Large concrete mixers from 150 l

These models can already be classified as professional and, accordingly, they cost several times more than products of minimum and medium capacity.

Craton SM-180

Advantages:

- Convenient to operate;

- Cement interferes well;

- The angle of inclination is fixed;

- Double insulation.

disadvantages

- Don't just move from place to place;

- Great weight.

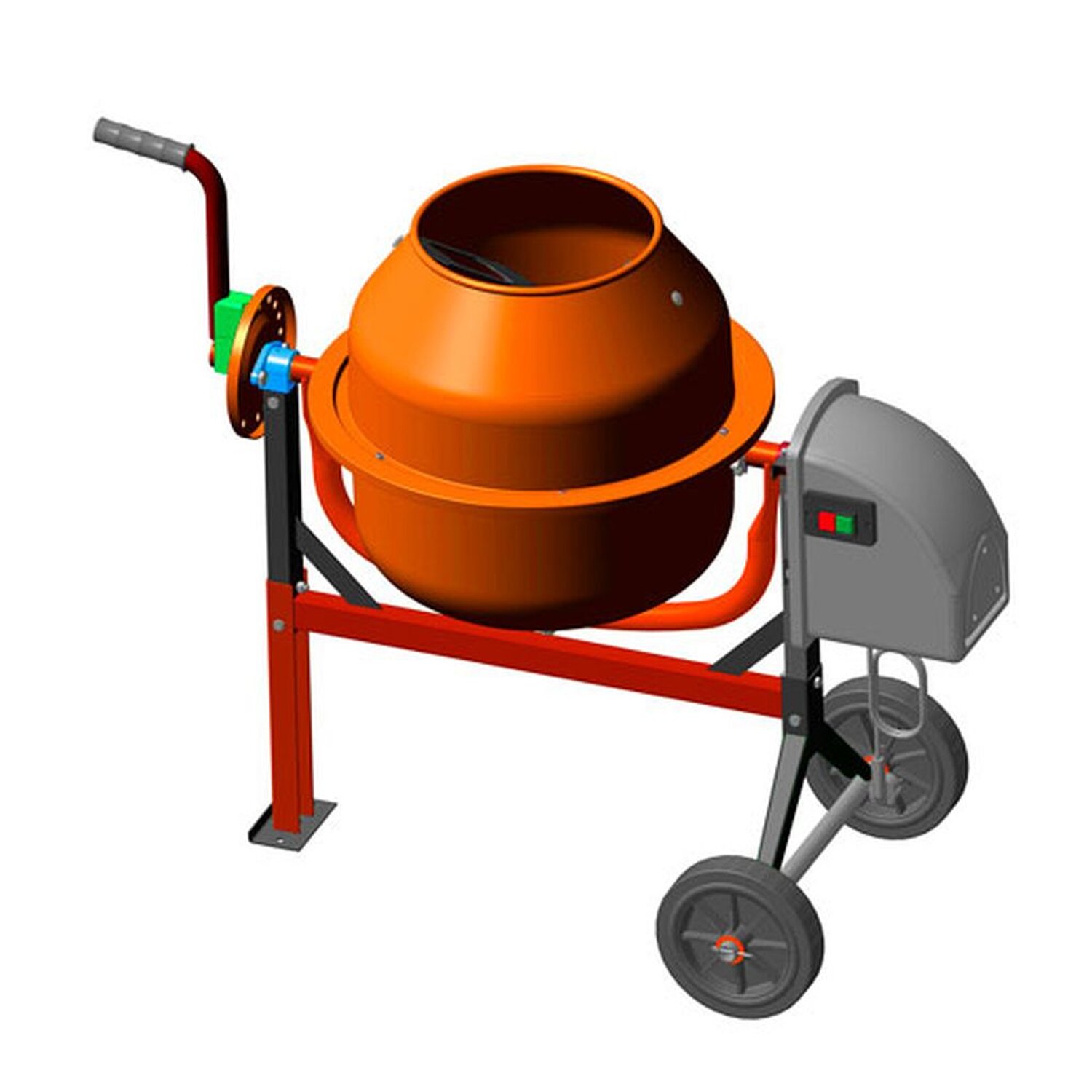

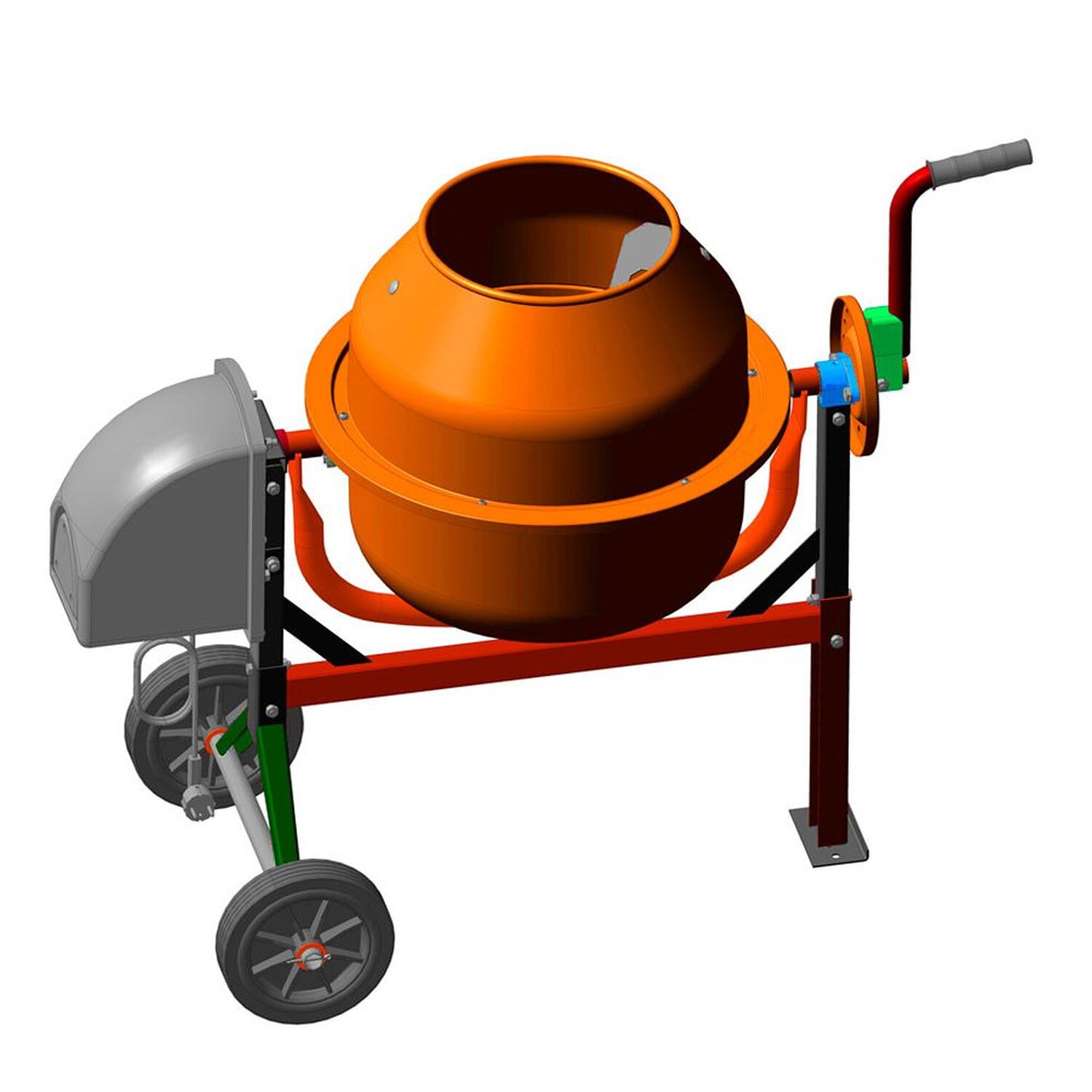

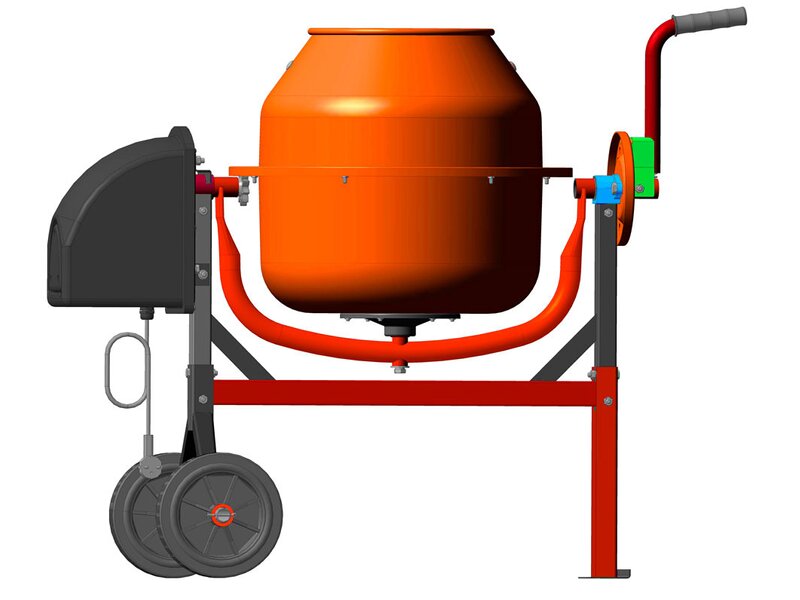

Techprom BM160T-750W

This budget model is used for the preparation of plaster, lime mortar, concrete mixtures. Their quality is high due to uniform mixing. The volume of the tank here is 160 liters, which is quite decent for a low price. 750W of power ensures good performance, and the simplicity of the wheel design ensures ease of use.

Advantages:

- Affordable quality;

- Acceptable price;

- Low power consumption;

- Convenient.

disadvantages

- Short cord;

- A little noisy.

Peculiarities

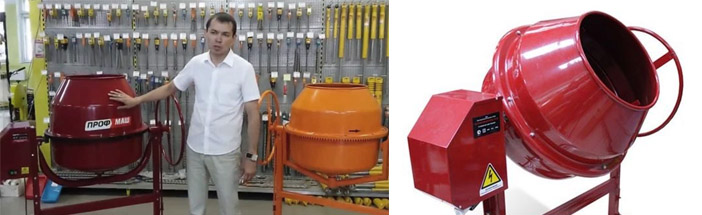

The products of the Stroymash company have their own characteristics.

- Simplicity. The technique is not equipped with complex functions, fulfilling only its main purpose - the manufacture of a mixture. You can use such concrete mixers without experience, you just need to get used to the work process.

- Reliability. And although the equipment has been on the domestic market for many years, it does not lose its main qualities, among which high reliability is noted.

- Wide range of models. You can choose a concrete mixer according to the technical characteristics and the desired price. The range of cost of the device is quite wide and available to the average buyer.

Small concrete mixers: up to 100 l

These are the cheapest models that are bought most often for private use - the construction of small buildings such as baths, summer showers, and toilets.

Whirlwind BM-63

This Russian-made mixer is suitable for non-professional use on small construction sites. It has a 63 l drum, in which up to 45 l of the working mixture can be mixed. It is prepared quickly enough due to the high engine power and rotation speed (up to 30 rpm). Unloading and loading raw materials is quite simple thanks to the large opening of the barrel with a diameter of 26.7 cm. There are no problems with transportation, since there are wheels here. There is a comfortable handle on the side. This weighs one of the best concrete mixers unloaded 24 kg, which makes it mobile.

Advantages:

- Works fast;

- Low price;

- Low weight.

- Compact, does not take up much space;

- Protection of the engine by a casing from dust and dirt;

- Convenient tilt lever.

disadvantages

Not detected.

You can download the technical data sheet for Vikhr BM-63 here.

Lebedyan SBR-132

This mixer is designed to prepare a solution with a particle diameter no more than 40 mm... You can get up to 60 liters of the mixture at a time. The finished composition is easily unloaded thanks to the collar and the change in the angle of inclination of the barrel. The construction is stable, the build quality is high, in particular, due to reliable connection bolts. The cast iron crown allows the tool to be operated frequently and without breakdowns.

Advantages:

- Cheap;

- Thick metal;

- Good mixing plates;

- Tolerates small overloads;

disadvantages

- No connection cable;

- The engine casing is heated;

- Fixed dump on one side only.

Which concrete mixer is better to buy

The following nuances also need to be taken into account:

- For the construction of small structures (barn, garage, bathhouse), for example, in the country, a mixer with a volume of up to 100 liters is suitable. In this case, the weight of the installation should not exceed 20-30 kg, otherwise it will be uncomfortable to work with it yourself.This is exactly what the Vortex BM-63 72/1/1 and Lebedyan SBR-132A.3 95443 models will become.

- If you plan to build a one-story house, then you need to fit at least 100 liters of the mixture at a time into the barrel. In our rating, the best in this category were, recall, Prorab ECM 125 and RedVerg RD-CM280.

- On large construction sites, 150-liter concrete mixers or even larger ones are indispensable. We are talking about Kraton SM-180 and Tekhprom BM160T-750W.

At what volume of the drum do you still need to stop, see this video:

In the end, we note that the best concrete mixer should still be chosen precisely according to the volume of the barrel, this is one of the most important guidelines, but it is also necessary to pay attention to the type of device, its purpose.

What are concrete mixers according to the principle of action

The main task of a concrete mixer is to create conditions under which several components loaded into it will turn into a homogeneous solution. There are a large number of concrete mixers on the market designed for industrial and domestic use. They differ in the volume of the working capacity, power, ease of use, but the main classification is made according to the principle of action on the solution - what are the concrete mixers according to the method of mixing it.

Forced concrete mixers

A classic stationary forced-type concrete mixer is a stationary container, inside which blades rotate on a shaft, mixing the components of the mixture. Such a mixer perfectly mixes the solution, but due to the need to maintain a small gap between the shovels and the body, it can only work with fine fractions of components. There are horizontal and vertical shaft with blades.

They show a good result in industrial production, but they are rarely used at private construction sites due to the high cost of production and the high price of the device. The main disadvantage is the need to seal the working shaft at the points of its attachments in the working container and the need for high-quality components that are constantly in contact with the concrete mixture. Partially these problems are removed in devices with a vertical arrangement of the working shaft, but their cost is still high.

Gravity Concrete Mixers

This is a class of home-made devices, often even without an engine - a good concrete mixer is useful for giving without electricity. Mixing is done by lifting the components up and pouring them down. When dropped, they mix and after a sufficient number of cycles a homogeneous solution is obtained. They are rarely used due to the likelihood of sticking lumps in the finished solution.

Combined devices

They are gravity concrete mixers, but with a constructive modification, which consists in adding blades or spargers of a mixing mixture inside the container. In these devices, the ideal ratio of labor-intensiveness-price-quality-cost of production, for which they are loved by manufacturers and buyers who choose a concrete mixer for the home.

What to look for when buying, in the following video:

The design does not imply contact of the mixture with the mechanism that rotates the drum, therefore, anti-corrosion treatment is needed only inside the mixer container. An additional advantage of combined concrete mixers is that they can work with any fractions of the mortar components, therefore, the vast majority of household concrete mixers on the market are of this type.

The lineup

SBR-120

SBR-120 is one of the most popular models for 120 liters, which is used in domestic construction on its own site. The volume of the finished solution reaches 50 liters, the engine power is 700 W, which is quite enough for such equipment. Power is supplied from a 220 V network, the cast-iron crown makes the structure more wear-resistant and reliable.There are transport wheels, and the weight of this concrete mixer is 50 kg. The small dimensions of the model are combined with its performance and ease of use.

MS-160

MC-160 is a simple concrete mixer with a volume of 160 liters, of which 80 liters is a ready-made solution intended for use on site. The power is 700 watts. The key difference from the previous model is the increase in weight to 60 kg, which is due to the greater capacity. The design has not undergone any special changes - it is still a simple technique with transport wheels.

MS-180

MC-180 is a unit that fully corresponds to MC-160, but has changes in the parameters of the volume and total weight of the device. The total volume of the concrete mixer is 180 liters, of which 96 liters are ready-mixed. At the same time, there was an increase in weight by 1 kg, which is not so significant when compared with the previous characteristics. Performance remains the same - 700W electric motor.

MS-200

MS-200 is another concrete mixer from the MS series, which is similar to other aggregates in this category. The mixer volumes of 200 liters and the ready-made solution of 110 liters required additional power, so the manufacturer equipped the equipment with a 1 kW electric motor. This improvement has increased the productivity of the workflow. As for the dimensions, they have also been changed. The device weighs 66 kg.

SBR-220-01

SBR-220-01 is a construction unit that is most often used in large projects due to the large volume of the mixer of 220 liters. The finished solution is 120 liters. With a small amount of work, one batch can be enough for quite a long time. The available 800W electric motor makes the work process a little tedious to wait, but overall the power of this model allows it to be productive.

As for the weight, it is equal to 125 kg, which can cause difficulties when moving this model around the construction site. Considering the quite affordable price, SBR-220-01 can be called a good choice if there are budget constraints, but a concrete mixer with a high-volume mixer is needed.

Review overview

Buyers in the majority of reviews consider Stroymash concrete mixers to be reliable and safe products with convenient operation. The simple design allows the use of these units without any special knowledge in the field of technology and construction. In addition, the presence of clear instructions for describing, assembling and operating the device is considered a plus. And users also like the availability of technology, which lies in an affordable price.

Among the shortcomings, we can note the fact of some uniformity of the model range, which differs only in several characteristics, mainly in the volume of the mixer, weight and engine power. Because of this, some users consider Stroymash concrete mixers to be of the same type and narrowly focused.

Concrete mixer from which company is better to buy

Several Russian brands in our rating prove that the domestic production of mixers is in demand on the territory of the Russian Federation and not only. By the way, it is these products that are most often preferred by buyers because of the acceptable combination of price and quality.

The leaders included:

Whirlwind - products under this brand are distinguished by an average price tag and availability for buyers. There are both large and medium-sized barrels. All of this comes with a 12 month warranty.

Lebedyan is a brand of JSC Lebedyansky Plant of Construction and Finishing Machines with a long history, modern equipment and European technologies. The quality of products is confirmed by international certificates 9001: 2008.

Prorab is a Russian brand, but production is located in China, which allows us to provide the buyer with inexpensive products. She pleases with a good value for money.

RedVerg is a large supplier of concrete mixers made in China. High quality of the goods is ensured by step-by-step multistage control. In many large cities, it has service centers to serve customers.

Kraton - this Russian company has been operating since 1999 and in 2017 it has more than 15 mixer models in its assortment.

They pay special attention to insulation, stability, drum rotation speed.

13 good tile cutters according to customer reviews

Operating rules

Since concrete mixers have an electric motor, you need to carefully consider the operation of equipment operating under the influence of electric current. If the power cable is faulty, disconnect it from the outlet. Before work, it is necessary to check the equipment for visible defects.

It is very important not to change the original design, otherwise the manufacturer cannot guarantee the safety and reliability of his product.

Before loading the dry mixture, it is necessary to turn on the unit for its uniform mixing. Water is added after mixing the dry components. When mixing the solution, its readiness is visually determined, and the consistency is adjusted by adding dry components or water. It is necessary to observe safety precautions when operating rotating mechanisms, make sure that hands or clothes are not accidentally caught in the elements of the rotating mechanism.