main parameters

- the weight of the device;

- shank rotation speed;

- the number of work equipment included.

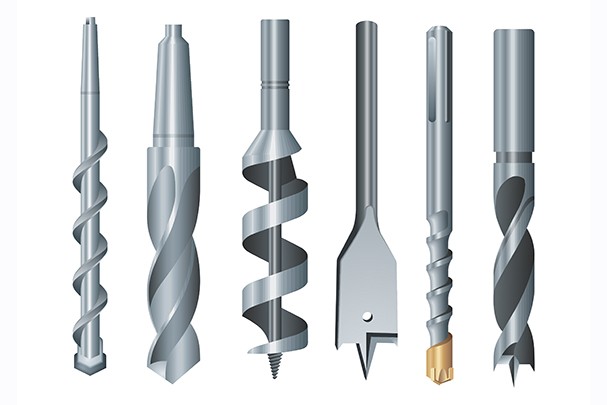

The variety of attachments affects the functionality of the instrument and the complexity of operations. The work can be used:

- collets, cam-type mechanical clamps, couplings;

- decorative carving attachments;

- edging, grinding wheels;

- drill;

- bora.

Shank rotation speed

Advice! Check the availability of the speed control when purchasing. High-quality products are equipped with this function, and budget models are equipped with a device that reduces the voltage of the electric motor. They are not suitable for high-precision tasks.

Rigging

There are a large number of rigs:

- made of aluminum oxide or alloy steel - they are spherical, cylindrical, rounded, they allow you to process ferrous and non-ferrous metal;

- diamond-coated - used for cutting marble, glass, tiles;

- silicon carbide - for processing stone, plastics, ceramics;

- made of rubber with the addition of abrasive grit - for grinding various surfaces;

- felt cones - allow you to polish various materials using a special paste, which is purchased separately or included in the kit;

- made of fine sandpaper - used for sanding wood, steel products, etc.

Supporting components

- corner equipment - allows you to work in inaccessible places, is able to make a mini-drill a multifunctional angle grinder;

- flexible shaft with vise or bracket - increases comfort during use;

- stand - makes a drilling machine out of a mini-drill.

Price

Important! An engraver from a well-known brand cannot be cheap. Otherwise, it is most likely a fake. Prices for mini drills vary widely.

The simplest model will cost 20 US dollars, and a multi-functional pro-class tool - 1200 and more. For beginners, an average cost tool is suitable - $ 30-120

Prices for mini drills vary widely. The simplest model will cost 20 US dollars, and a multi-functional pro-class tool - 1200 and more. For beginners, an average cost tool is suitable - $ 30–120.

How to choose?

When buying a drill, you should pay attention not only to additional functions, but also to the type of battery, the number of revolutions and the charging time. It is good when an indication is provided by the manufacturer in the design of the instrument, which allows you to estimate the amount of remaining energy.

The number of speeds and high torque are especially important when choosing a drill for professional use when faced with concrete and masonry work.

As far as the chuck is concerned, of course, the keyless chuck helps to save time spent changing the tooling. True, such equipment costs more, but this price fully justifies itself over time.

Some models are equipped with a special hook, thanks to which you can hang the tool on the belt and free your hands for a while

Whether or not this is taken into account is up to the buyer

As for the motor, it is best to purchase a unit with a brushless motor, which is designed in such a way as to reduce friction and resistance. Its advantage is higher speed and increased power.