Combined "trimming"

In much the same way, you can cut parts with a combination miter saw. There are not many such two-in-one models on the market, but they deserve the closest attention.

The peculiarity of their design is that the saw blade works on two sides: the lower part is used for facing and sawing at an angle, the upper part is used for sawing workpieces lengthwise. For this, a special platform is provided above the electric motor, like a stationary circular saw. The guide fence allows you to set the width of the cut part.

Of course, in terms of their characteristics, such models are somewhat inferior to their highly specialized counterparts in the accuracy of their work, but their strength lies in their multifunctionality.

Such tools are loved by professional craftsmen. For example, in the work of installing doors, "trimming" will help to connect the details of the box and platbands "on the mustache", and on the upper platform, you can quickly saw off the extensions to the required width.

Technology

Section 26. Sawing wood

Various saws are used to cut wood blanks (Fig. 94). In the direction of cutting wood fibers, a distinction is made between transverse, longitudinal and mixed sawing.

Rice. 94. Types of carpentry saws: a - hacksaws: 1 - longitudinal, 2 - transverse; b - bow saws: 3 - with metal and 4 - wooden frames

When crosscutting, the cut (kerf) is directed perpendicularly to the wood fibers, when longitudinally sawing - parallel, with mixed sawing - at an angle to the fibers.

For transverse sawing (Fig. 95), saws with straight teeth are used, and for longitudinal (Fig. 96) - with inclined.

Rice. 95. Cross cut wood, side view: 1 - saw; 2 - blank; 3 - cutting edge of the tooth; 4 - apex of the tooth

Rice. 96. Longitudinal sawing of wood, side view: 1 - saw; 2 - blank; 3 and 4 - cutting edge and tooth tip

On cross-cut saws, the sharp cutting edges of the tooth tips alternately cut the wood grain with the right and left bent teeth. The pieces of wood that have broken off in this case are carried out by the teeth from the cut in the form of sawdust.

On rip saws, the forward cutting edges of the slanted teeth cut and separate the wood grain.

For convenience, when sawing, a special device is used - an emphasis (Fig. 97). The block must be firmly held with the left hand, aligning the end of the stop with the marking line on the block. With the movements of the saw along the line, an incision is made, then the emphasis is removed and the workpiece is sawed further. At the end of the cut, the pressure on the saw is released to avoid chipping the wood fibers when the saw exits.

Rice. 97. Sawing with an emphasis: 1 - blank; 2 - stop

For sawing bars and boards at an angle (30 °, 45 °, 60 °, etc.), a miter box is used (Fig. 98). It consists of a base and two sidewalls with grooves. The workpiece to be sawn is clamped between the sidewalls. A saw blade is inserted into the grooves and the workpiece is cut at the desired angle.

Rice. 98. Sawing in a miter box: 1 - blank; 2 - base of the miter box; 3 - sidewall; 4 - manholes

Safe work rules

- When sawing, securely fasten the workpiece, use stops, miter box and other devices.

- Saw only with a serviceable, sharpened saw.

- Do not make sudden movements with the saw.

- Keep your left hand away from the saw blade.

- Place the saw on the workbench with the teeth facing away from you.

- Do not blow off the sawdust or sweep it by hand - use a brush to do this.

Practical work number 28

Sawing wood blanks

Work order

- Mark the pieces of wood for sawing and detailing your design product.

- Find the right saw.

- Having securely fastened the workpiece in the clamp of the workbench, use a stop or a miter box to make an incision and cut out the part.

- Saw the workpieces in the miter box at the desired angle.

Control questions

- What is called sawing wood?

- What are the emphasis and miter box used for?

- What is the difference between cross and rip saws?

- Examine the sawdust and determine where the teeth will cut when cross-cutting and ripping.

Electric drive types

The electric drive can be either a collector type or an asynchronous one. All other things being equal, preference should be given to asynchronous. According to experts in the field of electrical engineering, such devices are unpretentious to operating conditions and more reliable, which means they will not require expensive repairs. The disadvantage is their higher cost. Although recently, relatively inexpensive machines equipped with a drive of this type have appeared on the market.

On most models, the drive is structurally located behind the disc. Although there are also models in which the engine is located on the right or left. If so, the engine box will obstruct your view and could result in serious injury. Therefore, it is better to take machines on which the electric motor is located at the back.

Best cordless reciprocating saws

The cordless reciprocating saw is a tool with the same functionality as a corded tool. Its only difference is absolute independence from the network and lower performance. Such a device is more convenient to use, it is not limited in the distance from the power source and is relevant in the absence of electricity.

Metabo SSE 18 LTX Compact

... The Metabo saw that its compact size makes it easy to work in places where large tools cannot penetrate ...

Expert opinion

The TOP electric reciprocating saws are headed by the Metabo SSE 18 LTX Compact battery model, which is designed for sawing wood, plastic, metal and other building materials. The special fastening of the blades significantly expands the area of use of the tool. The handle is rubberized, which prevents the palm from sliding and allows you to comfortably grip the tool. The package includes a hacksaw, a charger, a sufficiently capacious 3.5 Ah / LiHD battery.

Dignity

- Lightweight;

- Convenient when working in inaccessible places;

- Easy adjustment of the depth gauge, no tools required;

- Simply monitor the battery status;

- Good illumination of the cutting area by means of LED lighting.

disadvantages

- Not very fast sawing wood with a diameter of more than 2 cm;

- No additional features;

- When working with thin blades, they can be easily broken.

Bosch GSA 18 V-LIC 0 L-Boxx

Reciprocating saw Bosch GSA 18 V-LIC 0 L-Boxx is a universal tool for cutting various materials, mainly wood and metal. It can even cut thick workpieces, as the cutting depth is 20 cm. The LED light on the reciprocating saw ensures a good view of the material when cutting. The ventilation slots ensure excellent air distribution, which prevents overheating and prolongs the life of the device. The set includes 3 canvases, this will allow you to immediately start working.

Dignity

- A special system facilitates quick one-handed tool change;

- Long-term use on a single charge;

- LED illumination provides a good overview when working;

- Comfortable rubberized grip;

- High quality control electronics.

disadvantages

- No battery included;

- High price;

- It is impossible to change the frequency of revolutions;

- Doesn't do small diameter radius cuts very well;

- If the material has a high density, then you can push with the other hand only on the small protrusion at the rubberized gearbox.

How to buy a cutting machine profitably

Before choosing a certain model of a cutting machine, you need to understand what characteristics it should have. When choosing the optimal size of the cutting disc, you need to proceed from two points: the dimensions of the workpieces that are planned to be processed on the machine, and the material from which they are made.

After that, you need to resolve the issue with the option of placing the car. The cut-off unit can be made in two versions: table-top or floor-standing. The latter type is intended for cutting massive and oversized products. For heavy-duty use, the tool purchased must be equipped with a powerful electric motor that will enable the operator to cut very thick metal workpieces.

Table-top cutting machines are characterized by their mobility, therefore, they are suitable for use on construction sites. They allow you to repair various metal structures, as well as solve a number of other tasks.

Choosing a cutting machine

When choosing a machine for cutting metal, special attention should be paid to the technical parameters, since the quality of cutting, the performance of the equipment, its service life, etc., to a large extent depend on them. Regarding the choice of cutting equipment, the following technical characteristics should be highlighted

Regarding the choice of cutting equipment, the following technical characteristics should be highlighted.

They are most important for the efficient performance of the machine's direct functions, namely:

- Machine dimensions and weight.

- Overall characteristics of the cutting element.

- The number of revolutions per minute of time, as well as the ability to change them.

- The ability to rotate the cutting unit to the required position in relation to the workpiece.

- Torque transmission method.

- Electric motor power indicators.

At the very end, you need to study the technical characteristics of the built-in vice. Depending on the characteristics of this element, the machine can process metal parts of different dimensions.

Features of the choice of pendulum saws

With the circular sawing equipment, you can cut profile elements of any design, which can be made of cast iron, non-ferrous metal or steel.

The equipment in question can be used for cutting the following types of rolled products:

- channel;

- round;

- I-beam;

- rectangular;

- square.

These machines can be used in small batch and one-off production of workpieces.

Cutting machines for cutting metal can be used for work:

- assembly rooms;

- carpentry;

- finishing;

- making furniture.

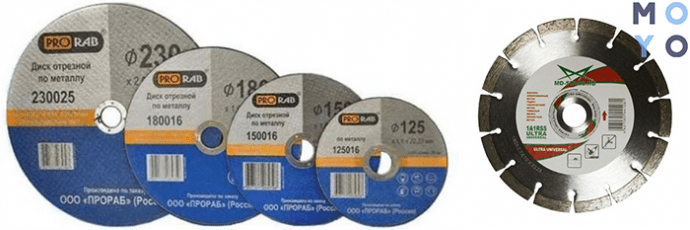

Depending on the type of workpiece used, it is necessary to select the appropriate type of disc and in a certain way adjust the frequency of its revolutions.

Considering that the working disc rotates at a high speed, and the machine uses a power drive with a large reserve of power, the wear of the cutting element is very slow. In this mode of operation, the cutting machine provides high efficiency in cutting metal.

Review of the best models

Of the greatest interest to buyers among the offered models is the Makita 2414NB cut-off machine, which has a portable design. With this equipment, you can cut workpieces from:

- PVC;

- ceramics;

- stone;

- metal.

The Makita manufacturer's lineup includes a lot of reliable and high-quality equipment. However, the model under consideration is designed for medium-level loads.

The manufacturer of this tool provides a shaft locking feature that allows you to quickly change the tool. The installation itself is small in size and weighs 16 kg. The equipment is reinforced with double insulation.

The Hitachi CC14SF pendulum saw for cutting metal is a kind of cutting machine designed for professionals. The model is equipped with a 2000 W power drive, which is able to provide high cutting quality and a fairly large cutting depth - 11.5 cm. Since this equipment surpasses most analogues in technical parameters, it is actively used to perform a wide variety of tasks.

However, the quality of cutting depends not only on the design of the equipment, but also on the disc used. It must be selected taking into account the characteristics of the blanks that are planned to be cut. If this consumable does not match the workpiece, the most unpleasant consequences are possible, up to and including premature failure of the equipment.

Useful tips for choosing and using saw blades

You can often find offers for the sale of universal discs that can be used for cutting metal and wood. This is a very misleading proposal. Reliable brands do not produce such products, because not only the quality of work, but also the master can suffer from their use. Unfortunately, injuries resulting from improper cutting of materials are not uncommon today.

Saw blades are designed for a certain service life, which depends on the intensity of use of the products. When the cut quality decreases, the disc needs to be replaced. Craftsmen often save money and sharpen the old instead of buying a new product. This is not always advisable, because high-quality sharpening is possible only on special machines.

Disc features

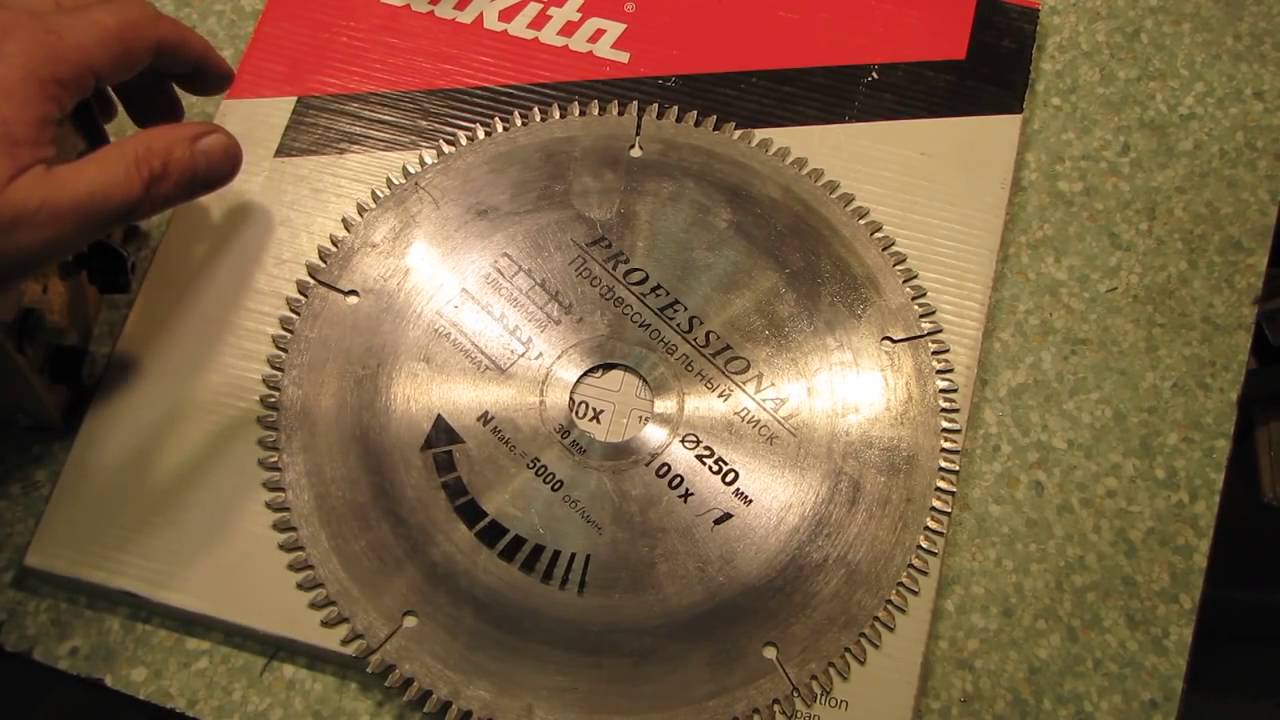

A disc for metal facing can have a diameter of 15 to 35.5 cm, the inner diameter is always 3 mm. The disc can be changed as needed. Considering the diameter of the disc, one can take into account the recommendations of specialists who speak of the need to purchase several elements of different diameters at once. The kit will allow you to choose the most suitable option for a specific metal with the highest quality cutting. However, when choosing, you need to take into account that not every disk can be installed on a specific machine.

Based on this, it is worth taking a closer look at models with a disc that have fine teeth and a smooth wave. Such units cut metal with high quality and at the same time do not overheat the working blade of the disc.

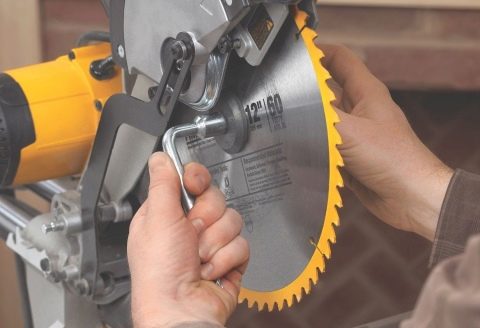

It is important to pay attention to the fact that the blades for miter and circular saws are different, which should be indicated by the marking. Speaking of the seat, equal to the diameter of the axle on the gearbox, it should be noted: it should be selected especially carefully, correlating with the axis parameter

Of course, you can use adapter rings, but only the right option will contribute to the high-quality and efficient operation of the miter saw

The presence of soldered inserts on the disc itself is important, as well as the number of teeth. Such a product is more expensive than monolithic varieties, but will last many times longer than other analogues.

The larger the diameter, the more expensive the disc will cost.

How to choose the right one?

In modern renovations, miter saw blades for aluminum, plastic and stone are most often required. These materials are actively used to create modern decor.

In order to choose a blade for soft metals and polymers, you need to know that there is a difference in sawing a hollow structure or a dense solid. The quality of the cut here mainly depends on the number of teeth. So, to obtain a result close to ideal, with hollow structures, it is better to use discs with a large number of teeth. Dense material is better sawn with a small-toothed nozzle.

An important criterion is the thickness of the disc and the material from which it is made. The best choice is a solid carbide (high carbon) metal cutting attachment. It lasts longer and can be re-sharpened. The same cannot be said for welded teeth.

This quality is inherent mainly in European brands.The cost when choosing an expensive brand name pays off during operation.

If we talk about the angles of inclination, then for soft materials such as plastic, it should be negative. This gives the cleanest cut possible. At the same time, the shape of the teeth is quite varied. The universal drive may be the best option. You can never go wrong with him.

A simple alloy of metals is not enough to perform a high-quality cut in stone. A harder material is needed here, in the role of which is diamond sputtering. In this case, the decisive factor in the selection is the grain size of the abrasive coating. The larger it is, the less beautiful and high-quality the end cut will be. Fine diamond plating is much more useful and clean. But to prevent overheating of the engine, it is better to choose not the smallest value.

Peculiarities

Saw blades have a number of basic parameters that help you differentiate between the two.

Namely:

- outer diameter;

- inner diameter;

- number of teeth;

- tilt of the teeth;

- the shape of the teeth;

- product thickness.

Outside diameter is generally not a significant indicator for cutting speed. He is responsible for the depth of the cut. It can be determined by the inner diameter of the saw cover. A large circle (305-355 mm) is not placed on a product with a smaller casing diameter. (By the way, it is not recommended to remove the protection for safety.) Most often, products with an indicator from 130 to 250 mm are taken for such a saw.

The inner diameter must have the same value with the dimensions of the power shaft on which this product is fixed. If it is larger, then during the operation of the saw, the off-center disc creates large vibrations, which leads to severe wear of the bearings and the shaft itself, as well as breakage of the disc or its teeth. In addition, such a fastening is a gross violation of the work regulations, and is dangerous for humans.

The cutting speed depends on the number of teeth on the disc in direct proportion. In addition, a large number of them gives a smoother and more accurate cut. But there is also a significant drawback of this approach - it is an increased load on the sawing tool engine. There are disks:

- with a large number of teeth (from 80 to 90 pcs.);

- with an average number of them (from 40 to 80 pcs.);

- small-toothed (up to 40 pcs.).

For high-quality sawing, the inclined angle of the teeth is also very important. It is fixed by the deviation of the cutting edge of the tooth from the radius of the saw blade. This parameter can be:

- standard (the angle varies in the range of 5-15 degrees);

- positive (tilt 15-20 degrees);

- negative (from 0 to minus 5 degrees).

Finally, the configuration of the prong. Each shape is designed for a specific cut. Therefore, a tooth is distinguished here:

- flat - cuts longitudinally at high speed;

- trapezoidal flat (alternation of high trapezoidal and low flat teeth) - cuts wood, plastic and soft types of metals (aluminum);

- replaceable (the teeth have an alternate slope to the right and left) - helps to saw wood, chipboard and composites cleanly both along and across;

- combined (one flat cutter follows four replaceable ones) - completely universal;

- Replaceable with a larger sloped side - used for choppy types of material, as well as for clean cuts at right angles.

As for the thickness of the saw blade itself, the thickness of the cut depends on it. The standard is 3.2 mm. If the indicator is higher, then this will reduce the amount of material, and if it is much less, then this will lead to overloading of the equipment and possible deformation of the disk.

What you should pay attention to when choosing saw blades for aluminum and metal:

Sawing material. In their structure, plastic, hard plastic, aluminum, practically do not differ, so one type of discs can be used for sawing them

But when making a choice, it is important to know which workpiece you will have to work with - hollow or massive.Usually, manufacturers indicate on the packaging and in the description of products, for which products the saw blade is suitable.

The number of teeth is one of the main factors affecting productivity and cutting quality.

The more teeth, the better the cut will be. And, accordingly, the cost of the saw blade increases with the number of teeth. For example, ALU-positive 11.1000 is the best option for high-quality and fast work.

Types and angles of teeth. For quality work, you need to choose saws not only with a large number of teeth, but also their correct location

It is important to pay attention to the angle of inclination. The best cut is obtained with a negative tilt angle

A positive tilt angle ensures good working speed. But with a small number of teeth, this factor has little effect on performance. Therefore, for a high-quality production process, first of all, it is worth paying attention to this factor.