The main criteria for choosing an electric saw

There are many parameters to rely on when choosing an electric chain saw. But experts take into account only 5 criteria that will really help you choose a model for specific needs.

Performance parameters

Saw performance is influenced by two parameters: engine power and cutting attachment quality. For those who are looking for an inexpensive saw for working in a summer cottage, a model with a power of up to 2 kW is enough. She will cope with sawing logs, with pruning the crown of trees and dry branches. If a full-fledged construction is planned, then it is better to buy slightly more powerful tools - up to 3 kW. It is 3 kW that is considered the maximum power indicator for household saws and average for professional counterparts.

Saw performance is influenced by two parameters: engine power and cutting attachment quality. For those who are looking for an inexpensive saw for working in a summer cottage, a model with a power of up to 2 kW is enough. She will cope with sawing logs, with pruning the crown of trees and dry branches. If a full-fledged construction is planned, then it is better to buy slightly more powerful tools - up to 3 kW. It is 3 kW that is considered the maximum power indicator for household saws and average for professional counterparts.

Bus length

The working length of the bar is one of the key parameters for an electric saw. The longer the bar, the larger the diameter of the log it can cut. But it must be borne in mind that a large tire has a high resistance to the motor torque. Therefore, it must be equivalent to power. Otherwise, the tool will work at the limit of its capabilities and can quickly burn out.

The working length of the bar is one of the key parameters for an electric saw. The longer the bar, the larger the diameter of the log it can cut. But it must be borne in mind that a large tire has a high resistance to the motor torque. Therefore, it must be equivalent to power. Otherwise, the tool will work at the limit of its capabilities and can quickly burn out.

For domestic models, the optimal bar length ranges from 25 to 40 cm. It is better to buy saws with an indicator of 35 to 40 cm, because they will demonstrate good performance with minimal effort on the part of the master. But if two electric saws have the same power, but a different bar length, then it is wiser to buy one with a shorter bar length. The average proportion between power and tire length will provide the tool with high performance without rapid engine wear.

For professional tools, the length of the splint varies from 45 to 50 cm, which significantly expands the scope of their application. These saws can be used to work with wood of different density, including hard types (oak and ash).

Engine location

The convenience of working with the tool and its shape depend on the location of the motor. This is essential for production saws as the operator has to hold the saw for a long time.

In electric chain saws, there are two ways to mount the motor:

- longitudinal (the axis is strictly parallel to the tire);

- transverse (the axis is at an angle of 90 ° C).

The main advantage of saws with a longitudinal motor is the good maneuverability when the tool is tilted at an angle. They are perfectly balanced, so they do not lean to one side. This is a huge bonus for the master, since it does not burden the hands in case of prolonged work. There are also disadvantages to such modifications: when switched on, they can often "jump" to the side, they have more weight, and the gear transmission incorporated in them levels out some of the power.

The main advantage of saws with a longitudinal motor is the good maneuverability when the tool is tilted at an angle. They are perfectly balanced, so they do not lean to one side. This is a huge bonus for the master, since it does not burden the hands in case of prolonged work. There are also disadvantages to such modifications: when switched on, they can often "jump" to the side, they have more weight, and the gear transmission incorporated in them levels out some of the power.

The advantages of the transverse arrangement of the engine can be considered:

- full transmission of impulse to the circuit without taking power;

- lack of recoil when starting;

- increased reliability.

Chain pitch

The chain pitch is usually understood as the interval between several adjacent rivets, divided in half. This parameter is responsible for the cutting ability of the saw and, therefore, for the quality of the work performed. Electric saws have three chain pitches: 0.325, ¼ and 0.375 ″.

The chain pitch is usually understood as the interval between several adjacent rivets, divided in half. This parameter is responsible for the cutting ability of the saw and, therefore, for the quality of the work performed. Electric saws have three chain pitches: 0.325, ¼ and 0.375 ″.

Chainsaws with 0.325 pitch and ¼ ″ are low-power, budget models aimed at home use. They have minimal vibration, but they also dull quickly enough. Saws with such chains are worth buying only if there is no need for constant work with the tool. For example, for seasonal tree cutting.

Models with a chain pitch of 0.375 ″ (also sometimes referred to as 3/8) account for more than 90% of the total range. This is the largest indicator, so manufacturers use it most often. 3/8 inch saws are versatile configurations that suit a wide variety of tasks. Moreover, they can work for a long time, which does not lead to their wear. One of their main disadvantages is high vibration, but excellent performance overrides it.

Chain tensioning technology

There are two types of chain tensioning: with or without a wrench. Based on customer experience, nut tension is better because it is more reliable and provides the right level of safety. Manual tension can loosen during the sawing process, causing the chain to fly off the base. And this is very dangerous for the master. This technology is most often implemented on inexpensive power saws designed for very short working sessions.

What kind of work is the back saw intended for?

This version of the hacksaw is difficult to attribute to ordinary household models. Yet it is a specialized tool that is used in the furniture industry and in the creation of decorative wood products. In the household, such a saw can make connecting grooves when installing wooden structures. Moreover, it must be borne in mind that the blade, precisely because of the stiffening rib, imposes restrictions on the cutting depth. In this sense, surface sampling from solid wood or the formation of small holes can be considered as the target operations of the back saw. Why do you need such a tool in construction? When installing door and window frames, this hacksaw will allow you to make complex joining edges, spending a minimum of time. Likewise, when laying wood flooring, a complex selection may be required at the points of passage of communications - it is a thin canvas with a fine tooth that can easily cope with such tasks.

Tool manufacturers

The segment is highly specialized and little in demand among a wide audience, so not every manufacturer turns to it. The best developments are offered by the companies KRAFTOOL, IRWIN and Bahco. So, in the family of the first company there is a Multi-M hacksaw with a length of 320 mm with a rounded top. This version is suitable for rigid sheet workpieces made, in particular, of combinations of wood and plastics. IRWIN sells the Xpert XP3055 hacksaw with a length of 300 mm. The small design with a two-component handle is ergonomic, reliable and safe. As for the Bahco company, in its assortment stands out the Superior butt saw with original NXT teeth, which are subjected to high-precision hardening. This model is suitable for medium to small workpieces of varying hardness. The thickened butt increases the durability of the thin blade and increases the quality of the cut.

Most popular models

To understand all the variety of hacksaws, you can pay attention to the most popular products. The most demanded products include the following:

- Stanley JetCut (SP 2 \ 15 \ 288). This model is equipped with a D-shaped handle. The blade length is 50 cm and the tooth pitch is 7 mm. High quality Swedish steel is used for the production of this saw. The teeth hardly wear out, so the durability of the Jetcut reaches 5-10 years. The cost varies from 1200 to 1400 Russian rubles.

- Expert Bison. A very popular model. The biggest advantage is the price. It starts at 700 rudders. In addition, this hacksaw is versatile. The triangular teeth made of hardened material allow both transverse and longitudinal cuts. The high efficiency is due to the special setting of the teeth. The model is equipped with a comfortable handle made of durable plastic.

- Stanley General Purpose. This model is designed for accurate and precise sawing of wooden parts. Length - 380 mm. The cost varies from 650 to 750 rubles.

- Banco Laplander. The perfect tool topping the list of the best hacksaws for wood, with which you can cut both wet and dry wood. This model is often chosen by builders, gardeners, tourists, fishermen and avid hunters. The excellent quality of the steel ensures high reliability of the tool. However, such a saw costs from 1,500 to 2,500 rubles.

There are other models that also deserve attention. One way or another, but such products are recommended to be taken from trusted suppliers.

After buying a summer cottage, I needed a good saw. At first I thought about choosing a Japanese model, because such products pass various tests and are considered very high quality. However, my budget was very limited, so I opted for the Bison saw. I do not regret my decision at all, because the device is very high quality and reliable.

Semyon Grishin

On the eve of my husband's birthday, I started running around the shops and looking for a good gift for him. Then I accidentally went into the store of various tools and decided to give him a good hacksaw, since the old one was already all rusted and had been gathering dust on the balcony for several years. The husband was very happy with the gift, because he just wanted to make an extension from a bar.

Galina Petrova

I used to have a hacksaw made in the USSR. Of course, it was a good thing, but it is outdated, and the canvas is already all rusty. Went to the store and bought a Stanley Grand. A wonderful thing. Very convenient and, most importantly, inexpensive.

Ivan Fedin

Originally posted 2018-07-04 07:10:56.

Nuances of operation

The power tool is sensitive to low temperatures and humidity. Therefore, before starting after winter storage, you should dry it, heat the saw in a warm room - condensation inside the case is fraught with short-circuit.

The reducer rigidly connected to the armature is not designed to compensate for excess return energy. There is no clutch on electric chain saws. The sharpening of the chain must be checked before starting work without fail.

Recommendations for choosing a saw headset (bar length, chain parameters) are completely identical to the tips for chainsaws.

Kickback remains a major concern for the chain saw operator. It is discarded when the end of the tire contacts the surface of the lumber, log. Therefore, several technical protection solutions are used:

- sector covering the end of the headset web

- chain brake

Automatic chain lubrication is the default, but for professional users, some models offer an additional manual adjustment. Depending on the knotty and hardness of the wood, the amount of oil can be increased.

Experts say that the resource of electric household chain saws is limited to 5 - 7 years, even with gentle operating conditions. Models with a powerful drive cost twice as much, but they last much longer.

There are battery modifications with high mobility. However, they are heavier, less powerful with a short saw blade.

The switch-on lock is used on all electric saws, it prevents injuries when the button is accidentally pressed (carrying, gripping with one hand, uncomfortable grip).

Saw headset (chain and bar)

In a domestic gasoline-powered tool, the tire length of 40 cm (12 - 16 inches) is limited by the engine's capacity. If you wish, you can buy a longer rig for cutting a thick tree, however, with constant use, the resource of the tool will decrease many times. Similar requirements apply to farm-class chainsaws.

This is not the case with professional saws:

- they can be completed with one canvas or several different sizes (30 - 75 cm)

- the operating manual contains the min / max values of the tooling length

This tool solves various tasks, the motors are much more powerful, which allows multiple replacement of chains and tires.There are tires with a replaceable head for professionals, lightweight for work at height (trimming of knots), flat narrow, guaranteeing no "kickback", making it possible to secure the work of hobbyists with household tools.

The characteristics of the circuits are:

- pitch - determines the cutting speed

- "Tail" - the thickness of the links in the part that moves along the saw cut

- profile - also affects performance

- length - corresponds to the size of the tire

- number of links - usually standard, but dependent on shank width

Household low-power (0.5 - 3.5 HP) modifications are equipped with a 0.325 ”chain with a low sawing speed. 4 HP saws m you can use the 0.375 ”chain, which is not in demand, but allows you to cut thin wood. In professional chainsaws from 5 HP high performance 0.404 ”chains can be used, as this tool is with increased torque.

The wider the shank, the more stable the saw head in the cut. Therefore, professionals use chains with a 1.6 - 2 mm "tail", in farm saws there are 1.5 or 1.6 mm links, in household models only 1.1 mm and 1.3 mm.

The depth of cut per chain revolution depends on the profile height, which is 0.635 or 0.762 mm. In the first case, there is no kickback; in the second, the chain must be used by a professional who can handle it without injury.

The cutting links of the equipment have a crescent shape (chippers) or a “seven” type (chisels). The former cut faster, but are susceptible to abrasive substances (sand, dirt on the trunks).

Attention: Chainsaws are designed for cross-cutting, it is better to open boards with a circular tool. Recommended sharpening twice in half a year

In lightweight and standard versions of chainsaws, tires are available in two versions:

- armored bow (H) - made of super-strong stellite alloy, has a wide W or oblong S radius of the nose bend

- the nose part is equipped with a sprocket (SP) - allows to reduce friction, increases cutting performance by 20%, but is not intended for nose tapping, since there is a high probability of damage to the bearing by the wood, on which this sprocket rotates

Lightweight tires are marked L, have grooves in places of minimum operating loads, filled with rubber or silicone. The toe of the tire can be equipped with a sprocket or can be armored.

The cutting links of the saw equipment are of several types:

- shaving - rounded knives, minimal sharpness

- half chisel - suitable for household saws, edges are slightly rounded

- micro chisel - the shape is close to a square, they are completed with a low-power tool, the side edges are rounded

- chisel - flanks mate with top at right angles for maximum cutting performance, built for powerful tools

The drive links of the chain are turned inward, pass through the drive sprocket, supply oil and throw the shavings outward, cleaning the grooves.

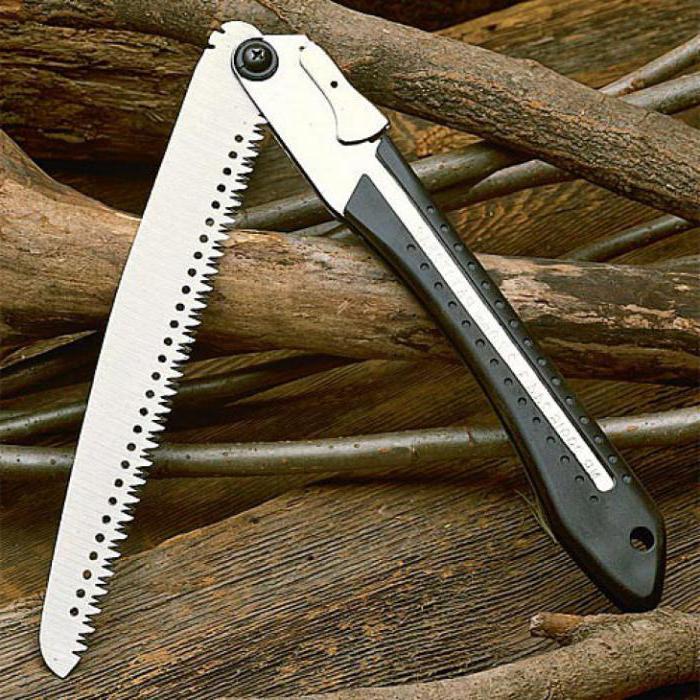

Foldable

Another popular type of hand tools for woodworking is Japanese folding saws. According to their purpose, they are very different: models of small sizes, which are convenient to use on a hike or fishing; products with straight or curved blades for cutting fresh wood and pruning trees; professional devices for various jobs. The widest selection of folding saws is offered by Silky.

The universal Pocketboy model (blade - 130 mm) with blade fixation in 2 working positions costs 2,100-2,200 rubles.

Gomboy Curve product (curved blade - 270 mm) - 3700-3800 rubles.

And a professional folding Japanese obturator saw Woodboy Dozuki (blade - 240 mm) will cost 5200-5400 rubles.

The main parameters of hand tools for cutting wood

A hacksaw is one of the most essential tools in every man's inventory. This device allows you to easily resize wood and plastic lumber.With the help of a hacksaw, you can perform a lot of operations in construction, saw down branches in the garden, shorten the fence poles, and so on.

A hand saw is used for working with lumber

But when buying such, at first glance, a simple tool, not everyone thinks about how to make the right choice and what criteria should be taken into account. The hacksaw has its own special parameters that can affect the quality of work. There are four basic parameters when choosing a hacksaw: blade length, tooth size, steel type and handle type.

Blade length

For the convenience of work hacksaw blade length chosen so that it is twice the size of the material at the cut. This allows you to effectively remove sawdust during operation due to the fact that all the teeth of the blade will come out of the board / log. In addition, this ratio of the sizes of the hacksaw and lumber contributes to a greater range of motion of the hand. This, in turn, takes much less energy. In construction, a universal hacksaw with a blade length of 45-50 centimeters is most often used. To work with small bars and boards, a canvas with a length of 30–35 centimeters will be enough.

Tooth size

This is perhaps the most important parameter. After all, the speed and accuracy of the cut depends on the size of the tooth. The number of teeth per inch of blade is commonly referred to as TPI. For more accurate work with the material, it is necessary to use a hacksaw with a high TPI coefficient, that is, with a large number of teeth. When choosing a blade with a TPI of at least 7-9, and the distance between the teeth no more than 2-4 mm, the surface at the cut will be smoother and without torn edges. A blade with TPI 3–6, tooth spacing over 4 mm, will work well for working with large beams and garden trees. The use of such a hacksaw will reduce the effort expended and increase the speed of cutting the working material.

Tooth pitch correspondence table

| 1 TPI = 25.5mm | 10 TPI = 2.5mm |

| 2 TPI = 12mm | 11 TPI = 2.3mm |

| 3 TPI = 8.5mm | 12 TPI = 2mm |

| 4 TPI = 6.5mm | 13 TPI = 2mm |

| 5 TPI = 5mm | 14 TPI = 1.8mm |

| 6 TPI = 4mm | 17 TPI = 1.5mm |

| 7 TPI = 3.5mm | 19 TPI = 1.3mm |

| 8 TPI = 3mm | 22 TPI = 1.1mm |

| 9 TPI = 2.8mm | 25 TPI = 1mm |

Sharpening teeth

The usual triangular shape of the hacksaw teeth is taken as the standard one. The teeth are made in the form of an acute-angled triangle or isosceles, depending on the purpose of the cut. Such a blade can be sharpened with particular ease by repeating all the corners of the teeth. You can use such a blade for both longitudinal and cross-cut to avoid rough chipping.

The teeth of a classic hacksaw are made in the shape of a triangle and can be sharpened

Video: self-sharpening hacksaw teeth for wood

But modern hacksaws, unlike classic ones, have hardened teeth with a non-standard trapezoidal shape. These saws are endowed with increased strength and wear resistance. Their steel will not give in to sharpening, and it is very difficult to observe all the angles of the sharpened teeth.

Modern hacksaws are made with hardened trapezoid-shaped teeth.

Steel type

For the production of hacksaw blades, high-grade stainless steel is most often used. Usually saws for wood are made of steel with a hardness of HRC45. Very often, manufacturers combine steel in the blade. In a hacksaw with a combined blade, most of it is also made of steel 45, but the cutting part is made of steel 55 and 60. When the cutting edge is hardened, the wear resistance increases. This type of tool can be easily distinguished from a conventional hacksaw by its dark hardened teeth.

The ease of use depends on the correct choice of the saw handle. Handles are made of wood or plastic. A very important point - the surface at the place of the grip should be such that the hand does not slip. This is eliminated by making scars on the handle, or covering it with a rubber layer. The hacksaw can be either a classic cast or with a folding blade.The latter allows you to replace the canvas, which is very convenient.

Specifications

Work with wood products and materials is carried out with various tools, however, the electric saw in this range stands out due to its versatility and performance. This is due to a number of characteristics that are inherent in a power tool for working with wood.

- The device does not require the use of various fuels and lubricants for refueling. This significantly reduces the cost of work where the saw is operated.

- As practice shows, the tool is quite unpretentious in maintenance and easy to use.

- The comfort during the operation of electric saws is also due to the fact that the device emits several times less noise in operation.

- The configuration of the tool allows the saw to be considered a harmless tool, since the unit does not emit any exhaust gases. This feature makes it possible to carry out various work with the saw, not only outside, but also indoors, which greatly expands the functionality of the tool.

- An electric cutting device will work at any temperature, unlike some analogues, for example, gasoline units, which have problems starting at low temperatures.