Attachments

Additional attachments increase the functionality of the walk-behind tractor, turning it into a universal agricultural implement. For motoblocks Mole, it is possible to aggregate with a wide range of attachments.

Cutters

Used to cultivate soil to a predetermined depth.

Cutters are of two types:

- Saber-shaped (active), assembled from steel knives. They are included in the package, but their number varies, depending on the power of the walk-behind tractor - weaker models have 4 cutters, more productive ones - 6.

- “Crow's feet” have triangular tips that easily cut through even virgin soil without leaving sticking.

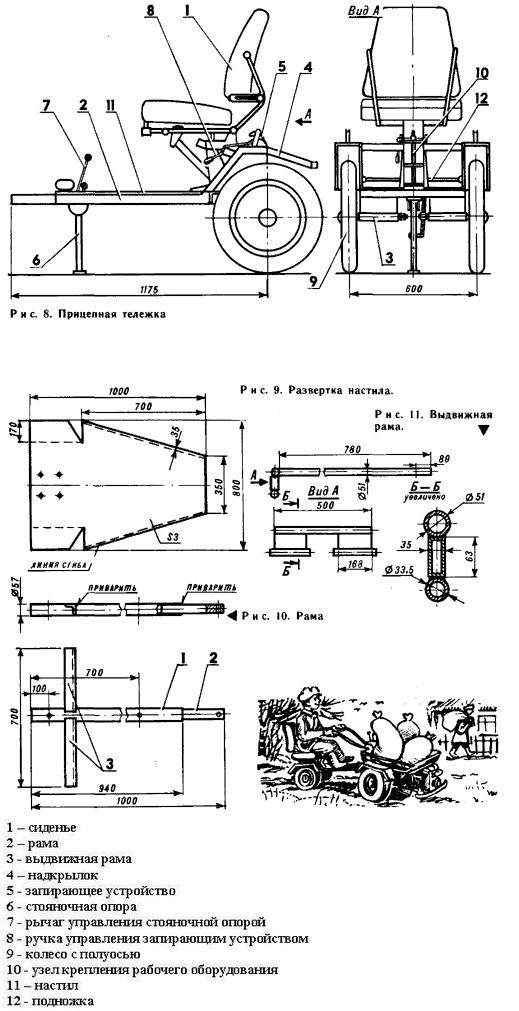

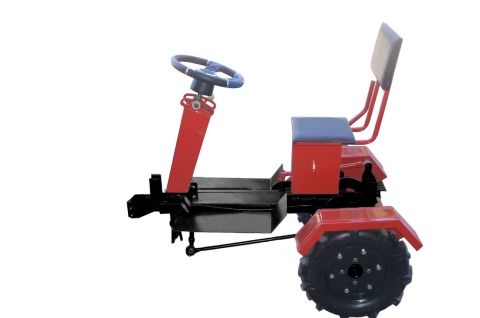

Adapter

This is a special device consisting of a seat, a frame and additional wheels (one or two), which is mounted on the walk-behind tractor using a hitch.

Adapter

Thanks to the adapter, the unit turns into a light mini-tractor.

Trailer

The trailer trolley can have various dimensions and carrying capacities. The maximum weight that she can carry is 500 kg.

Cart

The main purpose of the trailer is transportation of piece and bulk cargo.

Mowers

In the summer, it is advisable to use the walk-behind tractor as a mower, for this you only need to purchase, or make yourself, the appropriate attachments.

There are several types of mowers:

- segment;

- rotary;

- frontal.

The most popular is the segment mower. It works like a scissor.

Wheels

Pneumatic wheels

They are present in all Mole models and are used for:

- transportation of goods in conjunction with a trailer;

- to transmit forward movement when working with a mower and snow blower;

- for transporting the walk-behind tractor itself to the place of work (then the wheels are removed and either cutters or lugs are installed in their place).

To improve the grip of the unit with the ground, the wheels are equipped with powerful protectors.

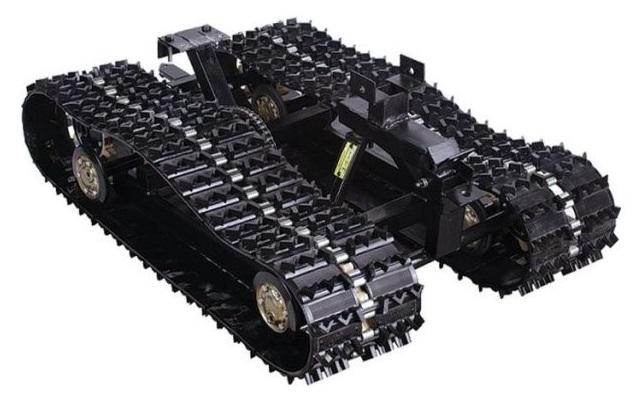

Track attachment

Track module

This linkage increases the contact area with the ground, improves traction and flotation, especially in winter.

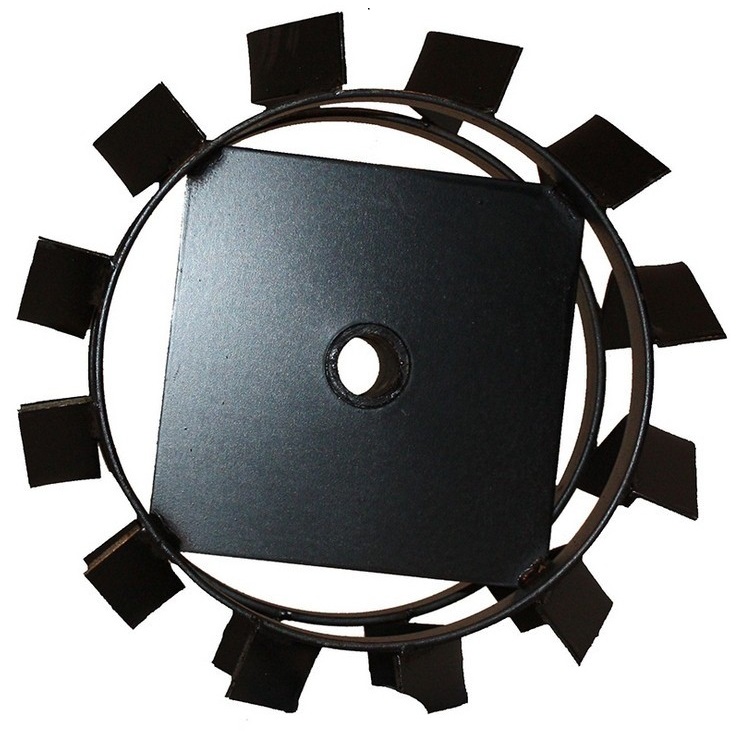

Lugs

These are large metal wheels with welded-on ribs that fit onto the shaft instead of pneumatic wheels. The role of the lug is to transport the walk-behind tractor forward and till the soil with ribs.

Grousers

Plow

A reversible plow is used for plowing the land. It has similar functions to milling cutters, but the plow is more relevant to use in the primary cultivation of virgin lands and in the fall, as an additional weed control.

Plow

In other cases, it is better to plow with cutters - they do not damage the fertile soil layer and cultivate it perfectly.

Snow blower

In a winter walk-behind tractor, the Mole in aggregation with a snow-removing hitch is suitable for clearing the territory from snow patches.

There are several types of snow plows:

- auger snow thrower (throwing range up to 5 m, auger with blades, impeller is involved in the work);

- brush;

- blade (a shovel with which you can work not only with snow, but also with other bulk materials).

Potato planter

Used to mechanize the potato planting process.

Potato planter

Seed potatoes are poured into the bunker, a special device grabs them one by one and places them in a previously made furrow to a certain depth. Then a soil ridge is formed on top of the vegetable. The distance between tubers is set in advance.

Potato digger

This equipment allows you to quickly and efficiently harvest potatoes.The vegetables are grabbed and pulled out, while the soil is sifted through special rods, leaving the potatoes intact.

Potato digger KRT-1

Weights

Weights are put on the shaft and wheels of the walk-behind tractor and allow the unit to sink deeper into the soil. The use of weighting materials is relevant on machines whose weight does not reach 100 kg.

Weights

Hitch

One of the most important components of the walk-behind tractor is the hitch. This device allows you to aggregate the walk-behind tractor with any attachments. There are two types of couplings: with and without regulation.

Hitch

In adjustable models, you can set not only the horizontal, but also the angle of attack.

Specifications

Here are some data on the walk-behind tractor.

- dimensions of the walk-behind tractor: 1560/790/1050 mm;

- ground clearance 270 mm;

- cylinder volume 0.475 l;

- weight - 125 kg;

- with a fuel tank volume of 6 liters, fuel consumption is less than two liters of gasoline;

- four-stroke engine with right-hand rotation, single-cylinder, uses gasoline with any octane number, reacts well to gas;

- air-cooled;

- the battery shows high charge rates.

Advantages of the Ural walk-behind tractor:

- when the unit weighs more than a centner, it is not necessary to additionally press on the handles with its own weight, which makes it easier to cultivate the land;

- there are numerous opportunities for self-improvement and design upgrades;

- high resource indicators of the engine;

- the air filter does not require replacing the gaskets.

At the same time, the following disadvantages were also noted:

- Frequent leakage of lubricant at the joints of the engine / gearbox;

- you have to check the oil level frequently;

- the gas distribution mechanism leads to an increase in the consumption of gasoline and engine oils due to design features;

- not recommended for long journeys with a load (low speed).

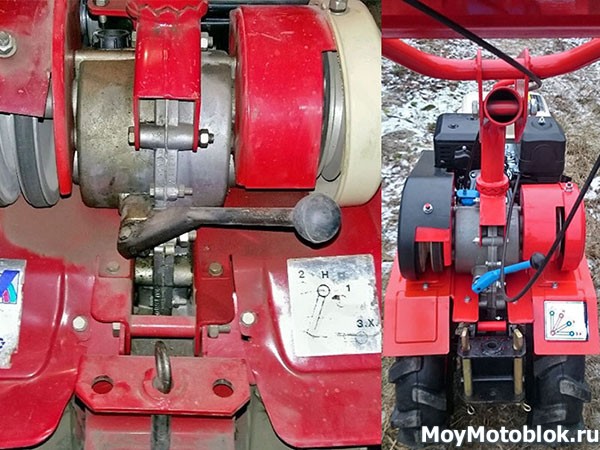

Engines UMZ-5B and its variant UMZ-5DU-B have the following characteristics:

- four-stroke, power up to 5.4 liters. with. (more than 3.5 kW);

- equipped with a two-stage gearbox with a gear ratio of 1 to 6 or 1 to 2.91;

- one cylinder;

- forced cooling.

The UMZ-5DU-B model differs in that its gearbox is single-stage and its gear ratio is 1 to 6, and a ratchet is not installed on the gearbox shaft.

As an alternative to Ural engines, if it becomes necessary to replace it, imported products from the Chinese manufacturer Lifan are often chosen.

Lifan was founded in the early 90s of the twentieth century and today is one of our most famous large companies in the automotive market. In addition to engines, Lifan also produces other motor vehicles with an optimal price-quality ratio. The products are certified, and each product must be accompanied by a technical passport and operating instructions.

Lifan presents different types of engines on the Russian market. One of the most important characteristics when choosing an engine is the mounting dimensions, since they do not always correspond to Russian standards.

Another important characteristic is engine power, since in most cases Lifan engines have 6.5 liters. with. against 5 liters. with. at the "Ural".

Disassembly itself is not particularly difficult and is performed in a couple of stages even by a specialist with little or no experience.

- The old engine is removed from the mounting connectors using standard open-end wrenches.

- First, disconnect the fuel and oil lines, if any.

- Next, remove the centrifugal regulator.

- Sometimes, at the stage of installing a new engine, it is necessary to use gaskets, but with the correct selection of sizes, this is not necessary. The easiest way is to install an adapter plate with holes for fastening.

Lifan offers several lines of gasoline engines: 168F, 168F-2, 177F and 2V77F.

Ruler 168F:

- four-stroke;

- power - up to 5.4 liters. with. (more than 3.5 kW);

- 1 cylinder;

- cooling - forced;

- the crankshaft is located at an angle of 25 degrees;

- cylinder - 163 cm3;

- fuel tank - 3.6 liters;

- cylinder with a diameter of 68 mm;

- shaft with a diameter of 19 mm;

- started manually;

- dimensions 312х365х334 mm;

- weight - 15 kg.

The 168F-2 engine is of interest to buyers in that it differs from the previous version in its increased resource and higher parameters - it is more powerful (6.5 hp), has a larger cylinder (196 cc).

Engines in 9 liters. with. represented by Lifan 177F models:

- four-stroke;

- power - up to 9 liters. with. (more than 5.6 kW);

- one cylinder;

- forced air cooling;

- the crankshaft is horizontal;

- cylinder - 270 cm3;

- fuel tank - 10 liters;

- started manually;

- dimensions 378x428x408 mm;

- weight - 27 kg.

The Lifan 2V77F model has even higher characteristics and more power, according to its characteristics - the best heavy engine in its class:

- four-stroke;

- power up to 17hp. with. (more than 12.4 kW);

- two pistons;

- mechanical speed controller;

- cooling - forced, air;

- the crankshaft is horizontal;

- cylinder - 615 cm3;

- fuel - 27.5 liters;

- launch - manually;

- dimensions 455x396x447 mm;

- weight - 42 kg.

Models and modifications

The company's engineers were tasked with creating reliable equipment that would cope with a number of complex jobs. Ensuring the durability of the main components of the structure is critical. This allows the use of walk-behind tractors in the household, the agricultural industry and other areas. As a result, the Salut brand produced two high-quality models.

Salute 100

This model is multipurpose and is equipped with a gasoline type of power plant. Motors for walk-behind tractors are manufactured by several companies:

- Chinese Lifan and Hwasdan;

- Japanese manufacturers Honda and Robin Subaru;

- American brands Briggs & Stratton and Kohler.

A gearbox with a convenient switch on the steering wheel allows you to work with a walk-behind tractor and transport cargo at speeds from 2.8 to 7.8 km / h. Also, the owner of "Salyut 100" can choose the optimal speed mode, which is suitable for a certain type of attachment.

The volume of the fuel tank of the Salyut 100 walk-behind tractor is 3.6 liters. The oil tank has a capacity of 0.6 liters.

Depending on the type of unit, the mass of the walk-behind tractor may differ. For example, the weight of the Salyut-100 with Subaru and Hwasdan engines is 78 kg, a walk-behind tractor with a B&S or Kohler engine weighs 70 kg.

The transport track of the model is 260 mm. The technique processes the soil to a depth of 25 cm.The processing width during cultivation varies between 35-88 cm.

A distinctive feature of the Salyut-100 model is soil milling cutters for 3 pairs. They are equipped with quality knives made of spring steel. The characteristic sickle shape of the knives allows for the best cultivation of various types of soil.

Salute 5

Motoblocks Salyut-5 have a universal design, modern developments of the company have made it one of the most efficient in various areas of the economy. The main advantages of the Salute "5" model:

- a large selection of engines from famous brands;

- reliable type of gearbox;

- two V-belt transmission belts, which increases efficiency with reduced element slippage;

- the presence of 4 gears when moving forward and 2 backward;

- a special shaft that allows you to connect attachments of an active sample;

- switching to reduced speeds;

- two planes of steering wheel adjustment;

- the center of gravity of the structure is shifted down and forward, which makes the technique more stable on uneven ground;

- a wide range of attachments.

Motoblock Salyut 5 is presented on the market in several configurations. The difference lies in the use of motors from different manufacturers. The power of modifications can be 3.5-6.5 hp. In this case, the configuration may include the following components:

- cutters for soil with fasteners (4 pcs.);

- coulter bar;

- bracket for equipment support;

- 2 shields;

- bracket for fixing accessories.

Among the popular modifications it is worth highlighting "5P" with Robin-Subaru EY-20, "5X" with Honda GC 160 and "5BS-1" with B&S Vanguard 6.5.

Assembling the walk-behind tractor

A steering rack is installed above the gearbox of the walk-behind tractor and secured with a special handle. Avoid sharp bends in the clutch and throttle control cables.

The steering wheel itself is installed on the Salyut-5 rack, screwed with a bolt and clamp of the handles of the walk-behind tractor. The clamp nut is tightened just enough that the eccentric lever will firmly lock the handlebars when turned 180 °. On some modifications, the clamp comes without a separate nut, it is built into the clamping handle. In this case, you need to tighten this lever with a nut until it stops and lower it by half a turn. The steering unit must be held securely and not displaced under load.

The coulter bar is placed on a support, secured with a bolt and nut and locked with a latch. The structure is installed on the support bracket for the hinges and is fixed in the middle hole. The bracket is attached to the hitch with two pivots, which are locked with clamps.

Assembly of cutters

Please note that the right and left cutters differ in the position of the knives in relation to the holes for the retainer in the rotor shafts. For reliability and correctness, check the diagram in the instructions

One set of cutters consists of 2 right and 2 left knives. The cutters are mounted on the cutter shafts with square flanges.

Do not place knives on the side of the safety washer!

- The first are cutters with a bend "outward" from the gearbox (right), then with a bend "inward" (left) - all are bolted.

- Tillers are placed so that when the walk-behind tractor moves forward, the cutting sides of the knives enter the ground.

- The cutters are mounted on the gearbox shaft of the walk-behind tractor instead of wheels and are fastened with axles with spring clips.

- Before starting work, tighten the nuts and check the tightness of other parts. It is recommended to set the fenders to the maximum in order to protect the walk-behind tractor from the ground.

- Try to manually rotate the installed cutters: the knives should not touch the MB and its parts.

Description

The design and operating principles of the Salyut 100 BS-V are similar to the 100 L6.5 model.

The main differences are:

- Powerful Briggs & Stratton Vanguard engine (USA).

- It has a gear reducer, two forward gears, thanks to which Salute can easily cope with any task.

- Large pneumatic wheels provide increased flotation, even on difficult terrain.

- Economical fuel consumption allows the walk-behind tractor to work smoothly at one gas station for a long period of time.

- The advantageous feature is the low center of gravity, which greatly facilitates maneuverability, handling and work in general.

- Works stably in areas with a medium slope.

- The walk-behind tractor has compact dimensions - with the wheels removed and the steering control, it can be conveniently placed in the trunk of a car.

Engine

The salute is powered by a high quality Briggs & Stratton Vanguard OHV four-stroke petrol engine with 6.5 hp, which is specially designed for installation on garden equipment.

Briggs & Stratton Vanguard engine

The American company Briggs & Stratton provides a sufficiently high precision in the manufacture of engine parts, so the idling process is completely ineffective.

In the engine operating instructions, the company gives only a few simple recommendations:

- Oil change after 5-8 first hours of engine operation, which is run-in.

- Gasoline should be used pure, without oil additives, with an octane number higher than 77, more stable engine operation is ensured by the Briggs & Stratton additive.

- SJ / CF oil is used at different temperature conditions. At negative temperatures, according to the instructions, it is recommended to use synthetic oil or non-synthetic 10W-30, article 998208. It should be borne in mind that at temperatures above 4 ° C, when using 5W-30, 10W-30 oils, the consumption increases significantly, so you will have to constantly monitor its level.

The recently launched Briggs series with the EXI marking does not require an oil change at all throughout the entire period of operation, which is explained precisely by the high accuracy of the engine assembly.

Transmission

The motoblock transmission consists of:

- clutch;

- reducer.

The clutch in the Salyut-100 BS-V walk-behind tractor is due to a reliable V-belt transmission.If one belt breaks, the operation of the unit does not stop.

V-belt transmission of the Salute walk-behind tractor

The gearbox of the Salyut 100BS-V walk-behind tractor is gear-type, which means it is distinguished by reliability, durability with a motor resource of more than 3000 hours. It has the highest efficiency among gearboxes, provides minimum power losses and practically does not require maintenance. Due to its quality, it is possible to use various motors.

Control handle

In this model of Salut, the speed switch is moved to the steering wheel, so there is no need to bend over to engage the required gear. The clutch handle is designed so that when pressed, resistance is felt, and in the position pressed against the handle, the holding force is minimal. Thanks to the adjustment of the handle in 2 planes, it is possible to optimally adjust the walk-behind tractor for any user.

Oil level control TM 5-18 (TAD17I) is carried out with a special dipstick - another characteristic innovation in the design of the walk-behind tractor.

Pulley

The power take-off pulley of the Salyut 100 BS-V walk-behind tractor is the middle stream of the driven pulley; it is used for mounting external trailed implements, including stationary ones.

PTO pulley

Frame

The frame of the walk-behind tractor is made in the form of two steel squares with the main units and mechanisms fixed on it.

Motoblock Salyut 100 BS-V

Coupling bracket

For the installation of interchangeable devices (directly or through a universal hitch) and front mounted units, there is a coupling bracket in the tail of the walk-behind tractor. The connection can be installed directly and by means of a universal hitch.

Coupling bracket

Coulter

The position of the opener bar (included in the package of the Salyut 100 BS-V walk-behind tractor) adjusts the depth of soil cultivation. With a larger deepening of the bar, the processing depth is correspondingly greater - within the range of 100-250 mm.

Coulter

Cutters

The real pride of the walk-behind tractor, like all hundredths of Salutes, are the three-row sickle-shaped cutters. Forged knives are made of high quality spring steel. Cultivation width - 360-800 mm, depending on the number of cutters.

Cutters

Wheels

Pneumatic wheels with expressive tread are installed on the shaft, used when working with installed units and to move the walk-behind tractor.

Pneumatic wheels

Conclusion

Attached equipment is an additional auxiliary tool that allows you to significantly increase the scope of the walk-behind tractor (for example, a caterpillar for a neva walk-behind tractor).

Thanks to him, you can do absolutely all the work typical for rural areas, where the main concerns are in planting and subsequent harvesting.

Of course, you will have to purchase additional equipment separately from the walk-behind tractor, which may seem like a pretty big price to pay for the possibility of full-fledged work on the ground.

However, the owners of large farms will appreciate all the advantages that such devices give, because they allow you to process more than a dozen acres of land at an accelerated pace. In conditions of high competition in the field of cultivation and subsequent sale of the crop, this can play a decisive role.

Perhaps you will be interested in the article assembling a walk-behind tractor.