Concept

A miter saw is a tool designed to make straight cuts at a given angle. The saw cut angle can be either 90 degrees or 45. Its main advantage is that it copes well with long details and unusual shapes of surfaces. A striking example of these is a plastic floor plinth.

But this tool has other features as well.

The appearance of this unit resembles a conventional circular saw (circular) mounted on a movable arm. It allows the discs to descend not only vertically, but also at any angle of inclination. This tool can cut various materials:

- wood;

- metal (in particular aluminum);

- plastic;

- stone.

Views

Saw blades are divided into two types: carbide and monolithic. This division describes a difference that is immediately apparent. The fact is that on some discs the cutting part is soldered to the teeth, and some are simply a single product (monolith).

Monolithic

A distinctive feature of monolithic discs is the large number of teeth. Working with such a blade, it is much easier to get a clean cut. But it is worth noting the poor ability of these cutting wheels to keep sharpening and the need for periodic divorcing of the teeth.

Sharpening the metal is not difficult, but the large number of blades slows down the process.

Carbide

Carbide teeth are considered more reliable because they are stronger and do not require constant sharpening and patching. These scoring discs have the widest range of options and help you save time thanks to their reliability. However, a significant drawback is the large number of low-grade counterfeits, even of famous brands. In such a product, the soldered ends quickly fly off. After 5 minutes of cutting the cross-sections, only a few remaining blades can be seen on the disc.

But counterfeiting can also be successfully combated if you pay closer attention to the correct spelling of the brand, as well as the high quality and durability of the paint with which the marking is made.

Specifications

In total, there are two main indicators that you should pay attention to when buying

Diameter is a characteristic that affects the speed of rotation of the motor shaft. The size of circular saws is different, this also changes the parameters of the circle. The optimal ratio of size and speed can be presented in tables:

| Diameter mm. | Rotation frequency |

| 80 | 23 800 |

| 100 | 19 100 |

| 120 | 15 900 |

| 250 | 7 600 |

| 350 | 6 300 |

With an increase in diameter, the comfortable operating frequency always decreases

What to look for when buying a tool. On a circular saw with a permissible diameter of 100 mm, it will not be possible to install an eighty disc

Each disc is designed for a specific rpm allowed by the manufacturer. High revolutions are the main cause of metal burnout, after which it changes its shape and becomes soft.

To find out the baseline suitable for working with the snap-in, you need to read the information on the disk. The main characteristics of the brand will be written next to the brand label:

- Diameter;

- Working speed of rotation;

- Additional information (low noise level, anti-temperature coating materials).

Visual inspection of the web

For comparison, several discs will be shown that differ in appearance.

Selecting disks to check

Checking the flatness of the disc

The geometric flatness of the disc is checked with a metal ruler.To do this, a ruler is applied between the teeth from the side of the disc marking and the gaps are observed.

Checking the disc from the side of the marking

Then a ruler

applied from the back of the disc and also reveal gaps.

Checking the disc from the back

If the disc is flat, then

the metal ruler fits snugly on the canvas and there will be no gaps.

Teeth inspection

The teeth of the disc are carbide-tipped

soldered. The geometry of the teeth must be correct. A low-quality disc has teeth

go out of order and have different angles of inclination. This can be seen with careful

examining each tooth.

Inspection of the condition of the teeth

Inspection of the drinks

High temperature

the cutting plates are soldered to the disc. Solders come in different geometric

shapes: beveled, straight, conical, trapezoidal. All soldering on the disk

must be of the same size and of the same geometric shape.

Inspection of the drinks

If you compare the two

disc: expensive branded and cheap Chinese, then the branded disc has a size

more tricks. Such a disc is designed for 10-12 sharpenings, and a disc with small

it is impossible to sharpen more than 5 times by soldering.

Comparison of disc soldering

The quality of the cuts of the selected

disks are the same. However, it is better to have a disc with large soldering

withstands heavy loads and repeated sharpening.

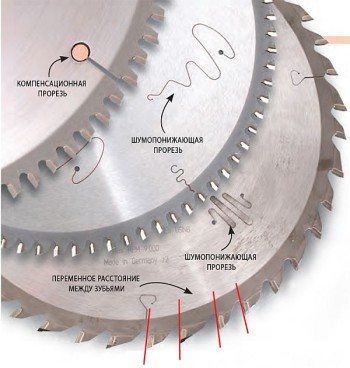

Checking the thickness of the blade

Steel blade blade

it can be thin or thick. It is made by laser cutting. To reduce

Noise and vibration compensation slots are made on the disc blade. Quality

disks are provided with undulating expansion.

If the thin disc bends

under the pressure of the hands, the thick disc cannot be bent.

Checking the canvas under

hand pressure.

Thick discs

used when you need to make an even cut with a powerful saw. For rechargeable

circular saws buy thinner and cheaper blades.

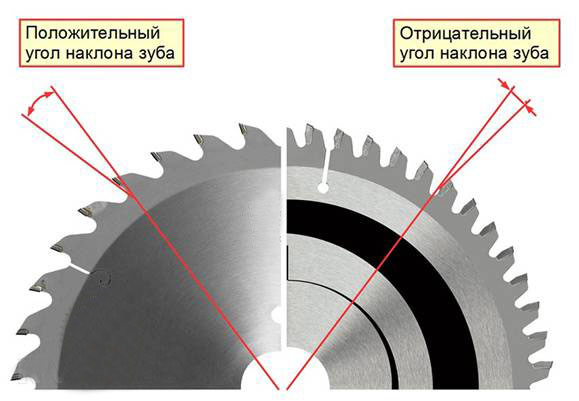

Checking the angles of sharpening of teeth

The teeth have many angles

but the main one is the front angle of inclination. It can be positive or

negative.

Sharpening angles of teeth

From the front corner of the disc

disk capabilities depend:

- longitudinal cut - 15‒25 degrees;

- cross cut - 5‒10 degrees;

- universal application - 15 degrees.

Laminated

surfaces, plastic and aluminum are sawn with discs with a negative angle. The wood is sawn with discs with a positive angle

sharpening.

Positive angle disc

Longitudinal sawing

perform with discs with a positive sharpening angle and a small amount

teeth. If the sharpening angle is 18‒25 degrees, then sawing will take place quickly, but with

low quality.

Rip saw blade

Typically cuts

wood along and across is produced by a universal version of the saw blade,

for example, with a sharpening angle of 15 degrees.

Universal disc

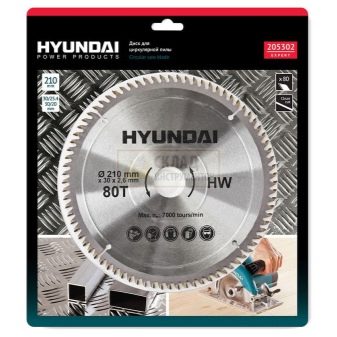

Selection by number of teeth

Saw blades distinguish

by the number of teeth. It is believed that if the teeth are from 10 to 40, then this is a small

number of teeth. 40 to 80 is the average tooth size and 80 to 90 is

this is a large number of teeth.

Rough cut

is obtained by a disc with 16 - 24 teeth.

Disc with 16 teeth.

When you need a smooth

cut, then choose a disc of 36-48 teeth.

48 teeth disc

Assessment of the sharpness of the teeth

Experienced users

always check the condition of the teeth. A disc with blunt teeth does not cut well,

heats up, saw marks remain on the wood.

Verification is carried out

fingers. When the disc is sharp, the teeth catch the skin and feel light

tingling. A blunt disc has smooth teeth.

Finger Checking the Disc

Evaluation of web coverage

So that the disk does not

wood resins adhered, and it did not get stuck in the cut, the blade has a smooth

mirror coating. There should be no scratches on it.

Disc cover

Output

There are no universal discs. The choice of each disc must be approached carefully.Sometimes an expensive but high-quality saw blade is more profitable to buy than a cheaper and short-lived model.

Based on the materials of the master class from the "Aquila Workshop" carpentry workshop, processed by Viktor Prokhorov

Category: Machine tools

Go to groups and Odnoklassniki

Outside diameter

This selection parameter is in direct proportion to the dimensions of the saw cover itself. If you take a disc with a large diameter, then it will not be possible to install it on a tool with a small diameter casing. Operating with discs that are too small is also fraught with consequences.

The outer dimension does not affect the cutting speed, but it determines the cutting depth. In hand tools, cutting components with a diameter of 130-250 mm are used.

With a large immersion of the blade into the surface of the material, the load on the engine increases. It is recommended that the teeth do not protrude more than 10-20 mm above the working plane.

Influence of tooth shape on cutting

Significant the quality of the cut is influenced by the shape of the teeth.

- With a flat top. The saw blade for wood with this tooth shape is well suited for cutting hard wood. It pulls out tough fibers, allowing efficient sawing motion. Best suited for ash, oak, beech, birch. The tooth is symmetrical, without setting.

- With pronounced wiring. Designed for strong gnawing into wood. Provides high performance with dirty cuts. The places of processing must be additionally sanded with sandpaper.

- Triple shavings. Such a saw blade for wood is designed according to a specific system that combines the two previous technologies. First comes the set tooth, which cuts out large blocks of wood. The next prong cuts off the tracks from the previous one. This creates a high cutting performance, but the cut itself is clean and free of sticking out fibers.

- Fine. The most common finishing disc technology is four teeth with negative tilt and set and one for undercutting. This technology even allows for finishing cutting. Suitable for cutting chipboard and MDF in the manufacture of furniture.

Types of discs

There are no universal discs on the market that can handle all kinds of materials. The main difference is the shape of the cutting edge. Even for one type of raw material, like wood, there are several circles on the market that are designed for hard and soft woods. Some are designed to work with soft wood (pine, fir, spruce) and hard wood (ash, beech, cherry).

The indicator of durability is the presence of victorious or diamond tints on the teeth. These are small pieces of carbide minerals (tungsten carbite) that are significantly harder than metal and wood.

Metal monolithic models are manufactured carbon steel... The cutting edges are thermally hardened, which increases their density and hardness. Thanks to this, they do not dull longer and remain suitable for normal operation. If the edge is dull, it can be sharpened with stones or special emery machines. Much cheaper in comparison with the victorious ones. The metal used for manufacturing must not be overheated. As the temperature rises, tempering of the steel may occur. From this, the metal will become soft, practically inoperative.

Brazed models offer better performance as the linings are significantly harder than conventional metal. They do not require additional sharpening, which is why they can last longer. But cannot be repaired if damaged. Diamond will win and is afraid of overheating.

If the soldering has worn out, they can be sharpened. This requires an engraver with a diamond disc and additional polishing with a vulcanite wheel or felt with GOI paste.

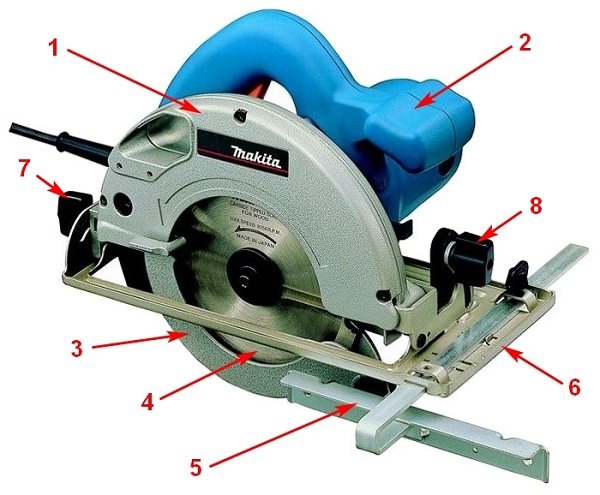

Saw blade marking

To the choice of the disk always

proceed after studying the marking.

Disc blade

be sure to mark.In order for the marking to persist for a long time,

high-quality disks make it with a laser. Long-term paint

erased, and information from the marking is needed not only during the purchase of the disc, but

and with its repeated use.

Saw blade marking

Thanks to the marking

the user will find out:

1. Manufacturer's brand and logo

To famous brands

include discs of brands: Bosch, Hammer, Makita,

"Bison", "Attack" and others. These are high quality discs. At the same time on the market

there are many medium quality discs that are made in China.

2. Purpose of the disk

Circular saw

sawing different materials. This is not only wood, but also laminate, rubber,

aluminum, chipboard.

3. External disk size

Size is limited

under the saw guard. This parameter determines the cutting depth.

Hand saws work with 130-250 mm discs.

4. Bore size

The cutting blade must

fit well on the shaft. This is a prerequisite for safe work. Disks

produced with bore holes from 16 to 32 mm.

5. Cutting width

From the thickness of the canvas

the cut depends. The thin blade makes a narrow cut, but the blade is short-lived. At the disk

with a thick blade, a wide and sloppy cut. For hand tools

select a 3.2 mm disc.

6. Number of teeth

On saw blades

the number of incisors is different. This is necessary for working with different materials and

performing different cuts. It is considered optimal to have 5 or more

discs with a different number of teeth.

7. Rotation speed

Parameter depending on

the possibilities of the circular saw and the diameter of the blade. It is determined by the number

rpm. At high blade speeds, the cut is more

high quality.

8. Direction of rotation

As indicated by the arrow

the material is cut. In the opposite direction, not only will there be

cut, but safe work with the cutting tool will not be ensured.

For the final

the choice of the saw blade, proceed to inspections and checks.

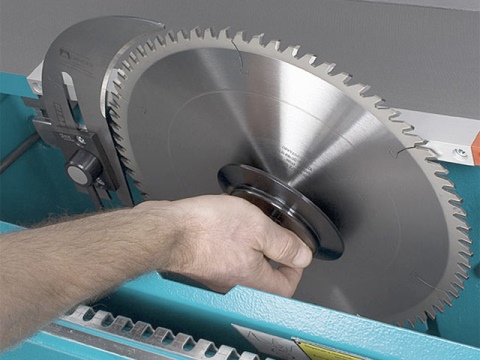

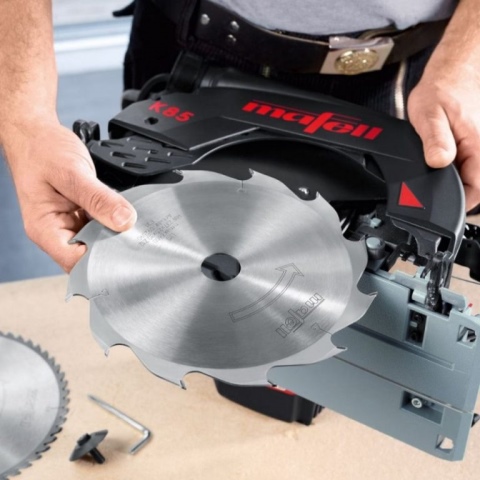

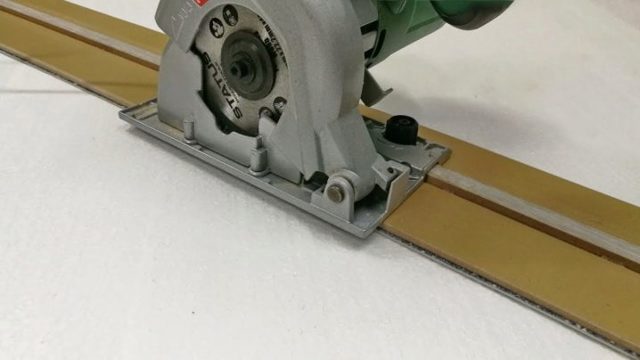

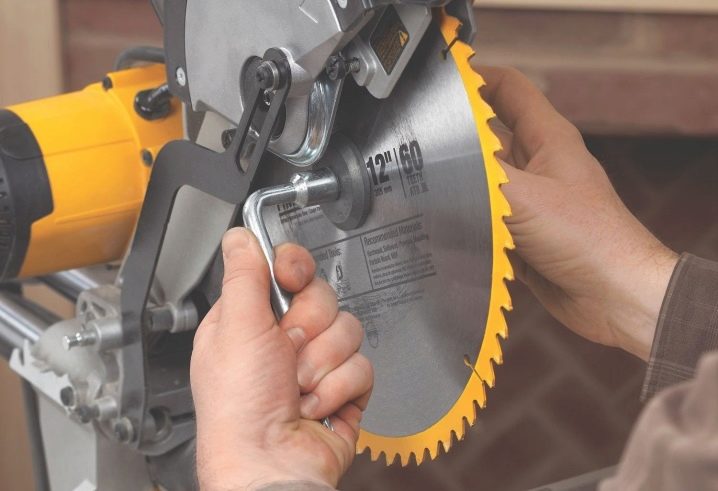

Circle replacement

When performing repairs even at home, the periodic change of materials also requires the replacement of the saw blade. It is not difficult to change it, but it is still worth knowing the correct sequence of actions for your own safety.

It is necessary to start by installing the protective plastic casing (if any) in the upper position. To do this, unscrew the side auxiliary bolt, raise the structure, and then fix it with the same bolt, just in a different position.

Next, take a hexagon, which unscrews the clamping bolt in the center. In this case, on the back of the saw, it is necessary to press the button of the shaft locking mechanism, which is a stopper. It prevents the shaft from moving. Therefore, while holding it, you can press out the central bolt using the hexagon. Then the bolt must be unscrewed (you can use your hands), remove the side stopper (looks like a wide washer) and then the disc.

Installation is carried out upside-down. The disc is put on the shaft, then a lock washer is placed, then the bolt is screwed in by hand until it stops. To clamp the nozzle, you must press the button, and, while holding it, tighten the central bolt to the limit using the hexagon.

For information on how to sharpen a miter saw blade, see the video below.