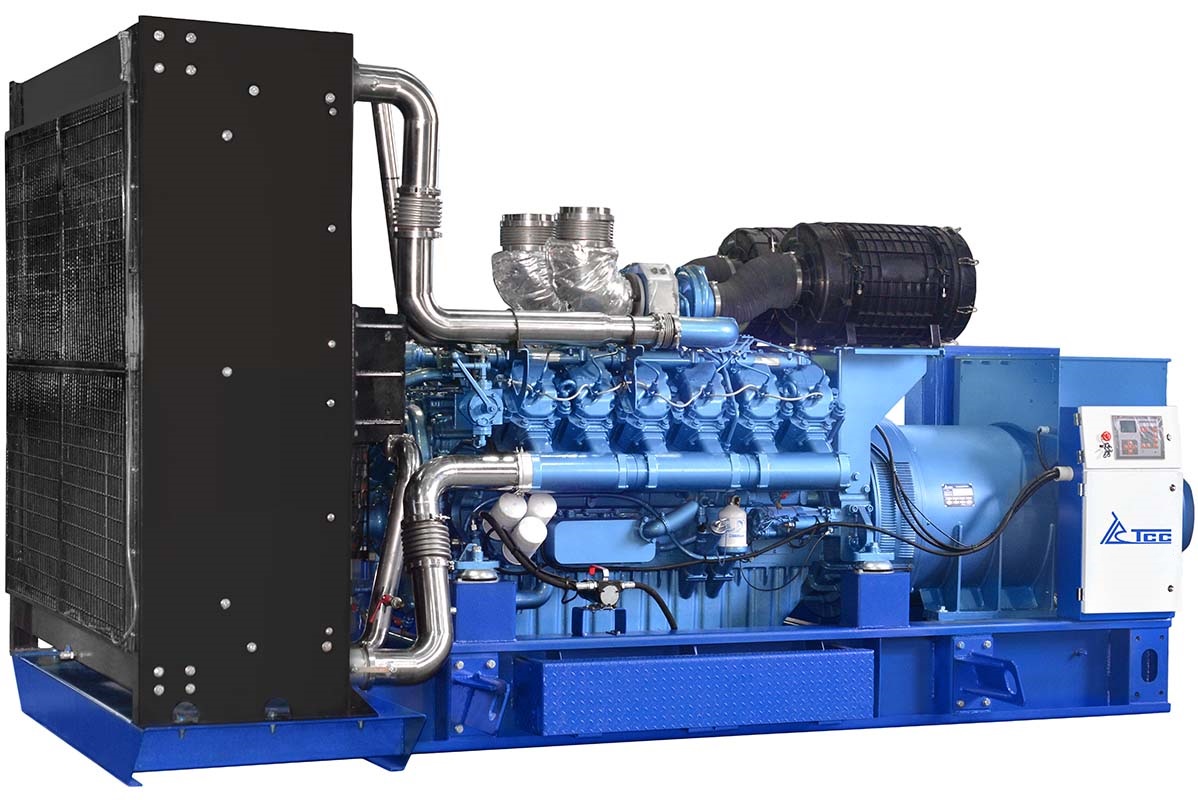

AD 100 S-T400-1RM2

Diesel generator AD 100 S-T400-1RM2 is a device of increased power, equipped with a four-stroke eight-cylinder TSS Diesel engine with a displacement of 14.9 liters. The unit has high efficiency, good starting characteristics and a long operating cycle. Its fuel consumption is 20 l / h. The volume of the fuel tank reaches 200 liters.

Diesel generator AD 100 S-T400-1RM2 is a device of increased power, equipped with a four-stroke eight-cylinder TSS Diesel engine with a displacement of 14.9 liters. The unit has high efficiency, good starting characteristics and a long operating cycle. Its fuel consumption is 20 l / h. The volume of the fuel tank reaches 200 liters.

Three-phase generator of synchronous type delivers currents with voltages of 230 and 400 V

The plant has a weight of 2.0 tons. Users of this power plant pay attention to convenient control and the presence of an advanced control system in the device, which effectively protects the operating units of the generator from overloads.

Cummins C150 D5

The Cummins C150 D5 power plant has a rated power of 100 kW. It is based on a six-cylinder engine with a fuel consumption of 23 l / h at 75% load. The device is equipped with a three-phase generator, which produces a stable voltage of 400 V. Thanks to the presence of an improved muffler and soundproof covers, the unit emits a minimum noise level of 67 dB.

The Cummins C150 D5 power plant has a rated power of 100 kW. It is based on a six-cylinder engine with a fuel consumption of 23 l / h at 75% load. The device is equipped with a three-phase generator, which produces a stable voltage of 400 V. Thanks to the presence of an improved muffler and soundproof covers, the unit emits a minimum noise level of 67 dB.

The decent operating weight of 2.1 tonnes is compensated by the large fuel tank, which has a capacity of up to 340 liters. Consumers speak positively about the power level of the unit and its reliability, and negatively assess the cost of repairs and the possibility of purchasing original spare parts.

Equipment power

In order for a diesel generator to serve for a long time, it is necessary to correctly calculate the power. An incorrectly calculated parameter will lead to an overload of the device and high fuel consumption.

The power of the device should be sufficient to ensure the operation of many devices.

If you do not plan to turn on the washing machine or dishwasher, heating boiler and other energy-intensive appliances in the absence of electricity, then you can get by with a low-power emergency generator.

To determine the type of device, you must:

- Determine the power of all devices. All equipment is divided into inductive and resistive devices. Resistive devices work without an electric motor. They convert active power into heat and / or light. Inductive devices have an electric motor. Representatives of this type of equipment are drills, compressors, refrigerators. After turning on this equipment, a starting current appears for a few seconds, increasing the power of the device several times. To operate such devices, a more powerful generator is needed. Information on the technical characteristics of the devices is available in the passport.

- Add up the power of all devices and multiply by the safety factor. To the obtained value, you need to add another 20%, which will give a supply of consumed energy.

- Check the optimality of the calculations. For long-term operation of the generator, a load must be connected to it, which is from 40 to 80% of the power of the unit. If you took into account a lot of devices in the calculation, but do not use all of them all the time, the calculated value can be reduced by 10-15%.

Diesel Generators work in three modes:

- Long lasting. Used for a long time, but the load should not exceed 75% of the device's capacity.

- Basic. The generator is loaded to 90%, but it works no more than 8 hours a day.

- Spare. The load is maximum, but the unit operates no more than 500 hours per year.

In the passport of the unit, two powers are indicated - nominal and maximum.

The first shows the load at which the device will work for a long time, but there will be no overload. The maximum power indicates the value at which the device will be able to operate for a limited time.

1) Choice of power plant capacity

Determining the maximum power of the consumers to be connected to the power plant is very important. The full load of all consumers determines the rated power of the power plant. When the rated load of a diesel power plant (within its maximum load) is exceeded, its service life is significantly reduced due to an increase in the load on the drive diesel engine, heating of the insulation of the power generator, which will ultimately cause increased wear of the engine, destruction of the generator insulation, corrosion of wires and short-circuiting of windings ... That is why we do not recommend that you calculate the required power of a power plant (even a short-term one), based on its maximum power. Nevertheless, in order to protect the diesel power plant in extreme cases, when the power of consumers exceeds the maximum value, the circuit breaker will turn off the power plant.

When choosing a diesel generator, we ask you to take into account the inadmissibility of long-term operation of the power plant with minimum power consumption. So, during long-term operation of the power plant (more than 5 minutes) with a load of less than 30% of its rated power or no load at all, accelerated carbon formation occurs in the engine cylinders, which worsens its characteristics, and it is not always possible to then "burn out" carbon deposits when operating at high load, the engine may require major repairs

The calculation of the total power of consumers should be carried out as follows:

The starting power of some equipment can be 3-10 times their rated power.

For consumers with resistive loads, such as incandescent lamps, heaters, power tools, the power consumption is close to their rated power. However, for inductive or mixed inductive and resistive loads such as fluorescent or mercury lamps, transformers, fans, air heaters, it must be taken into account that their starting power consumption will be 60% higher than their rated power.

Criterias of choice

A 100 kW diesel generator is a rather complex and high-tech unit, when choosing which it is necessary to be guided by the following factors:

- Installation power;

- Generator type;

- The way to start.

Power

Power output is the most important generator parameter. Its value is calculated as follows:

Power output is the most important generator parameter. Its value is calculated as follows:

- For active consumers, the power indicators of all devices that are simultaneously connected to the generator are summed up. To the obtained value, 20% of the power reserve is added and the required indicator is obtained.

- For inductive consumers, the total value of their power needs to be increased by 3 times, since these devices need high starting currents at the moment of switching on. Only in this case will the normal operation of the power plant be ensured.

As the practical experience of using diesel generators shows, an installation with a capacity of 20-40 kW is quite enough for a country house with an average level of energy consumption. For private estates, where regular feeding of an impressive number of electrical appliances and lighting of large areas is required, a 50-70 kW unit will be needed at the time. And for construction sites, industrial enterprises, offices and civil buildings, diesel generators from 80 kW and above are recommended.

Generator type

A generator is a device that generates electric current. The devices are divided into synchronous and asynchronous.The first type has a complex design, easily withstands a high load from inrush currents and is capable of delivering electricity for a short period, the power level of which exceeds the nominal four times. It is recommended for powering electric pumps, refrigeration plants, compressor stations and welding equipment.

The second type of generators has a simpler device, is well protected from environmental influences and is short-circuit proof. Such an installation is capable of maintaining a high accuracy of the generated current and supplying equipment that is sensitive to voltage drops.

Start method

The diesel power plant can be equipped with three starting systems:

- Manual. Here you will need to pull the cord or turn the handle, applying the necessary physical efforts;

- With an electric starter. In this case, the user only needs to press the button or turn the key. There are a number of generators that are equipped with a remote start system, which is carried out by means of a control panel;

- Automatic. With this method of switching on, a 100 kW diesel generator with auto start turns into a full-fledged unit for autonomous power supply without the participation of an operator.