Review of popular models

Makita offers several varieties of electric screwdrivers. They differ in appearance, functionality and technical parameters. Consider the most popular models sold by the manufacturer.

Makita TD022DSE. A device designed to work with materials such as: plastic, thin metal, various types of wood. Supports two working modes: shock and bumpless. This model is reversible. It can not only twist, but also unscrew the fasteners. The device is equipped with a backlight, due to which it is possible to work in limited lighting conditions. The device is powered by a Li-lon rechargeable battery. The set with a screwdriver comes with 2 power sources, a charger, a case for its storage and careful transportation.

The company offers an extensive range of screwdrivers that any home craftsman can get confused about. To make the right purchase and not regret your choice, you need to familiarize yourself with the important characteristics of the equipment in advance. The speed, quality and convenience of work will depend on them.

How to choose?

The correct choice of the required tool is the key to a high-quality and successful implementation of the task. The main parameters that affect the choice of the tool are the number of revolutions, the torque, the type and capacity of the battery, as well as the number and types of attachments.

For home use, experts recommend paying attention to tools that have the following parameters:

- level of torques - 5 Nm;

- the number of revolutions - 400 per minute;

- battery charging time should not exceed 2 hours;

- the average voltage level should be 5 V;

- the presence of a spindle lock, which will allow you to use the tool in manual mode and safely change tips;

- the presence of a reverse, which rotates the device in different directions;

- number of batteries - two;

- light indication;

- the presence of rubber elements on the handle;

- availability of auxiliary components.

For work in closed rooms, you must choose a lithium-ion battery, for conditions with unstable temperatures, a nickel-cadmium device is suitable, and a nickel-hydride device is considered universal. The most popular are models that have a speed control sensor, which makes it possible to change it depending on the type of working surface. The powerful battery will allow you to carry out work without recharging for a long period. The electric screwdriver comes with a case with bits. The number of attachments in a set depends on the characteristics of each model and country of manufacture. A standard set of bits is sufficient for the most common types of construction and renovation work. In a set of professional screwdrivers, you can see caps and drills.

When buying a tool, professional builders advise you to know and apply the following rules:

- low price is a sign of a low-quality product with a short service life;

- a product of a well-known brand always has high quality and reliability;

- lithium ion batteries significantly extend the life of the equipment;

- the presence of a special organizer will give the device greater functionality, compactness and simplify the process of its storage;

- the presence of additional functions will significantly expand the scope of work and increase the functional value of the device.

Popular models

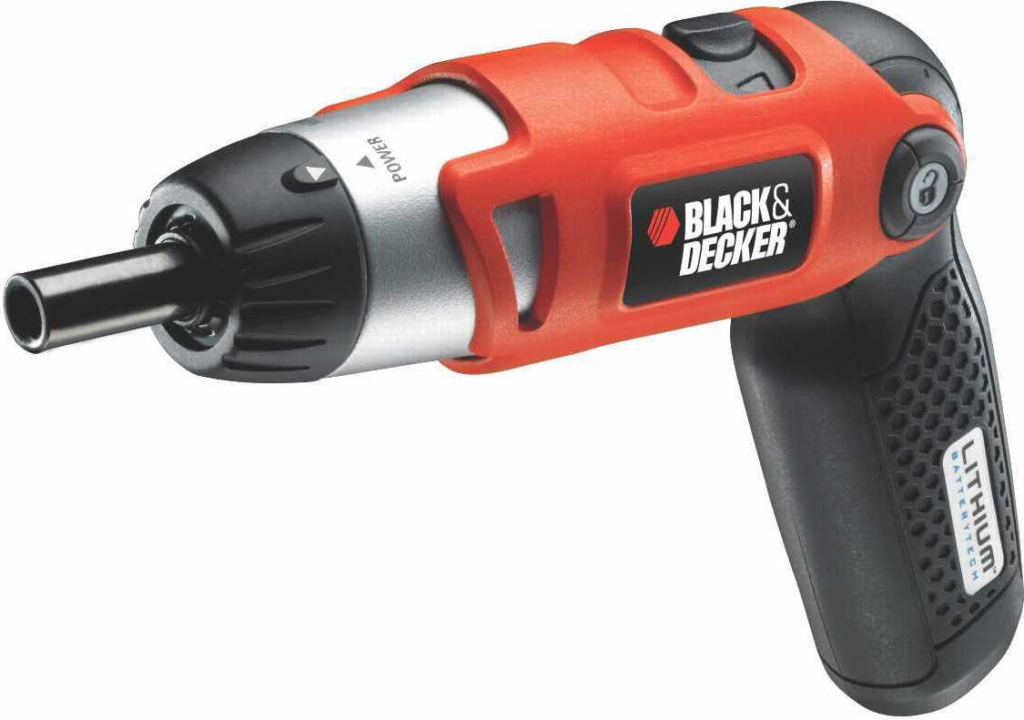

Among the best manufacturers of electric screwdrivers and models, the following brands can be distinguished.

Makita 6723 DW.It is considered one of the best in terms of value for money. The set includes 80 attachments. Main characteristics: torque 4.5 N * m (220 rpm), battery capacity - 1.5 Ah (battery recharge time 5 hours).

Bosch PSR Select. More expensive option. Supplied with 12 attachments with a secure attachment system. Main characteristics: 4.5 N * m (210 rpm), battery capacity - 1.5 Ah.

Sparky Professional GR 3,6Li. Compact and lightweight version weighing 300 grams. It has a torque of 4.4 N * m.

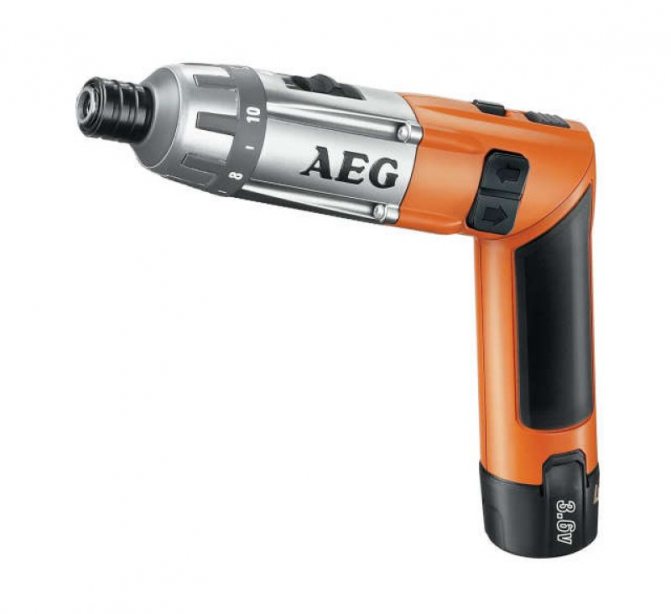

AEG SE 3.6 Li. It has the largest force indicator of the options presented - 6.5 N * m. Large battery capacity - 1.5 Ah. The number of revolutions can be adjusted, the maximum rate is 600 rpm. However, you will have to pay twice as much for high performance.

Interskol OA 4.8. The most budgetary option. Main characteristics: torque 3.4N * m (180 rpm), battery capacity 1.1Ah (5 hours recharging). From the advantages: as you can see in the photo, the electric screwdriver has a comfortable adjustable handle and can be a good household option.

Usage Tips

In the process of using a screwdriver by novice craftsmen, a large number of questions and difficult nuances arise. To solve these problems, professional advice from experienced builders will help. With a minimum amount of knowledge, you can fix all breakdowns yourself. The disassembly process will not cause difficulties even for inexperienced craftsmen. To remove the internal parts, simply disassemble the housing and remember to disconnect the motor from the gearbox.

If the screwdriver does not turn on, you need to perform the following manipulations:

- check the power wire;

- check the charge level;

- check the integrity of the wires going from the charger to the button;

- press the power button;

- check the wire from the motor to the button.

For diagnostics, you need to purchase a multimeter. Damaged and deformed parts must be replaced. In the absence of rotating movements, the diagnosis consists of the following measures:

- checking all contacts of the button;

- checking the engine disconnected from the gearbox;

- checking the shaft, buttons and brushes.

To replace the battery with a lithium-ion, you need to purchase the following components:

- new battery;

- charge microcontroller;

- soldering iron;

- special glue;

- wires;

- drill;

- files.

The capacity of the new device must fully match the capacity of the old battery.

It is worth paying attention to the following stages of work:

- disassembly of the device;

- disconnecting the old battery;

- installation of a new battery with a microcontroller;

- drilling a hole for the wire;

- installation of wires to the board, socket and battery;

- fixing parts with special glue;

- final assembly of the device.

If you need to change the charger to power from the mains, you must purchase a power adapter that matches the motor voltage and a socket. The installation process consists of the following steps:

- parsing the case;

- soldering wires to battery contacts;

- installation of a socket with wires;

- drilling a hole for the plug in the back cover;

- collecting the device.

To simplify the implementation of construction and repair work, modern manufacturers offer craftsmen a new type of device - cordless screwdrivers. This tool is a universal device with which you can quickly and efficiently perform a large amount of work. Before going to a specialized store, be sure to carefully study all the features of this product and consult with experienced craftsmen. The quality of the work performed depends on the reliability and versatility of the selected device. Novice craftsmen need to know the main rule - a quality product cannot have a low price.

An overview of the BOSCH IXO V cordless screwdriver is presented in the video below.

Which cordless screwdriver is better to buy?

The cordless screwdriver allows high-speed installation or repair work associated with the use of a variety of fasteners. Battery power is usually enough for dozens and sometimes hundreds of simple operations.

Let's consider the main points that you should pay attention to when buying such a tool.

What should be the maximum torque

Driving a medium-sized screw into dense wood requires a force of about 4-4.5 Nm. This is what the lower torque bar should be for most electric universal screwdrivers. Modern models are often equipped with an adjusting mechanism that allows you to adjust the torque for each type of fastener.

What you need to know about the number of revolutions

Working with self-tapping screws and screws does not require a high rotation speed. Most of these operations are performed at a frequency of 200-500 rpm. Sometimes it is necessary to equip a screwdriver with a drilling function. Only in this case she needs a faster speed limit.

How to determine the type and capacity of batteries

The rechargeable battery is the most important element of electric screwdrivers. It should be compact, powerful and capable of retaining the accumulated charge for a long time. In modern household appliances, two types of batteries are most widely used: Ni-Cd and Li-Ion.

Ni-Cd batteries

Nickel-cadmium batteries withstand a large number of charge-discharge cycles, work stably even at sub-zero temperatures, can be stored for a long time in a discharged state and are quite inexpensive. Their main disadvantages are the tendency to gradual self-discharge and the need for a complete discharge before the next charge due to the pronounced "memory effect".

Li-Ion batteries

Lithium-ion batteries with the same capacity have the most compact size and minimum weight. They can be charged at any convenient time without fear of reducing the charging range. They keep the accumulated energy stably. The disadvantages of such devices include a decrease in performance at low temperatures and a higher cost.

What does the battery voltage affect?

The operating voltage of a battery is directly related to its capacity. The lightest tool is equipped with 2.4 batteries; 3.6; 4 or 4.8 volts. The most powerful screwdrivers require at least 7.2 volts.

What does the battery capacity affect?

The battery capacity corresponds to the maximum amount of stored energy and the amount of work performed in one cycle. For most screwdrivers, this figure lies in the range from 0.6 to 1.5 A * h. A battery with a larger capacity is able to provide the electric motor with energy for a longer time without reducing the voltage, and, accordingly, without reducing the power. It must be remembered that as the capacity increases, it takes longer to fully charge. This problem is usually solved by using a pair of replaceable batteries.

About the brand

Interskol is one of the world's largest manufacturers of power tools. Its products have been popular in Russia for the past 15 years. During this time, the company has gained invaluable experience in the development and production of power tools.

The company's success is based on the study of consumer needs. Moreover, before getting to the user, new models of power tools are tested in our own engineering center and pilot production of the company. Despite the high quality, Interskol maintains low prices for its products, which is good news.

What is the difference between an electric screwdriver and a screwdriver

The electric screwdriver is the simplest electric tool.In fact, it is an ordinary screwdriver (it performs only the functions of unscrewing and twisting), only equipped with an electric motor. People who rarely encounter repair do not know the fundamental differences between a screwdriver and an electric screwdriver, but there are a lot of them, and often both of these devices are called the same term, but this is wrong.

This is important: screwdrivers are produced only in the form of a classic pistol, and an electric screwdriver has several body shape options.

An important difference between an electric screwdriver and a screwdriver is its small size and weight. This makes it easy to carry, and if necessary, just put the necessary thing in the pocket of the jacket.

The main differences between these power tools

- The screwdriver does not have a chuck, the presence of which in the screwdriver allows it to be used as a drill (the chuck is unclenched and a drill or an adapter for a nut head is inserted into it).

- Since the screwdriver is intended not only for loosening screws, but also for drilling, it requires a higher power of the electric motor. In addition, the screwdriver motor has a low torque and low speed, which will allow you to tighten a small number of long screws. This will quickly drain the batteries.

- The screwdriver does not have replaceable batteries. When the charge is over, you will have to stop working and wait for the tool to recharge.

- Almost all modern models of screwdrivers have two batteries independent from each other and easily detachable from the tool. They are easy to charge and when one is discharged, they can be replaced with another.

It will be advisable to purchase an electric screwdriver when there is a rare need to tighten a small number of self-tapping screws or screws. The screw gun is more often purchased by professionals who often perform medium to large construction work.

One of the main external differences between a screwdriver and a screwdriver is that it is produced with different types of housing:

- Direct - allows you to easily access any location.

- The L-shaped one has a large comfortable handle, and due to its small size and ergonomics, it makes the process of screwing screws easier.

- The classic pistol reduces the load on the human hand when working.

This is important: the main similarity between a screwdriver and a screwdriver is that they use rechargeable batteries as a battery, which are charged from a regular household 220 volt network.

When buying an electric screwdriver in a store, you need to understand that it can only be used to tighten or unscrew screws, screws or screws. It cannot be used to drill holes in concrete or wooden walls - this will lead to a quick failure of the screwdriver. For such purposes, a drill or screwdriver should be used.

Power tool characteristics

Torque. This indicator indicates the maximum effort that the device is capable of delivering. Choose a screwdriver with an indicator of at least 4.5-5 N * m, otherwise there is a risk of being disappointed in the purchase.

Battery capacity. The indicator is measured in Ah. The higher this indicator, the longer the tool will work.

Lever. For maximum comfort, the screwdriver should be selected individually. It is better to buy a screwdriver with a "fitting" - before buying, try how comfortable it is in your hand.

Spindle lock. This option allows you to tighten a screw or bolt when the battery is dead.

Selection rules

Before choosing a tool, it is worth deciding what kind of work it will be intended for. For solving professional tasks, electric screwdrivers are practically not suitable. For these purposes, it is best to take a closer look at screwdrivers with a reverse function.

If you still need a cordless screwdriver, it is important to pay attention to some parameters.

- Power supply type.Makita manufactures rechargeable NiCad and Li-ion screwdrivers. The first ones are distinguished by their affordable cost, the ability to work at various temperature conditions. Their main disadvantage is the memory effect of the battery, because of which, if the battery is incorrectly charged, the battery will quickly lose its capacity and become unusable. Most Japanese-made models are equipped with lithium-ion batteries. Such batteries are not prone to self-discharge. They have greater capacity and durability, but, unlike lithium-cadmium, they are not as budgetary.

- Battery voltage. The performance of the tool depends on this indicator. The higher the voltage, the more powerful and weighty the equipment will be.

- Battery capacity. The indicator affects the duration of the screwdriver's operation without recharging. The lower the capacity, the less time the tool will run.

- Maximum number of revolutions. The higher the value, the faster the operator can screw in or out the fastener.

- Additional functions. These include the spindle lock (when activated, it is possible to tighten the fasteners manually with the required force), reverse, LED backlight, operating modes.

- The ergonomics of the handle are also important. Before buying, you need to hold the tool in your hand and decide whether it is convenient to use or not.

How to make an electric screwdriver with your own hands

If you do not have the opportunity to buy an electric screwdriver, then you can make it yourself and inexpensively.

Manufacturing from scratch

You will need: a cheap glue gun, a mini switch, a power connector with a piece of wire, a 12 V power adapter, a 9–12 V motor with a gear, a bit holder, hot melt glue, electrical tape. Adjust the bit holder so that its bore fits over the engine gear and does not wobble. The adapter plug must match the connector.

Photo gallery: parts for making an electric screwdriver

From the tools, prepare pliers, a stationery knife, a screwdriver and a soldering iron.

-

Take a cheap glue gun and take apart the body. Extract all content from it.

-

Try on the engine.

-

Use a utility knife to cut holes for it. Do not touch the attachment points of the halves of the case.

-

Cut off the part of the housing where the bit holder will be attached to the motor shaft.

-

Install a connector with a wire into the hole in the gun body, into which the sticks with glue were fed. Fix it to one half of the body with glue.

-

In place of the old button of the glue gun, place the mini switch on the hot melt glue. Wait for it to cool down. Then screw it on with the fasteners.

- Take the motor with gear. Lubricate it generously with hot melt glue. Place the bit holder on the gear.

-

A simple daisy chain circuit is required to connect the motor.

-

Solder one wire of the connector to the button, and the other to the motor. Connect the free contacts of the motor and the button to each other. Insulate the soldering points well.

-

Assemble the gun body.

Video: how to make an electric screwdriver yourself

In the holder, you can insert not only bits, but also adapters with holders of other shapes.

Bit holder with adapter

You can do the same in another building. For example, pick up a plastic pipe with an inner diameter for the engine. To regulate the speed and reverse, you can buy a button with an integrated microcircuit. Then make a hole in the pistol grip for it. The connection diagram is the same.

Soft start and reverse button

How to convert a battery to a lithium-ion

To work, you will need a lithium-ion battery, TP4056 charge microcontroller, wiring, soldering iron, hot melt glue, drill, needle files. Select the capacity of the lithium-ion battery in accordance with the total capacity of the old batteries.

-

Disassemble the screwdriver body and remove the old batteries.

-

Place a new battery with a microcontroller. The microcontroller has a USB connector.If you will only use it, then use a drill to make a hole for it in the screwdriver body. And if you want to connect a regular jack, then you also need a hole for it.

-

Solder the wires to the board. + and - go to the jack, OUT +/- to the engine, B +/- to the battery.

-

Put everything in the body. Fill all parts with hot melt glue. Wait until dry. Cut off the excess.

-

Assemble the case.

How to change battery power to mains power

When running on battery power, the screwdriver quickly loses its charge. It can be redesigned so that it works on the network. You will need a power adapter with the same voltage as the motor or slightly more. And a nest for it.

- Disassemble the case.

-

Take two wires and solder them to the battery contacts.

-

Take the jack and connect it to these wires.

-

Drill a hole in the back cover for the adapter plug. Place the nest on epoxy or hot glue.

- Collect the screwdriver.

Possible malfunctions and their elimination

The cordless screwdriver is easy to disassemble. Unscrew the case and remove all components from the grooves. The motor is easily disconnected from the gearbox.

The screwdriver does not turn on

To find a malfunction, you need to check the entire electrical circuit in the following order:

- Power cord, if available.

- Battery charge level.

- The wires from the battery to the button.

- Power button.

- Wires from the button to the engine.

Use a multimeter for diagnosis. Check the wires and the button in the ringing mode, and the battery in the constant voltage measurement mode. Charge the battery beforehand. If the capacity is less than the stated, check the voltage of each cell separately. Replace defective ones.

Does not twist

It is necessary to diagnose the button and the engine.

- Check all button contacts with a multimeter. If it is faulty, replace it.

- Go on to check the engine. To do this, disconnect it from the gearbox.

- Click on the button. If the motor does not turn, turn the shaft several times. The brushes could oxidize. Press the button again. If the problem persists, replace the engine.

Rustles and crunches

Often, it is enough to change the lubricant of the gearbox to correct the malfunction. But it doesn't always help if there are faulty parts.

- Disassemble the instrument.

- Disconnect the motor from the gearbox.

-

Remove all gears and satellites. Put everything in order.

- Clean out old grease. Inspect all the elements carefully. The satellite could have a broken tooth. This place is pressed onto a large gear. From here comes the crunch. Replace defective parts with new ones.

- Clean the gearbox housing too. There may be debris in it.

- Apply new grease.

Video: disassembly and lubrication of the gearbox

Due to its low torque and small size, the cordless screwdriver is used for its intended purpose. It is easy to use and easy to repair. If you wish, you can make a screwdriver with your own hands.

Specifications

The tool is characterized by parameters that you need to know about:

- battery voltage. This characteristic is equivalent to the power of network devices. With increasing voltage, the device has a greater efficiency. The maximum value is reached with a fully charged battery. Decreases over time until the screwdriver can still be turned on. During storage, the voltage also decreases. Therefore, after a long period of non-use of the instrument, it must be fully charged;

- battery type. Three types of batteries are used in screwdrivers:

- nickel-cadmium Ni-Cd. Cheap, resistant to different temperatures. Due to their low resistance, they have high charge and discharge currents. They can be charged about 1000 times. But they are toxic due to cadmium, have a memory effect and a small capacity;

- nickel metal hydride Ni-MH. The memory effect is less than that of nickel-cadmium. Due to their higher density, their capacity is 25–35% larger than previous ones with the same dimensions.Not harmful to the environment. But they have less charge. It is undesirable to discharge them to the end;

- lithium-ion Li-Ion. They have the highest capacity. Due to this, they are reduced in size. They have no memory effect at all. Discharges very slowly during storage. But they also have their drawbacks. Higher cost, shorter service life and poorly tolerate high and low temperatures;

- Battery capacity. The operating time of the screwdriver depends on it. At high speeds under load, energy is consumed faster, so the operating time also depends on the intensity. Lithium-ion batteries may not be fully recharged for fast charging;

- battery device. There are two types of battery for a cordless screwdriver:

- removable. Installed in powerful devices, charges quickly. Allows you to work continuously if there is a replaceable battery;

- non-removable. located in the housing. Such a tool is light in weight, size and cost. It is convenient to use it. But the capacity is also small, so you have to charge it often. And this leads to interruptions in work. After all, the battery cannot be removed from the case, and another cannot be put in its place;

- charge time. Depends on the type of battery and ranges from 1 to 10 hours;

- maximum torque. It determines the force of rotation. When interacting with the material, the moment decreases. Using the tool at high loads leads to a rapid loss of battery power and wear of the screwdriver elements;

- maximum number of revolutions. This is the rotation of the shaft. With a high-speed screwdriver, self-tapping screws can be easily screwed in.