Trailers and adapters

The adapter and trailer are types of attachments for a walk-behind tractor, designed to increase the carrying capacity of equipment and move various loads. Next, we will take a closer look at which trailers and adapters can be used with the Oka walk-behind tractor.

Specifications

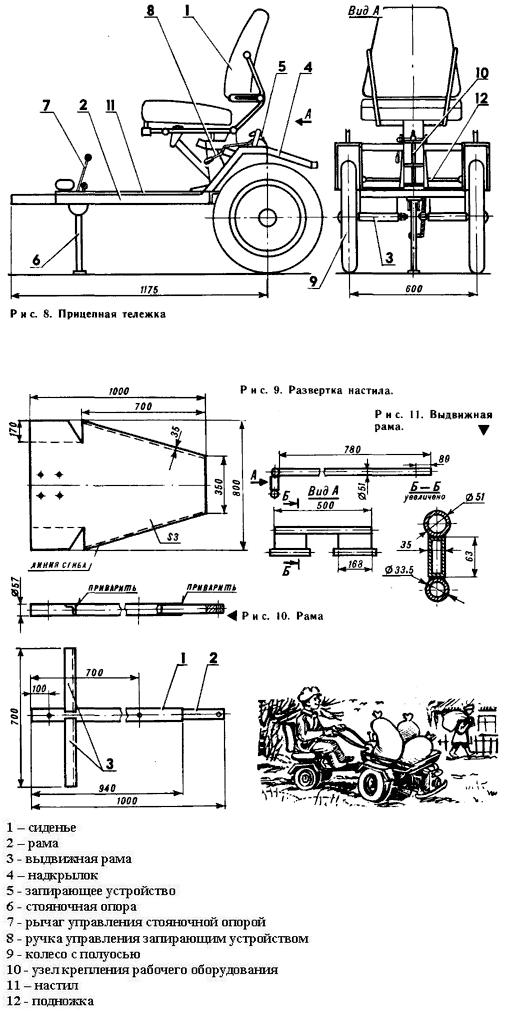

The adapter is a seat and two wheels design. The device is attached to the unit with a two-piece hitch. One is needed to connect directly to the mini-tractor, the second is to adjust the distance between any attachments and the walk-behind tractor. The adapter can be operated by foot or hand.

A trailer is a design that looks like an adapter, but with rear-wheel drive. A small box can be placed on the back of the adapter or trailer, directly behind the seat, into which the operator can place various loads for transportation, including the crop harvested from the site.

Factory adapter AMPK-500

in the line of factory attachments for Oka, he developed a universal all-wheel drive adapter AMPK-500. It can be used with heavy walk-behind tractors, including the Oka.

This model is equipped with rear wheel drive. The body can be easily removed. Thanks to the use of such a device, the operator can transport goods weighing up to 500 kg.

The adapter from Kadvi can be used without a body - in combination with a potato planter, plow, hiller or harrow.

Of course, the use of adapters and trailers provides certain advantages, for example:

- the ability to sit while performing agrotechnical operations;

- the swap body is easily detached;

- the trailing mechanism allows you to attach any additional equipment;

- increase in work productivity at least twice;

- giving the car more weight.

| dimensions | |

| Length | 2550 mm |

| Height with wheels | 1350 mm |

| Width | 1,070 mm |

Included with the adapter, the buyer also receives a packing list, an instruction manual and two cotter pins.

EMK riding module

For those interested in a smaller-scale adapter, the EMK Riding Module can be a convenient option. HE is suitable for motor-blocks "Oka" and "Ugra". This module can be used to mount a hiller, mower or snow cleaner. The unit is also equipped with a seat, so the operator can perform more manipulations on the ground with less effort.

Motor-block cargo trailer PMG 300-1

A lighter version from "Kadvi", which replaces the AMPK500 adapter described above, is the PMG 300-1 motoblock cargo trailer. The device can lift loads with a total weight of up to 350 kg, body dimensions are 1200x1600x340 mm.

| General characteristics | |

| Body size: | 1200 mm / 920 mm / 1050 mm. |

| Weight: | 95 kg. |

| Dimensions: | 2800 mm / 1300 mm / 1050 mm. |

| Transport track: | 1178 mm. |

| Carrying capacity: | 250-300 kg. |

Analogs

For heavy motoblocks, which include "Oka", you can use adapters and trailers not only produced by JSC "Kadvi", but also other Russian manufacturers, for example, located in the city of Gagarin; LLC "Vulkan", Kanash; Vsevolzhsky RMZ CJSC, as well as Mirotech Ural LLC, Chuvashpiller Plant LLC and others.

There are currently quite a few manufacturers of agricultural machinery, therefore, high-quality factory attachments can be combined with the Oka walk-behind tractor.

It is only important to make sure that the suitable parameters of the coupling match the parameters of the walk-behind tractor.

Motoblock OKA with adapter PNO-1:

How to assemble

Either the front or rear version should be done, it all depends on the model of the walk-behind tractor. If there is no difference, choose the second type, since it is much easier to manufacture. Follow the simple instructions, it is advisable to see the photos of finished products in advance, clearly understand how the result of the work should look like.

Rear-mounted design

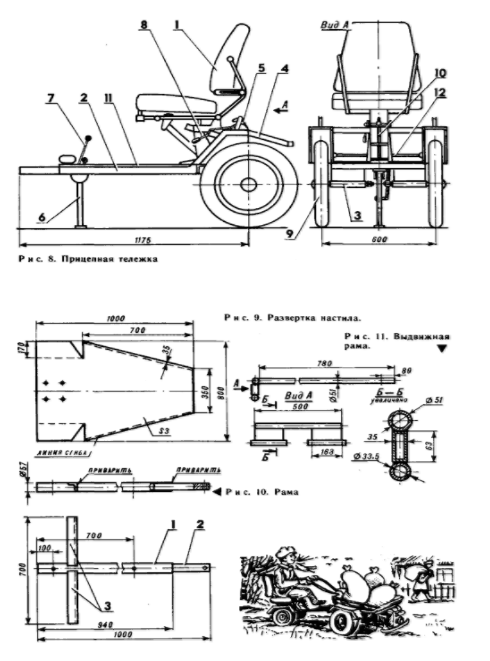

It is called a trolley because it is placed on a standard hitch.Before starting work, make a drawing with all dimensions, or find a ready-made one, there are many options, there is plenty to choose from. It's good to figure it out, if necessary, make adjustments in order to accurately fit the product to your technique. To carry out the work like this:

Cut the pipe or corner, clean the ends to be welded. Fold the pieces on a flat surface, check the geometry with a square and measure the diagonals. Weld the main part of the frame. First grab, then double-check the position again, only after that make continuous seams along the entire length of the joints. Grind off the beads of metal with a grinder. Weld the hitch to the shank, select the position exactly, remove all dimensions on the walk-behind tractor. It is more convenient to work with an assistant, since it is difficult to expose the details yourself and control their position. Secure the floor and pedals or levers. Fit all parts exactly, align and check if they move normally. Install the seat. First select the correct position, then either weld the slide or bolt it. In this case, drill holes in the right places, use fasteners with washers. Reinforce the floor at the bolt locations with additional stiffeners. Put on the wheels. Here the work depends on the type of attachment to the frame. The easiest way is to make separate modules from a square profile and a hub, which are inserted into the pipe and fastened

Pay attention to the rear hitch position. It is best if it can be adjusted in height.

Making a mounting plate with holes, it will allow you to mount the node higher or lower, this is the simplest solution.

When assembling a system with a movable joint, the connecting unit must be rigid and rotate only in the horizontal plane. It is easier to buy a ready-made hinge, since it is difficult to precisely fit this part of the structure at home.

After assembly, check whether the hitch is normally attached to the walk-behind tractor, whether it is convenient to operate. It is better to find all the shortcomings at this stage, immediately eliminate them. Then clean out all the centers of corrosion on the metal, if any, paint the surface in 2-3 layers for reliability.

Front-mounted version

The front adapter for the Neva walk-behind tractor with steering can be bought ready-made. It is also suitable for other vehicle models - Oka, Kaskad, Luch, Celina. But it will cost from 23,000 rubles, so it makes sense to make it on your own, using finished products as a sample. Drawings are easy to find, which is also good. Carry out the work like this:

Consider the location of all controls. Most often, problems arise with this. The easiest way is to use levers or pedals, plan their location in advance, eliminate any problems. Weld the supporting frame

Pay attention to the place of connection to the walk-behind tractor, it should be additionally strengthened. Use a corner or pipe with a safety margin so that the elements do not deform under loads

The easiest way is to use a ready-made steering column and rack. Buy any small option for auto dismantling, then you don't have to come up with anything. Put the wheels with hubs, adjust the steering gear in place. Weld the floor, expose the seat and all controls. Check each assembly during installation to make sure that it works as expected and there will be no problems after assembly. A ready-made adapter with a steering wheel to the Neva walk-behind tractor, assembled by hand, must be tested after assembly. Pay attention to steering and handling. Paint all unprotected metal surfaces, before doing this, clean the steel from corrosion.

Such options are good because during operation a standard motoblock hitch is used and a power take-off shaft is available for active units. You can additionally put headlights in order to move or work even in the dark, for this, in the front of the frame, make two mounting brackets and conduct wiring.

It is easy to assemble an adapter for a walk-behind tractor if there is a detailed drawing with dimensions, all the necessary materials and tools. The frame is best welded for reliability, the rest of the parts can also be bolted, then you can quickly assemble or disassemble. Paint the metal, otherwise it will start to rust.

Adapter manufacturing at home

The first thing to do is draw up a kinematic diagram.

To keep the structure in balance, as well as to prevent other overloads. The kinematic diagram can be created by hand, or purchased ready-made.

The second is to make the basic details.

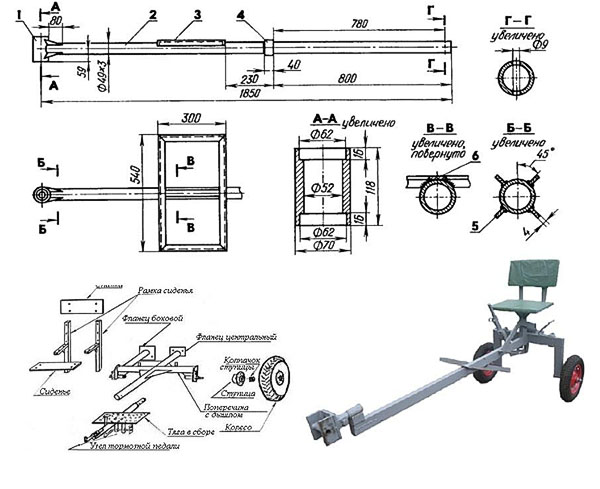

In the process of making and assembling the frame, you can make a fork and a bushing, thanks to which the trailer turns freely. The body is made from a sheet of steel with a side height of at least 30 cm.

The simplest option for the production of a coupling assembly for the entire structure is a pin, 15 cm long. It is stuck into the drawbar (i.e. its hole) with a U-shaped motoblock hitch.

At the third stage, the seat is installed.

It attaches directly to the adapter beam (ridge frame), 80 cm from the front-most edge. Fixing is done with bolts. And that's all, you can check the device's performance and start it up!

General information about the tractor

The walk-behind tractor can be operated separately, as well as connected to a wide variety of additional equipment, such as:

- cultivator;

- harrow;

- mower.

Such devices can significantly increase the possible range of work that the walk-behind tractor can handle. In addition to this, you can use a mini-tractor as a vehicle if you prepare a special block adapter for it in advance.

Such devices can significantly increase the possible range of work that the walk-behind tractor can handle. In addition to this, you can use a mini-tractor as a vehicle if you prepare a special block adapter for it in advance.

This device makes it possible to sit quite comfortably on the seat with which it is equipped, and then do exactly the same work, but with an incomparably greater share of comfort. For example, in specialized stores you can purchase an additional steering unit for the Neva walk-behind tractor, or make it yourself. Fortunately, there are enough drawing materials on the Internet, which greatly facilitates the assembly process.

How to assemble an adapter for a walk-behind tractor with your own hands

A simpler and more complicated design can be made. Both of these options will be shown below.

Do-it-yourself assembly of a simple version of the adapter for a walk-behind tractor

To make it you will need:

- rectangular pipes;

- wheels;

- channel # 10, 40 cm long;

- coupling knot;

- welding machine;

- bearings;

- mounting bolts;

- sitting.

Before starting work, you need to create a drawing. You can use ready-made schemes or make them yourself.

After that, work begins. First, the pipe is cut into lengths of 1.7 and 0.5 m. The end of the short pipe is welded to the long one, and strictly perpendicularly. It will be the basis for attaching the wheel struts. Immediately make marks of 30 cm, indicating the height of the racks from the axis.

Then wheels are attached to the hubs, which can be used from an old garden cart. Bearings are first attached to the bushings, after which the braces are welded to the central tube of the bushing by welding.

Recent Entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the earth

Frames are made with dimensions 40x40 cm, but if necessary, these dimensions are reduced or increased. A channel is attached to the rear end of the frame by welding, and the side pipes are bolted to each other. A lever is also installed on the frame. To increase the adjustment force, an additional 75 cm long lever is installed.

Quite often, couplings are purchased in stores. But it should be noted that this element must be of high quality.

Therefore, if you plan to make it yourself, then quality must be given special attention.

The seat is attached to a metal support, which is welded in advance to the base of the frame, i.e., the central tube.

Assembling a complicated version of the adapter for a walk-behind tractor with your own hands

To make such an adapter for a walk-behind tractor, you will need:

- steel tubes;

- Sheet steel;

- seat;

- corners;

- a pair of wheels;

- welding machine.

Such an adapter for a walk-behind tractor will be more functional. The assembled equipment can not only cultivate the land, but also be used for the transportation of goods. Additionally, a harrow, plows, tillers, etc. are used. And in winter, the walk-behind tractor can be equipped with a scraper for cleaning snow.

This design consists of the following elements:

- rim;

- seat;

- wheels;

- coupling devices.

Before starting work, a kinematic diagram is created. This is necessary in order to correctly calculate all loads. You can also use ready-made drawings.

When making a frame, do not forget about installing a fork with a bushing, which are necessary for the trailer to turn freely. A sheet of steel is required for the bodywork. The hitch assembly looks like this: an iron pin 15 cm in size is inserted into the aperture of the drawbar, which has the shape of the letter "P". However, it should be noted that this option wears out quickly, since the coupling holes very quickly become unusable due to the regular rotation of the trailer. In this case, it is necessary to lengthen the U-like chain.

The seat is fastened at a distance of 80 cm from the front end of the frame. This process is carried out using bolts.

Thus, making a homemade adapter for a walk-behind tractor is not so difficult. Therefore, there is no need to buy expensive equipment when you can do it yourself. All items can be bought in the store or found in the barn at your summer cottage. A properly created structure will allow summer residents to greatly facilitate their hard physical work.

How to make an adapter to a walk-behind tractor with your own hands

To design a trailer for a walk-behind tractor yourself, you do not need special knowledge, skills - only drawings and welding. The materials are of low cost and are available for purchase at any hardware store.

Scheme and structural elements

As already mentioned, the above adapter is a trailer that is located either behind the walk-behind tractor or in front. Schematically, it looks like this:

Drawing of the MTZ-0.5 walk-behind tractor with homemade attachments

The adapter for the walk-behind tractor provides the following basic structural elements:

- Frame - can be spinal or ladder. Sometimes you can find an option where the frames of the unit itself and the trailer are combined into a single element. However, in this case, it is necessary to create a new pedestal for the transmission and engine.

- Suspension - axial, bridge, swivel, portal. It is usually made without elastic elements.

- Portal - used only in the rear view. In the case of the front, it becomes the portal of the unit itself.

- The hitch is the most important element of the adapter, since it makes the walk-behind tractor stable and ensures a reliable connection. If the trailer has steering, then the hitch will be rigid, in the case of a movable joint, fasteners are created on the horizontal joint. There is an option of creation, taking into account two degrees of freedom: twisting and rotating.

- Sitting - created depending on the preferences of the owner.

- Steering - applies only with a rigid hitch. You can create it yourself, or purchase it in a specialized store.

Required materials and tools

To make a trailer yourself, you need the following materials and tools:

- metal corners;

- metal sheets for leg support;

- square metal profile;

- wheels (2 pcs.);

- welding machine;

- other tools (saw, screwdriver, etc.).

Drawings and dimensions

An example of a simple circuit

The adapter will be based on a square metal profile. Usually it is taken from 160 to 180 cm in length. A smaller profile is attached to it directly perpendicularly - 50-60 cm (depending on the size of the desired track).

Wheel stands are attached to the resulting structure. As for the racks, their size is 25-40 cm. It is determined depending on the walk-behind tractor itself. Then braces are welded, the length of which is determined from the desired size of the entire structure and other parameters.

Next, a frame is created, the side rails of which are attached to the wheel struts with bolts. The attachment is subsequently attached to the frame, then the control lever. It has 3 knees in sizes 20, 35 and 55 cm.

To increase mass and effort, another lever is created with a larger size - 80 cm.

Assembling the adapter for the walk-behind tractor

Stage 1. Creation of a kinematic diagram.

From the very beginning, at the design stage, it is necessary to create a kinematic diagram, in which it is necessary to provide for the balance of the entire system and the prevention of additional overload. In this case, it is appropriate to use ready-made options (as an example below) or create it yourself.

Simple adapter diagram

Stage 2. Creation of basic elements.

In the manufacture of the frame structure, it is necessary to provide for a fork with a sleeve. It will allow the trailer to turn freely. The frame itself is made of metal corners and pipes, the body is made of steel sheet. To create wheel stands, a diagram is drawn or a ready-made one is taken.

Often a 15 cm pin is used to create the hitch assembly. It is inserted into the hole of the drawbar of the U-shaped hitch of the walk-behind tractor.

Stage 3. Seat installation.

The seat is fixed 80 cm from the front edge to the adapter beam frame and bolted.

Often additional elements are added to the adapter: seat adjustment, additional levers - here it all depends on the creator's imagination, as well as the goals and time of using the walk-behind tractor.

A DIY adapter for a walk-behind tractor will be a great helper for a gardener. It not only reduces the time of working on the walk-behind tractor, but also makes it easier and more automated.

Video compilation

Category: Attachments

What is an adapter for a walk-behind tractor

two-wheeled trailer

Some models have a special lifting lever, which makes the operation of mechanisms more comfortable. If necessary, the walk-behind tractor is used to transport small loads.

Depending on the purpose of using the drawbar technique, there are:

- elongated (for large machines);

- shortened (for light structures).

To connect the adapter to the walk-behind tractor, a single enlarged hitch is used, which consists of two parts. The first acts as a link, and the second is a regulator. If it becomes necessary to equip the equipment with several implements at the same time, then a double universal hitch is already used.

Operation and maintenance

The lifting mechanism for the adapter is nothing more than a lifting lever that greatly simplifies the work with additional attachments. Typically the lifting mechanism on steering models is located behind the adapter. Attachments necessary for this or that work are attached to it. For example, it can be a plow for plowing or preparing the soil for hilling. The mechanism itself is structurally uncomplicated and can be set in motion by manually turning the lever.

By fixing the two-wheel adapter to the walk-behind tractor, you can take a comfortable position and work while sitting. This will contribute to greater stability of the walk-behind tractor. Handcart options are relevant for large farms. Also, they can be used not only for harvesting, but also to transport construction waste and various goods. With the adapter, you don't have to worry about getting your feet under the cutter.

To extend the service life of the walk-behind tractor and adapter, you need to remember about the first start, for which you should first fill in oil and gasoline, and then run in. It should also be borne in mind that during operation, overheating of the engine of the main unit is unacceptable and timely lubrication of parts is necessary. Depending on the type of models, some of them will have to cover the operator's seat due to the material of its manufacture. For example, if the base of the seat is plywood, it may deform in the rain.

Considering that the adapter can be made independently, using improvised means (for example, wheels from a wheelbarrow or other spare parts), it is important to observe all the subtleties of the drawing and the correct assembly of the attachment lifting mechanism. As for the wheels, it is worth keeping in mind: metal options are better for working in the fields, rubber ones with treads are suitable for working on a dirt road

At the same time, their radius is of great importance in operation, because excessively large or, conversely, too small wheels will lead to frequent overturning of the unit.

At the same time, for models with an engine located at the rear, the track width should be greater, since otherwise the walk-behind tractor will not be able to properly balance during operation. In this case, the wheel axle should be wider. In the process of working with a walk-behind tractor, you can use landmarks or cultivate the land in a circular manner. This depends on the size and shape of the site and the adapter model. For example, plowing or loosening the soil is easier done in rows with a turn at the end of each of them.

In the process of work, the user can ensure that the soil cultivation is uniform, and the attachment does not go deeper into the ground more than it should be. It is necessary to set the adjustment before work. Timely it is necessary to inspect the adapter and walk-behind tractor. This will ensure uninterrupted and safe operation of the walk-behind tractor during its entire service life.

It is necessary to change the oils in the motoblock units in a timely manner, to prevent the electric motor systems, to adjust the control and lifting mechanisms

It is also important to keep the unit and adapter clean. This means that they must be cleaned of dirt and soil, after which the walk-behind tractor must be installed in a horizontal position using the third wheel (if any) or a stand that can ensure a stable position of the unit

We must not forget about sharpening tools, since the processing of the soil and the quality of its loosening directly depend on this. If your area is small, it is advisable to walk along it in advance and remove large stones that can blunt the attachment.

The tiller with an adapter must be stored correctly. The room must be dry and well ventilated. In this case, it is desirable to place the equipment in conditions in which it will be free from contact with alkalis and acids. The car must not only be cleaned of dirt, but also the fuel must be drained from the tank and carburetor. It is also necessary to drain the oil from the engine crankcase. If the walk-behind tractor will be idle for more than three months, you need to install it on supports, unloading the tires.

It is recommended to periodically inspect the tires for damage and defects. Do not use a walk-behind tractor with reduced tire pressure, as this will shorten the life of the wheels. High pressure will also accelerate their wear.

It is important to check the air filters of the walk-behind tractor, spark plugs and, if necessary, replace the muffler. In addition, you need to inspect the strength of the adapter connections, because the safety of the operator depends on this.

For information on how to make an adapter to a walk-behind tractor with your own hands, see the next video.

Algorithm of actions

To start assembling additional equipment for a motor-cultivator, you will need a drawing, in accordance with which the fastening elements and the construction of fragments will be made.If you have special skills and experience, a homemade adapter for a walk-behind tractor and a drawing can be done independently. If you are afraid to make a mistake, you should take ready-made drawings. Before designing, it is recommended to check and verify the compliance of dimensions and numbers.

Tools and consumables:

- metal corners, square profile;

- bearings for the steering wheel and column;

- metal sheets;

- a pair of wheels, preferably on an axle;

- drills, electrodes, grinder discs;

- fasteners;

- wrenches of various sizes;

- electric welding apparatus;

- lubricants - grease;

- Bulgarian;

- screwdriver;

- drill.

Work progress:

- The beginning of work is the manufacture of the frame. A construction is made from cut parts of the selected steel building material. The metal is cut to the desired length using a grinder. Fragments are fastened with bolts or welding.

- A piece of a square metal profiled product 1.8 m is welded to a metal profile 60 cm long. The elements are placed perpendicularly. This fragment will serve as a mount for the tires. The wheel stand must be at least thirty centimeters high.

- The spacers are welded to the main frame and wheel hubs. The size of the frame is 40x40 cm, it can vary depending on the individual project.

- A profile is welded to the edge of the frame. The axle pipes are bolted together.

- A control lever is attached to the frame by welding. To increase the power indicators during control, the lever is constructed with one or more knees with a length of 70-80 centimeters. The knee fragments are bolted together. The dimensions of the adapter for the walk-behind tractor are recommended to be checked against the drawings and diagrams, because they will help you create an error-free design with your own hands.

- A 30-40 cm long pipe serves as a support under the seat; it is welded to the main frame. The driver's seat makes it easier to operate the machinery while gardening.

- The coupling part of the mechanism is welded to the rear of the walk-behind tractor. The mount is made of steel or cast iron material. An electric welding machine is used to connect spare parts. Fasteners are an important component that provides a reliable hitch. The most suitable is the U-shaped connecting node. Thanks to this spare part, the transport becomes sustainable.

- Wheels for the adapter to the walk-behind tractor are suitable for two types - rubber or metal. The latter option is used to carry out work in the field. The rubber wheel has a deep tread, which will allow you to move on a dirt road and, if necessary, drive off-road. Wheel radius fits 15 to 18 inches. Wheels from the domestic auto industry are suitable - "VAZ", "Moskvich".

- The resulting device is treated with a primer and painted. This technique will prevent the appearance of metal corrosion.

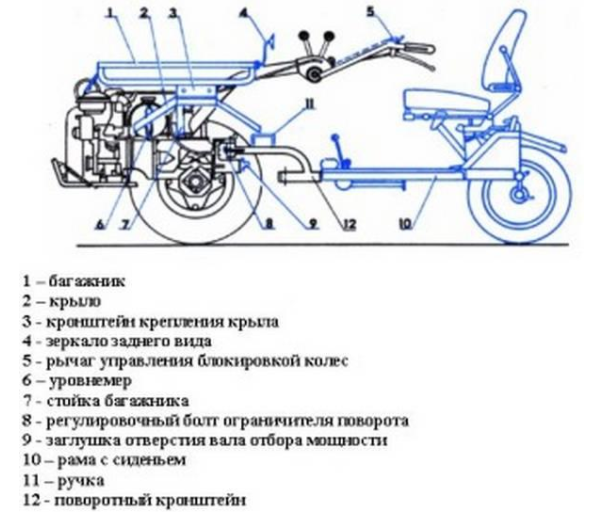

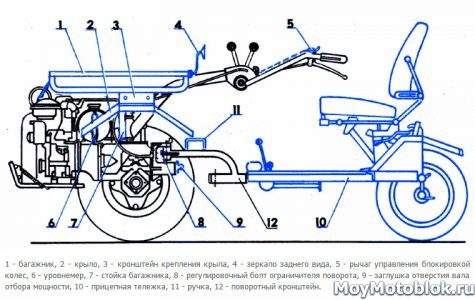

Motoblock with steering

With this method, the power unit will be located behind the driver's back and rigidly attached to the front adapter. Consequently, the coefficient of adhesion of the driving wheels to the soil will increase. This, in turn, will increase the tractive effort, which will make it possible to work with any attachment. For such experiments, the lightweight Salute walk-behind tractor is best suited, having a mass of about 75 kg and a power of 6.5 liters. with.

In this case, you will need a steering column with a gearbox. But this is for this case, if you dare to make a walk-behind tractor with front steering. This procedure is much more difficult and painstaking than a simple articulation, but the result will please - you get a walk-behind tractor with a steering wheel and a seat, and all the necessary levers will be at hand.

During the manufacture, you will need not only a steering wheel and a gearbox, but also tie rods with openers. You will definitely need gas, clutch and brake pedals located under your feet. They are connected to the standard controls with homemade rods or steel cables.

On the right side of the seat, a lever is installed to raise or lower the attachment, as well as a parking brake handle. Fenders with headlights are placed on the front wheels. And the mini-equipment, finally, takes on the finished look of a walk-behind tractor with a front adapter.

It should be noted that the price of such a product with a steering wheel starts from 24 thousand rubles. At the same time, the adapter has good technical characteristics that allow you to fully appreciate the advantages of working on your mini-equipment.

The walk-behind tractor is a mechanized assistant to the gardener, which reduces labor costs and the user's health. When combined with a steering adapter, this device increases driving comfort and further reduces exercise.

In fact, the adapter allows you to turn the walk-behind tractor into a kind of mini-tractor. From the material of this article, you will learn the device of the adapter, its purpose, varieties, installation nuances and subtleties of operation.

Tips for assembling an adapter for a walk-behind tractor

You may have already assembled the adapter yourself. And if not, listen to the tips of experienced craftsmen who will simplify the choice of one or another work option:

You may have already assembled the adapter yourself. And if not, listen to the tips of experienced craftsmen who will simplify the choice of one or another work option:

The width of the motoblock adapter wheels is directly proportional to the ground passability. If you do not know exactly the required parameters, be guided by a wheel width of 200 mm. Just make sure that the power unit is not narrower than the wheels.

A universal rule: if you are in doubt about the dimensions of a particular part, look at the dimensions of a similar factory-made model. Make fragments of a homemade adapter using this pattern.

The length of the adapter drawbar depends on the power of the walk-behind tractor. The lower the performance, the more you need to lengthen this element. The short drawbar of the adapter is suitable for a powerful walk-behind tractor.

Try to lighten the structure as much as possible. For example, a plastic seat. But do not overdo it so that "lightness" does not come at the expense of reliability.

Another thing about reliability: do not skimp on the hitch. It is better to buy ready-made, which is guaranteed to last longer than homemade.

Device

Regardless of the type, the structures always consist of the same parts. The difference lies in their layout and size. You need to understand each element well in order to understand the details when creating a drawing or assembly, to do everything reliably and correctly. Any errors lead either to a decrease in reliability, or to the need to redo the node.

- The frame bears the entire load, the rest of the parts are placed on it, so strength is important here. It can be rigid or with a movable joint in the middle. The second option is more difficult, but you can turn around in a smaller space, the handling improves. A separate view is a full frame, where the engine and the control unit are on the frame, in this case you will have to make mounts for the motor and transmission.

- Wheel assembly. There is no suspension, so it consists of bearings that are placed on a common axle or separate levers attached to the frame. Often the design is made adjustable, then you can quickly change the track width for different types of work. Wheels are taken from any technique, the main thing is to choose the right size.

- Steering gear. For options with a front location, it can be different, but the easiest way is to buy a ready-made rail and fix it in place. The second solution is a gear drive in a flexible joint, when two modules are bent relative to each other when cornering.

- Seat. Use any option that is at hand, and if it is not there, buy it at a car breakdown yard for little money. Pick it up for yourself, fasten on a sled, so that it is possible to adjust the position for people of different heights.

- Foot pedestal. The pedal assembly, if available, is also located here, and the handbrake is also attached to this part, which is used in the rear adapters.Made from durable perforated steel sheet, feet will not slip on the surface.

- The hitch connects the two parts of the structure. The easiest way is to buy a finished product; it is sold separately in the same place as the equipment. It is desirable that the hitch is movable in a vertical plane, then when driving on uneven ground, the wheels firmly cling to the ground and do not rise on bumps.

In addition to the main parts, there may be additional parts in the design, it all depends on the drawing. Often supplemented by tool box, it is most convenient to attach it behind the seat or under it if there is room. Braking and steering systems are developed separately.

General information about the tractor

The walk-behind tractor can be operated separately, as well as connected to a wide variety of additional equipment, such as:

- cultivator;

- harrow;

- mower.

Such devices can significantly increase the possible range of work that the walk-behind tractor can handle. In addition to this, you can use a mini-tractor as a vehicle if you prepare a special block adapter for it in advance.

This device makes it possible to sit quite comfortably on the seat with which it is equipped, and then do exactly the same work, but with an incomparably greater share of comfort. For example, in specialized stores you can purchase an additional steering unit for the Neva walk-behind tractor, or make it yourself. Fortunately, there are enough drawing materials on the Internet, which greatly facilitates the assembly process.

It is interesting: The best serial mtz walk-behind tractors and possible attachments

Advantages and disadvantages

After the walk-behind tractor has been modernized, the designers note the positive qualities of the front adapter:

On this topic:

BACK

FORWARD

1 of 3

- ease of use;

- disclosure of the traction resource - the existing abilities increase;

- the possibilities of work are expanding - tillage will be accelerated;

- if necessary, the unit is disassembled and assembled;

- good balance in weight and axes;

- you can move around on the device.

The disadvantages include the fact that in the presence of a movable hitch, stability deteriorates.

The adapter for a walk-behind tractor consists of the following structural elements:

- The frame is built with a central or staircase. Metal pipes, corners are suitable as a material. The design model must include a fork and bushing that will allow the trailer to turn freely. There are converted vehicles in which the aggregate device and the trailer are combined. In this case, a new stand for the transmission and motor should be made.

- Suspension systems are axial, bridge, swivel, portal. It is built without the use of elastic fragments.

- A steel sheet is used for the body.

- The hitch is an important element of the converter, it makes the walk-behind tractor stable and reliably connected. The hitch assembly is made from a 15 cm pin.

- The seat is the driver's workplace.

- The steering is used with a rigid connection. It is built with your own hands or purchased in a special store. Craftsmen install the steering rod and rail from a VAZ or Volga car.