Circular saw blades parameters

The disc is a metal circle with teeth at the end. Circular saw blades for wood are designed for different tasks that you need to consider when buying. The wrong tooling will lead to an uneven cut, it will go tight with the expected damage to the consumable.

When cutting, be sure to monitor overheating. Steel is characterized by an increase in body temperature with constant friction, especially against wood. In this process, the metal expands, which leads to a skew of the "figure eight". The deformation begins to manifest itself in a slight beating, which has not been previously experienced. Often, an increase in temperature causes small bulges on the metal body, which are not visible to the eye, but are felt to the touch. Over time, they begin to expand and become even more visible. Operation of a circular with such a disc will lead to engine wear and breakdowns in the armature.

When buying, you need to take into account the possible expansion, since even a disc that matches the characteristics of the tool can begin to expand from temperatures. There are temperature compensators to eliminate this defect. These are slots that take on the expansion and prevent it from deforming. In addition, for safety reasons, you need to take periodic breaks to ensure the cooling of the engine and the circle.

The indicator of the cleanliness of the cut is the number of teeth. Performance models have smaller and larger teeth. They also have a positive slope. They are much faster at cutting wood board or wood, but the edges are covered with debris and uncut fibers. You will have to clean them yourself with a chisel.

The saw blade for wood for a clean cut has a larger number of teeth (from 42) with a negative slope. Their productivity is reduced, but in return they give a clean end, without protruding fibers.

It is important to look at the destination of the disc. The circular has accessories for:

- Metal;

- Wood;

- Wood boards (fiberboard, chipboard, MDF, plywood, OSB);

- Plastic;

- Aerated concrete and foam blocks.

Specifications

During the selection of parts, a number of fundamental parameters of the products should be taken into account.

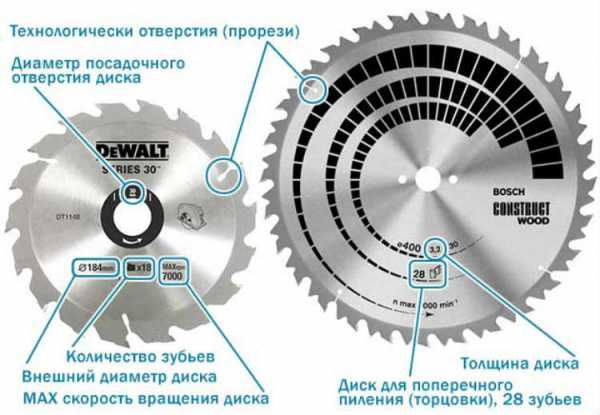

The size

In this case, you must first familiarize yourself with the instructions for the tool. Saw manufacturers indicate this information in the characteristics that a particular device has. As for the outer diameter, its choice is based on the dimensions of the protective casing in the circular saw, therefore, a cutting wheel with a large outer diameter cannot be placed on a device with smaller dimensions in the mechanism. The most common disc sizes are in the range 120–250 mm. This criterion is not responsible for the intensity of the cut, but is of great importance for the depth of cut.

And the inner diameter influences the power shaft of the tool. It can be of the following sizes - 16 mm, 20 mm, 22 mm, 30 mm, 32 mm. The size of the blade must match the size of the shaft in the saw. In modern models of equipment for fixing circles, there are special holes that allow you to fix detail using pins.

Number of teeth

Too many teeth will put additional stress on the motor and may also slow the cutting speed. If you use consumables with fewer teeth on the surface, it will be easier to remove chips from the working material, but the cleanliness of the cut will be imperfect. Based on this parameter, disks can be of the following types:

- discs with incisors, the number of which will be in the range of 80–90 pieces;

- products with average values, where the number of teeth will be in the range from 40 to 80 pieces;

- cutting discs with a minimum number of cutters ranging from 1 to 40 pieces.

Teeth inclination

Most of the blades for circular saws for wood are made with a positive inclination, which increases the quality of the longitudinal cut. With a negative tilt angle, the radius of the tooth will be directed towards the back of the disc. However, longitudinal types of cuts are most often performed by products with a positive deviation of the tooth from the radius, since such a configuration provides a more reliable grip of the raw material. Slope classification is based on the following principle:

- an angle of 5 to 15 degrees is considered the standard incisor position;

- the positive slope is within 15–20 degrees;

- negative - from 0 to 5 degrees.

Based on these values, it will be easier to find the consumable for the job.

Disc thickness and soldering options

The thickness of the slice itself directly depends on this parameter. However, products that are too thick can cause overheating. The most common size is 3.2 mm.

Design features of the cutters on the disc

In this issue, there is a clear gradation of circles according to the type of purpose. So, flat teeth are used to create a longitudinal cut on soft or hard wood. The element is marked by the manufacturer with the abbreviation FT. The second type of cutters is called interchangeable, it assumes the arrangement of the components in an alternating form, where the teeth are in turn tilted in opposite directions. With such a disk, both transverse and longitudinal cuts of wood and wood-containing raw materials are performed. In this case, the cutting disc is marked with ATB.

The combined type discs contain cutters that repeat the configuration of the previous two types. The hand tool or the electric type tool with the Combi disc can be considered a multifunctional device of the universal type, with which almost all types of wood cutting can be carried out. Trapezoidal cutters are flat teeth and are abbreviated as TCG.

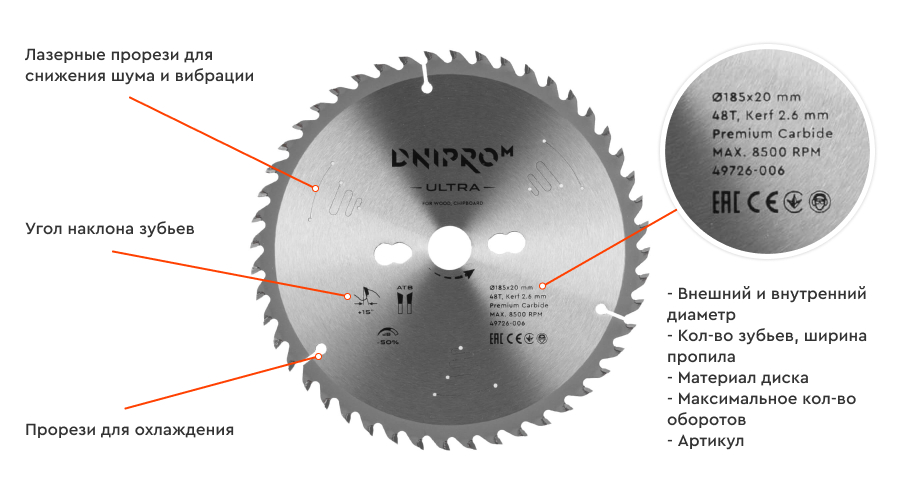

Circular saw blade marking

To determine the parameters of the proposed products, the manufacturer applies certain values to his products, which determine the outer diameter of the circle, the thickness of the solder and the circle. Among the most popular discs for wood, one can single out products with markings of 190x30 mm or 190x20 mm.

Raw material type

As a rule, high speed steel is used to make circles for circular saws. Vanadium, chromium and molybdenum are also used to increase its strength.

Circular saws for wood

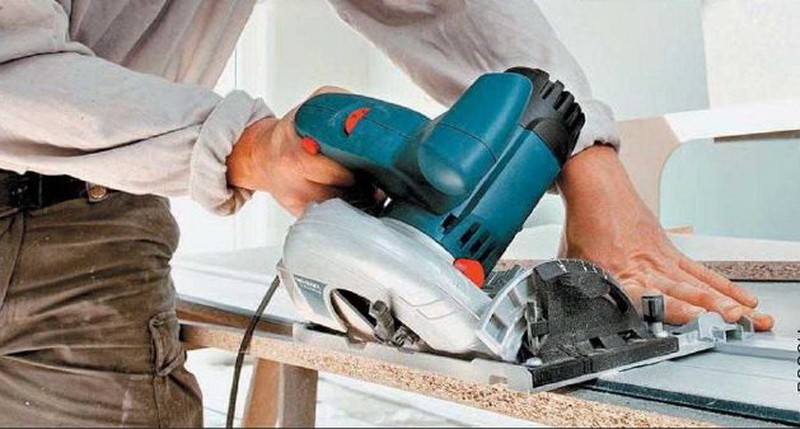

The circular saw is successfully used not only in the industrial field, but also at home, when you need to make an accurate and fast cut of the product. A circular saw is something transitional between a jigsaw and a more advanced electric saw. Today we will look at the features of circular saws for wood, and how to choose the right one.

Technical features of a saw for wood

When choosing circular saws for wood, first of all, they pay attention to the engine power of the tool, since it depends on this characteristic how much wood thickness the saw can process and how quickly the process will take place. If you intend to work with various workpieces, then it will be most convenient to choose a tool with power adjustment

With this option, you can easily achieve a quick cut without overloading the tool.

If you intend to work with various workpieces, then it will be most convenient to choose a tool with power adjustment. With this option, you can easily achieve a quick cut without overloading the tool.

Physical selection criteria include inspection of the entire tool body, a robust body, and an additional handle. Also, the model must be equipped with a safety lock against accidental starting.

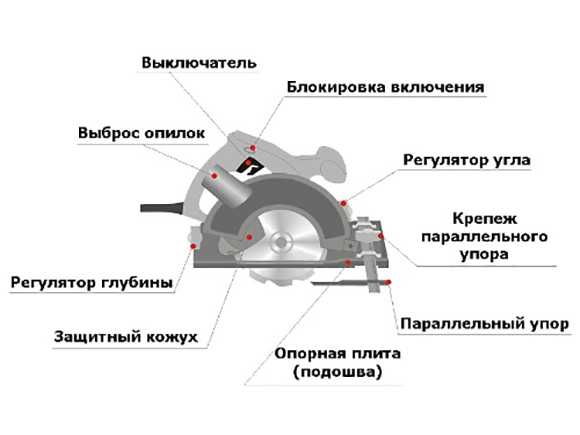

Parts and mechanisms of saws for wood

A circular saw is a very handy tool that every professional and home craftsman should have.With the help of the tool, you can cut any blade evenly, as well as perform an angle cut. For miter cuts, the tool is mounted on a base plate and the tilt can be adjusted up to 45 degrees. More professional models allow you to cut with a slope of 60 degrees.

Together with the ability to tilt, the depth of immersion of the wooden panel is also adjustable. The most popular models are those equipped with an eccentric mechanism. Another useful part in the tool is the guard, which consists of a movable bottom guard and a fixed top guard.

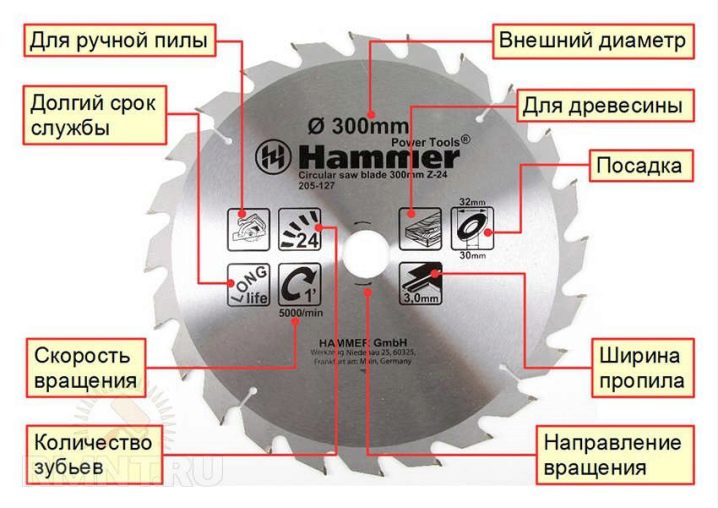

Saw blades

Circular saws for wood are equipped with saw blades that differ in diameter, bore size and thickness. All data is indicated on the disk itself. Saw blades differ in carbide and solid. The disadvantage of monolithic ones is that they quickly lose their sharpness, but they can self-sharpen. The advantages include affordable cost.

Carbide wheels are more durable and one of the most common

When choosing a blade, you need to pay attention to the shape of the teeth, which affects the quality and speed of cutting.

If you need to do a quick roughing job, choose a flat straight tooth. For longitudinal cuts, a disc with a small number of teeth and a positive slope is ideal.

Cross-cutting is most conveniently done with a disc with a large number of teeth.

Work with aluminum, chipboard or laminate will be of good quality if you choose trapezoidal teeth. This will provide a good cutoff frequency and help avoid splitting the material.

It is best to purchase material in specialized stores, where all detailed information about the discs is indicated on the packaging.

Consumers should be aware that pendulum miter saw blades are not used for circular saws and hand-held circular saws. Visually inspect the cutting tool, which should be smooth with laser markings.

An important feature is the thickness of the cutting disc. A thin saw uses much less energy and reduces waste

However, this material is prone to deformation and is not suitable for frequent and difficult work.

Now you know how choose circular saws on wood and what criteria to pay attention to when choosing

How to choose

When choosing a saw blade for wood, first of all, you should consider the applicability to the cutting tool. Depending on its model, the outer diameter and the diameter of the seat are selected.

After that, you need to select from the appropriate disks the one that will ensure the most efficient execution of tasks. In this case, the configuration of the teeth must be taken into account in accordance with the recommendations given above.

From the existing ones, you can choose a manufacturer in accordance with personal preferences, guided by considerations of reliability or considering the most successful combination of "price-quality". The leading companies in the production of tools are the companies of the brands Bosch, Makita, Metabo, Stayer, Zubr, and Praktika.

The quality of products made by well-known companies remains high, even if they are produced in third countries. Good, high-quality saw blades can last for a long time, while ensuring high safety of work and guaranteed high-quality results.

How to choose blades for a circular saw

There are many tasks that a circular saw can handle. But, unfortunately, for the whole range of work, one saw blade cannot be dispensed with. It is necessary to take into account a number of factors in order to correctly select the necessary part and achieve the task assigned to it. Starting from dimensions, ending with the number of teeth and material. An illiterate choice can lead to tool breakage, and sometimes to an accident.

When choosing, pay attention to the technical characteristics of the circular, and already starting from this, you need to select a suitable circle. Some of these increase the load on the engine and may not be suitable for your tool.

Dimensions (edit)

Much depends on the type of your circular saw - everything is indicated in the instructions. But there is also a dependence on the type of work - what kind of material will be processed.

- External diameter. It is matched to the size of the protective cover.

- Inner diameter. Depends on the size of the circular force shaft.

- Number of teeth. A large number of teeth has a negative effect on cutting speed and engine load, but the quality and cleanliness of the cut increase.

- Tooth tilt. Most often, wheels have a positive angle of inclination of the teeth, which is well suited for ripping.

- The thickness of the circle and soldering. Determines how thick the cut will be. Larger widths increase strength but increase engine load.

Saw blade marking

Typically, high-quality products are laser-marked. Based on the marking data, you can get information about the thickness of the blade, the outer and inner diameters, the number of revolutions, the number of teeth.

For example, a disc with values of 190 x 1.8 x 20 mm means that the disc has outer diameter 190 mm, soldering thickness 1.8 mm and a circle thickness of 20 mm. Solder thickness is a key factor when choosing a disc. Moderate thickness will not overload the gearbox, which will ensure tool durability. This blade is well suited for cutting 40 mm boards.

Material

The material for the discs is high speed steel, sometimes chrome vanadium steel. This steel is alloyed with molybdenum, tungsten, vanadium, chromium, which significantly increases the strength characteristics. Marking - CV or HSS.

Carbide saw wheel

High speed steel is strong enough, but not enough for some jobs. Then carbide materials with TC marking are used. The disc is half chrome vanadium steel, and the teeth are tungsten carbide, which are soldered onto it.

Diamond circular saw

For cutting stone, concrete and other durable materials diamond-brazed discs are used, which are attached by laser welding. One of the strongest disc types to handle high density materials.

For cutting stone, concrete and other durable materials diamond-brazed discs are used, which are attached by laser welding. One of the strongest disc types to handle high density materials.

How to choose a circular saw blade

Before buying, it's best to rely on the following tips:

- Diameter. Equipment is selected depending on the required results. For high productivity and sawing large blocks of wood, you need to purchase a circular with a large disc diameter. Despite the low RPM, the saw can remove more material in one turn. 250 and 300 diameters are suitable if you need to cut small slats in large quantities, small circulars that are designed for 80 circles are suitable.

- Disc material. The main difference is service and price. All-metal ones can be sharpened, additionally processed at any time using elementary abrasive tools. They can last a long time if handled correctly. It is possible to buy several types of circles for different types of wood at once. Models with victorious or diamond brazing can significantly increase productivity. They rarely require maintenance, but if the cutter is grinded, it will be necessary to process them with an engraver with diamond and felt nozzles.

- The shape of the teeth. For a productive and fast cut, the adjustable teeth wheel is suitable. They can quickly cut large blocks of wood, which will significantly increase productivity. For a clean one, discs with a number of teeth of 42 or more and a negative sharpening slope are suitable. The combination of these two technologies will allow for high productivity with a relatively clean cut.

When working with different types of wood (professional assembly of furniture, creation of carved gates), you must have a set of different discs. Some manufacturers offer a set of discs with different teeth. The kits cost less than buying a piece.

You can rely on the manufacturer:

- Bosch. German brand that manufactures power tools and accessories. The production is of good quality and reasonable price. There are monolithic and victorious variations in the catalog.

- Makita. Japanese manufacturer that has become the benchmark in the amateur power tool segment.

- Bison. Russian brand leading on the CIS market. Manufactures a full range of accessories for circular saws.

Circular saw for wood - can open fully when using the correct circle.

main parameters

A circular saw blade for ripping wood has a fairly large number of characteristics:

- Outside or outside diameter. Almost all circular saws have a protective cover that prevents sawdust from flying around. It is he and other geometrical dimensions of the machine that determine which discs of what diameter can be installed. On sale, the most common design options, the diameter of which is in the range from 130 to 250 mm. The outer diameter affects the depth of cut, as well as the load of the installed electric motor, from which rotation is supplied to the cutting tool.

- Inner bore diameter. The fixation of the cutting tool is carried out along the inner diameter, which can be very different. Some disc models have additional holes that allow you to fix the disc on the pins.

- Number of teeth. A different number of teeth can be located along the outer diameter. This parameter determines how fast the material can be processed. By increasing the number of teeth, the quality of the cut increases, but the load on the installed electric drive increases.

Circular saw blades for wood (the price depends on a wide variety of indicators) can have an average number of cutters. Such options for the execution of cutting tools are called universal, so how are they suitable for processing with a wide variety of cutting conditions.

What to look for when choosing a saw blade

Obviously, for high-quality wood processing, achieving high results in woodworking, efficiency and economy, the choice of the "right" saw blades must be taken with the utmost responsibility.

Before buying a Pilana saw blade or products from other manufacturers, you should consider the parameters of the circular saw itself:

- shaft rotation speed (maximum number of revolutions per minute);

- electric motor power;

- dimensions of the protective casing;

- the seating size of the motor shaft.

When buying a cutting tool, pay attention to whether this model is allowed to solder circular saws. This option allows you to completely restore the saw blade performance and not spend extra money

The configuration of the saw blade teeth should be based on parameters such as engine power. Installing the blade with a negative or “zero” slope places increased stress on the power tool. If this parameter is neglected, it is quite possible that the circular saws will need to be repaired in the near future.

When evaluating the spindle rotation speed, as well as the shaft rotation speed (revolutions per minute), it is necessary to achieve the maximum correspondence of these parameters to those requirements determined by the manufacturer of the disks.

Saw blades for wood: types, features of choice

In the modern market, there is a very rapid increase in the sale of furniture made from wood of various types. From this it is clear that woodworking workshops operate continuously.Where there is woodworking, wood saw blades are always needed. Circular saws (saw blades) are always in demand.

There is a very large selection of saw blades on the market, they are different both in diameter and thickness. In diameter they can reach from twenty millimeters to two and a half meters.

Such a variety of saw blades is due to the requests for them from furniture factories themselves, wood processing enterprises and large workshops that produce small wooden products. For each process in the tree, different disks are selected according to their characteristics.

Some wood saw blades are designed to work on different machines with different woods.

Consider the most basic parameters of the saw blade:

- Bore size

- Number of teeth

- External diameter

- Thickness. It does not always matter and is not indicated. As a rule, it is equal to 3 to 4 millimeters.

The outer diameter must be indicated, it depends on it whether the disc is suitable for a particular machine. For example: a saw blade for attack wood is used on different machines, but each has its own outer diameter. Also, each disc has its own hole for planting, the most common bore diameter is 30 millimeters for saw blades at

200-400 mm. Discs with a diameter of 150-160 mm have a bore size of 20 or 22 mm. The variety of these bore diameters avoids the problem of replacing the old circular saw with a new one.

An important characteristic is also the number of teeth (segments)

What is the Difference Between Disks

with more teeth and less? The cleanliness of the cut during sawing depends on the number of teeth, the more teeth there are on the disc, the cleaner the cut is. A large number of circular saws for laminated material have 96 segments with a diameter of 300 mm. And, in general, the number of teeth varies from 40 to 100.

Wood saw blades for laminated material are paired with an additional scoring disc that makes a shallow cut from the bottom of the tree towards the main disc. The width of these cuts, lower and upper, is the same and goes along the same axis.

This is a difficult operation and a good clean cut of chipboard, without any blots, can only be achieved by an experienced sawmaker who has experience in installing and adjusting saw blades.

Circular saws are:

- Monolithic: solid metal

- Solid

- Carbide brazing is made on each tooth of the saw blade

The third option has a very big advantage over others. The term of work is much longer than in 1) and 2) options.

After all, an ordinary iron disk quickly dulls and needs to be constantly sharpened, while a soldered disk does not need to be sharpened, it does not need it, the ego does not need to be done, but simply needs to be corrected on a sharpening machine.

And it can save you a lot of money or time, which is so important in business. For example, how saw blades for makita wood most often come with solders

Carbide teeth have their own specific profile, which is optimal for effective cutting. But usually in discs on wood, sharpening is "a mirror through one tooth."

Each wood is hard in its own way and for the hardest rock they take discs of the same shape of teeth, while for a chipboard, discs with completely different shapes of teeth are needed.

If we take aluminum, then its drag coefficient is much higher than that of wood, and it requires its own profile of the cutting edge of the saw blade. But on the market you can find a large number of different saw blades for both aluminum and wood, as well as find blades for cutting other non-ferrous metals.