Internal combustion engine problems.

The reasons for this may be the following:

- Lack of elements necessary for engine operation - fuel, oil, uncontaminated air filter. The presence of these components is the key to good operation of the gas generator; in their absence, a protective mechanism is triggered and the device stalls.

- There is no ignition spark. You can fix the problem as follows: using a special key, unscrew the candle, then, using sandpaper and an iron brush, clean off the carbon deposits that appear when using low-quality fuel due to its incomplete combustion. Then you need to wipe the candle with gasoline or alcohol, let it dry. After that, you should re-check for the presence of an ignition spark and try to start the generator.

- Insufficiently adjusted carburetor, the occurrence of soot when the generator is not working at full strength. Additional carburetor adjustment will help solve the problem.

- Other serious damage to the generator.

Problems in the operation of an electric generator usually arise from a lack of voltage, which arises for a number of reasons. This may be a lack of contact, a malfunction of the brushes, burnout of capacitors, PWM units, etc. If voltage surges are observed at constant motor speed indicators, then, most likely, the matter is in a malfunction of the excitation regulators. It is necessary to disassemble the device in order to find out the exact reason for its failure to work.

Difficulty starting the engine usually indicates a malfunction. Finding the cause in a timely manner means preventing its further development and suppressing the negative impact on the operation of the unit.

Often, several interrelated factors act as the cause of a malfunction. In this case, they have to be eliminated in a complex manner.

Most often, the circumstances that prevent the normal start of the engine are:

Poor ignition system. The following options are possible here:

Problems with the spark plug: the distance between the electrodes is too large or too small (it is necessary to place the electrodes at the optimal distance), insulation failure (replacing the spark plug with a new one will help), the formation of strong carbon deposits (the spark plug must be thoroughly cleaned);

Problems with the ignition coil: insulation failure or winding rupture (replacement is required), incorrect connection of circuit elements or interruptions in its operation (if it is impossible to eliminate the malfunction of the microcircuit, it must be replaced).

Poor fuel system

Reasons and remedies:

- Lack of fuel in the tank (it is necessary to fill the tank);

- Clogged or pinched fuel hose (requires thorough cleaning or complete replacement of the hose);

- Air trapped in the fuel hose (check the tightness of the connections, tighten if necessary);

- Low quality gasoline or diluted with water (fill with higher quality fuel);

- Problems with the carburetor: breakdown, fuel or debris getting into it. Disassembling and cleaning the carburetor will solve the problem. Also, the reason may be in an incorrectly installed throttle valve, which is solved by carefully adjusting this part.

Problems in the main components of the engine

Reasons and remedies:

- Loosely tightened cylinder head bolts (tighten tighter)

- Piston, piston rings or cylinder worn out (needs repair or complete replacement)

- Poor contact between working chamfers and saddles (repair needed)

- Stuck valve (repair needed)

- The gap between the valves, the value of which differs from the gap value provided for this model (careful adjustment of the gap size is required);

- The intake manifold gasket does not impede the passage of air (tighten the bolts; if air continues to flow, the gasket must be replaced)

- Poorly tightened spark plug (tighten the spark plug more tightly)

More about the generator

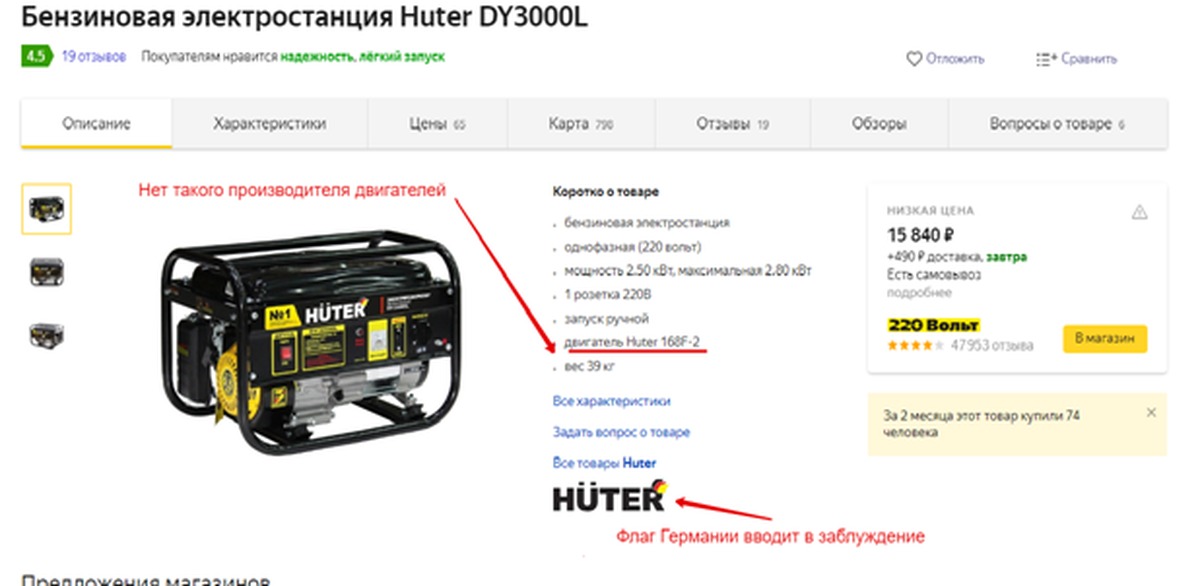

The Huter DY3000L is a power plant with a reliable combustion engine. Generator intended for household use... You can use the equipment in the country, in garages, as well as on expeditions. Available gasoline AI-92 is used as fuel. Big advantage - roomy fuel tank 12 liters.

Since the average fuel consumption is 1.3 liters per hour, it is quite possible to operate the generator at medium loads for up to 10 hours in a row, without additional refueling.

It is also convenient to use this model for those who wish to purchase gas as fuel. If you install a special power system, the generator will operate successfully on gas. Propane will do, as well as propane-butane.

It is also convenient to use this model for those who wish to purchase gas as fuel. If you install a special power system, the generator will operate successfully on gas. Propane will do, as well as propane-butane.

The developers have provided a special overload protection... If there is a danger of overload, the unit will shut down by itself. Mobility is ensured by a compact body and low weight. It is not difficult to install the power plant, since there is a special installation site on the body. It is convenient to operate the generator, since there are indicators on the case: it is always easy to determine the oil level and voltage from them.

The engine in the Huter DY3000L is a four-stroke, single-cylinder. It has air-type forced cooling. There is a 12V output, which is useful for all motorists to charge the battery. The working power of the generator is 2.5 kW.

It is also important that the noise level is low here.

Device and principle of operation

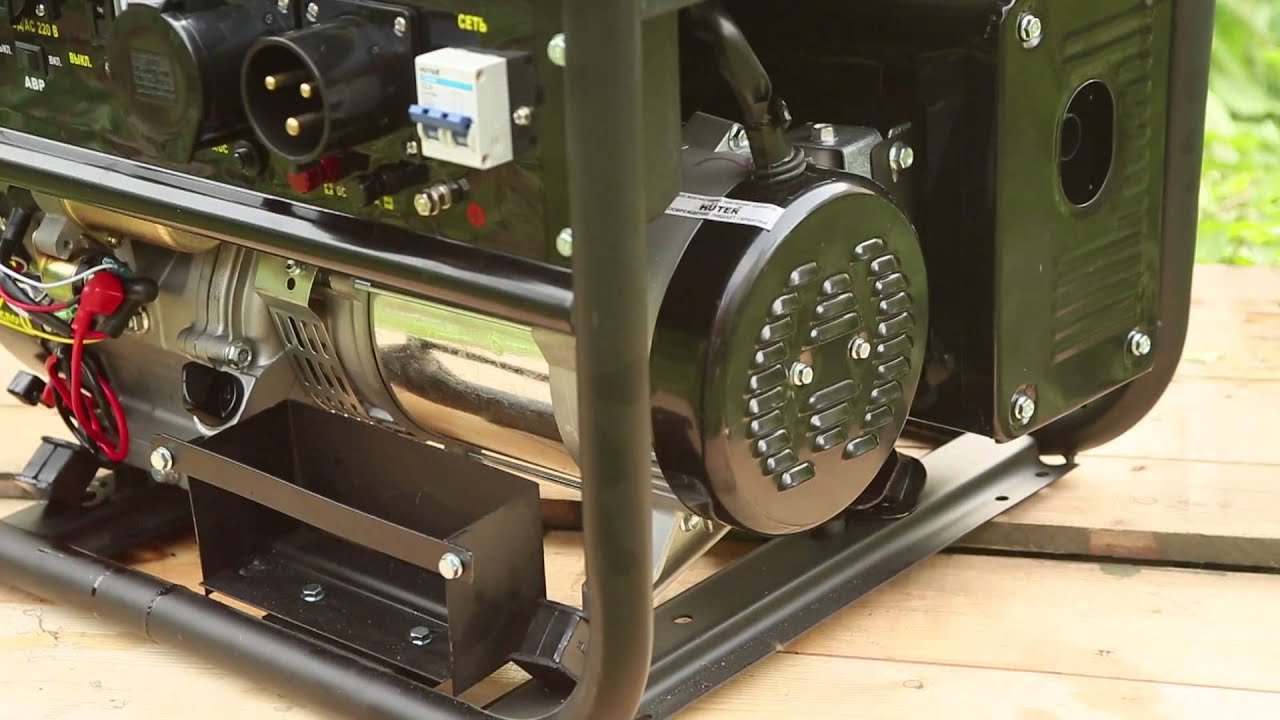

The most important element in the design is the piston internal combustion engine. The piston generates mechanical energy, which is then converted into electrical energy. The camshaft is at the bottom of the engine and the valves are at the top. Food carburetor type. For lubrication, oil is sprayed forcibly into the catheter. It is necessary to start the motor manually using a starter rope.

The most important element in the design is the piston internal combustion engine. The piston generates mechanical energy, which is then converted into electrical energy. The camshaft is at the bottom of the engine and the valves are at the top. Food carburetor type. For lubrication, oil is sprayed forcibly into the catheter. It is necessary to start the motor manually using a starter rope.

The case attracts with its excellent assembly. It is framed by a special metal frame. There is an installation platform at the bottom: it increases the area of contact with the surface.

All elements for operating the unit are cleverly placed on the front panel. There are terminals, positive and negative. The socket is suitable for connecting electrical equipment, tools. The starter rope is located on the side. The fuel tank is located at the top. There is a light indicator showing the fuel level.

The manufacturers ensured the safety of the equipment operation. The unit has several circuit breakers. They protect 12 V DC circuits as well as 220 V AC circuits. Even in the event of a short circuit, the equipment is protected from damage.

The developers have tried to do everything so that the gasoline generator works for a long time, without failures and breakdowns.

Specifications

Consider all the most significant technical characteristics of the Huter DY3000L gasoline generator.

| Gasoline generator model | Huter DY3000L |

|---|---|

| Power | 2.5 kW, maximum power is higher. |

| Reliability | Yes |

| Noise level | 67 dBA |

| Purpose of use | Household, backup power supply |

| Price | 12 730 - this offer is currently the best on the market. You can choose the best option, taking into account the cost of delivery to a specific address. |

| The weight | 45 Kg |

| Start method | Manual |

| Fuel consumption | 395 g / kWh |

| Battery life | Up to 8.5 hours at 50% load, at the maximum recommended load of 75%, the generator runs without additional refueling for 6 hours. |

| Type of fuel | AI-92 |

| Number of phases | 1st phase |

| Number of sockets | 2 sockets: 12V outlet, 220V socket. |

| Service | There is |

| Reviews |

Varieties of gasoline engines

The generator can have a two-stroke or four-stroke gasoline engine. The two-stroke engine modification does not provide for a separate crankcase for oil. In this design, the engine uses a premixed mixture of gasoline and oil. For this reason, the choice of lubricants for such a generator makes special demands.

The oil should dissolve easily in gasoline, and it should burn completely. A range of 2T special oils are available for air-cooled two-stroke engines.

When purchasing, please note that TC-W3 oils, also designed for two-stroke engines, must not be added to the generator. This oil can be used on engines with a water cooling system (installed on jet skis and motor boats)

The choice of oil for four-stroke engines is much wider. If your generator is equipped with such a motor, then you need to understand a little about the types and classifications of fuels and lubricants. Engine oil for engines of this type are classified according to the following indicators:

- SAE (viscosity);

- API (performance properties).

The SAE parameter informs the consumer that at what temperature environment, this oil will work most efficiently in the engine, providing the best lubrication of all its parts and knots. According to this standard, there are winter, summer and all-season oils. Gasoline generator sets can be filled with the following types of oils:

In the warm season, 10W30 oil may be the best choice. If the autumn-winter period of operation comes, then you need to choose from the bottom of the table, first of all, giving preference to the type of lubricant marked SJ or SL according to API. This is a modern oil, which, in terms of its quality characteristics and performance properties, is best suited for a gasoline engine.

It is this marking that you should pay attention to when choosing generator oil by API (performance properties)

In order for the gasoline generator to maintain its performance and its characteristics as long as possible, it is important to adhere to several rules

The engine of the new unit is “run-in” within 20 hours of operation. After that, it is worth completely changing the oil;

Do not forget about the need to replace fuel and lubricants in accordance with the manufacturer's recommendations (most often these are 50 hours for mineral oil and 100 hours for synthetic oil);

It is advisable to change the oil at the operating temperature of the engine;

Check the level with the dipstick before starting the engine. If necessary, add oil to the mark indicated on it;

After starting the engine, let it idle for a few minutes

During this time, the engine will warm up, and the oil will be distributed throughout the system and lubricate all parts;

In continuous operation, check the oil level every 5 hours;

Even if you rarely use the generator, you should change the oil at least once a season;

Important: the gasoline generator cannot be operated continuously - it needs periodic rest.

Remember that the quality and characteristics of the oil you use in your generator largely determines how it will work. Failure to properly lubricate engine parts can lead to premature engine failure.

It is very important to remember that the oil should be selected according to the season, as well as the need for regular monitoring of the adequacy of its level in the crankcase.

Our experienced managers will help you to ease the problem of choice.Use the feedback form on the website and get expert advice on the choice of fuel and lubricants, as well as recommendations for the maintenance and operation of your generator.

How to connect?

Connecting an electric generator for your home is no more difficult than connecting a battery or other autonomous power source. Diesel and gasoline vehicles are activated in the same way. The housing must be grounded - for this, a conductor must be connected to the threaded terminal. The generator must always be stopped before refueling. The same applies when changing the fuel type on multifunction models.

For gas fuel

Multi-fuel equipment may require connection of a gas cylinder or connection to the main gas pipeline. Any work in this case must be carried out with the involvement of specialists and in agreement with the resource supplier. In the case of bottled fuel, the connection is made through the supplied fitting - a flexible hose in a metal braid is connected to it.

When connected to the line, there must be a separate branch on it, equipped with a shut-off valve and a union. Since there are not so many individual gas models Huter produces, we are almost always talking about multi-fuel models. Before switching to gas, make sure that the liquid fuel supply is shut off and that there are no traces of fuel in the carburetor float chamber. You can drain it from the compartment by unscrewing the bolt on the gas reducer.

The procedure for connecting a gas or multi-fuel generator will be as follows.

- Close the tap on the gas tank.

- On the front panel, attach the flexible hose to the fitting, fix it with clamps.

- Move the gas supply shut-off valve to the operating position.

- On the front panel of the generator, you need to turn on the ignition.

- Move the choke lever to the closed position.

- Select the required type of fuel supply source using the gas type change lever.

- Press the forced gas supply button on the body. Hold for a while.

- Start the engine with the starter. Move the lever responsible for the air damper position to the "open" position.

Gasoline generator oil and diesel generator oil

Oil is an essential consumable for a power plant. It serves to lubricate the rubbing parts of the gearbox and engine, reducing their wear.

Oil is an essential consumable for a power plant. It serves to lubricate the rubbing parts of the gearbox and engine, reducing their wear.

While the equipment is operating, a sufficient oil level in the crankcase must be maintained to avoid engine stalling and serious damage.

In addition, the used composition requires replacement after running-in (after the first 5 hours of operation), also every 20 - 50 hours of operation, and during seasonal maintenance of the generator.

But mindlessly pouring the first thing that comes along generator oil

it is impossible, because a specific composition is intended for each type of engine and operating conditions. A knowledgeable person can easily determine this by looking at the information on the package. To make it easy for you, we will tell you more about how the marking is read.

According to the API system (American Institute of Petroleum Products), the compositions are marked with two letters. The first letter determines the type of fuel used: S - for gasoline, C - for diesel. The second letter in the marking indicates the quality characteristics of the oil, depending on the use of special additives. For example, oils labeled A, B and C are classified as low grade.

For diesel generators, it is recommended to use high-quality oils with CD, CE or CF-4 marks, for gasoline generators - SJ, SL. In addition, different oils are used for 2- and 4-stroke engines (see packaging for details).

The composition distinguishes between mineral, synthetic and semi-synthetic oils. They contain special additives that impart such quality characteristics as viscosity and fluidity. Note that under different temperature conditions, these properties can change, therefore, for each composition, its own temperature range of operation is determined.

For example, mineral oil is great for use in freezing temperatures, but once the temperature drops below freezing it can crystallize and the generator engine won't start.

That is why it is important to differentiate oils according to the season of use. There is an SAE standard for this.

So that you do not get confused in the complex values of the indices, we will present all the information in the table:

The recommendations presented in the table are approximate, since for each brand of internal combustion engine, each manufacturer gives a list of the most suitable oils and additives. It all depends on the degree of acceleration, the thermal intensity of the engine and other individual characteristics. You will find information on the compositions for your generator in the instructions.

Professional advice

Installation and launch

It is extremely important to properly start up, prepare the equipment for operation. All the necessary recommendations, instructions can be found in the official operating manual

We will cover the most important points.

First you need to pour oil into the catheter. It must be of a certain type, in accordance with the instructions. The oil tank is only filled up to the bottom edge. The final level is checked using a dipstick

Note! Do not allow the generator to operate with a low oil level, as this will cause wear and tear. When there is a critical oil shortage, the engine is automatically locked

To start the engine again, you will need to add the required amount of oil.

Grounding is another prerequisite for the operation of a gas generator. There is a threaded terminal to which the grounding conductor is connected. Fill the tank with fuel only after earthing! Remember that the unit must be turned off when you refuel. It is also recommended to use fresh gasoline: it should not be stored for more than a month.

If you want the gasoline generator to serve you for a long time, not to break down, you must always act according to the instructions.

Regular equipment maintenance is required: spark plugs, oil level, and fuel filters should be checked.

Store equipment properly. It must be protected from moisture, as well as from direct sunlight. It is not recommended to operate the unit in a closed, poorly ventilated area. The exhaust is high-temperature, so there should be no flammable objects near the generator.

If you follow the recommendations, properly operate the gas generator, it will serve for many years.

Gasoline generators with a capacity of 1 kW: the most popular models, their advantages and disadvantages

Electric generators for 1 kW use gasoline as fuel and are characterized by relatively small dimensions and weight. Some models of 1 kW electric generators are so compact and mobile that they can be easily carried by hand or transported by light transport.

Thanks to this, low-power gasoline generators are very much appreciated among tourists, hunters, fishermen, in general, among people who are forced to stay far from the usual power grid for a long time. For example, an electric generator with a capacity of 1 kW is capable of simultaneously supplying electricity to several incandescent lamps, a radio receiver, a boiler and even a low-power electric stove - for a small summer cottage you don't need more. At the same time, there is one more plus - the low price of such models.

Consider several of the most popular models of 1 kW power generators.

Huter HT1000L - gasoline mini-power plant, weighing 28 kg, The electric generator uses a single-cylinder four-stroke Hunter 152f OHV manual start engine. The advantage of this unit is simplicity in operation, the electric generator works equally well both on expensive gasoline and on cheap 92. The output voltage is 220 V, with a current strength of 5 A, the output power is 1 kW. A standard socket is provided as a plug socket.

SDMO INEO 1000 - 0.9 kW petrol inverter generator. The unit uses a 38-cube Olymp ES-38-1 OHV four-stroke engine. To fully fill the tank, you will need 2 liters of gasoline 92, which will allow the unit to operate for about 4 hours. The advantage of this generator is its low weight, only 13 kg, and the presence of a soundproof casing. The built-in socket has an output voltage of 220 V.

ENERGO EA 1000 I - generator with output power from 900 W to 1 kW. Unit weight is 14 kg... The generator uses a Honda GXH-50 OHV four-stroke single cylinder engine. The electric generator has one small drawback - the lack of sound insulation, that is, it is noisy. However, there is also the advantage that this generator is equipped with a 3.8 liter fuel tank. At a flow rate of 0.6 l / h, the generator can operate autonomously for more than 6 hours.

Huter DN1000 is a portable inverter power plant weighing only 12 kg. The power of the generated voltage is 0.85-1 kW. The unit is equipped with a miniature 4-stroke single-cylinder engine running on 92 gasoline. The disadvantage is that with a fuel consumption of 0.6 l / h, the developers equipped this model with a too small fuel tank, only 1.6 liters. This is approximately 2.5 hours of work. However, this model has the advantage of quiet operation. The generator is soundproofed and has a built-in silencer.

Fubag TI 1000 is an inverter-type electric generator with a power of 0.9-1 kW. The weight of the unit is 14 kg, which can easily be carried by one person. The generator uses a 4-stroke 1-cylinder engine designed for 92 gasoline. The fuel tank holds 2.6 liters of gasoline, with an average fuel consumption of 0.65 l / h. Cons: The generator is quite noisy (how can the noise be reduced). Pros: This model provides digital indicators for oil level and operating mode. The output voltage of the unit is 220 V, the current is 3.9 A.