Benefits of Bauer equipment

All models have the following advantages:

- high performance;

- low weight of equipment combined with high power;

- ease of maintenance;

- the ability to work in any temperature conditions;

- even balancing due to the location of the main winch in the stern of the unit;

- the frame moves horizontally and the mast moves in two directions.

The creators also took care of workplace safety. The operator's cab is equipped with an air conditioning system and heaters, which ensures comfortable conditions at any time of the year.

At night, bright lights come on in the cockpit and at the top of the rig.

An audible signal notifies the operator of unacceptable loads on the cables.

Consumables are of great importance for drilling rigs. Their timely replacement extends the service life of the mechanisms and the unit as a whole, improves the drilling step.

Special equipment performance

The Bauer BG 28 deep drilling rig, price, which varies depending on the specific equipment installed, shows a high level of productivity, on almost any type of soil. High performance was achieved thanks to a powerful engine that produces as much as 354 kW of power. With the help of special gearboxes, the rotational force of the drill increases almost 10 times. The standard torque of this unit is 270 kNm.

The Bauer BG 28 deep drilling rig, price, which varies depending on the specific equipment installed, shows a high level of productivity, on almost any type of soil. High performance was achieved thanks to a powerful engine that produces as much as 354 kW of power. With the help of special gearboxes, the rotational force of the drill increases almost 10 times. The standard torque of this unit is 270 kNm.

In addition, the unit is equipped with an electric generator (power 13 kW), which fully meets the demand of the complex of systems for electricity during operation. Each of the systems has its own sensor, thanks to which the plant manager has the ability to fully control all work processes. For the safety of drilling, special counterweights with a mass of 5.3 and 10.5 tons can be hung on the drilling machine. There is also an automatic idle speed control system, which carefully monitors overruns and, if necessary, limits the number of revolutions of the engine crankshaft.

Technical description

Drilling equipment Bauer BG 28 technical characteristics, which can vary from operating conditions and the type of attachments, demonstrates fairly high performance indicators on the construction site. The drilling rig URB 2A2 is a similar type of special equipment and can be used as an alternative replacement. But at the same time it is worth noting that The Bauer BG 28 has a wide range of different systems to make the drilling process easier.

Technical specifications:

- engine - diesel, four-stroke with a power of 354 kW and a torque of 270 kNm;

- main winch power - calculated - 250 kN, nominal - 317 kN;

- winch pressure - 330 kN;

- feed stroke - 19.3 m;

- total weight of the installation - 96,000 kg;

- maximum borehole diameter - 1900 - 2150 mm;

- maximum drilling depth - about 71 meters;

- additional equipment - an electronic control system B-TRONIC, armored glazing, a powerful compressor with a capacity of 1000 cubic meters per minute, a system for relieving excess pressure in the system, overheating protection and a fuel economizer.

The operator's cab is equipped with an air conditioning system during the hot season, as well as efficient heating systems for the passenger compartment. The oil used in the crawler chassis is biodegradable. On top of the drilling rig and on the cab, special lighting is installed, of increased brightness, to improve the safety of work at night.There are systems on the cables that limit their stretching, as well as provide full control over the breaking work. In case of unacceptable loads, the sensor informs the driver with an audible signal.

The operator's cab is equipped with an air conditioning system during the hot season, as well as efficient heating systems for the passenger compartment. The oil used in the crawler chassis is biodegradable. On top of the drilling rig and on the cab, special lighting is installed, of increased brightness, to improve the safety of work at night.There are systems on the cables that limit their stretching, as well as provide full control over the breaking work. In case of unacceptable loads, the sensor informs the driver with an audible signal.

Drilling Rig Service

The Bauer BG 28 drilling rig, which can be purchased from an authorized dealer, has a special maintenance schedule.

Compliance with the recommendations and the established procedure for passing the service is mandatory. Hydraulic cylinders, drilling unit, hoisting ropes, tensioners, fastening systems, etc. are considered critical components. Each element is checked separately, if necessary, its full or partial replacement is carried out. Repair work is carried out in special workshops that deal with special construction equipment. Spare parts are supplied through official dealer networks. It is worth noting that after serious repair work, the equipment is being tested.

How to choose?

In order to most accurately select equipment for construction work, a careful calculation of the amount of work is necessary - this applies to the scope of application. As you can see in the overview of some of the models, certain rigs are designed to drill long wells, which can be used in various industries. At the same time, there are also small units that work more actively and allow you to drill wells faster, although they will be of shallower depth.

As a rule, when renting such equipment, you should pay attention to the technical characteristics. There are times when only one or several parameters are needed, which also plays a significant role.

It is impossible not to mention the price that the landlord will demand for the use of the equipment.

Bauer drilling rigs

Today Bauer has established subsidiaries all over the world. Each company is a separate legal entity. Among the countries where there are Bauer offices, China, Australia, Sweden, Italy, Canada should be especially highlighted. There is also a representative office in the Russian Federation, where, in 2006, the production process of drilling rigs under the control of the parent company has begun.

Scope of use

The rigs of the drilling mechanism are used in various fields:

- for the construction of the foundation of a structure on piles;

- in construction in general;

- for drilling soils, including hard rocks;

- in the extraction of minerals of non-metallic origin;

- in the construction of water intakes;

- for drilling wells where explosives are placed to destroy hard rocks.

Benefits and features

Drilling rigs of this popular brand have a lot of advantages and benefits:

- Excellent performance level.

- Easy operation.

- High power is combined with a relatively low weight of equipment.

- The basic equipment allows you to work in extreme temperature conditions.

- The main winch is built into the rear of the machine to ensure even balancing.

- Horizontal movement of the frame and independent movement of the mast in two directions.

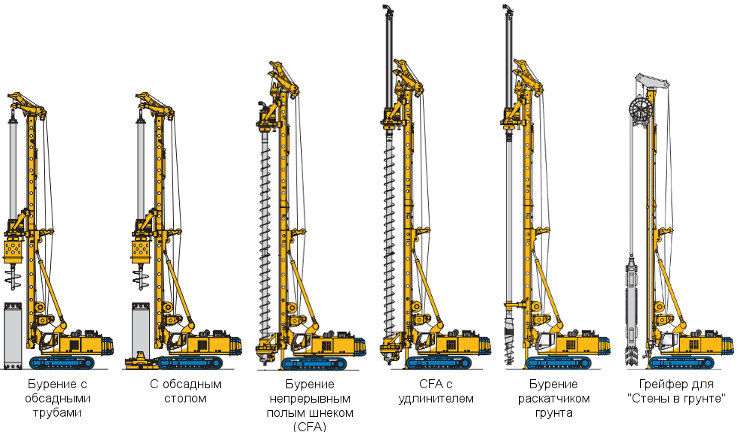

- The chain drive system allows for work with an endless auger and with full replacement.

- The caterpillar track of the machine is equipped with a sliding trolley.

Peculiarities

The German company Bauer is known as a manufacturer of large-scale construction equipment, which is sold all over the world and is used on many projects. Of the features of the technique, the following can be noted.

- High level of mobility. Thanks to the chassis, the equipment can actively move around the construction site. At the same time, a small base area does not interfere with the work of other equipment located nearby, when it comes to large-scale construction.

- Performing a large amount of work. Bauer drilling rigs have considerable capacity, which, together with the available equipment, allows you to drill large wells in a fairly short time.

- Functionality.All the equipment available on the installation allows the production of depressions of various widths and shapes, which makes the result of the work process more preferable for the consumer.

- The possibility of modernization. If desired, this technique can be equipped with other parts and installations, which makes the original characteristics valid only until the first design changes.

The lineup

Now it is worth making an overview of some of the models that have become the most famous from this manufacturer.

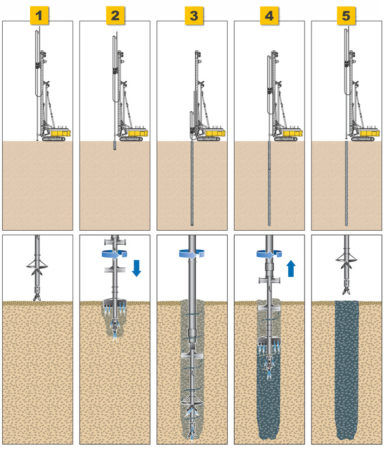

BG28

One of the first models for universal use. The main areas of application are the creation of bored piles with a diameter of up to 1900 mm, as well as drilling of wells with various types of nozzles, including auger and soil unroller. This model is used to create wells without and with casing. There is a possibility of immersing sheet pile pipes used for enclosing excavations. The maximum drilling depth reaches 71 meters, the total installation height is 26470 mm. The rotary drive KDK is available with a torque of 275 kNm at a pressure of 320 bar. The maximum rotational speed is 35 rpm, the pressure and thrust forces are respectively 200 and 330 kN.

The average speed is 7 m / min, in rapid traverse mode this parameter increases to 8.5. There is both a main and an additional winch. In the first case, the length is 90 meters at a speed of 80 m / min, in the second 60 meters and 74 m / min. Pulling force of the effective type is 100 kN, nominal 125 kN. As for the working cab, it is equipped with a CAT C11 engine, whose rated power is 313 kW, the fuel tank of 800 liters allows you to perform work for a long time. In the cab sound level 78 dB, hydraulic power 230 kW, undercarriage width 3700 mm in extended position. Travel speed 1.1 km / h, operating weight 96 tons.

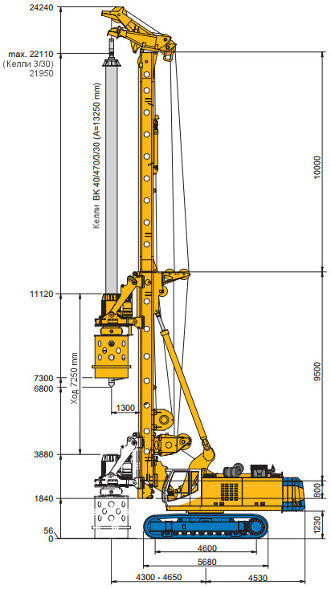

BG36

A larger drilling rig that allows you to drill holes up to 68.6 m deep. The main method of work is to use a kelly bar, auger or a soil reamer. The total height is 24240 mm, rotor power 367 kNm, maximum rotational speed 46 rpm, traction force 400 kN. The stroke in the kelly system is 7250 mm, for the CFA 16700. A distinctive feature is the high rapid traverse speed of 26 m / min, in standard mode only 6.5. The length of the main winch is 90 meters with a maximum speed of 90 m / min, for the additional winch these figures are 67 meters and 55 m / min, respectively.

The working cab is equipped with a 354 kW CAT C15 engine. An 800 liter fuel tank is provided to power the entire unit. The ambient temperature during maximum load can rise to 45 degrees Celsius, the sound pressure level is about 78 dB. The hydraulic power of 277 kW and the pressure of 320 bar allow efficient drilling. And the UW 110 self-propelled chassis with a convenient swivel mechanism - to move over the entire area of the object. The maximum speed is 1.3 km / h, the width of the extended bogie is 4600 mm, and the operating weight is 127 tons.

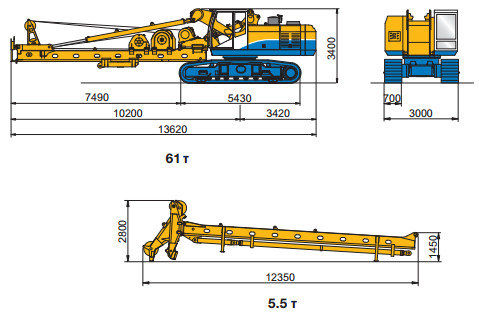

MBG12

Small unit designed for medium-sized jobs compared to previous models presented. Height - 14450 mm, total weight with the equipped kelly bar is 34.5 tons. The MDK rotation drive has a maximum rotation speed of 35 rpm; a vertical feed cylinder is built in. Its pressure is 80 kN, and the thrust is 100 kN. The upward speed in the middle operating mode is 4.5 m / min, and the downward speed is 5.5 m / min.

If you use the high speed mode, accelerating the cylinder, then up - 11 m / min, down - 19 m / min. The main winch has a pulling force of 100 kN in the actual position, in the nominal value it increases to 125 kN. The cable is 50 m long and has a diameter of 20 mm.

The maximum speed of the main winch is 60 m / min. The thrust force is 30 and 38 Kn, respectively, in the actual and nominal position. The auxiliary winch is 35 meters long and 14 mm in diameter and has a maximum speed of 45 m / min.A travel speed of 2 km / h is possible due to a more mobile track mechanism, as well as a low operating weight relative to other models. In terms of design, various attachments and functions, they do not differ much from the standard set of past drilling rigs.