Works in the garage

A car requires continuous attention, care and skill from its owner. The motor should work without interruption in different modes and in any weather. Undercarriage - to provide movement in space on any road and at any reasonable speed. Instruments - give accurate information about the condition of the machine. The salon is always to be clean and comfortable. And the appearance of the car must be flawless, because it gives the first characteristic to its owner.

And to meet all these requirements, the car owner must have the appropriate knowledge and skills:

- understand how the engine works;

- understand electrics;

- be able to adjust the chassis;

- disassemble and assemble the transmission;

- and many many others.

Enthusiasm alone will not leave here. It is necessary to have the appropriate tools and equipment for the job. And in order to be able to get to any point in the car, you need to have either a viewing hole, or a lift, or both at the same time.

Types and models

There are several options for traverse jacks.

- Hand-operated hydraulic car lift. Such a mechanism has a manual pump, thanks to which it raises a fairly significant weight, but at the same time to a small height. This mechanism is characterized by a fairly democratic cost.

- Pneumohydraulic car lift. This device is connected to the pneumatics of the service center and thus frees the employee from doing manual work. Simply press a button to start the jack.

- Pneumatic traverse. These scissor jacks today are the most perfect mechanism. To work with it, a car mechanic does not need to make any effort to lift a car, even a multi-ton car. The lifting capacity of this jack is quite simply determined from the calculation that to lift each ton, a pressure of about 2 atmospheres is required.

The range of pit lifts on sale is diverse and makes it possible to choose a device that will fully meet the existing needs of the workshop. Modern traverses differ:

- clearance;

- lifting height;

- ultimate load;

- size;

- type of drive;

- carrying capacity;

- swing of the paws;

- degree of reliability.

Domestic and foreign manufacturers in the production of pit mechanisms use the most modern technological solutions and materials that ensure the safety and reliability of the device. In any case, the choice of a particular design is largely determined by the comfort of its use in each specific situation.

The hydraulic jack for the inspection pit is of greatest interest as a budget option for service station equipment. Such a device can be used to lift small-sized machines, the weight of which does not exceed 2.5 tons. Among the disadvantages of hydraulics, it is necessary to note the need for constant monitoring of the oil level in the system, as well as the need for periodic lubrication of all articulated joints.

The pneumatic traverse does not require any special technological maintenance, it can lift machines weighing up to 6 tons.

The pneumohydraulic traverse, depending on its design features, may differ in the lifting capacity parameters. It is easy to operate and does not require expensive maintenance.

Depending on the structural features of the pit jacks, certain options are distinguished.

- Two-stage mechanisms with a pair of hooks placed at different heights.This mechanism combines low-grip and traditional jacks.

- Low foot lift. Its distinctive characteristic is a laterally protruding pick-up paw, which is capable of clinging to a load under its lowest fragment. By the way, it was from here that another name for the mechanism came from - a hook jack.

- Low-profile traverse - used to lift cars with low ground clearance.

Peculiarities

The success of any service station directly depends on the ability of its owner to provide his clients with the widest possible range of services. At the same time, the quality of diagnostics and car repair directly depends on the technical equipment of the service center. Since the adjustment of the camber-convergence process, like the main part of the work performed on the maintenance of the walker, is carried out on the inspection pit, the presence of a special lifting device - a traverse is considered an indispensable condition for work at the station.

If a regular standard jack is enough for a motorist to perform some everyday manipulations, then in the conditions of professional repair and service, a more serious mechanism is required - it is called a pit jack, it is also called a ditch jack or an axial traverse.

The use of a traverse is considered the most optimal and practical way to lift a car in a garage, where the dimensions of the room, as a rule, do not allow to put any other universal car lifts for cars. Often, inspection pits are, rather, a good addition to such lifts and can be of interest as a workplace for unscheduled minor repairs of the vehicle.

And if we are talking about trucks, then the only mechanism that can raise the rear or front axle of a multi-ton unit is a powerful pit jack. In fact, the traverse is one of the elements of a four-post, scissor or plunger lift, which is an alternative to the traditional inspection pit. Such a lift is fixed on pre-prepared guides, the peculiarity of their design provides free and easy movement.

The main purpose of any pit traverses is to raise the front or rear axle during:

- carrying out locksmith and diagnostic work on the walkway;

- inspection and repair of the underbody, as well as the fuel and exhaust systems;

- adjustment of the camber-convergence mechanism.

Traverses (pit jacks)

The traverse is a lifting device that is used in conjunction with a four-post or scissor lift or on a pit for partial lifting of a car. It is used for similar breakup and general locksmith works. By the type of drive, they are divided into traverses with manual and pneumohydraulic drives.

Servo offers hydraulic traverses (pit jacks) from manufacturers:

In garages, mainly hydraulic traverses or trench jacks are used.

With the help of hydraulic traverses, alignment of wheel alignment is carried out, diagnostics, repair or maintenance of the suspension of any type of vehicles within the established carrying capacity are carried out. Depending on the location, the hydraulic traverse is installed on a car lift or on a viewing pit.

Traverses (pit jacks)

Traverses (pit jacks)

Ditch jacks, or in other words, traverses, are equipment used by car services, car workshops, service stations during the repair of a chassis car, to raise its front, as well as rear, and to adjust camber alignment. Pit jacks (the same traverses) can be installed both on a car lift and in a viewing ditch, from which they were classified - a traverse for a viewing pit and a traverse for a lift.

In addition to installation on auxiliary lifting equipment installed on a pit, it can also be installed on a four - post lift for hanging one vehicle axle.

An inspection ditch, which is not equipped with a traverse, cannot be considered a full-fledged equipment, since almost seventy percent of all work with a car requires hanging the chassis. Without it, by the way - do not carry out the collapse - convergence. It is for this reason that the crosshead must be purchased together with wheel angle adjustments.

With regard to the repair of larger vehicles - buses, trucks and more - here the pit jack plays a very important role, being considered the main lifting unit. It is possible to use roll-up columns while lifting a freight transport, but they are several times more expensive than pit jacks and do not differ much in efficiency.

Pit jacks are pneumohydraulic (quite expensive, they start work, or rather lifting, after connecting to a pneumatic generator and pressing the traverse button) and hydraulic manual (they are somewhat cheaper than the first option; they lift the load by manually pumping a hydraulic pump into a horizontal plane).

It is worth noting that this equipment is capable of lifting two car wheels at the same time, which is very convenient when carrying out the operation of compensating wheel runout.

The main characteristics of such a device include:

• The height of the rise, which is from thirty to fifty centimeters;

• Carrying capacity - from one thousand and a half to thirteen and a half thousand;

• Paws span - from eighty centimeters to one hundred and fifty.

As a rule, the set of the pit jack has an automatic locking device, which is released by pneumatics; automatic safe lowering system; and a valve producing maximum pressure.

Pit traverse - how does it work?

So, pit traverses are a combination of the following elements:

Loading …

- base, or the carriage on which all other elements are located. It is a rectangular frame made of high quality steel. It can be additionally equipped with a roller system for moving both along the bottom of the ditch and along its walls (if there are special grooves);

- hydraulic or pneumohydraulic drive located on the carriage and driving the lifting mechanism. Equipped with an impermeable hose and pump, with the help of which pressure is pumped up in the system (usually manually, although there are models that are controlled remotely);

Pneumatic traverse for pit

- scissor lifting mechanism - a system of cross levers that comes into motion as the pressure in the hydraulic system builds up. In this case, the levers move towards each other, while simultaneously lifting up the platform with the load. The number and location of levers may differ - depending on the required lifting height and lifting capacity;

- platform located at the top of the scissor system and is directly responsible for lifting the load. It is made of high-strength steel with a protective coating. To increase the lifting height, it can be used in conjunction with removable supports in standard or telescopic design.

The lifting force is the pressure of hydraulic oil or compressed air, depending on the type of drive. The pressure in the system increases when the pump is pumped up; in this case, liquid or air flows from the tank / cylinder into the system through a sealed hose. Next, the drive starts pushing the pistons, which drive the lifting mechanism.

When the lift is made to full height, the pumping stops, the hose is disconnected from the tank / cylinder and the valve is returned to the opposite position. After completion of the work, the pressure is completely bled from the system.

We recommend to buy

How to make an inspection pit in a garage

After you have decided on the dimensions and what material you will make the walls from, what thickness they will be, you can start marking the pit. This can be done with pegs driven around the perimeter. The second option is to pull the string / rope between the stakes driven in at the corners. We begin to dig a foundation pit according to the markings. The land is usually taken out and temporarily stored near the gate.

Made of bricks: a step-by-step photo report

Along the way with excavation, monitor soil moisture. If you have reached the design depth (required + floor screed thickness), and there is still no moisture, you can do without waterproofing. Those who do not want to take risks can be advised to immediately lay the film.

We level the walls. It is not necessary to achieve ideal geometry, but there should be no noticeable humps and pits. We also level the bottom of the pit, ram it, compacting the soil well. Usually a manual rammer is used. A layer of crushed stone is poured onto the bottom (twice 5 cm each), each layer is also carefully rammed. Next comes a layer of sand. It is enough 5 cm. The sand is moistened, tamped to a high density - so that the foot is not imprinted. Next, we lay a waterproofing film.

We level it well, tucking it into the corners. We lay the sheets with an overlap of 15 cm, which we glue with double-sided tape. To prevent the edges from rolling, we press the materials at hand - boards, stones.

We put a layer of insulation on the bottom, on it - a reinforcing wire mesh. We fill all this with concrete of grade M 200. The thickness of the layer is at least 5 cm. To make it easier to navigate when laying, we make marks on the film by which you can control the thickness of the layer.

If you use Portland cement M 400, the proportions will be as follows - 1 part of cement, 3 parts of sand, 5 parts of medium and fine crushed stone.

We are waiting for several days until the concrete gains 50% strength. The exact time depends on the temperature. If it is around + 20 ° C, you will have to wait 5-6 days. If + 17 ° C it is already two weeks.

Let's start laying out the walls. It was decided to do it in half a brick. Used bricks used, about 850 pieces went (pit size 4.2 * 0.8 * 1.7 m). The walls were laid out in a circle to the level of the elbow.

At the level of 1.2 meters from the floor, it was decided to make a niche for the instrument. Its height is 3 rows of bricks, the top is covered with a processed board.

In order not to have to lay out a brick niche, a metal insert is inserted. A box is welded, suitable in size.

Further, the walls were driven out almost level with the garage floor. Part of the walls was replaced by two sections of channels. Jacks rest on the bottom, if necessary. A metal corner with a shelf of 50 mm is laid on the top row, the thickness of steel is 5 mm.

The corner unfolds so that one of its shelves hangs down, the second covers part of the upper surface of the brick. To prevent the wall from collapsing under load, mortgages are welded to this corner, which are then connected to the reinforcing belt of the concrete floor in the garage.

Further, preparatory work was carried out on the construction of the concrete floor and it is filled with concrete.

Features of the manufacture of walls made of concrete

When casting concrete walls, formwork must be made. It is easier to make it from sheet material - construction moisture-resistant plywood with a thickness of 16 mm, OSB. Shields of the required size are knocked down, reinforced with bars on the outside. They are necessary so that plywood or OSB does not bend under the pressure of concrete. First, put the outer parts of the formwork. If the walls of the pit are even, there will be no problems. Just lean them back, put them straight.

Then the internal formwork panels are exposed. There should be a distance of at least 15 cm between them. So that the walls are not deformed during the pouring process, spacers are placed between them.

It is advisable to fill it at a time. The filled portions must be bayonetted or processed with a submersible concrete vibrator. Remove the formwork after two to three days. After that, you can install a corner with welded embedded rods (strips) and start pouring the floor.

What materials are they made of

The inspection pit in the garage (its walls) is laid out with bricks, heavy building blocks, made of monolithic concrete. If we talk about brick, it is better to use ceramic brick: it is not afraid of moisture. The walls are made in half a brick or brick. The thickness of the wall, depending on the method of laying, turns out to be 12 cm or 25 cm. This must be taken into account when marking the pit.

You can use bricks on dry, dense soils. The groundwater level should be low. If the water rises high, it is better to make the pit walls of reinforced concrete.

Building blocks also need to be chosen those that are not afraid of high humidity. These are concrete blocks. The rest, if used, then with the obligatory external waterproofing, and then this is not a guarantee that they will not crumble, especially if the groundwater is located close.

With a concrete inspection pit, everything is easier: concrete is not afraid of moisture, it only gets stronger from it. M 250 concrete is used to fill the walls, M 200 is enough for the floor. Why is this so? Because during winter heaving, the main load falls on the walls. In order for them not to "fold", a margin of safety is required, which is achieved by reinforcement and the use of high-strength concrete. By the way, in order to avoid heaving of the soil under the garage, it is necessary to make a good blind area so that the water leaves and does not absorb into the soil.

The wall thickness when filling the inspection pit with concrete is from 15 cm. The stacks must be reinforced. To do this, use a ready-made mesh with a wire thickness of 5-6 mm and a pitch of 150 mm (if the groundwater is deep) or knit a frame made of reinforcement with a diameter of 10-12 mm. The step of installing the reinforcement is 20 cm. For greater strength, you can make a single rod on the bottom and walls, bending it accordingly.

Waterproofing methods

The inspection pit in the garage can be protected from moisture penetration in two ways: by using external waterproofing, which is carried out exclusively during the construction process, and internal, which can be done during operation.

Outdoor protection

If at the construction site of the garage the groundwater is deep, lower than 2.5 meters and does not rise higher even in spring or after heavy rains, you can do without waterproofing. On the other hand, the hydrological situation is constantly changing, and where it used to be dry, water may appear. If the inspection pit in the garage has already been built, you cannot do external waterproofing. It remains only to use deep penetration impregnations to reduce the hygroscopicity of the walls. Therefore, if possible, do external insulation in any case.

How to prevent moisture from entering the inspection pit in the garage? Most often, waterproofing films or membranes are used (butyl rubber, aquaizol, etc.). They are laid with panels, covering the pit from one edge to the other, with 10-15 cm protruding from each side of the pit to the garage floor. The sheets are laid with an overlap. They should overlap by at least 15 cm. To obtain a more airtight joint, they are glued together with double-sided tape, in two strips, at the beginning and at the end of the "overlap". The film is well straightened so that it fits snugly against the walls of the pit

During further work, it is important not to damage the membrane.

Internal waterproofing

Internal waterproofing is usually the impregnation of walls with coating waterproofing. If possible - composition for swimming pools. It creates a waterproof, dense film that closely resembles rubber. It has a blue color and after hardening it washes well. It is better to process the walls with this composition twice, or more.

Another option is a cement-based deep penetration primer. The polymer particles contained in it block the capillaries through which moisture penetrates through the thickness of the material. One such treatment significantly reduces the hygroscopicity of the material. In the case of water in the garage pit, at least two treatments are required (and even more is better).

Caisson device

There is another option to escape from the ground - to make a metal caisson. A box of appropriate dimensions is cooked from sheet metal, treated with anti-corrosion compounds, and then installed in a pit. If the welds are sealed, there will be no water, but another problem may arise. Large quantities of water can squeeze out the caisson. They say that it "pops up".

To avoid such a situation, corners, rods, which go 1-1.5 meters into the ground, are welded to the sides of the caisson from the outside. So that at the same time the volume of earthwork is not very large (the foundation pit, taking into account these struts, turns out to be large), you can cheat. Before installing the caisson, drive corners or metal rods into the ground, releasing their ends outward. They can be welded to the caisson body after installation. The pit will still have to be made larger (it must be cooked outside), but its dimensions will still be smaller. The second plus of this method is that the rods will be driven into dense soil, which means they will better hold the caisson.

Another way to exclude the "floating" of the caisson is to make a hole in the wall at a certain height. If the water rises to its level, it will begin to pour inward. The water can then be pumped out, the main thing is that everything remains in place. The inspection pit in the garage, arranged according to this principle, stood for more than 20 years - until the metal rusted.

Sump for collecting water

If the pit has already been built, and the coating waterproofing or impregnation did not give the desired result, it is necessary either to arrange a drainage system around the garage, or to collect water in one place. For this, a pit is made in the garage inspection pit, at one of its ends. Water accumulates in it, from where it is pumped out by a pump. In order for the system to work in automatic mode, a water presence sensor is installed, which, when triggered, turns on the pump.

Formwork is made under the pit, poured with concrete. Then the pit is waterproofed together with the entire pit waterproofing. For reliability, you can also put a metal box inside.

Since it is impossible to get rid of the dampness completely in this case, the boardwalk is knocked down onto the floor of the pit. To make the boards rot, they can be impregnated with working off. If you don't like its smell, take a special impregnation for wood that has direct contact with the ground (Senezh Ultra, for example).

Hoist manufacturing

The very first step is the choice of the model of the lift and the development of its drawings. For the manufacture of any type of lift with a movable bed, you must first acquire materials and tools. Of the materials, a steel profile is needed - an angle or channel of 45-55 mm in size, round timber for wheel axles to fit the size of the bearings, a rod for hinges.

If a design with a worm drive is chosen, then the lead screw should either be selected ready-made, or ordered by professionals. You can't do it yourself at home. Find a suitable hydraulic mechanism for the hydraulic lifting option. From the tools you will need a large locksmith vice, a grinder, a hacksaw for metal, keys, screwdrivers. It is imperative to have welding equipment and to master the welding technique.

Tipper

The easiest option is to install the machine on its side. This is sometimes sufficient for many suspension applications. The base frame is welded from a 50 mm corner.

PHOTO: Tipper for setting the machine on its side

PHOTO: Tipper for setting the machine on its side

The device is placed under the bottom of the machine, then the lead screw is rotated, and the machine is mounted on two side wheels. The device is lightweight and can be dragged.

Mobile engine lift

Sometimes it is required to remove the engine from the car and transport it to the workbench. A small mobile crane is suitable for this. The boom is lifted with a small jack. Its manufacturing technology is the same as that of the tipper. To move the crane across the floor, it is mounted on rubberized bearings.

PHOTO: podelki.org Mobile engine lift

PHOTO: podelki.org Mobile engine lift

Floor mobile lift

When working, it may be necessary to move the lift. This means that such a lift must satisfy two requirements - to withstand a car and it is quite easy to move, even if without a car.

Floor mobile lift

Floor mobile lift

It is required to move it when installing it under the car and when cleaning after the end of work.

Installing the lift under the car

Installing the lift under the car

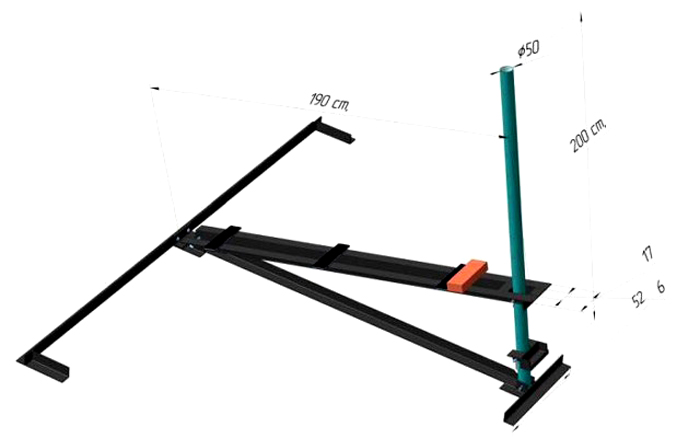

Pit jack

The top of perfection is the pit jack.

PHOTO: Mobile lift built into the pit

PHOTO: Mobile lift built into the pit

Although it is mounted in a pit, and it is impossible to quickly remove it from there, it is still mobile: its cargo area can move both along and across the pit along with a car installed on it.

The lift has retractable "legs" that allow you to install a machine on it with any track gauge.

PHOTO: Sliding feet "paws"

PHOTO: Sliding feet "paws"

Unscrewing stops are installed on the "paws".

PHOTO: youtube.com

PHOTO: youtube.com

The support beam can move across the axis of the pit, and the entire structure rolls along the pit on rollers.

PHOTO: youtube.com

PHOTO: youtube.com PHOTO: youtube.com Roller with hub

PHOTO: youtube.com Roller with hub PHOTO: youtube.com Moving the bed along the pit

PHOTO: youtube.com Moving the bed along the pit

To make a good powerful lift, you need to purchase a 100 mm channel, an angle with a wall size of 50 mm, and profile pipes of 50 and 40 mm. The lifting mechanism is a 12-tonne jack.

PHOTO: youtube.com

PHOTO: youtube.com

The bottom of the machine rises 60 cm above the floor level.

You can put a smaller jack, but it will have a low lifting height. You will have to lift the car in several steps, placing thick plates under the jack.

PHOTO: youtube.com

PHOTO: youtube.com

For completeness of the set, a movable hoist is placed above the pit.

PHOTO: youtube.com Hoist in the garage

PHOTO: youtube.com Hoist in the garage

All parts are electrically welded.

DIY pit traverse

You can make a pit traverse with your own hands, taking an ordinary hydraulic jack as a basis. All that is required for this is a well-made drawing, which, in addition to the overall dimensions, will take into account the expected loads and dimensions of the ditch, a certain amount of metal profiles (beams, channels and pipes), electric or arc welding, if necessary, wheelsets, bolts, etc. nuts.

DIY pit traverse

If you are not strong in geometry, you can contact a specialist to create a drawing, or look for a ready-made one on the Internet.

The finished design, of course, will not amaze with elegance - however, this is not required of it. The most important thing is performance, which, if done correctly, will be at its best.

Pits and lifts

Normal work with the bottom of the car requires the ability to get to this very bottom.

This can be done in three ways:

- Place the machine on its side on a regular level surface.

- Organize a pit under the machine and work while standing in this observation pit.

- Place the machine on a lift and raise it to the required height as required.

There is a fourth, hybrid version - the pit is dug shallow, and the lift has a small lifting height. But in the sum of the depth of the pit and the height of the lift, the machine is above the head of the repairman.

Hoists designed to work in the absence of a viewing hole are manual and mechanical - hydraulic and electric. Their common property is that they are relatively easy to move around the garage space on their own wheels.

Lifts, working in conjunction with a viewing pit, are more complex in design, but along the pit, and sometimes across, they also move without spending much effort.

Related article:

How to choose?

The main point that interests any car mechanic and service station owner when choosing a lifting mechanism is its carrying capacity. But there are also other important technical parameters.

The height of the working stroke - everything here directly depends on the place of installation of the mechanism.It is one thing if you place the jack in a viewing pit, and quite another when the equipment is part of a four-post or scissor lift.

Track width - you need to be well aware that, ideally, the parameters of the inspection pit and the traverse should be the same. In practice, this is not always possible, so you have to look for a suitable mechanism or carry out reconstruction of the pit. However, the track width in the overwhelming majority of models can vary, so the width of the stanchions becomes a slightly more significant parameter.

The mass of the pit hoist is not of particular fundamental importance, since such a jack is installed on skids, and the locksmith does not have to move it manually.

How to make a pit jack with your own hands, see below.

Dimensions of the inspection pit in the garage

You will not find strict recommendations for the size of the garage pit. They are mainly based on the parameters of the machine and their own growth. The dimensions of the garage pit are selected from the following considerations:

- The width should be large enough for you to work comfortably in it. At the same time, it is limited by the distance between the wheels of the car - each wheel must have room to maneuver. On average, the width of the inspection pit is from 80 cm and more.

- Its length depends on the length of the vehicle. Add 1 meter to the size of the car. This is enough for a comfortable work.

- The depth is calculated depending on your height: your height is + 10-15 cm. In this case, you don't have to worry about hitting your head. If you need to work for a long time with your hands up, you can knock down a special small stool and stand on it. You can raise the floor in the observation pit a little more using wooden ladders.

This is far from being dogma. Everyone does as he sees fit. To some, deep holes seem uncomfortable and they make them almost exactly in height, and sometimes even lower - 1.5 meters. If we take into account the clearance of the car, from the floor of the pit to the bottom of the car it will turn out to be about 1.7-1.8 meters. You can do that.

Another point in length. Sometimes it is not possible to make a long hole. Then it is made about half the length of the car, driving it forward or backward, depending on which part of the car needs inspection or repair.

Now about where to place the hole in the garage. Usually it is slightly shifted to one of the walls, leaving a wide side for installing equipment, storing spare parts, etc. In this case, from the edge of the pit to the near wall should be at least 1 meter.

That's all for this.

Just note that we were talking about the final dimensions of the pit. When marking the pit, it will be necessary to add thickness to the walls, and dig deeper to the height of the floor screed (if you do it)

Insulation of the inspection pit in the garage

If you spend a lot of time in the garage, then you will most likely have heating. To warm up faster and faster, it makes sense to insulate the pit. EPS (extruded polystyrene foam) is best suited for these purposes. It can withstand significant loads, is not afraid of dampness, does not rot, fungi and bacteria do not multiply on it.

EPS thickness for creating a tangible effect - from 50 mm. They lay it between the ground and the wall of the pit. Then the outside-inside pit will look like this:

- waterproofing film;

- EPPS;

- wall.

Expanded polystyrene can also be laid under the screed at the bottom of the inspection pit. A reinforcing mesh is usually laid on top of it, and then concrete is poured.