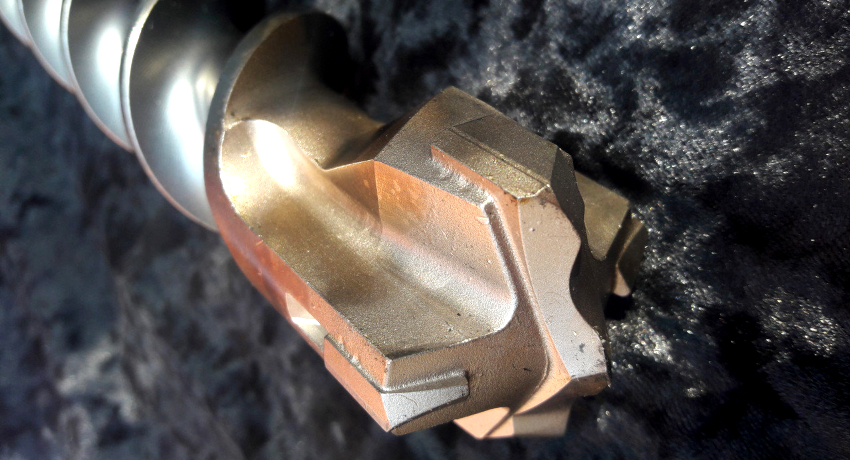

Photo of drills and drills for rock drill

We also recommend viewing:

- What are aluminum rivets

- Best screwdriver bits

- Which polyurethane foam is better

- Choosing a blade for a hacksaw for metal

- Overview of diamond core bits for concrete

- The best concrete drills for drills and hammer drills

- How to choose a good diamond blade for concrete

- Which abrasive disc is better to choose

- Wood milling cutters for hand router

- How to find the right grinding wheel

- Which drill chuck is better

- Choosing good wood drills

- Types and sizes of staples for the stapler

- Why do you need a unipack

- Metal brush for grinder and drill

- What and how to choose a line for a trimmer

- Which drills for metal are better

- Which chainsaw oil to choose

- Cut-off wheels for grinders

- Metal pipe clamps

- How to choose a galvanized bucket

- How to choose a circular saw blade

- Types of jigsaw files

- Varieties of petal circles

- What is tow

- Nylon ties

- Types and application of electrical tape

- Choosing a light plastic bucket

- How to choose safety glasses

- Why do you need masking tape

Help the site, share on social networks

Views

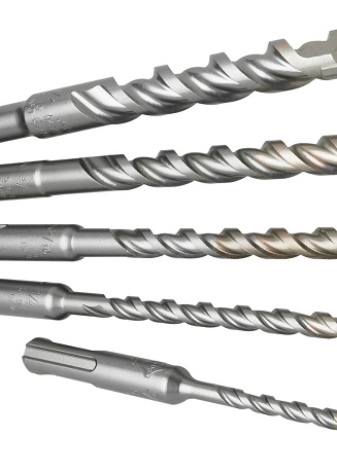

Boers are of various types. Specimens for metal work are not very effective for use on the ground, a good option for wood is not very suitable for work on tiles. The differentiating criterion can be not only the quality of the metal or alloy, but also the design features. Auger is a self-sharpening "worm gear" option used when working at great depths of drilling. It removes the formed crumbs well, is "hardy", more durable in conditions of severe exploitation.

It is customary to classify percussion-cutting consumable tools into several types.

- As a conventional drill - well suited for creating cylindrical holes.

- Pica - used in concrete operations. Serves as an "electric hammer" for wide holes.

- Chisel - Suitable for materials that need to be dismantled. For example, when dismantling tiles or old plaster.

- Crown - this type is used to solve specific problems, for example, when preparing for the installation of electrical outlets. The purpose is to create deep holes of the correct shape. The creation of wide openings for routing water pipes is another typical application.

- The use of wood is much more efficient than the use of similar drills. The working forces are reduced, the chips are separated faster, the structure of the wood under such a cutter does not collapse.

- Earth and construction drill are different manufacturing themes for a similar design. The first one is applicable not only with a motor, but also in a manual version, with a drive of human muscular strength, since it does not require a high intensity of rotation.

How to use?

Always make sure that there is no damage before using it and clean the instrument if necessary. After that, lubricate the rubbing parts, then with some effort insert the drill with the shank into the chuck. A click can be considered a signal of correct action. A control attempt to unsuccessfully pull the drill back is for insurance.

After finishing work or to replace the drill, it is necessary to press the chuck ring in the direction of the tool along the axis, after which it can be expected that the extraction will work. Unfortunately, in practice, there are times when this does not happen. This is typical if the shank was deformed during operation. One of the possible reasons is the poor quality of the metal under excessive pressure during the working operation.The lack of lubrication provokes this matter even more, because the tool heats up.

Practitioners suggest using a vise, where the drill is clamped, and the hammer is pulled out with swinging from side to side. In this case, the cartridge is in a strictly open position. Anyway, the consumable is no longer suitable. If this does not help, clamp the hammer in a vise using shims to prevent damage to the case. A stuck drill is also crimped with a gas wrench, which plays the role of a lever. A few hammer blows on the key will show how futile hopes are. If success is not achieved, you will definitely have to disassemble the puncher, for which it is better to contact a regular service center.

Sometimes the user is faced with a different kind of trouble - the drill flies out of the cartridge. The phenomenon does not allow high-quality work and threatens safety. This may be due to prolonged tilting operation, a defective consumable, or wear on the locking mechanism. If the matter is not in the storm and the conditions of its use, the repair of the rock drill can be assessed as a sudden task that has arisen. Is it possible to sharpen a drill - beginners are constantly talking about this.

Sharpening is fundamentally possible, but the effectiveness of this work is very controversial:

- an appropriate industrial tool is needed for the operation;

- an experienced master is needed.

Drill design features

What is the design of any concrete drill used to complete the rock drill?

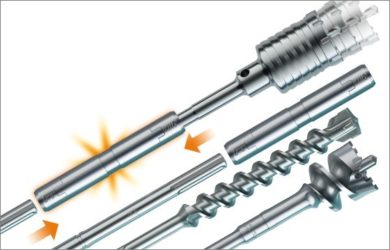

Shank

With this structural element, the tool is fixed in the chuck of the hammer drill. Depending on the category of the fastening system, as mentioned above, the shanks of the drills can have significant design differences.

Body

This structural part bears the main load. To ensure high reliability of the drill body, extra strong grades of steel are used for its manufacture.

Cutting part

This element performs the basic work of drilling holes. Depending on the purpose of the tool, its cutting part can have a different design and be made of different materials. They produce cutting parts with diamond dusting (diamond drill), as well as from carbide plates.

Set of diamond core drill bits

Victory or diamond tip: which is better?

Which drills are best to choose is determined depending on what the surface to be treated is made of. The rod of any rig is topped with a tip or soldering. It has edges of various configurations and hard alloys are used for its manufacture.

Victory solders are divided into three strength classes:

- soft ones are inexpensive, they will be able to choose low grade concrete and brickwork for the hole;

- medium-strength are most often used in everyday life for minor repairs and amateur construction. Tips of this hardness cope well with concrete floors;

- high-strength types of drills can compete with diamond counterparts, but not on reinforced concrete foundations.

All winning nibs (if used as intended) are designed for repeated use without sharpening.

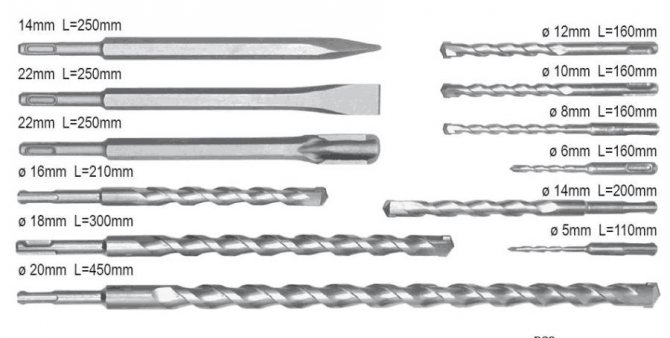

Dimensions (edit)

Length and diameter are also important differences. For purely domestic work, products with diameters in the range from 6 to 10 millimeters are applicable. The dowel must comply strictly. A prerequisite for securing large objects is a long drill and a 20 mm diameter. The maximum cross-sectional diameter can be up to 5 centimeters. The length of the product is 10, 50, 80 or even 100 centimeters, depending on the thickness of the punching material.

An idea of the possibilities of a sample is given by the marking, which is applied by any self-respecting manufacturer. For example, a combination of numbers 6.5x160 indicates a diameter of 6.5 mm and a length of 160 mm. Other dimensional options are the same. The manufacturer combines the length with the diameter so that the tool works efficiently and for a long time.

Advice

A quickly broken copy will be very upsetting, so it should only be used within its acceptable range of capabilities. Basic requirement: the harder the drilling material, the harder the tool tip material. Experts recommend using VK8 or VK8 alloy - a technology with a high tungsten content. Auger structures tend to "live" longer. The drill should not be forcibly inserted into the drill chuck, nothing good will come of it for sure. This is an option for a completely different design and power.

It is generally accepted that the more the spiral is twisted, the higher the rotation speed should be. A deeper hole is made in the same time. In any case, the recommended operating speeds should be used. The drilling axis should not change during the process, as this creates a potential deformation hazard.

In the event that you have to drill on concrete with reinforcement, the tip must be diamond-coated or consist of an alloy for which both concrete and metal are nothing at all. No matter how the circumstances develop in the course of the task, you should never forget about security measures. This is where the future success or failure of the operation always begins. Small holes are made with products where the spiral is flatter. In general, before starting, you need to clearly understand what kind of tool you need. Excessive effort does not improve the quality of the workflow. Any deformation makes the device unsuitable for use, including for safety requirements.

For information on how to sharpen a drill for a hammer drill, see the next video.

Selection criteria

The set of criteria for choosing a household or industrial product is very diverse. The basic requirement is a confident solution to the problem of overcoming the hardness of the material. The second question is the choice of the optimal solution based on price and quality. Here, as in other market cases, you need to be wary of fakes and not expect miracles from copies in a low price category. A good supplier naturally values himself, but that doesn't mean he isn't being counterfeited. A cheap copy may be a tool only for a one-time job.

Manufacturers such as Makita, Sturm or Bosch are among the most sought after

They do not need special recommendations, but you should pay attention to the manufacturing plants of the same company. Unfortunately, products of the same brand made in different countries may vary in efficiency and durability.

The most expensive segment is intended for professionals; for home use, marked parts in the middle price category are quite suitable. The quality of the material determines the range and potential resource of use. When choosing a purchase target, be sure to take into account the design of the tail section, which is fixed.

It is customary to divide shanks into different types according to a special fastening system. SDS and SDSplus are the most demanded for medium and low power with a cutting tool diameter of 10-18 millimeters, the length of the fixed part is 4 centimeters. SDStop is used when the drill bit is 14 millimeters in diameter.

SDSmax is used for more powerful devices, the fastening depth here is 9 centimeters, and the diameter is from 18 millimeters. SDSquick is a Bosch design for a "tail" in a hexagonal section, providing a tight and secure fit in conditions of increased stress and vibration. When choosing a consumable by the type of shank, you must first look at the instruction manual for the hammer drill. The manufacturer usually specifies this parameter accurately.

In some cases, an extension cord will be required to solve a production problem. It extends the drilling length without changing the hole diameter. It is very important when using crowns or in the process of excavation.One desired piece can be supplemented with a set of rods of various lengths, which increases production capabilities. For example, specialists who make a hole in the ground using a gasoline or electric motor can thus deepen up to one and a half to two meters.

What types of drills and drills are there?

If a home craftsman often needs to use a drilling tool, then it makes sense to look in the store for sets of drills for a hammer drill. With such a purchase, the master will be ready to work with any surface.

The set includes bits with different types of shank and all shapes of the working part. Rigging can be divided into two broad categories: straight-through and break-through.

The former choose the base material, gradually deepening inward. The second type destroys (cleaves, knocks off) an impressive part of the working surface. In each group, there is an additional breakdown into types.