Advantages and disadvantages

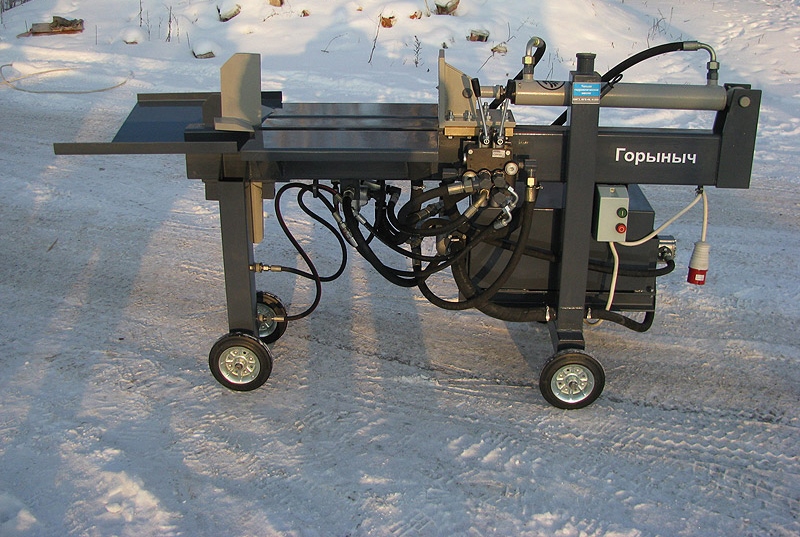

Like any technique, the Gorynych wood splitter has its advantages and disadvantages. Among the advantages are the following:

- one log splits in two seconds;

- the performance of the unit can be increased by adjusting the height of the knife;

- there is a copper radiator in the design, thanks to which the wood splitter can work without stopping in two shifts;

- the knife is made of high quality hardened steel;

- the manufacturer has thought of a comfortable workplace for the operator;

- the surface of the product is coated with a varnish that is resistant to negative weather conditions;

- all components and spare parts are on the market, so there will be no problems with repairs;

- the unit is patented and supplied with a quality certificate.

Application rules

The use of such equipment is accompanied by certain risks, but with the implementation of safety measures and knowledge of the features of the work, they can be minimized. The nuances of the operation of gasoline wood splitters can be divided into four main parts (preparation, inspection of logs, work process, maintenance), which we will study in detail.

Preparation for work

- Before starting the device, it is necessary to conduct an external examination for damage and leaks. If any malfunctions are found, the device should be sent to a special service center for their elimination.

- Check the position of the surface on which the wood splitter is supposed to be installed. It must support its weight, be level and horizontal. A slight deviation of the working surface is permissible only towards the lever, but in no case from the side of the cutting wedge. This way, you can not only position the device securely, but also use its full power.

- To cool the tool during operation, a so-called air jinkler screw is provided. Before starting it, it must be unscrewed by a couple or three turns.

Harvesting logs

A quick preliminary inspection and preparation of firewood in some cases will avoid breakdowns and costly repairs. The fact is that there may be nails in the wood, which interfere with the separation of the log and damage the cutting knife. In addition, the wood splitter cannot handle workpieces that are too large in size.

Splitting process

The work of the wood splitter begins with turning on its engine. After reaching the maximum number of revolutions, it is necessary to start up the piston, which moves the log to the knife. The device then cuts the wood, and you complete the process by lowering the lever.

Care

After the device has come to a complete stop, the finished logs have been removed and the worktable has been tidied up, the wood splitter should be cleaned. First of all, a guide and a cleaver need care and cleaning of debris and excess lubrication. The first one can be cleaned with a damp and dry cloth, while the second one has the screws checked, and the knife is sharpened if necessary.

Useful Tips

- If there is a problem with the separation of firewood, do not try to "help" the device with your hands. This is dangerous. Try changing the position of the log and starting the splitter again.

- High humidity can cause a short circuit, so do not use the device outdoors in wet weather.

- Keep an eye on the oil level and replenish it in time to avoid damage to the device.

- The machine can be operated by people who understand it, who know and follow the safety rules.

- It is better to entrust the elimination of minor problems and major breakdowns to specialized services, especially if the log splitter is still under warranty.

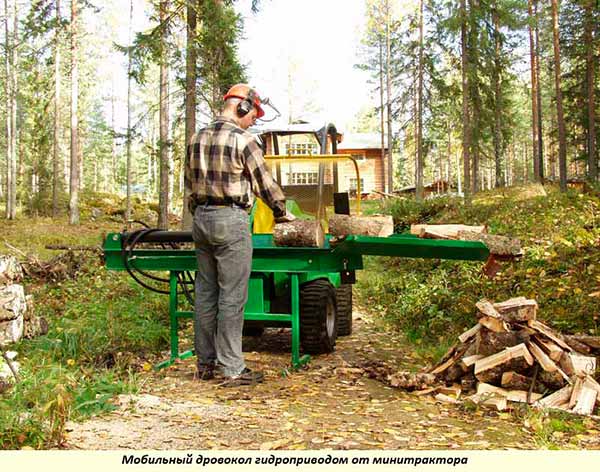

Hydraulic gasoline wood splitters are devices that can greatly facilitate the process of harvesting firewood for the winter. However, in addition to high performance, they have specific nuances of the operation process.

See the video below for an overview of the petrol wood splitter manufactured by Artmash LLC.

Views

Modern companies produce 3 types of wood chopping products. These are manual, electrical and hydraulic devices. Usually they are a screw (conical) cleaver, popularly called a "carrot".

If everything is more or less clear with the first two varieties, then the latter requires additional consideration. A hydraulic log splitter performs shredding like a hydraulic press: a cylinder pushes the workpiece towards a sharp wedge, which splits the log. Such a device is driven by a gasoline and, in some cases, diesel engine.