Battery cell types

These devices use elements of different types and voltages, each of which has its own advantages and disadvantages.

The most common are nickel-cadmium (Ni-Cd) with a voltage of 1.2V.

Advantages:

- low price;

- stored in a discharged state.

Disadvantages:

- have a memory effect;

- high self-discharge;

- small capacity;

- small number of charge / discharge cycles.

More advanced 1.2V nickel metal hydride (Ni-MH).

Advantages:

- lower memory effect and self-discharge;

- large capacity and number of charge / discharge cycles.

Disadvantages:

- higher price;

- do not tolerate low temperatures and storage in a discharged state.

The most advanced lithium-ion (Li-Ion) 3.6V.

Advantages:

- lack of memory effect;

- very low self-discharge current;

- high specific capacity, allowing to reduce the weight and dimensions of the device;

- the number of charge / discharge cycles many times higher than other types of batteries.

Disadvantages:

- high price;

- loss of capacity three years after manufacture.

Homemade PSU

It is necessary to start making a homemade PSU if you have knowledge in the field of radio engineering. It is necessary to prepare the parts and the tool in advance and fully concentrate on work, during which a radio element failure or electric shock is possible (supply voltage 220 V).

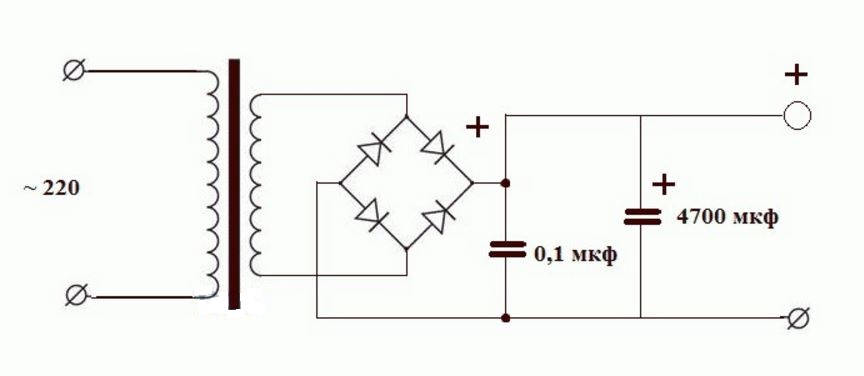

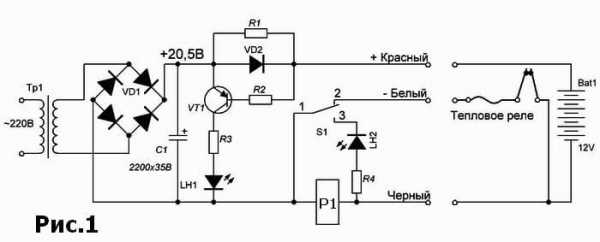

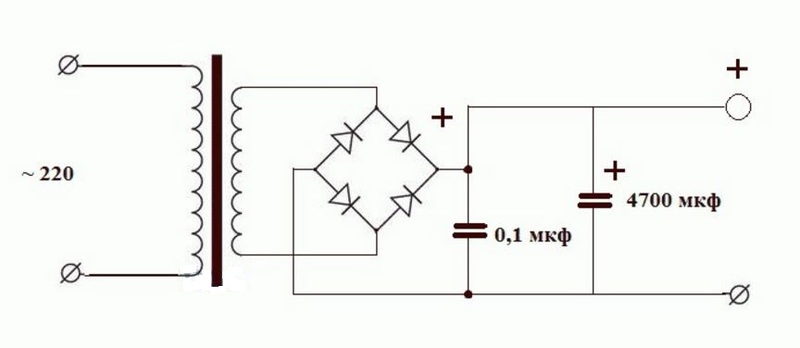

The simplest scheme

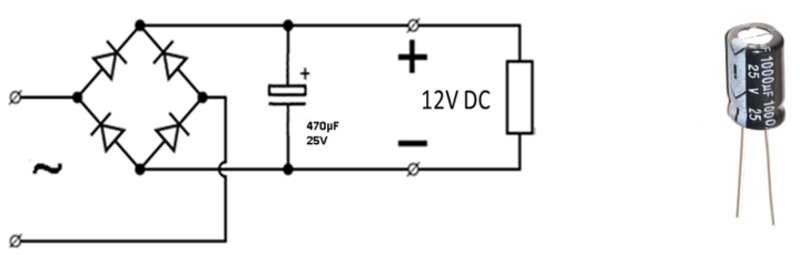

During manufacturing, it is necessary to prepare a case for mounting radio components, a tool, a piece of getinax, a wire and radio components. Then proceed with the assembly according to scheme 1.

Scheme 1 - Simple power supply unit for 12 or 18 volts.

The transformer will suit almost any one with the following parameters: power 250..300 W, voltage on the secondary 24..30 V, and current with a nominal value of 15 A and above. The diode bridge is assembled from powerful diodes (pick up according to the reference book). After assembly, it is necessary to check the supply voltage: if it is higher than the required value, then it is necessary to reduce the voltage of the II winding (decrease in the number of turns). At low voltage, wind the secondary with a wire of the same section. After assembly, mount in the housing.

Provided that the screwdriver is not powerful enough, you can install it directly in the battery compartment. If the PSU is assembled separately, it is recommended to provide cooling, because during the start of the motor, the rated current increases by 7 times. As a result of this increase, there is a load on the PSU, and it starts to warm up. Heating occurs due to insufficient power supply. After the power supply is ready, you need to check the screwdriver: run it several times and make sure that there is no heating of the radio elements. When operating a converted screwdriver, you must adhere to the basic requirements:

- Allow the tool to cool down after every 20-30 minutes of operation.

- Do not work at high altitudes or do it carefully (the power supply unit may fall and, as a result, loss of balance and injury).

- Monitor the condition of the supply cable, it should not be pinched (it can lead to a short circuit, which is fraught with negative consequences for the instrument and the person).

Thus, when the battery of an 18 V or 12 V screwdriver comes out, it is not at all necessary to buy a new battery or screwdriver. It all depends on the field of application of the tool: if you need the mobility of the tool, you should replace the battery or purchase a new screwdriver. In the case where mobility does not play a special role, you need to convert it to mains power.By following simple guidelines and observing safety rules, you can not only increase the likelihood of extending the service life, but also reduce the risk of injury.

Screwdriver device

This mechanism consists of the following parts:

- DC electric motor. It has the shape of a cylinder; instead of the field winding, there are permanent magnets in the housing. This simplifies the design and provides sufficient torque at low revs. The driving (sun) gear of the planetary reducer is put on the electric motor shaft;

- Reversible speed controller. The adjustment circuit is assembled on a PWM controller and a field-effect transistor. The reverse is carried out by switching the polarity of the power supply to the motor brushes;

- Planetary reductor. Made in a separate building. It got its name from its similarity to the solar system. Consists of a ring gear, a central (sun) gear, satellites and a carrier. The ring gear transmits the force through the spring loaded load regulator balls. There are models with two-speed gearboxes. The increased speed is enabled when using the device as a drill;

- Rotary force limiting mechanism. Serves to limit the force when tightening screws. Transmits torque through balls pressed by an adjustable spring;

- Removable battery. Consists of separate elements in one body. The voltage in different models ranges from 9 to 18 volts.

Screwdriver device

Screwdriver device

Homemade charging devices

It is quite simple to make your own charging for a 12 volt screwdriver with your own hands, by analogy with the one used in the Interskol memory. To do this, you need to take advantage of the ability of the thermal relay to break the contact when a certain temperature is reached.

In the circuit, R1 and VD2 are a charge current flow sensor, R1 is designed to protect the VD2 diode. When voltage is applied, the transistor VT1 opens, a current passes through it and the LH1 LED starts to glow. The voltage value drops on the R1, D1 chain and is applied to the battery. The charge current flows through the thermal relay. As soon as the temperature of the battery to which the thermal relay is connected exceeds the permissible value, it is triggered. The relay contacts switch, and the charge current begins to flow through the resistance R4, the LH2 LED lights up, indicating the end of the charge.

Two-transistor circuit

Another simple device can be performed on the available elements. This circuit operates on two transistors KT829 and KT361.

The magnitude of the charge current is controlled by the KT361 transistor to the collector, to which the LED is connected. This transistor also controls the state of the KT829 composite element. As soon as the battery capacity begins to increase, the charge current decreases and the LED, accordingly, smoothly goes out. Resistance R1 sets the maximum current.

The moment when the battery is fully charged is determined by the required voltage on it. The required value is set with a variable resistor of 10 kOhm. To check it, you will need to put a voltmeter on the battery connection terminals without connecting it itself. Any rectifier unit designed for a current of at least one ampere is used as a constant voltage source.

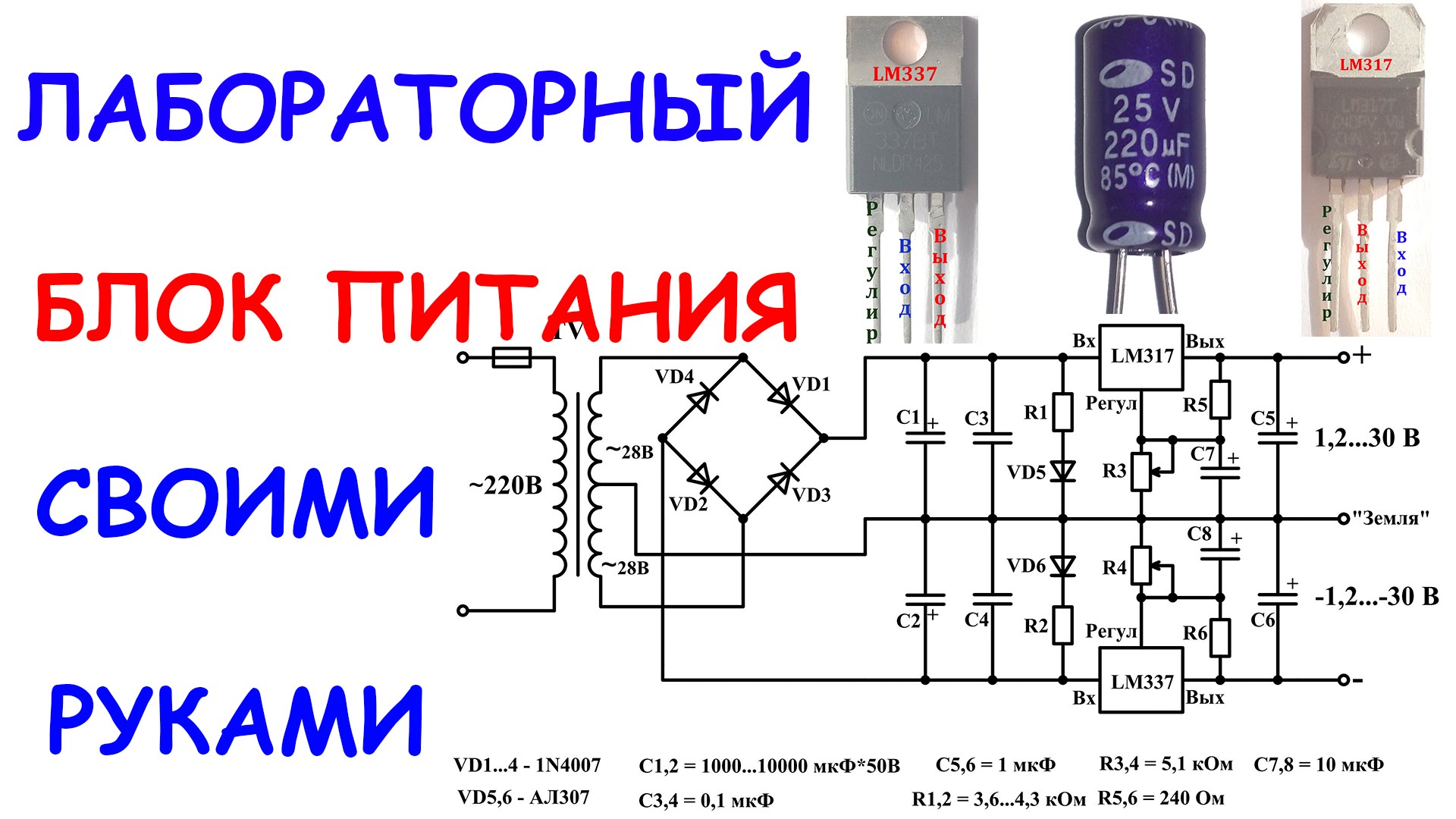

Using a specialized microcircuit

Manufacturers of screwdrivers are trying to reduce the prices of their products, often this is achieved by simplifying the memory scheme. But such actions lead to the rapid failure of the battery itself. Using a universal microcircuit designed specifically for the MAXIM MAX713 charger, you can achieve good performance in the charging process. This is what the charger circuit for an 18 volt screwdriver looks like:

The MAX713 microcircuit allows you to charge nickel-cadmium and nickel-metal hydride batteries in a fast charge mode, with a current of up to 4 C. It can monitor the battery parameters and, if necessary, reduce the current automatically. At the end of charging, the circuit based on the microcircuit practically does not consume energy from the battery.It can interrupt its work on time or when a temperature sensor is triggered.

HL1 is for power indication and HL2 is for fast charge display. The setup of the scheme is as follows. To begin with, the charging current is selected, usually its value is equal to 0.5 C, where C is the capacity of the battery in ampere-hours. The PGM1 pin is connected to the positive supply voltage (+ U). The power of the output transistor is calculated by the formula P = (Uin - Ubat) * Isar, where:

- Uin - the highest voltage at the input;

- Ubat - battery voltage;

- Isar - charging current.

The resistance of R1 and R6 is calculated by the formulas: R1 = (Uin-5) / 5, R6 = 0.25 / Isar. The choice of time after which the charging current will turn off is determined by connecting the PGM2 and PGM3 contacts to different pins. So, for 22 minutes, PGM2 is left unconnected, and PGM3 is connected to + U, for 90 minutes, PGM3 is connected to the 16th leg of the REF chip. When it is necessary to increase the charging time to 180 minutes, the PGM3 is shorted to the 12 leg of the MAX713. The longest time of 264 minutes is achieved by connecting PGM2 with the second leg, and PGM3 with the 12th leg of the microcircuit.

Assembling the working structure

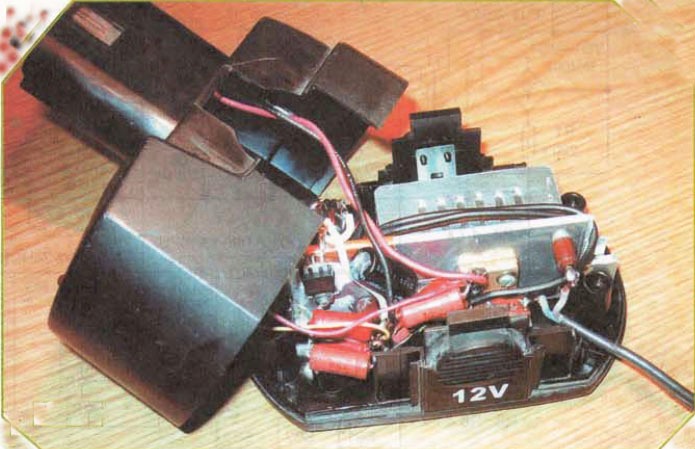

For ease of use and connection, I brought the cord from the power supply into the battery case. The cord took 3.5 meters

long, which was available. I removed all battery cells from the battery and installed an LC filter. Now,

if I somehow have a working battery, it can always be put on a screwdriver, and the unit

put away food in reserve. I did not throw out the batteries from the battery, there is an idea where to use them, but this is a topic for

another review.

Since the cord connecting the unit to the screwdriver has a certain resistance and inductance, you can

try to short-circuit the leads of the coil L1. In theory, this can increase the power by a tiny fraction.

meaning.

With a cord, the screwdriver feels great, but to be honest, it seemed to me a little weak when braking

hand. But the trial tightening of self-tapping screws dispelled my doubts: self-tapping screws 35 mm long are quietly screwed into plywood

20 mm. This means that a screwdriver will meet most repair needs.

At the block, I cut off all the output wires, leaving the green start, I soldered its end to the common conductor

boards where all black are soldered. It is best to carefully remove all the wires, but my soldering iron was too weak

for this I had to cut it off. To the common contact and +12 (where the yellow ones are soldered) I soldered two short, hard

copper wires and connected through a terminal block with a cord to the shura.

This concludes this review, we achieved what we wanted - the screwdriver works great from the computer unit

nutrition. In the future, I plan to make a solid plywood case without slots for the power supply board -

tests showed that the heatsinks on the board do not heat up at all and you don't have to worry about overheating of the elements in a closed

the case.

Do you need rework?

To redo the screwdriver or not? Before starting work, you need to evaluate the advantages and disadvantages of this solution. If we talk about the former, then as a result the owner will achieve:

- disappearance of problems with a suddenly discharged instrument;

- lack of dependence on low temperatures, because under such conditions the batteries are discharged very quickly;

- obtaining a stable torque;

- significant savings, since buying a new, rather expensive battery is not required.

In addition, this is the only remaining option if the model has already been discontinued, when the tool is urgently needed, and there is no time to wait for the arrival of a new battery. If the screwdriver itself works flawlessly, then there are no contraindications to its alteration. The only thing he will lose is mobility, but this disadvantage is still not so significant, it can be dealt with.

Easy tool recovery

The main advantage of the cordless screwdriver is its portability. A lithium-ion battery is used in such tools, which is protected from overload and complete discharge.In addition, there is also protection against overcharging in the form of a separate circuit built into the element itself. The main power source (primary) is 220 V, and the battery is being recharged.

Depending on the model of the screwdriver, the battery is supplied with a charging voltage from 14 V to 21 V. The battery output is supplied with a supply voltage of 12 to 18 V. This type of battery lasts a long time, but if the tool is not used for a long time, the built-in protection against discharge will not help. battery cells: continuous discharge.

To extend the service life, the battery must be constantly discharged and recharged. If, for some reason, it was not possible to "keep track" of the instrument, a particular battery element often fails. There are main ways to solve this problem:

- Replace the battery with a new one.

- Purchase a new tool.

- Rebuild the mains-powered screwdriver.

When replacing the battery, keep in mind that a new one is difficult to find. Tools are made so that it is difficult to find spare parts for them. It is unprofitable for the company to produce its product with a high maintainability, since it needs income from the purchase of products. Finding a new battery is only possible through dealers. In addition, another option is possible: disassemble the battery and replace the faulty battery.

When replacing the battery, keep in mind that a new one is difficult to find. Tools are made so that it is difficult to find spare parts for them. It is unprofitable for the company to produce its product with a high maintainability, since it needs income from the purchase of products. Finding a new battery is only possible through dealers. In addition, another option is possible: disassemble the battery and replace the faulty battery.

When buying a new instrument, the user seeks to buy a model of a higher quality sample, forgetting about the rules for using lithium-ion batteries. Basic rules that will help preserve the service life of the tool for a long time:

- When purchasing in the winter period, it is strictly forbidden to "launch" the tool immediately. You need to wait about an hour until it "warms up" to room temperature.

- Charge the battery.

- Perform the charging and discharging cycle of the battery about 3 times.

If none of the solutions to the problem is suitable, you need to start converting the screwdriver to the network with your own hands. This is easy to do. There are many simple and complex ways. Changing the tool model has several positive aspects:

- No need to recharge the battery.

- Reduces the stress on the mechanical part.

- Lots of power supply options.

- Increase in the quality characteristics of the product.

Interesting: Parquet sander, floor sander - we look at all the details

Connecting the screwdriver to the charger

Sequencing:

-

Solder or attach two wires to the terminals of the charger with crocodile clips.

-

Disassemble the old battery and remove the dead cells from it.

-

Drill a hole for the cable in the battery case, thread the cable through the hole. It is advisable to seal the connection with electrical tape or heat shrink tubing so that the wire does not break out of the housing.

-

The elements removed from the battery will disrupt the weight distribution of the screwdriver - the hand will get tired. To restore balance, a weight should be placed in the hull - it can be solid wood or a piece of rubber.

-

Solder the cable to the terminals of the former battery connected to the screwdriver.

-

Assemble the battery case.

- It remains to test the updated tool at work.

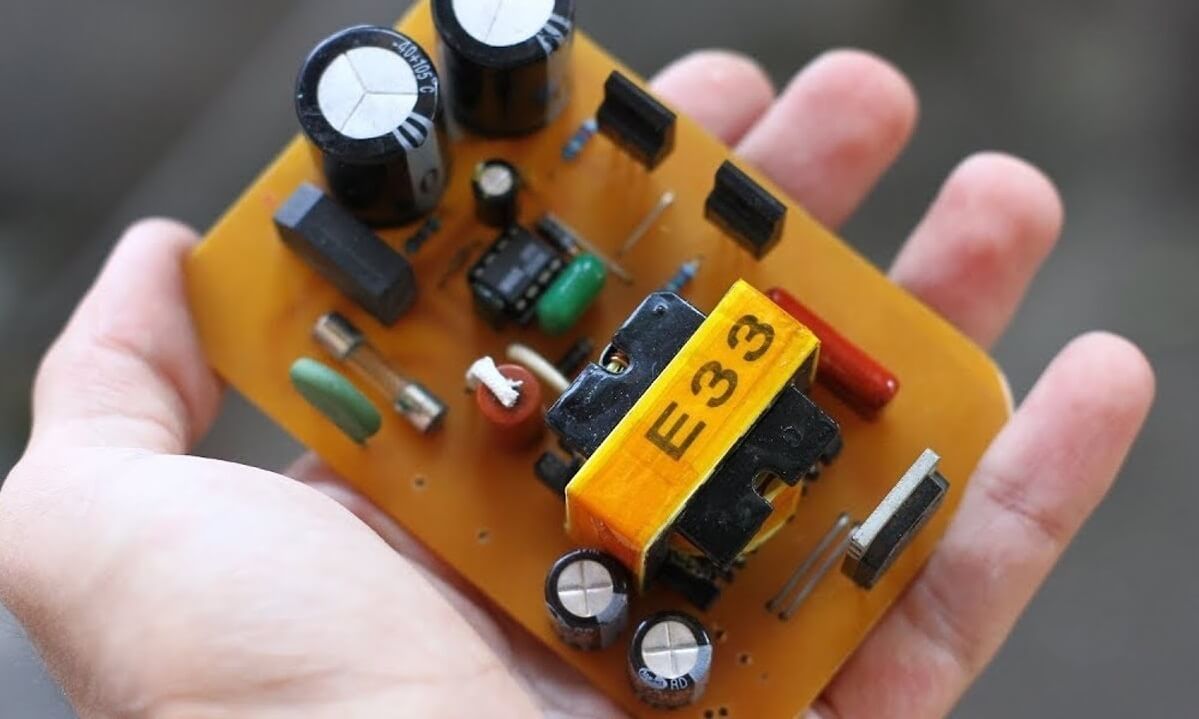

Mounting the finished power supply in the old battery case

Procedure:

-

Disassemble the old battery and remove the non-working cells from it.

-

Install the power supply into the battery case. Connect high voltage contacts and low voltage terminals.

-

Assemble and close the battery case.

-

Insert the battery into the screwdriver.

- Plug the power supply into a power outlet and test the updated mains tool in operation.

Homemade power supply

Step-by-step instruction:

-

Disassemble the case of the old battery, remove the dead batteries from it.

-

Install the elements of the electrical circuit of the power supply on the circuit board, solder the contacts.

-

Install the assembled board into the case. Check the presence of voltage at the output with a tester.

-

Connect the low voltage wires to the terminals of the old battery. Assemble the case.

- Connect the screwdriver to the electrical network and check its operation.

Connecting to an external power supply

What to do:

-

Disassemble the screwdriver and find the motor power wires inside. Install the power supply connector into the case and solder the wires to the connector. Fix the wires with hot melt glue.

-

Choose a suitable power supply unit, for example, from a laptop. Choose an adapter for the low voltage connector for it.

- Connect the screwdriver to the new power supply and check its operation.

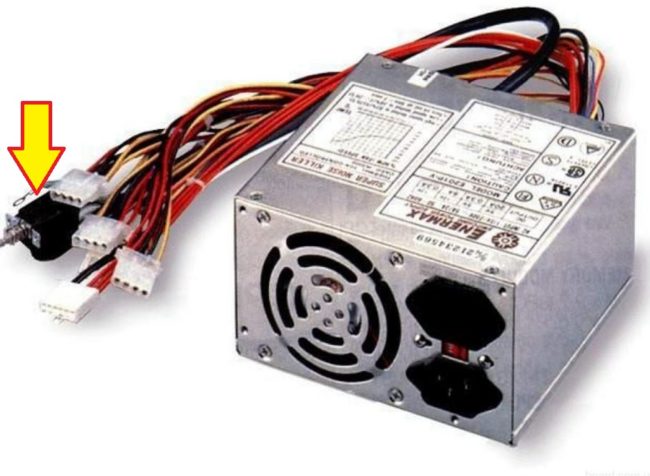

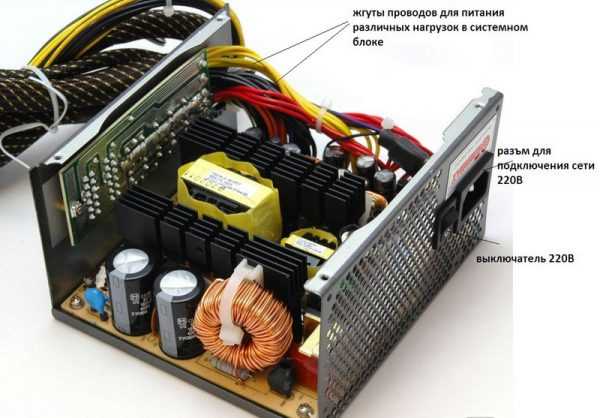

Connecting to the power supply from a computer

Instructions:

-

Find or buy a power supply unit from a computer with a capacity of at least 300 watts.

-

Disassemble the screwdriver body. Find the inside of the motor power wires. Solder the connectors for the computer power supply to the wires.

-

Remove the connectors for connecting the computer power supply from the case.

-

Connect the screwdriver to the new power supply.

- Connect the power supply to the mains and check the operation of the device.

Remote power supplies

There are several types of power supplies that can be used as a power source for a cordless screwdriver. Let's take a look at some of them.

Power supply unit from a personal computer. You will need an AT power supply unit from a PC. Such a power supply unit differs from others in that it always has a 220V power button on it.Also, such power supplies differ favorably in that the power indicated on it always corresponds to the actual one, in addition, such power supplies have good overload protection and a cooling fan ... We need a power supply with a power of 300–350 W, and the current in the 12 V circuit must be at least 16 A. To remake such a power supply, it is necessary, firstly, to remove the protection from switching on by unscrewing the power supply case. To perform this work, you need to find a green wire on the power supply connector and connect it by soldering or a jumper to any black wire located on the same connector. Secondly, in the MOLEX type connector (it is smaller), we leave only the yellow (+12 V) and black (body) wires, remove the red wire (+5 V). Next, with a flexible wire with a cross section of at least 2.5 mm and the length you need, we connect the wires of the power supply to the terminals of the screwdriver

It is very important to observe the correct polarity here, so the cable must first be marked.

Car battery charger. If you have an analog charger with manual adjustment of the voltage and charge current, then alteration is not required, it is enough to connect it via a cable to the screwdriver terminals and adjust the voltage according to the screwdriver voltage

And also we must not forget about the polarity of the supplied voltage.

Laptop charger. This method is simple as it requires almost no technical knowledge. If there is an unnecessary charger from a laptop that is suitable for voltage, then after checking its output voltage, you can connect the charging to the screwdriver contacts. To do this, you need to disassemble the battery pack of the screwdriver and remove the worn out batteries from there. Having made a hole in the case of the battery pack, pass the wires from the charger there and connect them to the contacts of the screwdriver, while observing the desired polarity. Having fed a 220 volt network to the charger, you can start work with a screwdriver.

Car battery. This method is used when the wires are removed from the screwdriver for connection from a network device. It is enough to connect them observing the polarity with the terminals of the car battery to continue working with a screwdriver.

Homemade power supply. In order to make a portable home-made power supply yourself, you need knowledge in the field of radio engineering, as well as be able to read electrical schematic diagrams. In order to make a homemade power supply, you will need a power transformer. Such transformers were previously used in tube TVs, as well as in other similar household appliances. The primary winding power of the transformer should be 205-300 W.The voltage of the secondary winding must be selected within the range of 18-30 V. The cross-section of the wires of the secondary winding must withstand a current of at least 15 amperes. A diode bridge or a bridge assembled from individual diodes must also be rated for the corresponding current. The losses at the diode post are approximately 1.5 volts, respectively, the output will be close to the required voltage. You can practically select the required voltage using a conventional incandescent lamp with a voltage of 220 V and a power of 100 watts. Having connected it as a load, the required voltage must be achieved by the number of turns of wire on the secondary winding of the transformer. Further, the assembled power supply unit must be placed in the case and the low-voltage wires must be brought out to the connector for connecting to the screwdriver. It is also important to install fuses in the primary and secondary circuits of the transformer, thus protecting the power supply from short circuits.

Sample tests

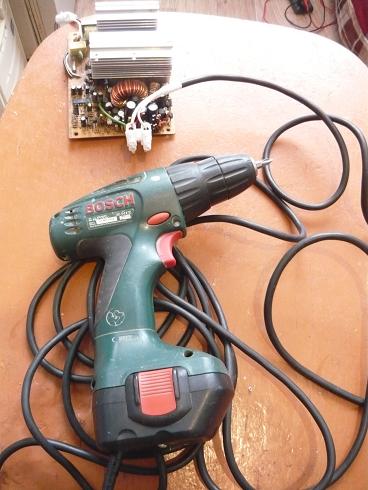

Before embarking on the construction of a working structure, you should test everything on the "knees", make sure

in the stability of the screwdriver under load and the absence of severe overheating in the power supply.

We take a computer power supply and check it: we turn it on, in the output bundle of wires we find

green (they say it may be of a different color, but I always came across green) and close it with a jumper

to any of the black ones (all black wires at the output are a common output, in our case it is a minus). The block should

turn on, a voltage of 12 volts will appear between the black and yellow wires. You can check this with a multimeter.

or by connecting any computer cooler to the named pins.

If everything is in order and the unit outputs about 12 volts on the yellow (+) and black (-) terminals, continue. If

there is no voltage at the output - we are looking for another unit or repair this one, this separate topic will be described

separately.

We cut off the plug from the output of the block and take 3-4 yellow and black wires each from the block and connect

them in parallel. When cutting off the plug, do not forget about the green starter wire, it must be shorted to the black one.

We got a 12 V source with a decent current carrying capacity of 10-20 A, currents depend on the model

and block power.

Now we need to hook up our 12 V to the screwdriver terminals without a battery, we look at the polarity of the connection on the battery.

Well, we check the screwdriver - at idle speed, then slowing down by hand. At this point, I ran into the problem:

when the button is fully pressed, the screwdriver works; when the button of the screwdriver is pressed slowly, smoothly, the power supply unit

goes to the defense. To reset the protection, it is necessary to disconnect the unit from the network and turn it on again. It will not work at all, you need

to somehow correct such instability.

I pulled the block board out of the case and hooked up an additional multimeter for constant voltage monitoring

I pulled the block board out of the case and hooked up an additional multimeter for constant voltage monitoring

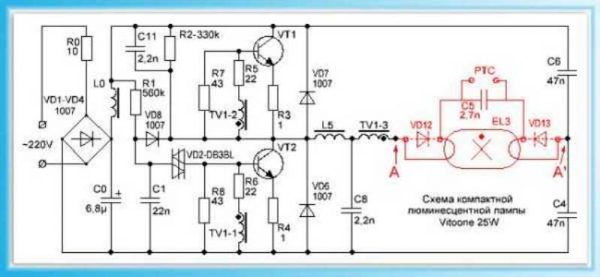

In my opinion, this phenomenon may occur due to the fact that the power supply unit and the screwdriver button

controlled by PWM controllers, due to interference on the power wires, the controllers somehow interfere with each other. Trying

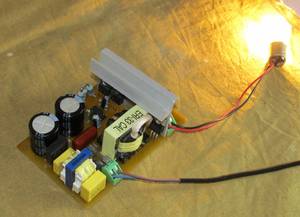

solve this problem by using an impromptu LC filter.

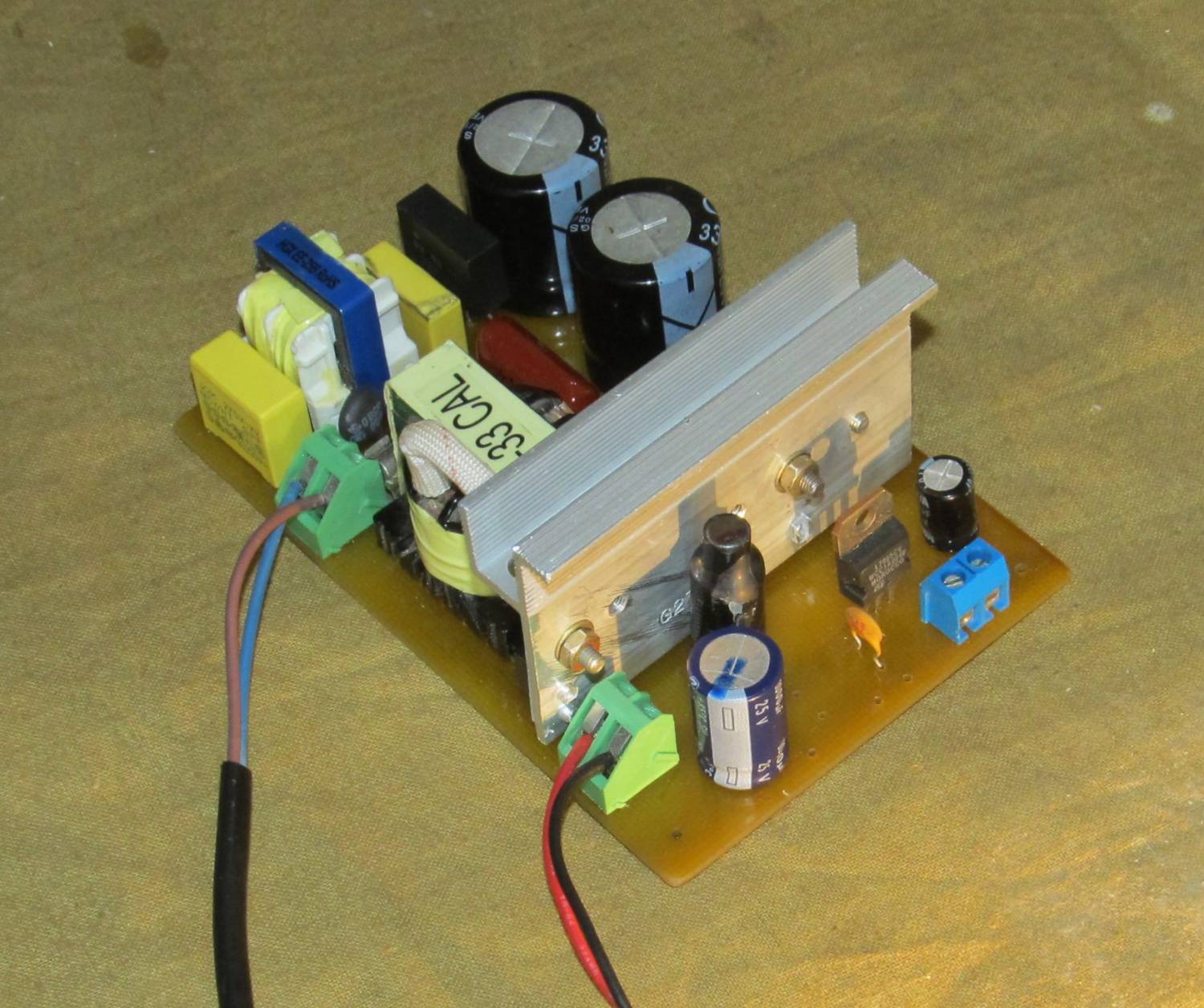

I assembled the filter in 5 minutes from what was at hand: 3 electrolytic capacitors of 1000 microfarads per

16 volts, non-polar capacitor less than 1 microfarad and wound 20 turns of copper wire with a diameter of 2 mm on a ferrite ring from another block. Here is it

scheme:

And this is how it looks. This is a purely trial version, in the future this design will be transferred to the battery case

screwdriver and will be done more accurately.

We check the entire structure: the block does not go into defense at any button positions, great! Now you can try

tighten a few screws - all in a bunch. It feels like a screwdriver will be able to screw larger

self-tapping screws.

Well, now you need to remove all the snot and heaps of wires, pull out the "dead banks" from the battery case, replacing them

to the LC filter and already test the screwdriver in more realistic conditions.