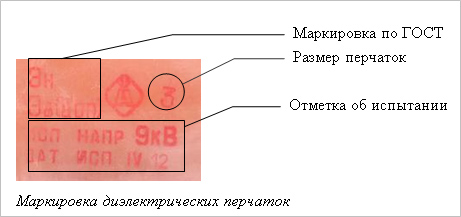

9.1. Marking

9.1.1. Gloves should

be marked for protective properties in accordance with GOST

12.4.115 or pictograms (see).

9.1.2. On every glove

the following information must be clearly indicated:

a) name, trade

brand or other identifiers of the manufacturer or its official

representative;

b) the purpose of the product,

commercial name or code,

allowing the consumer to clearly identify the product;

c) size;

d) if necessary

the expiration date must be indicated;

e) pictogram if

the product meets the requirements of the relevant standard.

9.1.3. On

packaging of gloves should be:

a) name and full

manufacturer's address or

official representative:

b) data on 9.1.2,

enumerations b), c), d);

c) the inscription "Only for

minimum risk "or a similar expression if gloves are intended for

protect the user only from the risks listed in;

d) product conformity

special European standards;

e) pictograms,

indicating the purpose of gloves (see);

f) appropriate

an indication when the glove protects only part of the hand.

9.2. To gloves

enclose storage and care instructions.

8.1. Measuring hands and gloves

8.1.1. Arm circumference

measured with a metal tape in accordance with GOST 7502

at a distance of 20 mm

from the bifurcation of the thumb and forefinger (see Figure 1).

8.1.2. Arm length

measured in millimeters as indicated in Figure 1.

8.1.3.

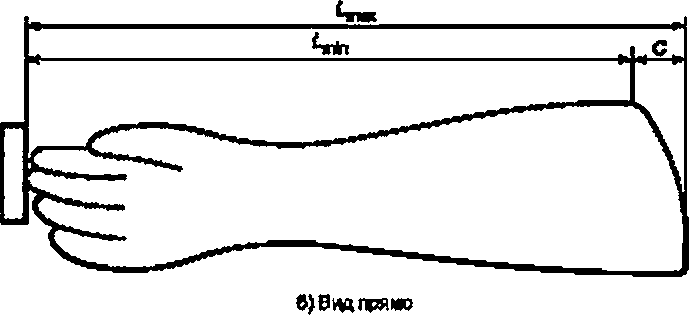

The length of the glove is measured from the top of the middle finger to the end of the glove on the back

side (see figure 2).

|

a - length Figure 1 - Measurement |

a is the length of the glove, Figure 2 - Measurement |

For measuring

the length of the glove must be freely suspended by the middle finger to the vertical

located ruler. Without stretching the glove must be smoothed by straightening

wrinkles and folds. The resulting minimum length is recorded with an accuracy of

millimeter.

8.1.4. If the glove

there is a sewn on cuff or it is made of elastic material, dimensions

indicate for the unstretched state.

Why test dielectric gloves

An ignorant person believes that testing rubber dielectric gloves does not make sense, since it is easier to buy new protective equipment. However, this is a dubious economy, because there are rules and regulations that must be adhered to. In accordance with the requirements of the Instruction SO 153-34.03.603-2003 "On

application and testing of protective equipment used in electrical installations "dielectric gloves, as well as safety ropes and safety harnesses received from warehouses or directly from manufacturers, must be checked for compliance with safety standards before use.

There are two types of dielectric gloves:

- For work on electrical installations with voltages up to 1000 V, where gloves are used as the main protective equipment. They must not be used for operation with voltages exceeding 1000 V.

- For work on electrical installations with a voltage of more than 1000 V, where gloves are used as an additional protective equipment when working with basic protective equipment - electrical and insulating pliers, rods, high voltage indicators, etc.

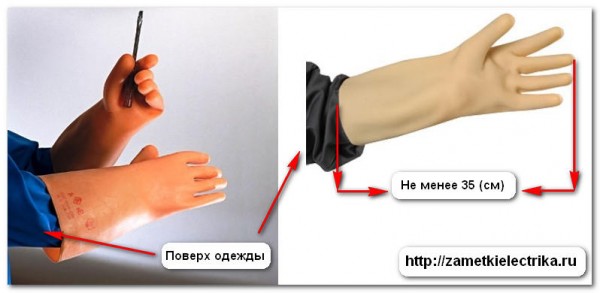

When installing and repairing switches, disconnectors and other equipment with a voltage of more than 1000 V, dielectric gloves can be used without additional protective equipment. Gloves for work on installations with a voltage of more than 1000 V can be used as the main protective equipment for servicing electrical installations with a voltage of less than 1000 V.Gloves should be worn to their full depth and the bell should be pulled over the sleeves.

Not allowed:

- Roll up the sockets of the gloves.

- Pull down the sleeves of work clothes over gloves.

- Do not comply with the test frequency.

We carry out testing of dielectric gloves for work on electrical installations up to 1000 V and more. Testing of dielectric gloves is carried out as soon as possible, according to the test results you receive a test report signed by the responsible persons.

Stationary laboratory "EnergoServiceGarant

»Performs high-quality tests of personal protective equipment for working with high-voltage equipment. Their verification meets all the requirements of regulatory documents, applicable rules and regulations. Before testing, a thorough examination of the products is carried out; if there are defects, the gloves are considered unsuitable and removed from the test.

If the external examination is successful, the electrical and mechanical characteristics of the products presented to us are checked. We test dielectric gloves in a state-of-the-art laboratory.

LabTestEnergo laboratory is a professional service related to electrical measurements and testing. We offer official services at an affordable cost with the issuance of an official opinion. The list of services of the LabTestEnergo laboratory includes test checks of electrical protection equipment, including testing of dielectric gloves.

Key points and terms

Electrical protective equipment - (items) that serve to protect people from electric shock, exposure to an electric arc or electromagnetic field when working in electrical installations.

They are divided into basic and additional.

The main electrical protective equipment - their insulation can withstand the operating voltage of electrical installations for a long time, which allows you to touch live parts that are energized.

Additional electrical protective equipment - by themselves, cannot provide protection against electric shock and are used in conjunction with the main electrical protective equipment.

All means of electrical protection in electrical installations must meet the requirements of state standards.

I recommend when buying them, be sure to check the availability of certificates of conformity. Especially if you buy them for your staff. Since if you are a leader and a malfunction is discovered, they will ask you.

The personnel carrying out the repair work of electrical installations must be fully provided with all the necessary protection, trained in the rules for their use, must use them to ensure the safety of work.

Protective equipment must be present as inventory, in the premises of electrical installations. They can also be issued for individual use.

Use only marked electrical protective equipment, indicating the manufacturer, name or type of product and year of manufacture

Be sure to pay attention to the test stamp! He must be present without fail. If the trial period is overdue, you have the right not to start work

Remember this, and always pay close attention to it. Your safety is at stake and more.

Insulating electrical protective equipment should be used only for their intended purpose and in electrical installations with a voltage not higher than that for which they are designed. These data are written in the operation manual, instructions, passport for one or another electrical protection device

Also pay attention to the weather conditions under which you are going to work.

We will not go into details about storage conditions, just a few words - you need to store protective equipment in conditions that ensure serviceability and suitability for use, they must be protected from mechanical damage, pollution and moisture.

To get a permit for electrical safety, you need to know all this!

Now more about the exam, as promised.

Testing of protective equipment in electrical installations, ignorance of norms and terms, this is not the main criterion for my failure. Everything went well, I told what kind of protection is in electrical installations, how to provide assistance to a victim in case of electric shock (release, artificial respiration, external heart massage, etc.). Internal rules for labor protection. And when I was asked what work I had already done and how I check the absence of voltage, I showed my homemade voltage indicator.

All on this I also failed! Who knows, he understood. Well, for those who don’t know, it is forbidden to use home-made devices and control lamps (a cartridge with an incandescent lamp and two wires) to check the voltage. I collected this index myself, under the strict guidance of a colleague, who is 74 years old, he is an electronics engineer and knows what's what. I use it to this day, it works properly.

=> Next exam.

Joke:

- What is step voltage? - This is the tension that arises between the legs when approaching the bare end ...

Storage rules and protection against deformation and damage

The rules for using dielectric gloves prescribe certain storage rules. In particular, in order to maintain operational characteristics, protective products should be thoroughly cleaned of contamination immediately after work is completed - for this, soap and water are used, as well as special disinfectants that are harmless to rubber and latex. Dry the gloves after cleaning.

During storage, dielectric gloves and boots must be protected from direct sunlight, avoid contact with oils, acids, gasoline. In the room where the protective equipment is stored, a certain temperature regime must be observed - from -30C to + 40C - there must be no high humidity, dustiness.

Dielectric gloves are a versatile and reliable means of protection when performing electrical work. The use of dense rubber and latex allows to ensure a long service life of the products, but it can still be extended even more if during work you do not wrinkle protective equipment, wear them correctly and do not use them in installations where sharp edges are present, open. For example, leather gloves can be worn over gloves.

What are dielectric gloves (video)

If a person remains alive, then further disturbances in the functioning of his body follow, such as loss of skin sensitivity, headaches or dizziness, a feeling of weakness and loss of memory, impaired hearing, vision and much more. During rehabilitation, you must periodically visit a doctor

It is important to be especially careful when working with electric current, observing all safety and operating rules

Dielectric Gloves

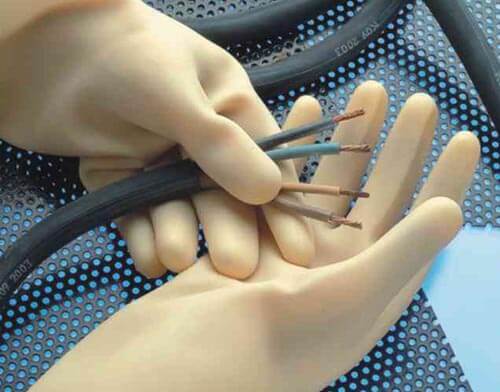

Dielectric gloves are designed to protect your hands from electric shock. When working in electrical installations up to 1000 V, gloves are used as the main electrical protective equipment, and in electrical installations above 1000 V as an additional one.

In electrical installations, it is allowed to use seamless latex gloves (according to GOST 12.4.183-91 and TU 38.306-5-63-97) or gloves with a seam made of sheet rubber, made by punching (according to TU 38305-05-257-89). The length of dielectric gloves must be at least 350 mm. The size of the gloves should allow woolen or cotton gloves to be worn under them to protect hands from low temperatures when servicing open devices in cold weather. The width along the lower edge of the gloves should allow them to be pulled over the sleeves of the outer garment. Gloves can be five-fingered or two-fingered.

Rules for the use of dielectric gloves

It is forbidden to use gloves whose verification period has expired.

Before using gloves, make sure that they are not wet or damaged. Check gloves for punctures by twisting them towards the fingers.

When working with dielectric gloves, the edges must not be rolled up. To protect against mechanical damage, it is allowed to wear leather or canvas gloves or mittens over the gloves.

Gloves in use should be periodically (according to local conditions) disinfected with soda or soapy water.

From personal work experience, I prefer seamless gloves. I used gloves with a seam, but either they were not of proper quality, or this is a feature of all gloves with a seam, but they crawled right on the hands and not only at the seams.

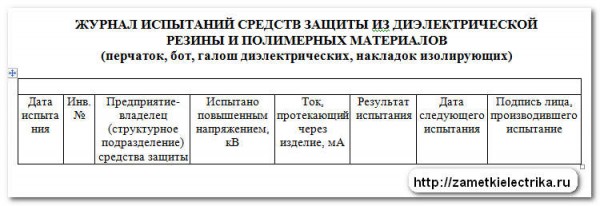

Dielectric Glove Testing

Once every 6 months, dielectric gloves must be tested with an increased voltage of 6 kV for 1 minute. The current through the glove during the test shall not exceed 6 mA.

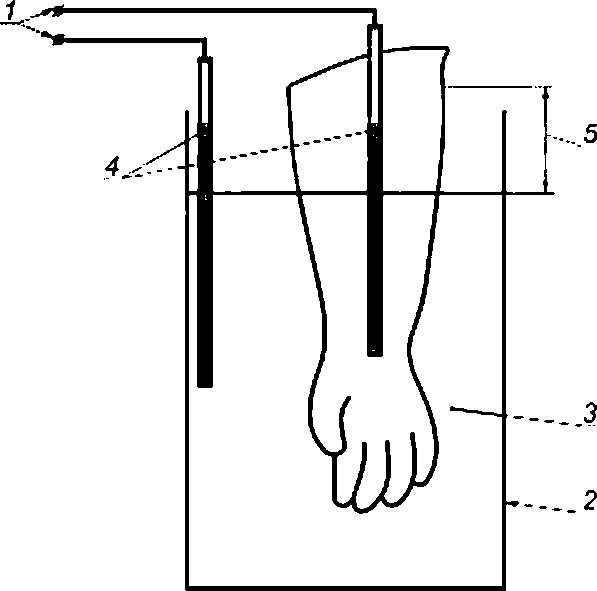

During the test, dielectric gloves are immersed in a metal vessel filled with water. Water temperature 25

±

10

°

C, water is poured into the inside of the gloves. The water level outside and inside the product should be 50mm below the top edge of the gloves. The protruding edges of the gloves must be dry.

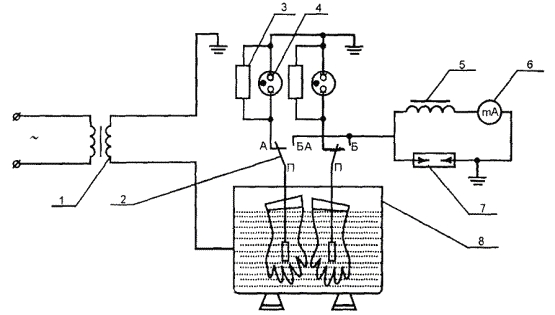

One terminal of the test transformer is connected to the vessel, the other is grounded. An electrode is lowered inside the gloves, connected to ground through a milliammeter. One of the possible test setup schemes.

Rice. Schematic diagram of testing dielectric gloves, bot and galoshes:

1 - test transformer;

2 - changeover contacts;

3 - shunt resistance (15-20 kOhm);

4 - gas discharge lamp;

5 - throttle;

6 - milliammeter;

7 - spark gap;

8 - bath with water.

During the test, the switch is first set to position A in order to determine the absence or presence of a breakdown from the signal lamps. In the absence of breakdown, the switch is set to position B to measure the current passing through the glove. A dielectric glove is rejected if the current passing through it exceeds the norm or sharp fluctuations of the milliammeter needle occur. In the event of a breakdown, turn off the defective product or the entire installation. At the end of the tests, the products are dried.

To order:

Inspection and Testing of Dielectric Rubber Gloves

Tel. manager:

495 195 03 88

Laboratory of high-voltage electrical measurements of LLC "EnergoServiceGarant"

»Quickly and efficiently test dielectric gloves used when working on high-voltage lines. The tests are carried out by qualified personnel with the necessary approvals and work experience. A specialized high-voltage stand is used for testing, after the test, the gloves are stamped with the date of the next test and the maximum allowable voltage.

Test reports are drawn up in the laboratory and provided to customers along with proven protective equipment. The testing period for rubber dielectric gloves is 6 months.

5.1. Convenience and efficiency of use

5.1.1. Hand sizes

Hand size

determined by measuring its length and the length of the girth of the hand,

Table 1 shows

six hand sizes, defined in accordance with anthropometric

measurements carried out in different countries.

Interpolation method

intermediate sizes can be obtained.

Table 1 -

Basic hand sizes

Dimensions in

millimeters

|

Brush size * |

Hand girth |

Length |

|

6 |

152 |

160 |

|

7 |

178 |

171 |

|

8 |

203 |

182 |

|

9 |

229 |

192 |

|

10 |

254 |

204 |

|

11 |

279 |

215 |

|

* The value is a conditional indicator of the size |

5.1.2. Glove sizes

Glove sizes

determines based on the size of the brush for which they are intended. Table 2

There are six basic sizes of gloves.

Table 2 -

Basic sizes of gloves

Dimensions in

millimeters

|

Glove size |

Brush size |

Minimum glove length |

|

6 |

6 |

220 |

|

7 |

7 |

230 |

|

8 |

8 |

240 |

|

9 |

9 |

250 |

|

10 |

10 |

260 |

|

11 |

11 |

270 |

|

Note - Actual dimensions |

5.1.3. Special purpose gloves

Special gloves length

application may not match the values given in table 2.

The manufacturer indicates that these gloves have a "special

purpose ", clearly indicating this in the instructions for use and the reasons for

which the specified gloves do not correspond to the values of table 2.

5.1.4 Ease of handling

Gloves should allow

easy to manipulate with your fingers.

Finger mobility

characterized by the level of freedom of movement.

Level of freedom of movement

evaluated in accordance with Table 3.

Table 3 -

The degree of freedom of movement

|

The degree of freedom of movement |

Minimum bar diameter corresponding to |

|

1 |

11 |

|

2 |

9,5 |

|

3 |

8 |

|

4 |

6,5 |

|

5 |

5 |

Inspection Principles and Test Times for Dielectric Gloves

Safety precautions dictate the need to test dielectric gloves every six months. Testing is carried out in laboratory conditions: first, the couple is subjected to a load of 6 kV for 60 seconds. If the products are suitable for use, they conduct no more than 6mA, if the material conducts more current, the leggings are unsuitable for use as electrical protection means.

Check sequence:

- Electrically insulating dielectric gloves are placed in a metal tank with warm or slightly cool (not lower than 20 C) water. In this case, the gloves are not completely immersed - the top should look 45-55 mm above the surface. This is necessary so that electrodes can be placed inside the gloves. The material above the water (as well as the walls of the tank that are not filled with liquid) must be dry.

- One of the contacts of the transformer is connected to the tank, the other is grounded. An electrode is immersed in the gloves, grounded by means of a milliammeter. Thanks to this method, it is possible not only to assess the integrity of the material, but also to test whether an electric current flows through the product.

- The load comes from the transformer equipment, which is connected with one wire to the tank, and the other to the DIP switch. The first test method: a chain of transformer-gas-discharge lamp-electrode; the second way: a chain of transformer-milliammeter-electrode.

Multiple pairs can be tested at once, provided that it is possible to check the load passing through each product. After testing, the leggings are thoroughly dried.

Inspection frequency for dielectric gloves must be strictly observed, since when working with currents up to 1 KV, this is often the only protection against possible electric shock.

Dielectric Gloves Life

Subject to the storage rules, dielectric gloves usually last 1 year or more (if there is a periodic check of the product - once every six months). The warranty period must be indicated on the packaging.

If safety precautions are not followed, a person wearing gloves can get an electric shock, which can cause muscle spasm, difficulty breathing, or even death.

For some people, the skin does not conduct electricity, so they do not feel discomfort at first when they are electrocuted. However, there are signs by which it can be understood that an electric shock has occurred and medical attention is needed. It:

- A sharp fall of an employee if he was standing next to electrical appliances or electrical equipment;

- Deterioration of vision (the eye does not respond to light), understanding of speech;

- Stop breathing;

- The onset of seizures, loss of consciousness.

Electric shock can cause skin burns. However, if it is not there, this does not mean that everything is fine: the current may not affect the outer skin, but cause problems with breathing or heart.

It is important to immediately remove the person from the focus of the electric shock, since he himself will not be able to remove his hand from the wire.You cannot use your hands for this, you need to act with an object that does not conduct electricity

Then it is necessary to check whether the person has a pulse, breathing. If not, you need to immediately call an ambulance and start resuscitation (artificial respiration). It is also important to find the place where the current entered, cool it with water for 10-15 minutes, wrap the damaged areas of the skin with clean bandages.

How to choose?

Despite the seemingly simplicity of the models and the narrow purpose of dielectric gloves, when choosing them, several points must be taken into account.

- The gloves must be sure to indicate which voltage level they correspond to. In no case should this requirement be ignored.

- The products offered must be free of any defects. The presence of irregularities in the material or, conversely, any other rubber residues is not allowed. If you buy the version with a seam, then the seam should be even and with the same stitches, there should be no loose ends of the thread or a break in the seam.

- When working outdoors in the cold season, products are selected one or two sizes larger. This is necessary so that warm knitted gloves can be worn under them.

- And of course, it is better to buy products directly from manufacturers. This guarantees product quality and compliance with the expiration date. In addition, the price in this case will be lower than that of other sellers.

There are a few more rules to take into account that must be followed in order for the selected dielectric gloves to serve properly for the entire period and guarantee reliable protection.

- Before using them in work, the products must be carefully examined from all sides. They must be free of dirt or moisture.

- Before direct use, they must be checked for leaks. Even micro-holes are not allowed, otherwise they will pass electric current.

- The edges of the products must not be tucked up during operation. Do not leave part of your hand unprotected.

- During the entire period of use, they must be washed periodically. To do this, you can use a soap or soda solution. Then rinse and dry thoroughly.

For information on how to check dielectric gloves for integrity, see the next video.

Dielectric Glove Classes

Depending on the voltage level, all dielectric gloves used today in production are divided into the following classes:

-

00 - 500 V (tests are carried out at a voltage of 2500 V);

-

0 - 1000 V (5000 V);

-

1 - 7500 V (10000 V);

-

2 - 17,000 V (20,000 V);

-

3 - 26,500 V (30,000 V);

-

4 - 36,000 V (40,000 V).

Grade 00 - The thinnest and weakest dielectric latex seamless gloves. According to GOST, they can only be used in installations of not too high power. Most often, these gloves are used when repairing household appliances.

Class 0 products are operated on relatively weak production lines and mechanisms. Seamless dielectric gloves up to 1 KV are allowed to be worn for more serious work, for example, on medium-power machines.

Class 2 protective equipment is currently the most popular in enterprises. Usually these are seamless dielectric gloves made of silicone according to GOST. With the use of class 2 protective equipment, powerful machine tools, automotive equipment, etc. are repaired.

The rest of the classes of gloves are used for protection against high-power loads. Such products are already classified as special accessories. They are repaired using high-grade gloves, for example, industrial electricians, powerful machine tools, etc.

Dielectric Glove Test

There is a generally accepted standard for testing dielectric gloves, namely once every six months. That is, every time the next test is due, this protective equipment should be taken to an electrical laboratory, where the gloves will be tested in accordance with the standards.Consider the test method for dielectric gloves.

A metal container is filled with water at room temperature (a temperature deviation of 10 degrees is allowed) and gloves are placed with fingers down, water is poured into the gloves. At the same time, both the outside of the gloves and the inside of the 50 mm remain dry. Testing of dielectric gloves is carried out using a special circuit with a test voltage of 6 kV for one minute. Voltage is supplied from a test transformer, one terminal of which is connected to the tank and grounded, and the other is connected to a switch that has two positions. The first position: the transformer-gas-discharge lamp-electrode circuit, the second position: the transformer-milliammeter-electrode circuit.

The switch is set to the first position, the electrodes are lowered directly into the dielectric glove, voltage is applied. If the lamp lights up, a breakdown has occurred. If there is no breakdown, then the switch is set to the second position and the milliammeter reading is monitored, the current at which should not exceed six milliamperes.

In case of breakdown, at current values of more than 6 mA, as well as in case of unstable readings of the device (oscillation of the arrow), it is concluded that dielectric gloves are not suitable for use.

After testing, the protective agent is dried at room temperature, a test report is drawn up, and a new stamp is applied to the protective agent, indicating the next test date.

Species overview

The assortment of electric gloves cannot be called diversified. Common materials for the production of such workwear are latex and plastic rubber sheets. The dimensions of the product are designed so that the electrician can wear insulated gloves or mittens under them during the cool season.

Gloves for working with electricity are classified according to several parameters.

In appearance

Personal protective equipment can be two- or five-fingered, while five-fingered are considered more convenient, since in this case the employee can fully use his hands - thereby greatly simplifying the process of wiring and repairing electrical equipment.

Depending on the manufacturing technology, they are seamless or have a seam. Suture (they are also called ditched) dielectric gloves are made of durable rubber, while the presence of a seam is provided for by their design features - such products are comfortable to wear and lightweight.

Depending on the functional purpose

Protective equipment for electricians is made in two versions.

- Models for installations within 1000 V are worn as basic protective equipment when working under overvoltage. It is strictly forbidden to use them in systems exceeding 1000 volts.

- Models for electrical installations of more than 1000 volts - in this case, they act as an additional means of protection, while the work itself is performed using a special insulating tool (electric clamps, all kinds of rods, as well as overvoltage indicators and some other types of professional equipment).

Depending on the maximum allowable voltage

There are several types of dielectric gloves, each of which has its own narrow scope of use. Let's consider each of them separately.

- Class 00 is the weakest dielectric protective gloves. As a rule, latex is used for their manufacture, they are used to perform electrical work on low-power devices (household appliances).

- Class 0 - these gloves can be used without the accompanying equipment. They are put on to carry out work on electrical systems, the voltage in which does not exceed 1 kW, they include relatively weak power lines and production mechanisms.

- Class 1 - used for more complex work, for example, on medium-sized production equipment. These gloves have a tolerance of up to 7.5 kW.

- Class 2 - In most cases, these gloves are certified for 10 kW voltage protection. Such protective equipment, as well as products of classes 3 and 4, are most in demand in a professional environment, they are universal and have a fairly wide scope - they are used in automotive technology, when installing and setting up machine tools, setting up electrical wiring and other types of work.