Equipment and requirements

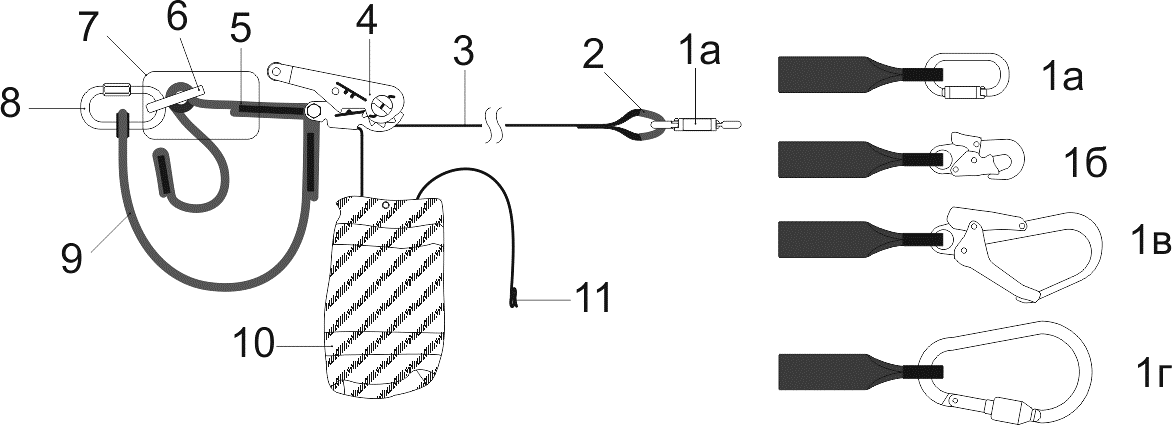

Each line has its own configuration. For flexible, a metal cable, intermediate and final anchors, dampers - (shock absorbers) in the event of a worker breakdown, reduce the load on the fasteners of the structure, mobile mechanisms, the system for tensioning cables and ropes.

The international standard GOST EN 795-2014 "Occupational safety standards system ... General technical requirements ..." sets the following requirements for the use of various anchor lines.

- These systems must be supplied with fasteners for the bearing sections of buildings. When using a sling (cable), a mechanism is required to tension it, which provides a comfortable installation, removal, movement and replacement of the cable.

- The design should minimize the chance of hand injury.

- The cable must be installed not below the level of the support surface.

- If the movement of the worker involves a transition along the support structures between the vertical beams, the rope is launched at a height of 1.5 meters above the support plane.

- The presence of intermediate supports is mandatory if the size of the cable is more than 12 meters. The surface of the structure of the structure must be free of sharp edges.

- The tensile strength of the rope, installed from the support surface higher than 1.2 meters, must be at least 40400 Newtons. If the attachment height is less than 1.2 meters, the force should be 56,000 Newtons.

- The thickness of the cable is from 8 millimeters.

- The working properties of parts should not change with temperature drops and increased humidity. Corrosion can be eliminated by using a special anti-corrosion coating applied to metal elements.

Rigid and flexible anchor lines

Rigid and flexible anchor lines

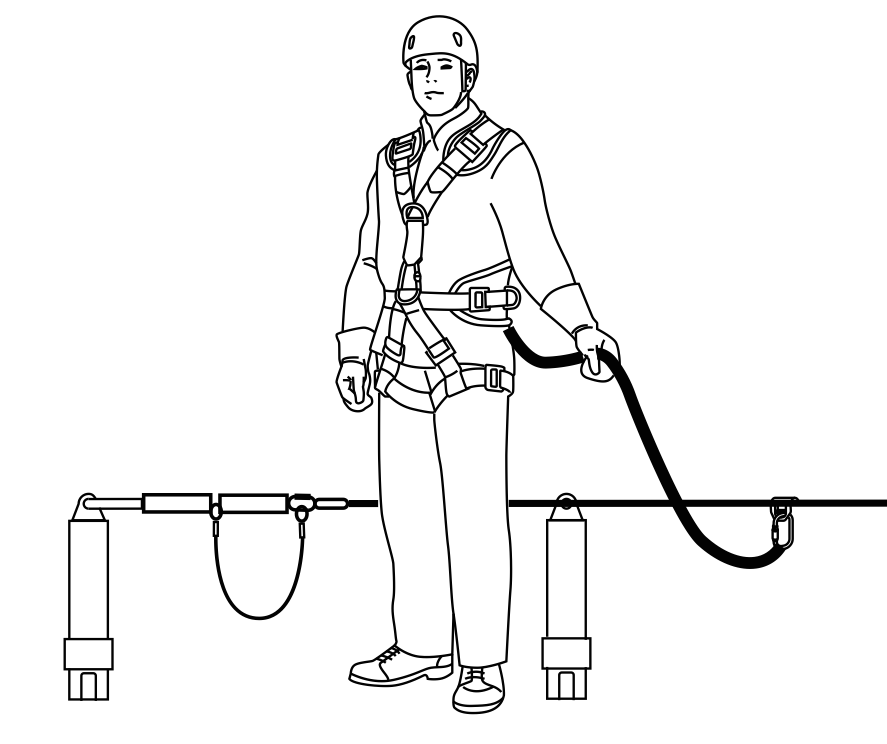

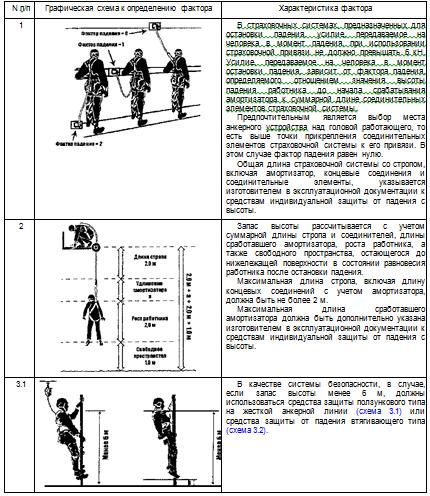

For a safe transition at a height from one workplace to another, fall arrest systems should be used, which include rigid or flexible anchor lines as anchor devices.

Anchor lines of specific structures must meet the requirements of the manufacturer's specifications, which determine the specifics of their application, installation and operation.

Anchor lines should be equipped with a device for attaching them to structural elements of a building or structure. When used in the construction of the rope - a device for its tension, providing ease of installation, removal, rearrangement and the ability to change the length of the rope depending on the distance between the attachment points.

The design of the anchor line parts must exclude the possibility of injury to the worker's hands.

The mass of the rope as a whole should be established by standards or technical specifications for ropes of specific structures.

When moving along the lower chords of trusses and girders, the rope must be installed at a height of at least 1.5 m from the plane of the support for the feet, and when crossing the crane beams - no more than 1.2 m.

With a rope length of more than 12 m, intermediate supports should be installed, the distance between which should not be more than 12 m; in this case, the surface of the intermediate support, with which the rope is in contact, should not have sharp edges.

The intermediate support and its attachment points must be designed for a vertical static load of at least 500 kgf.

Steel ropes of the horizontal anchor line, installed at a height of more than 1.2 m from the plane of the support for the worker's feet, must be at least 8.0 mm in diameter. Steel ropes should, in general, be of a marking group of at least 1558 MPa (160 kgf / sq. Mm).

The value of the pre-tension, taking into account the sagging in the middle of the span of the tensioned rope, is determined in accordance with the calculation of the load value in the anchor device provided for in Appendix No. 13 to the Rules.

The amount of sagging should be taken into account when calculating the headroom. Rope details should retain their protective and operational properties at temperatures from minus 45 to plus 50 ° C and relative humidity up to 100%.

Rope fasteners that may corrode must have anti-corrosion coatings.The organization must develop and approved in the prescribed manner instructions for the operation of ropes in accordance with the manufacturer's operating documentation.

Operation of the rope is allowed if, as a result of external inspection, no destruction or cracks in its parts are found. At the same time, in the structural elements of buildings, structures or other devices to which the rope is fixed, during operation, destruction or cracks should also not be detected.

Each anchor line rope shall be marked with:

- trademark (or short name of the manufacturer);

- the value of the static breaking force;

- rope length;

- date of manufacture (month, year);

- designation of the standard or technical conditions according to which the rope is made.

Species overview

There are many areas of social life in which structures such as anchor lines are needed. They are used in construction work, in towers and in the repair of power grids. Wherever safety at high altitude is important, different types of systems are used. They are divided according to the following criteria.

Structural Orientation

Depending on the type of work, they are classified into two types.

Horizontal

They are used in restraining and belay systems. These lines, with synthetic rope or cable, have a tensioning mechanism.

The horizontal structure is suitable for roof work and pitched roof maintenance.

Vertical

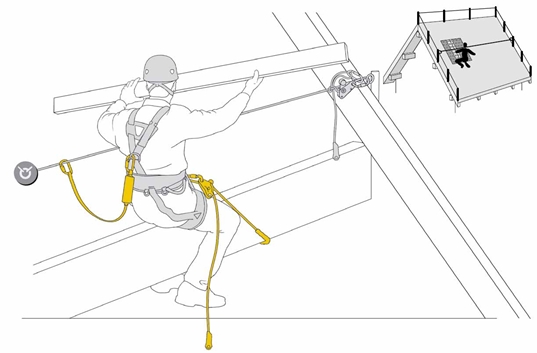

Designed for movement on a plane located vertically or at an angle. To connect the worker, a slider-type blocking device is used, which is fixed on the machine in case the worker fell from a height.

Time of use

According to this criterion, they are divided into the following types.

Temporary - after the work is finished, lines of this type are no longer used. They are quite cheap, but less durable and safe.

Allocate flexible and rigid anchor lines. Let's consider them in more detail.

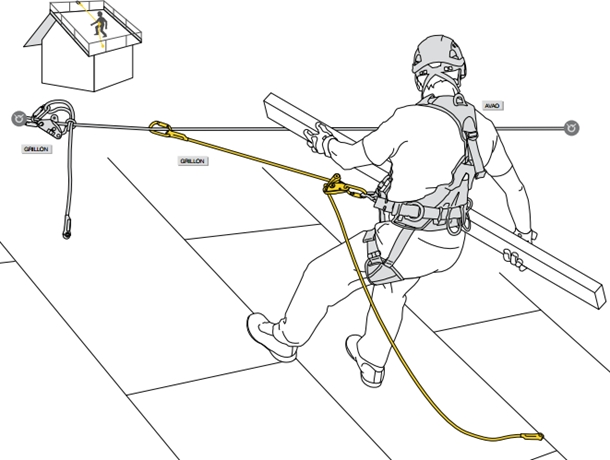

Flexible

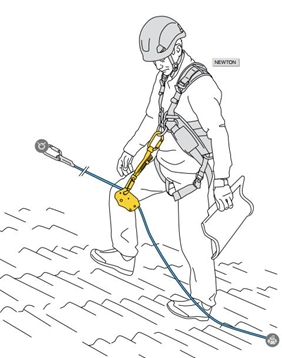

An important feature of their structure is considered to be a wire rope, which is the supporting (main) part of the lines. Installation can take place not only vertically, but also horizontally - it all depends on the type of work

It is fastened with end anchors, which are located every 10-12 meters. To reduce the load in the event of a worker falling, dampers and shock absorbers are used.

Among them, there are single-line (when there is only one guide in the structure along which the anchor point moves) and two-line (when there are two guides).

Flexible anchor lines are divided into permanent and temporary. In turn, permanent or stationary are divided into cable, tape and rope. All of them are needed for a variety of work - from lifting workers to evacuating people.

Use is possible in any conditions, the most important thing is that they must be protected from damage from sharp edges. They are installed at an angle of 75-180 degrees, which minimizes the risk of disruption of workers. Flexible lines can be attached to any surface.

Hard

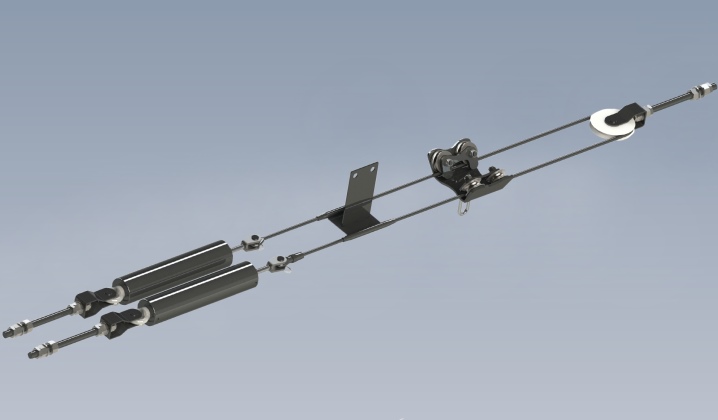

These systems are somewhat different in structure from flexible ones - here the line looks like a straight or curved rail. Large steel beams are taken as a basis, along which a special carriage moves. It can be with or without rollers.

Rigid anchor lines (RL) are mounted to the building in such a way as to limit the possibility of displacement of the side lines. They are fastened by means of end or intermediate anchors, which depends on the place of attachment of the beam to the surface. Such a safety structure is mounted for a long period and is used constantly. Compared to flexible lines, installation time and costs are higher.

Features of use

Safety during work depends not only on the quality of production lines, but also on compliance with safety regulations.

- Before starting work, it is necessary to undergo training and obtain a special permit for high-altitude work, as well as undergo re-certification every 3 years.

- Damaged items of equipment are not allowed for use; integrity check is carried out before each use. The use of anchor structures is permissible only in a complete set, the operation of individual elements is not allowed.

- The use of anchor lines is carried out according to the manufacturer's recommendations. A preliminary plan is drawn up for getting out of emergency and life-threatening situations.

- Storage should be in conditions that exclude damage to equipment.

See below for a demonstration of the anchor line.