Operating tips

The cordless rotary hammer is very popular not only among experienced craftsmen, but also among the owners of the house, who sooner or later have to make repairs. This tool is easy to use and has many advantages. In order for it to serve the maximum period, and the work was safe, it is necessary to adhere to certain rules in operation.

- A new attachment can be fastened only when the device is turned off.

- After drilling in hard material, do not handle the drill with bare hands as it gets hot. In the event that it is necessary to urgently replace the nozzle, wrap your hand with a cloth soaked in water.

- All nozzles, regardless of their type, must be treated with a special lubricant before screwing in. The fixing of the drills is simplified by turning them on the chuck or pulling the locking end back.

- You can start work only when the device is checked. If malfunctions or a suspicious sound are detected, it must be turned off immediately and diagnosed.

- When drilling a particular surface, a certain mode and number of revolutions should be selected.

- In the event that the model is not equipped with a dust collector, then after work, the perforator must be thoroughly cleaned of dust.

- Before starting work, the foreman should take care of personal safety and wear protective equipment such as gloves, heavy overalls, ear plugs and goggles. Long hair should be hidden under a hat; in addition, there should be no jewelry on the hands. They can get caught in the rotating attachment and cause injury.

- The attachments must be used strictly according to the instructions supplied by the manufacturer.

In the next video, you will find a comparison of budget cordless rock drills.

Let’s block ads! (Why?)

Types of cordless rotary hammers

There are many modifications of cordless rotary hammers on sale, differing in shape, principle of action of the impact mechanism, type of attachment attachment and other parameters.

The hammer drill belongs to the category of hand tools, which the worker has to hold in his hands, so it is important to choose the most convenient model

Varieties of the shape of perforators

All cordless rotary hammers can be shaped like:

- straight, with horizontal engine layout;

- L-shaped (L-shaped), with a vertical engine.

In straight rock drills, the motor and the percussion mechanism are located horizontally.

Rotary hammer with horizontal engine.

Vertical rock drills are bulkier, but more productive and last longer. This arrangement allowed the designers to reduce the length of the device, while increasing the engine cooling area.

Rotary hammer with a vertical engine.

For domestic conditions, it is recommended to buy a compact and maneuverable straight-shaped tool, and for professional purposes - a productive L-shaped one.

The difference between perforators on the principle of operation of the percussion mechanism

There are two types of hammer implementation in rock drills:

- mechanical;

- pneumatic.

The mechanical percussion system is based on an eccentric that actuates the spring of the lever, which in turn moves the percussion device. Then the impact device acts on the hammer and transfers the impact to the perforator rig. Thereafter, the recoil energy of the striking device is absorbed by the spring and is amplified as the striking device moves forward.All rotary hammers with a horizontal motor arrangement are sold with this type of percussion device.

Watch the principle of the mechanical shock system in the video:

The pneumatic percussion system is based on the work of a piston, which, while moving in the cylinder, compresses the air cushion and thereby moves another, free piston, which is in front of it. As a result, the free piston moves forward and acts on the firing pin. After that, the working piston begins to move backward, and the free piston, having pushed off from the striker, also begins to move backward.

At this time, the working piston begins to move forward, but the free piston still moves towards the working piston, squeezing the air cushion between them. At a certain moment, the working piston reaches the upper limit and the free piston changes its direction of movement. In this case, the speed of the free piston increases many times due to the effect of high pressure.

Thus, an impact force is created, which is transmitted to the tooling of the rock drill. The operation of this system is independent of the pressure that the user applies to the rock drill. That is why manufacturers of rotary hammers do not recommend exerting excessive impact on the tool, as this can lead to damage to both the equipment and the entire device.

Watch the principle of the pneumatic shock system in the video:

The difference between rotary hammers by the type of attachment attachment

Cordless rotary hammers can be used with one of two attachment systems - SDS PLUS or SDS MAX.

SDS-plus system.

The most common mounting option is used in compact household rotary hammers. This fastening system is designed for fixing drills capable of making holes with a diameter of up to 32 mm.

SDS Plus tool shank.

SDS-max system.

Professional models of cordless rotary hammers are equipped with this mounting system. The SDS MAX attachment system has a larger diameter and drills allow you to drill holes up to 52 mm.

Tool shank SDS Max.

Views

Cordless rock drills differ in their functionality.

Cordless rock drills differ in their functionality.

There are three categories:

- Household. Perforators of this type have a "starting" set of technical characteristics. They are used for home renovations or for light industrial work. Such devices are lightweight and inexpensive (there are exceptions). Household punchers are easy to use and do not have complex settings that a beginner will get confused in;

- Semi-professional. Devices from this group stand on the border between "home" rotary hammers and punchers for craftsmen. They offer more options and are suitable for people who already have experience with this tool;

- Professional. Such models are designed for specialized repair and construction work. Often, professional rock drills are heavy, but this factor is not decisive. The devices are made of quality materials and equipped with powerful batteries for long-term operation.

Household punchers are suitable for getting to know this device. A professional unit is undesirable for a beginner to acquire, since he can easily break it. Do not equate a household line with low quality. Among budget punchers there are decent and reliable models that are used even by masters of their craft.

Expert opinion

Torsunov Pavel Maksimovich

The weight of the hammer drill depends on its power and materials of manufacture. The stores offer tools from 1 to 10 kilograms.

Famous manufacturers and models

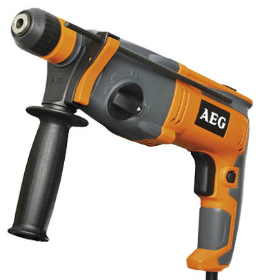

Today, cordless rock drills are represented by various brands. Premium products are produced by manufacturers such as AEG, Hilti, Bosch, Makita and DeWALT.Mid-range tools are affordable and are great for household work. They are produced by both domestic manufacturers (Interskol) and foreign (Hammer, Metabo). As for the budget options, these are punchers, which are produced under such brands as Soyuz, Zubr, Skill, Whirlwind and Bork.

Professional models have both pros and cons. For example, Hilti and AEG rotary hammers are equipped with high-quality parts and additional features. Their independent power supply lasts an average of three hours of operation, the battery charges quickly, in just 30 minutes. The disadvantage of the tools is their large weight and noise during operation. Apart from the fact that the hands get too tired from the weight of the device, these models have no other disadvantages.

Rotary hammers Makita, Hitachi and Bosch have proven themselves with high performance. These machines are equipped with three operating modes and are designed for chiseling, conventional drilling, and perforation. They are not overly powerful, but they do come with additional features that allow for adjustment and thus simplify work. So, in these tools there is a release clutch and an inverse run. In addition, the product range includes an SDS cartridge that allows quick and safe bit changes.

As for the Hammer, DeWALT and Metabo models, they can be operated in different modes. This is due to the unique characteristics and wide functionality of the tools. In addition to the powerful motor, the devices are equipped with a reverse stroke, LED illumination and a convenient nozzle change system. The motor of the rock drills is brushless, so their service life is long. In these models, manufacturers have also improved the control system, adding a two-position toggle switch to the tool.

How to choose

Before purchasing a cordless hammer drill, it is important to take into account the conditions of its operation, as well as the presence of LED backlighting, a dust extraction system and the possibility of setting the operating mode. Since the construction market is represented by a chic assortment of these devices, it is difficult to make the right choice in favor of one type or another.

Therefore, when making such an important purchase, you need to pay attention to the following instrument parameters:

- size and weight;

- battery capacity;

- engine power;

- type of striking mechanism.

Battery-powered perforators are most often designed for work in summer cottages and in apartments, therefore they are equipped with 220-volt motors. There are also devices on sale with a motor power from 550 to 2500 W, they have a fairly high level of performance and allow you to drill large holes. Therefore, it is necessary to determine in advance what kind of load the tool will be subjected to. If you plan to make small holes with a diameter of up to 14 mm, then you can give preference to the simplest models with a power of up to 500 watts. To make through holes 600 mm thick, you need to purchase a device with an engine power of 1000 watts.

The speed of rotation of the nozzles also plays a huge role; in most models of cordless rock drills, it ranges from 200 to 2300 rpm. In household appliances, it is usually standard and is set by the manufacturer. In professional devices, the rotation speed is adjusted automatically, depending on the complexity of the work. In addition, the performance of a hammer drill is also determined by the energy and frequency of impacts. For everyday tasks, a device with an impact force of 1.2 to 3 J.

When choosing a device, special attention should be paid to the location of the engine. It can be located in the vertical and horizontal plane of the case

The first type is usually typical for powerful models, the second is well suited for households, since it is small and much more convenient to work with.

Battery-powered rock drills have different operating modes, so before purchasing it is important to clarify which ones are present in a particular model. For household work, it is necessary to give preference to a tool with such modes as drilling, hammer drilling and chiselling

The design of the device includes a cartridge on which the attachments are attached. Therefore, if you have to additionally purchase crowns, chisels and drills, you will need to know the type of chuck. Products with minimum and standard power usually contain SDS and SDS-plus chucks... If you plan to work with a drill, then it is necessary to choose SDS-max cartridges. Their tail does not exceed 18 mm in diameter.

In addition, when purchasing a tool, you need to inquire about its additional functions. They will determine not only the increase in productivity, but also the safety of operation. For domestic use, it is recommended to choose models in which the following options are present.

- Reverse. It allows you to quickly remove the stuck drill from the holes.

- Protective sleeve. Automatically locks the rotation of the nozzle when it is jammed.

- Smooth start. Reduces potential network hops.

- Speed controller. It independently changes the rotation speed depending on the density and type of the processed surface.

- Ruler-stop. Allows you to measure the depth of drilled holes.

- Vibration protection. Makes work comfortable as it protects hands from vibrations.

- Case (box) for easy carrying of the tool. It will be possible to store not only the rotary hammer itself, but also lubricants, brushes for the engine, replaceable nozzles and cartridges.

- Dust removal system. Since dust is generated during construction work, many manufacturers complete the battery device with a special bag in which concrete chips and dust collect during drilling. After drilling is complete, the dust container is cleaned.

Criterias of choice

In the process of studying battery models, you need to focus on the battery!

When choosing rotary hammers, the buyer is faced with a lot of characteristics that are easier to get confused than to understand.

It is important to know which properties to look for in order to get the information you need.

The following parameters play a role:

- Material. Lithium-ion batteries are the most common option. They are suitable for continuous and intensive use. Due to the lack of memory effect, they are able to charge until they are completely discharged. Nickel-cadmium batteries are used when working in cold conditions (withstand up to -20 degrees);

- Voltage. The puncher voltage range is between 10 V and 36 V. This parameter determines the duration of the device operation. The higher the battery voltage, the heavier the cell;

- Capacity. The capacity affects the operating time of the device during one charge. There are rotary hammers on the market with a battery capacity of 1.3 to 5 A * h. With the increase in capacity, the price of the tool rises. 5 A * h is commonly found on professional instruments.

Lithium-ion batteries are labeled Li-lon, and nickel-cadmium batteries are Ni-Cd.

Which hammer drill do you use?

Electric Rechargeable

Other criteria that characterize a rock drill include:

- Impact energy / force. The parameter refers to the energy that falls on each hit of the rig. The increase in energy opens up more tasks for the owner of the tool that he can perform. For work with brick and concrete surfaces, perforators with an energy of 1.5 to 3 kJ are suitable;

- Chuck rotation speed. The number indicates the revolutions that the chuck makes at idle. This indicator can be different - from 200 to 2500 rpm. Models that come up to the upper limit compete with the drill.