Scope of the homemade saw

The main task of this equipment is to make a perfect long cut in wood. In order to guarantee the quality of a circular cut, several conditions are necessary: high speed of the cutting edge, its sharpness, rigidity of the "disk-working surface" system, safety, strength and convenience.

The small dimensions of the circular do not make it possible to use it during the construction of a house, when wood is required in large quantities, because the functionality of homemade equipment is not so wide.

But during repair work, such a machine will become a savior, an irreplaceable assistant. The circular will allow you to quickly and efficiently get all kinds of wooden blanks (bars, planks, slats), cut sheet material into plates of the required size.

Safety engineering

From a safety standpoint, the idea of using a grinder as a sawing machine is very dangerous and undesirable. Too high rotational speed of the disk, unreliable fastening of the tool, inability to install high-quality protection - all these factors unanimously require that you abandon the idea and turn to other options.

However, if a decision is made, the following requirements must be considered:

- stability, immobility of the bed;

- rigid fastening of the tool, the impossibility of vibration or movement of the grinder;

- use only high-speed saw blades.

In addition, it is necessary to follow the general rules for working on a circular machine, the main of which are:

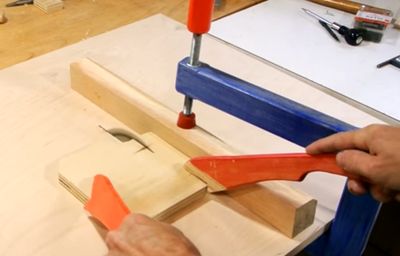

- the presence of hanging ties, sleeves, ends of clothes is excluded;

- it is forbidden to move workpieces with bare hands in the immediate vicinity of the saw blade;

- if the workpiece is jammed, immediately turn off the machine and eliminate the problem;

- start work only after reaching full rotation speed;

- it is forbidden to brake the disc after it has been disconnected by hands or foreign objects; you must wait until it stops automatically.

Compliance with safety rules is a prerequisite for working with woodworking machines. They are considered the most traumatic group of industrial equipment, therefore, the safety rules cannot be ignored in any case.

Alteration process + (Video)

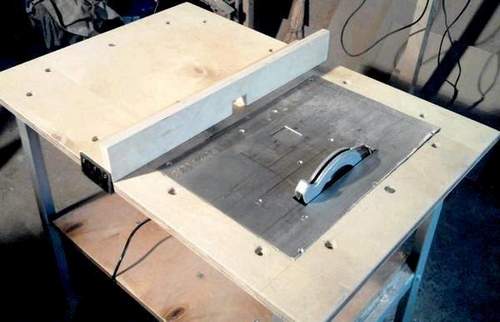

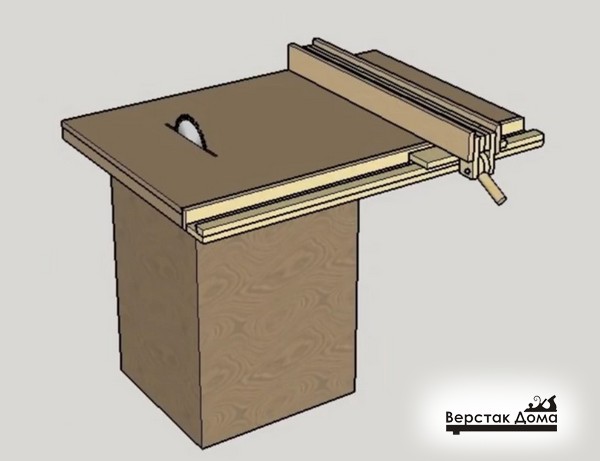

To be precise, it can hardly be called a rework, it is a refinement or expansion of the grinder's functionality. You can divide the revision into stages or steps in the work. First, let's define the main tasks. It is necessary to make a table for installing a circular saw. It can be of any available material, but a steel corner base is preferable.

The grinder should be painlessly installed and removed, so its attachment to the table should be open and accessible. The cutting disc will be mounted directly on the grinder shaft. It must be adjustable in height or change the height of the cutting blade above the table plane.

There should be an adjustable rail on the table. With its help, it will be possible to set the thickness of the board cut. As a special case, you can install a corner guide, if necessary.

So, we constructively make a machine for the existing grinder with adjustment for the height of the cutting wheel. For simplicity of construction, we will use wood:

We make a cut for the saw in the tabletop from the board. If it is a furniture board or plywood sheet, then it is advisable to strengthen it with an additional bar along the position of the cutting wheel;

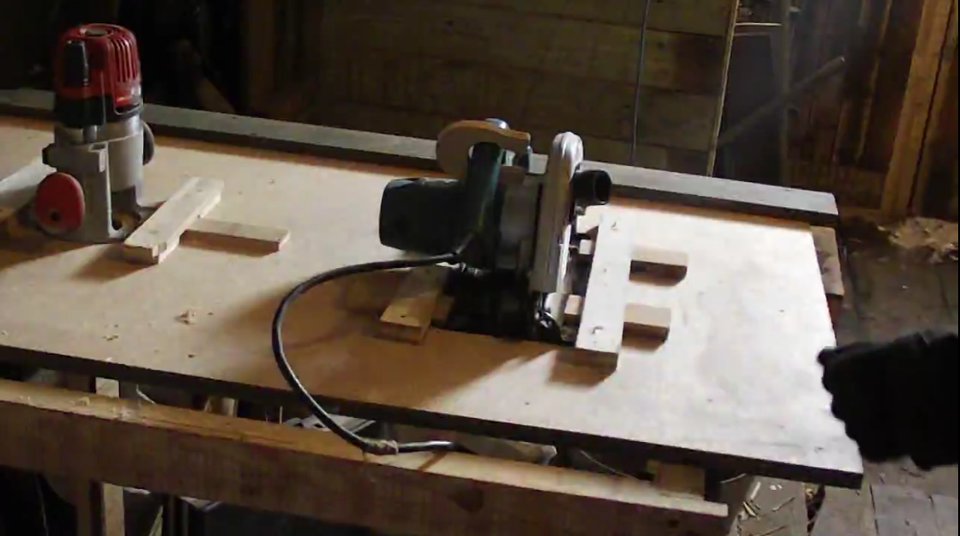

We fasten the rear part of the machine structure on a hinge. Then we fix the grinder. To fix it a short bolt with a locknut is required.The bolt will screw in instead of the handle and attach the grinder to the hinge part of the machine;

From the side of the grinder handle, we make a clamp with a sawn-through adjustment bar. This is a U-shaped bracket into which the handle of the drill should fit snugly. For density, you can glue rubber strips. An adjusting strip with a cut will be attached to the same u-shaped plate.

We fix the hinge and the adjusting bar from below to the table top so that the cutting wheel evenly enters the cut of the table top;

We install the tabletop on a base made of a steel corner or wooden blocks;

We supply electricity. Electrical safety conditions must be met. It is better to connect using a cable that is not afraid of a piece of board accidentally falling onto it;

We are doing a test run. The saw blade should rotate without catching the edges of the slot. If this is not the case, then it is necessary to change the position of the attachment of the hinge or u-shaped plate. The supply of material to the cutting wheel should not cause displacement or vibration of the grinder.

Both the grinder and the hand circular saw are a very successful removable drive for a stationary circular saw.

It is easy to make a circular saw from a grinder. To do this, the protective cover must be redone so that almost the entire saw blade is covered. And it is necessary to install a movable protection on the working sector of the disk, which will move during operation. It is also advisable to install a vacuum cleaner pipe on the casing if the saw will be used indoors.

An additional curved thin-walled tube handle must be installed at the front. With this handle it will be safer and safer to fix the position of the circular during operation.

You may have difficulty creating a stationary circular from a grinder or manual circular. On construction sites and forums, you can find the required drawings of simple structures.

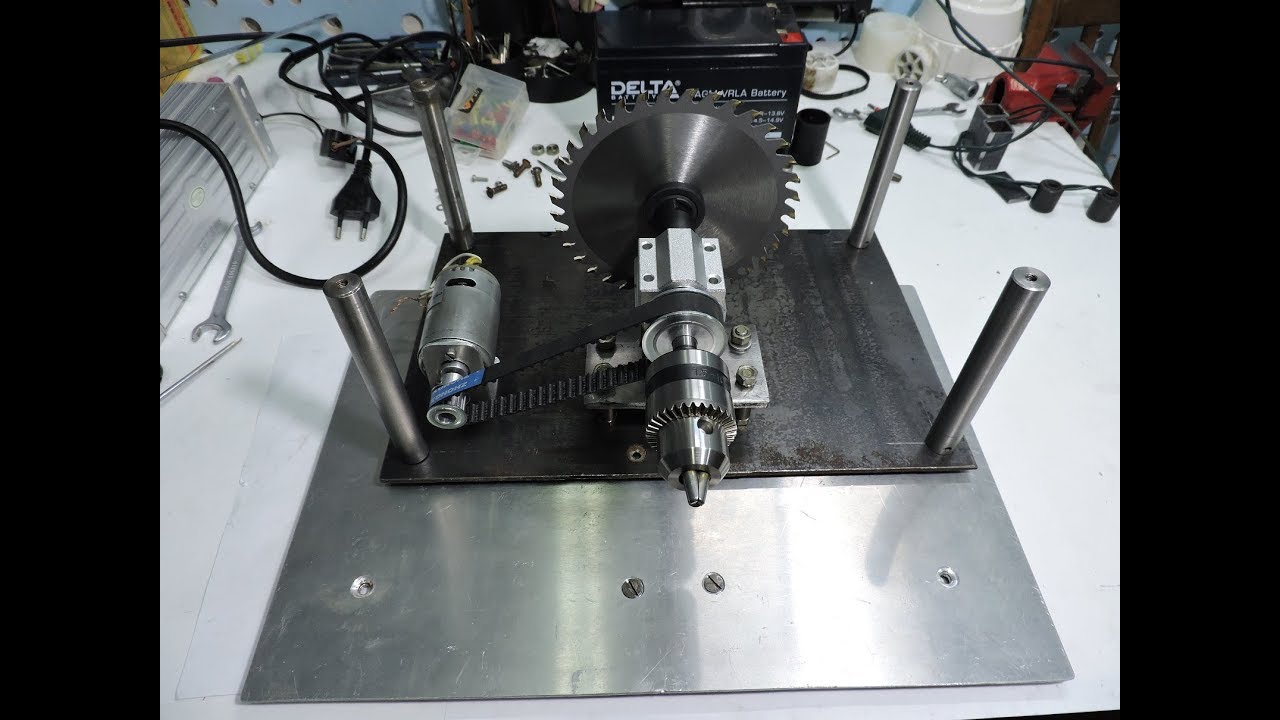

Pendulum engine mount

Those who can boast of the ability to work with metal can be advised to make a circular with a pendulum engine mount. The main feature of the device is that the motor, shaft and cutting disc are mounted in one common frame. On the one hand, it is hinged to the bed, the other is held in place by a screw with adjustable height. By changing the length of the screw, you can adjust the height of the disc exit from the tabletop.

This system allows you to adjust the cutting height, as well as use discs of different diameters. If, instead of an adjusting screw, you use a dipstick brought out to the tabletop, you can get a simple copying machine. The probe will allow you to adjust the cutting depth according to a certain template. This rather simple modification will turn a simple circular saw into a real woodworking machine. With such a device, you can not only cut the board into the necessary blanks, but also make precise cuts, make various samples.

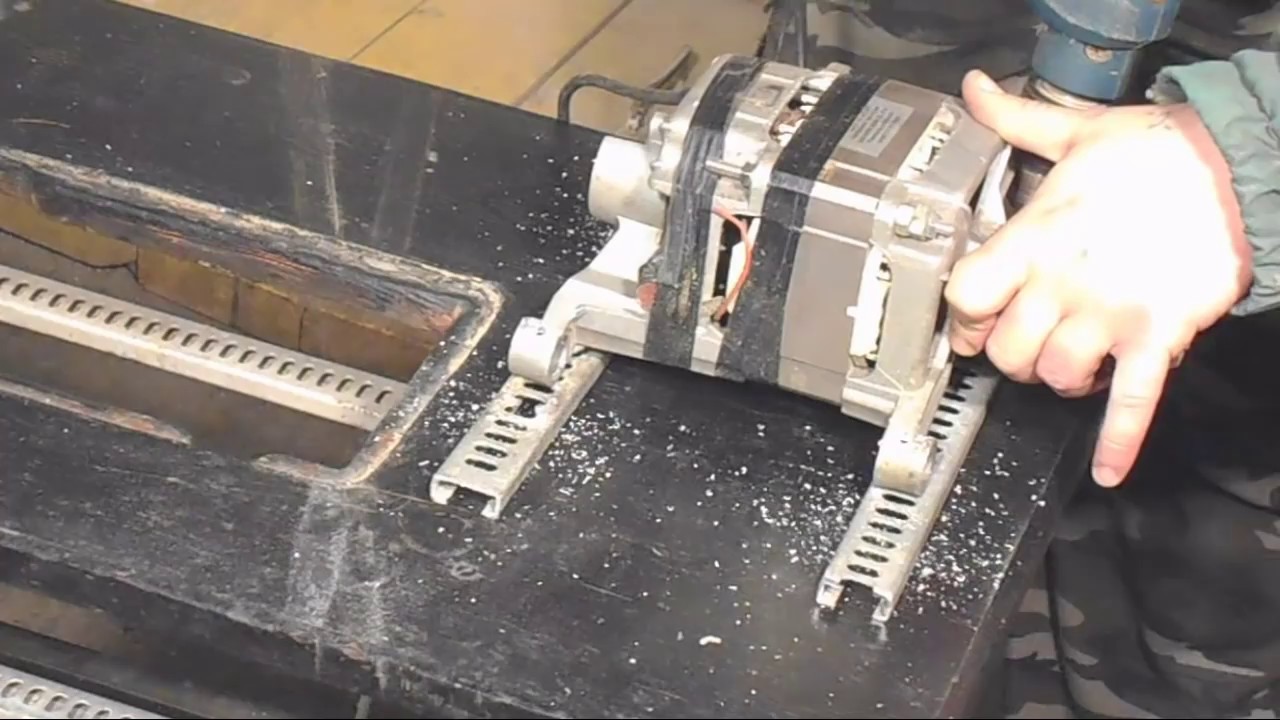

Circular saw from washing machine engine

If there is an old washing machine in the household that has exhausted its working life, you can use its parts. A washing machine motor can give life to a new tool.

If there is a choice, then the engine should be taken with a high power level. If there is no choice, then the engine that is available is taken as a basis.

Initially, you need to prepare the motor for the future circular. Using an ohmmeter, the coil with the highest resistance is determined. The following are subject to verification:

- connections at the outlets of the brush and the collector;

- speed sensor wires.

Next, you need to connect each of the two outputs of the collector with two contacts of the coil. After connection, a test run is made, the device is connected to the mains.

If you swap the contacts, rotational movements will be performed in the opposite direction.

You can increase the functionality of a homemade circular saw by equipping it with a device that reduces or increases the speed of rotation of the blade.

To do this, you can take as a basis a trigger from a handheld electrical device or a dimmer. They are connected in the following sequence:

- one of the coil contacts is connected to the armature contact;

- the second contact is connected to the mains supply;

- the remaining armature output through the dimmer is output in the same way to the mains supply.

After the motor is fully prepared, you can proceed to the further construction of the circular machine.

As a bed, it is better to take a welded metal frame, in the lower part of which the motor is fixed. The next step is to manufacture the motion module.

The cutting tool (disc with teeth) is rotated through a drive belt that is fixed on a pressed-in smaller pulley

It is important to make notches on the pulley that will prevent the V-ribbed belt from sliding.

To prevent slipping of the drive loop, a small protrusion is specially welded on the edge of the larger pulley.

Before starting the circular, it is important to check the reliability of the fastening of the disk and the engine itself. If the disc falls off during operation, it can cause serious injury, even in some cases even fatal.

Security measures

To avoid eye contact with small wood when sawing, as well as chips, it is imperative to work with glasses. Care should be taken to make sure that the sawing is done in a well-lit room or that the circular saw is in an area open to sunlight.

When working with cutting material, make sure that there are no nails or large knots in it. This circumstance can provoke a breakage of the disc or a change in the direction of a moving bar or rail. In the best case, the engine can be damaged and the disc dull. In the worst case, the building material escaping from the hands will injure the person who is engaged in sawing or people who are nearby.

Thus, anyone who knows how to work with construction tools and who has the skills to make wooden or metal structures can make a circular at home. It is necessary to follow the rules for operating the unit. Such a saw will become your assistant in the future and will significantly reduce the labor costs for processing sawn timber used in a personal household.

How to do do-it-yourself circular from the grinder, see the next video.