What you need to know about the handle and shaft

Now the choice of screwdrivers is large enough, so you can easily get confused in all the variety of this tool.

When choosing a screwdriver, you should pay attention to such an indicator as ergonomics - the handle should be comfortable, neat, non-slip. If rubber was used as a material for the handle, then there should not be unnecessary sagging or microscopic cracks.

If rubber was used as a material for the handle, then there should not be unnecessary sagging or microscopic cracks.

The quality of the rod is determined by the presence of markings on it, which indicates that the product was manufactured in the factory.

The strength of the tip is determined by the color, if the tip is darker than the rod itself, it means that special spraying was used to give additional strength.

Upgraded screwdrivers

The professional tool has an additional set of functions.

Of course, a sonic screwdriver has not yet been created in the image and likeness of the universal model from the "Doctor Who" series, capable of influencing various mechanisms through cybernetic waves.

But progress does not stand still, and who knows, maybe in the near future, humanity will receive new and ultra-modern devices.

Already there are models, against which a locksmith's screwdriver looks like a model of a tool from the past.

But still a set of reinforced all-metal screwdrivers remains a demanded case for specialists of a very different profile.

So what is so special about the modernized screwdriver types?

1. Dielectric

Screwdrivers of this type are used for electrical work.

The special insulation of the screwdriver shaft protects the craftsman from electric shock, which makes it possible to use the tool for loosening high-voltage parts.

This type of tool is often equipped with an indicator for recognizing hidden wiring, which allows you to "ring" these areas for the subsequent repair of electrical networks.

2. Percussion

This type of tool is used to work with large parts, since its principle of operation is aimed at creating an amplified impulse.

During screwing in, the impact energy is directed directly to the screw, which allows the part to be sunk without any special effort.

In a set with an impact screwdriver, there are various bits, all of them, as a rule, of a large size.

This type is often used when fasteners are damaged by corrosion, when the fasteners firmly grow into the surface.

Thanks to the impact mechanism, such bolts can be unscrewed without additional physical effort.

3. Reversible

A reversible ratchet screwdriver is designed for long-term work with fasteners.

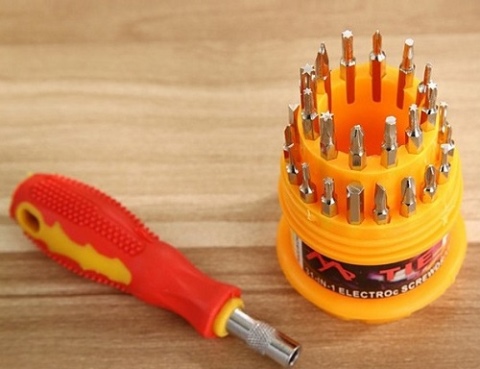

This type of tool comes with replaceable bits of different sections and diameters.

Thanks to this tool, you can easily twist and twist various parts without taking your hand off.

The product has a rotating tip that rotates due to reverse rotation, the hand of the master at this moment remains motionless.

The state-of-the-art mechanical screwdriver is best suited for professionals whose occupation involves frequent work with parts.

4. Rechargeable

Improved look, has a built-in battery, thanks to which the product can work as a screwdriver.

With such a tool, the master does not need to make any efforts to screw in at all, while the tightening will be of better quality with a verified effort than when manually screwing in with another type of tool.

Such models are used to assemble various products and repair them.

5. Telescopic

The tool has a special structure of the rod in the form of a rod, which allows you to adjust its length.

With the help of a special locking mechanism, the set length parameter can be securely fixed.

These models often have magnetic tips to facilitate the work of the craftsman.

For example, using a magnet, you can get a fallen screw out of a hard-to-reach place, or lengthen the rod length to work with a tool with deeper parts.

6. Dynamometric

Dynamometric models of the tool are used mainly in high-tech industries, for example, in aviation, shipbuilding, etc.

A special screen is built into the tool handle, which displays the indicators of the applied force when tightening any part.

This is a very convenient and useful function, because this is the only way a specialist can set the required moment and fix all parts with the same effort.

What types of screwdrivers are needed for the work of each specific specialist depends on the field of human activity.

Today there is a huge number of tools for performing a variety of types of fitter and assembly work.

When choosing a certain tool, it is especially necessary to pay attention to the product labeling, this is the only way to protect yourself from buying a fake of dubious quality and purchase a tool made at the factory

How to do it yourself?

Buying a ready-made kit means a significant expense. Sometimes it includes unnecessary tools that are not really needed. Or, on the contrary, such a delicate device is required that it is not sold in ready-made sets. Very small screwdrivers are made from needles. Not only tailoring needles are suitable, but also those with which household sewing machines are completed. You need to get rid of the sharp edge, because you don't need it anyway. Next, the metal is annealed, systematically heating one of the ends to 900 degrees. Subsequent cooling should be slow. The fact that the heating has reached the required stage is indicated by the orange color of the edge. If it is reddish, the heating should be increased, and when it reaches a light yellow or white tone, it should be weakened.

You can use a conventional gas stove burner to heat the workpiece.

It is necessary to cool the needle by carefully pulling it out. At this moment, the plastic qualities of steel will increase, so it will be possible to immediately give the desired shape on a small anvil by blows of a miniature hammer

Suitable anvil:

- the striking part of a larger hammer;

- steel pliers;

- pliers;

- another metal tool with a sufficiently large flat area.

You can improve the forging by reheating the needle. This time, the speed of withdrawal from the flame does not matter anymore. Having given the tip of the workpiece the required shape, it is modified using a flat file. Sometimes they just grind. After finishing processing, it is imperative to harden the screwdriver blade by heating its end to a dark cherry color and immediately after that dipping it into water.

A part hardened in this way is unnecessarily fragile. You should definitely resort to one more method of processing - the so-called vacation. First of all, the workpiece is heated so that it becomes either purple or light blue (iron acquires these tones in the range of 285-300 degrees). Since the dross appearing on hardened metal will make it more difficult to accurately recognize the colors, it must be removed. The tempering procedure ends with a gradual cooling of the needle in the air.

In the next video you will find unboxing and an overview of the watch screwdriver set.

Varieties

Quite widespread are watch screwdrivers with interchangeable blades. It is recommended to choose products with hardened and blued blades, in the manufacture of which chrome vanadium steel is used. Many delivery kits include 4 blades with a diameter of 1.5 to 3 mm. With their help, fasteners of various formats are easily unscrewed and twisted. In some cases, screwdrivers with a double-sided bit are useful.

Such attachments allow you to work faster and more efficiently without harming fasteners. Bits must be as strong as possible and resistant to wear, which severely limits the range of materials used. Precision equipment is used in the production of these parts.

When purchasing a 4-bar screwdriver, the mechanical strength of these parts must be given the highest priority. Chromium-nickel coating is better than chrome in anti-corrosion properties, but also more expensive

Special screwdrivers

In addition to the main types, there is a whole set of special screwdrivers designed for highly specialized work.

Often, such a tool is made by manufacturers of branded products, who want to thereby protect their goods from counterfeiting and unauthorized opening.

Specialized types of tools include: hexagonal models, screwdrivers with a slot in the form of an asterisk, trefoil, spanner, etc.

Such products have a non-standard shape of the slots, which allows you to screw in fasteners with a special thread.

More about types of specialized screwdrivers

1. Sprocket screwdriver (TORX marking) - has a tip in the shape of a six-pointed star.

The tool is rarely used - screws for this type are installed if the manufacturer wants to restrict unauthorized, trouble-free access to technically important parts.

The product is mainly used to repair small household appliances, mobile phones, etc.

2. The hexagonal slot has a product marked with HEX.

A distinctive feature of this model is a high level of torque force, which is several times higher than the performance of all the above options.

A tool of this type is used to work in the furniture industry, as well as in those places where a reliable connection is especially necessary.

3. Another version of the hex screwdriver is called hex and the difference from the previous type is the convex part of the tip.

4. Three-beam screwdriver has a non-standard slot in the form of a trefoil, which is actually its advantage.

Fasteners of this shape are almost impossible to disassemble on their own, this feature ensures the reliability and protection of the equipment from unauthorized penetration into systems, for example, sound equipment.

5. U-shaped screwdriver or "Spanner" - has a blade in the form of two pins.

Spanner is used in the repair of household appliances and elevators, thanks to the unusual shape of the tool, it is often possible to avoid the consequences of the actions of vandals.

6. Asymmetric cross - such a slot of hardware is almost impossible to find in everyday life.

A feature of this slot shape is that the tool is used in the aerospace industry.

Another advantage of the view is a strong tightening torque, which is not found in any other model.

7. The square screwdriver is also a rare type that has a narrow range of applications, because its tip is made in the form of a square.

This is a kind of hexagonal pattern.

The unusual shape of the tips of specialized screwdrivers allows you to screw in and out screws with complex threads quickly and effortlessly.