Content

Broiler chickens, obtained from crossing productive meat breeds, are raised for the purpose of slaughtering for meat. The main feature of broilers is intensive feeding with limited mobility, which leads to rapid weight gain.

Most often, broiler breeds are kept in special cages. The cellular content of meat chickens requires compliance with a number of rules.

Pros and cons of cellular content

Fattening birds can be kept in cages, nests or outdoors. Bird cages are small multi-tiered rooms with an area of 0.5 to 1.5 square meters. m, made of steel mesh. The main advantages of growing broiler breeds in cages include:

- Saving space;

- Energy saving;

- Convenience of service;

- Saving feed;

- Protection from the external environment;

- The best conditions for fast weight gain.

One square meter of the cage can be placed up to 25 broilers, and taking into account the installation of such cages in several tiers, the farmer gets the opportunity to place a significant number of chickens in a small area. The cost of lighting and heating a room is usually proportional to its area, so by saving space, additional savings on electricity are achieved.

The multi-tier cages are equipped with automatic drinkers with a central water supply and external removable feed trays, which allows servicing such trays without disturbing the bird. Cleaning the litter trays is easier than changing the litter.

Birds can neither scatter nor trample the compound feed in the external feeder, due to which the savings in feed with a cage content are 15-20% higher than with other methods of placing birds. With a large herd, this savings in feed is significant.

When kept in open enclosures or for walking, birds are exposed to many hazards:

- Attack of predators;

- Infection with diseases from wild birds;

- Adverse weather effects.

The cage content does not imply walking outside, so the probability of picking up part of the livestock by predators or infection tends to zero.

In addition, limitation of mobility allows broilers to gain the weight necessary for slaughter in a short time, and walking chickens leads to overconsumption of feed and a decrease in carcass weight.

It is important to remember that cellular content has a number of significant disadvantages. These include:

- Increased risk of infectious epidemics due to crowding;

- The need to carefully monitor temperature and humidity indicators;

- Poor quality meat taste.

Despite the relative infectious safety of birds due to isolation from the external environment, infection of even one individual in conditions of dense broiler stocking can lead to a massive pest of the entire livestock, therefore, the poultry farmer must regularly monitor the well-being of birds by external signs and resettle individuals at the first suspicion of infection. Increased indoor humidity can increase the risk of sickness in birds.

Despite the high rate of weight gain in caged broilers, free-range chicken tastes better than caged broilers.

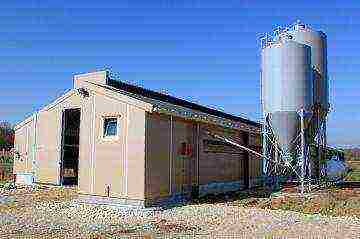

Arrangement of premises

The health of broilers and their performance indicators largely depend on the correct organization of the space of the chicken coop with cages. The room with cages should be equipped with:

- Ventilation system;

- Heating;

- Lighting;

- Humidity and temperature control devices.

The placement of cage blocks should be planned so as not to obstruct access to feeders and drinkers for maintenance and disinfection of cages.

Cell selection

Cages for beef breeds are made of a steel lattice with a rod thickness of at least 2 mm. Frames for installing cages can be of two types:

- Wooden;

- Metallic.

For large livestock, it is preferable to choose frames made of metal, since they are easier to disinfect and they do not accumulate moisture. The wooden frame is suitable for homemade production, as it saves metal, in small farms.

The stocking density of broilers in cages is usually 12 to 25 birds per square meter of cage floor, depending on the breed and age of the bird. One cell section can contain from 4 to 14 individuals.

Cells vary in size:

- Up to 50 cm wide - for 3-4 chickens;

- Up to 70 cm wide - for 6-8 chickens;

- Up to 1.2 m wide - for 10-12 chickens.

The depth and height of the cage does not change much depending on the number of birds being placed.

Large cages are designed for industrial production and are inconvenient for home use. The best option is to use a cage 65-70 cm wide, 30 cm deep and 25 cm high. This cage is designed to accommodate up to 8 broiler chickens.

It is important to know that the cage floor grating should be made of strong steel and have a rod thickness of at least 3 mm, as a less strong floor will bend under the weight of broilers, especially with a large cage width.

If the room for the cages is large, and it is planned to install tiers near the walls and in the center of the chicken coop, then wheels are attached to the central blocks to move the cages during harvesting.

Drinking bowls for cages should be installed of the vacuum type, as they minimize the risks of splashing, and automatic filling will make it easier to maintain the cages.

Heating, lighting and humidity

For a chicken coop with cages, it is important to maintain a constant temperature, since its increase above normal (24 degrees) will inevitably lead to diseases due to the inability of chickens to change location.

To control the temperature, it is recommended to use special thermostats to automate the maintenance of heat at the desired level. To heat a chicken coop with cages, you can use:

- Gas heaters;

- Infrared emitters;

- Electric heaters.

The installation of gas heating gives significant savings to the poultry farmer, but requires careful adherence to fire safety rules. Gas heating can only be carried out by organizations with a special license, so this method is suitable for large farms.

Electric heaters consume a lot of electricity in comparison with infrared emitters, which do not heat the air, but the objects themselves, from which the air is subsequently heated, therefore, the use of infrared emitters is most preferable.

Depending on the age of the bird in the cages, the following temperature regime is established:

- From 1 to 5 days - 34 degrees;

- From 6 to 11 days - 30 degrees;

- From 12 days - 18-24 degrees.

The transition from one temperature regime to another should be smooth and take 2-3 days.

Daylight hours in broilers should last from 15 to 18 hours, since light provokes birds to frequent feed intake and weight gain, so electric lighting in a chicken coop with cages is necessary even in summer. It is best to use configurable timers to maintain the desired light mode.For broiler chickens up to 7 days, daylight hours should be around the clock, upon reaching a week of age, it is reduced to 18 hours.

Daylight hours in broilers should last from 15 to 18 hours, since light provokes birds to frequent feed intake and weight gain, so electric lighting in a chicken coop with cages is necessary even in summer. It is best to use configurable timers to maintain the desired light mode.For broiler chickens up to 7 days, daylight hours should be around the clock, upon reaching a week of age, it is reduced to 18 hours.

4 square meters of the chicken coop should have at least 100 watts of incandescent light or 12 watts of LED lamps. It is not recommended to use fluorescent ("energy-saving") lamps, as birds get sick and lose weight due to their flickering.

Indoor humidity should be maintained at 55-65%, higher humidity can cause mold and bacteria to grow, and lower humidity can lead to brittle feathers and impaired water exchange in broilers.

Cell litter

Using sawdust or hay bedding keeps you warm and reduces the likelihood of colds and leg arthritis. The thickness of the litter should be between 5 and 10 cm.

It is important to remember that pathogenic bacteria can accumulate in the litter, in addition, the litter excludes the automatic collection of excrement on the subcellular tray, which will require an increase in the time for cleaning the premises.

The use of bedding in the cages instead of a slatted floor above the pallet is only permissible for a small number of chickens. The bedding in the cages must be changed every two days at the same time as the cage is completely disinfected. It is recommended to use dry sawdust as a material.

Using

fine water filter

the cartridge or membrane must be replaced regularly, otherwise the device may become unusable.

Using a brood hen to hatch chicks is an easy method that is great for beginners. Read more about this here.

How to store eggs for food and incubation? We talked about this in detail in our article.

Feeding rules

Feeding broilers can be started from the first week of keeping, but it is important to follow the rules of the first feeding. Since newborn chickens have a poorly developed digestive system.

For the first feeding, you can use:

- Grated white of boiled eggs;

- Finely crushed grain;

- Low-fat cottage cheese;

- Sour milk.

To feed the young, a special groove is inserted into the external feeders so that the chicks can get food. Feeders themselves should have hooks to adjust their height above the cage floor for broilers of different ages and sizes.

It must be remembered that young animals should be given a mushy feed (mash) once a day, which is prepared by diluting a dry mixture of crushed grain, corn husks and sunflower oil cake with warm water or low-fat milk, mixed in a 4: 2: 1 ratio.

Dry compound feed (home or factory) is used for feeding grown broilers. In a factory-made compound feed, all nutrients, vitamins and minerals are mixed in the right proportions, and the farmer only has to pour the feed into the feeders, but the cost of the purchased feed is much higher than the home-made one.

In compound feeds made by ourselves, the following components must be present:

- Crushed grain;

- Whole grain;

- Cellulose;

- Fats;

- Calcium;

- Vitamins.

As vitamins you can use special premixessold in agricultural markets, or chopped green weeds.

Whole grains should be mixed with crushed grains in equal proportions; for broiler feeding, wheat or corn is usually used due to the high carbohydrate content. The total content of grains should be up to 65% of the mass of the compound feed.

Fiber is necessary for broilers for normal digestion, it is found in sunflower meal, corn meal and seed husks. The fiber content in the feed should be at least 15%.

Sunflower meal also contains the fats that birds need for healthy plumage and well-being.If there is a lack of fat, you can add sunflower oil to dry food (one teaspoon per kilogram of dry mixture).

Boiled vegetables (up to 30% of the feed mass) will be a good addition to the broiler ration for self-production of compound feed:

- Potato;

- Carrot;

- Beet.

When adding food waste to a farmer's compound feed, remember that the amount of added waste should not exceed 15% of the feed mass. Waste (especially containing hard vegetables) must be boiled and chopped before adding to the feed, otherwise the chickens may choke on hard pieces of food.

Fresh water in the drinkers is an important factor in broiler health. You should know that the water for broilers should be at room temperature (not lower than +25 degrees), since chickens quickly develop colds from cold water.

So, keeping broilers in cages promotes rapid weight gain in birds due to limited mobility. A large number of broilers can be accommodated in a small area, but crowding of birds requires careful disinfection and proper ventilation of the room. Compliance with the rules of keeping and feeding broilers in cages will ensure rapid weight gain and low mortality in broiler chicken breeds.

Broiler chicken breeds are highly prized in households and farms. All modern broiler breeds are crosses obtained from crossing the best meat and egg chickens. In order not to be mistaken with the choice of the broiler chicken breed, we offer a description of the 8 most productive crosses that can be grown for meat.

Features of broilers

Broilers are distinguished from ordinary chickens by their large size and intense muscle gain due to genetics. If a regular chicken at the age of 2 weeks weighs no more than 0.5 kg, then a broiler chicken by this time can weigh more than 1 kg. Adults (5–6 months) reach a weight of 4–4.5 kg, and sometimes more than 5 kg.

The broiler has a compact body, small wings in relation to the carcass and short legs. The color of the plumage is predominantly white, although there is also an ash-black-white tricolor. These are phlegmatic and sedentary birds that prefer high-calorie feed. With proper fattening, their meat becomes tasty and nutritious in 2-3 months, so there is no point in keeping chickens any longer. With proper fattening, a broiler chicken gains about 2 kg in a couple of months and is actually ready for slaughter. Of course, not all crosses have such a growth rate. Broilers are raised to adulthood only to produce eggs and offspring.

Their productivity depends on what breeds of chickens are crossed to obtain broilers. Since the main goal in breeding crosses is to obtain meat, the egg production of these birds is low, but the hen's instinct is well developed. Of the shortcomings, one can only note the fact that broilers are not able to inherit their positive qualities, so their offspring are often weak, and crossing with each other is not practiced.

Best breeds

Every year, new highly productive crosses appear, so it is rather difficult to decide which breeds of meat broilers are best to grow. Below is a description and requirements for the maintenance of several breeds that have retained popularity over the past years.

ROSS-308

This breed belongs to the English selection. It is an ideal choice for small farms as it combines good egg production (over 180 eggs / year) with high meat performance. The daily weight gain of young animals is 55-60 g, and the chickens reach 2.5 kg at the age of 2 months. The birds are unpretentious and are able to breed quite viable offspring, which happens infrequently in broilers.

Not all consumers like the light skin color of carcasses, but this does not affect the taste in any way.

COBB-500

Broilers of this breed are distinguished by their large carcass sizes and a beautiful yellow skin tone, which is especially popular with consumers. The cross is characterized by early maturity and a rapid increase in live weight - at the age of 1.5 months, young animals weigh 2.5 kg and are ready for slaughter. It is also worth noting the high survival rate of chickens - 97%. However, the productivity of chickens is highly dependent on the conditions of keeping, diet and quality of feed.

ROSS-708

If you are interested in what breed of broilers is the best for obtaining and selling meat products, then this is undoubtedly ROSS-708. Provided the correct maintenance (diet, light and temperature conditions), young animals reach a weight of 3 kg in just 35 days. Carcasses of chickens are round, with a wide breast and short powerful legs, but the skin, again, is white. Chickens are easily adaptable and get along with other birds, which made this breed the most popular among broilers.

Broiler 61

A positive feature of this cross is a high coefficient of live weight gain with low feed costs. To build up 1 kg of meat, a chicken needs only 2 kg of feed, and with such a diet, it reaches a mass of 2 kg by the age of 1.5 months. Birds are undemanding to keeping, and the survival rate of young animals is 98%. However, due to the intensive growth, the chickens remain weak for a long time, and if you need to raise them to adulthood, you will have to tinker.

The egg production of chickens is average (140–150 eggs), but the meat is of high quality and unique taste.

Hybro-6

This is a multi-line hybrid, for which it was necessary to cross two types of chickens on the paternal and maternal lines. Cross does not differ in intensive growth (daily weight gain is 30 g) and large size - a six-month-old rooster weighs only about 1.6 kg, and a chicken is even less (up to 1.3 kg). However, the carcass of these broilers looks very attractive: the yellow skin and the large amount of subcutaneous fat put it on a par with the homemade product.

Cross Change

This is a domestic hybrid bred at the Smena breeding plant of the same name. According to its productive characteristics, it is considered universal - it combines good weight gain (up to 50 g / day), stable reproduction and good egg production (140–150 eggs per year). Unlike foreign crosses, these birds are perfectly adapted to domestic conditions. Chicks are 97% viable but require 2-3 ° C higher temperatures in the early days than other broilers.

Broiler-M

If we compare this cross with other meat hybrids, then we can say that these are poultry of the meat and egg direction. They have small muscle mass and compact build (adults weigh about 3 kg), but good reproduction and egg production. From one chicken per year, you can get about 160 eggs weighing 65–70 g. Chickens are unpretentious, they feel comfortable in cages, which allows them to be kept in factories and farms.

Cross Hubbart F 15

Choosing the best breeds of broiler chickens for home breeding, one cannot fail to note the cross of the French selection Hubbard F 15. It is characterized by high early maturity with low feed costs. Young animals are slaughtered at the age of 1–1.5 months, upon reaching a weight of 2.5 kg, since then the growth of birds slows down. This, of course, is not the most unpretentious cross. Its productivity depends on the quality of feed, keeping conditions (temperature, humidity, hygiene, density per 1 m²), and even climate, but the excellent taste of these chickens is worth it.

Video "Growing broilers"

This video will show you how to raise broilers at home.

In connection with the wave of "revelations" of well-known food manufacturers, people are seriously concerned about the quality of the food they consume and what they feed their children. It is not surprising that natural, farm products are becoming more and more popular.

If you are proud of the quality of your poultry meat and are ready to deliver it to the shelves, carefully consider how you can provide the required volumes. Most often, novice farmers are very limited in the area that can be used for keeping and walking chickens. Here, the best option would be to keep chickens of meat breeds in cages.

…

Raising broilers is fundamentally different from breeding egg chicken breeds. The main goal is to get the highest possible gain in the shortest possible time.

An important factor in the efficiency of cultivation is the consumption of feed, which will increase with the extension of the cultivation period. Therefore, in the industrial poultry industry, they try to reduce the duration of broiler feeding as much as possible - usually it is 35-40 days, while the poultry reaches an average weight of 2-2.5 kg.

Broiler cages are much more economical than floor rearing. True, this method has its drawbacks. Therefore, most meat producers raise broilers on deep bedding, and only in the last decade, with the advent of modern cage batteries, the cage is gaining more and more popularity.

Let's talk about why it is profitable to grow a bird in a cage and how this method looks in practice.

Unconditional pluses

The benefits of growing broilers in a cage are clear.

- Saving space, and, therefore, energy costs - lighting, heating, ventilation per head and one kg of weight gain.

- Saving feed due to its target consumption - the bird does not pick in feed and bedding and does not scatter compound feed.

- Increased body weight gain. The broiler is organic in movement, and, therefore, a significant part of the feed energy is directed to the growth of the bird and is not wasted.

- Restricting bird contact with each other - the chick only comes into contact with the neighbors in the cage. This has a beneficial effect on the veterinary situation and prevents the spread of infections.

- Manure is removed from the poultry daily. She does not comb in the litter, does not eat droppings, does not breathe ammonia. It also significantly reduces the risk of infectious and respiratory diseases. And if, nevertheless, an outbreak of the disease has occurred, it is easy to stop it, since the infection will spread slowly due to the limited contact of the birds with each other.

- Optimization of the process of feeding and drinking, caring for poultry and inspection of livestock, reducing the cost of service personnel.

- If necessary, it is easy to "thin out" the herd by taking part of the livestock from the cage for early slaughter.

Cellular content reduces the period of fattening by an average of 3-5 days, which in an industrial production gives a tremendous profit.

Minuses

What are the disadvantages of broiler cage raising? To get the desired effect, you will have to spend time and invest, namely:

- the cost of producing a cage or buying a ready-made set of equipment;

- creating favorable conditions for the chick in the house - temperature, humidity, ventilation and lighting;

- costs for compound feed or other balanced feed mixtures;

- the need to remove droppings daily;

- with a large weight in broilers on a mesh floor, problems with legs begin, bumps on the chest are possible, which affects the quality of the carcass;

- laborious process of disinfection after freeing the cage from the bird;

- the taste of meat and eggs of free-range chickens (in an ordinary chicken coop) is much higher.

As you can see, cellular equipment needs a good preparatory period, but in the process of operation there are practically no minuses, only pluses.

Cell batteries

How are broilers grown industrially? Cage batteries for poultry are produced by many Russian and foreign manufacturers. The most famous are German Big Dutchman, Belgian Roxel, Dutch Systemat, domestic KBP-B, BKM-3B, 2B-3.

Cell batteries are mounted in 4-6 tiers. The poultry house can be 25x120 meters in size, one room contains up to 150 thousand broiler chickens. There is a feeding and drinking system in the cages, sometimes artificial lighting lamps are additionally mounted. The floor near the cage is retractable (this is necessary for the catching technology), under the floor there is a manure removal tape.

Each battery is equipped with a feed and water supply system, manure removal lifts. The poultry house has an automatic heating and ventilation system designed for summer and winter. All technological processes are controlled manually and automatically through the shop computer.

Taken together, this creates a rather complex equipment system that requires constant attention and maintenance.

Backyard cage

In personal subsidiary plots, small batteries in two or three tiers, manufactured industrially or by hand, are often used. There are many options for such cells.

Turnkey version with installed feeders and micro-bowl drinkers.

Today, there are enough offers in the sector of cages for growing broilers on the market of domestic producers. They are designed for different levels of mechanization of the process (manual or automatic feeding and manure removal) and for different numbers of birds.

How to make yourself

You can make a broiler cage with your own hands at home. To do this, you will need material for the frame - a wooden beam or metal profile, a grill for the floor and walls, galvanized sheets for the pallet under the floor.

In such a cage, you can put an ordinary feeder and drinker for chickens, but this is convenient only with a small number of birds - up to a hundred heads.

When keeping a significant number of broilers - 200, 500 and more heads, the cage must meet the following requirements:

- the number of birds in one section - from 10 to 25 heads;

- cages are arranged in batteries, in 3 or 4 tiers;

- material - galvanized mesh (wood in this case is less wear-resistant);

- hand feeding - trough feeders outside the cage;

- mechanized feeding - feeders with an "umbrella" inside the cage;

- nipple water supply system inside the cage.

Subject to planting norms (about them - below), young broilers feel great in the cage.

Manure removal is usually carried out manually - for this, there are galvanized pallets under the cage, which should be easily pulled out. At first, during 5-7 days, the droppings can not be removed, then, as the chickens grow, they are cleaned every two to three days, at the end of the fattening period - daily.

For large farms, it is advisable to equip a mechanized belt system for manure removal.

The mesh of the floor should be fine enough to prevent day old chicks from falling through their legs, but not too much for droppings to fall freely onto the pan. Some manufacturers produce cages with plastic floors, which are preferable in terms of reducing poultry injuries.

The side walls can be made of plywood or fine mesh, the front wall is made of a longitudinal grate to provide access for birds to the feeders.

For day-old chicks, additional galvanized trays are installed in the external feeders so that they can easily reach the feed.

Microclimate in the chicken coop

The house needs to be kept at the recommended temperature and humidity, which will require a heat source. Broilers also need artificial lighting.

If the house contains a large number of chickens, then a forced ventilation system will be needed to ensure the flow of fresh air, and in the summer - to lower the temperature in the room.

Unlike laying hens, small broiler chickens need to be kept at a high temperature, while large ones generate a lot of heat and, on the contrary, must be removed, otherwise the bird may get heat stress.

Zootechnical norms

When growing broilers in a cage, the following zootechnical standards are followed.

- Stocking density - 20-25 heads per sq. m. polik area, but not more than 40 kg of live weight at the finish of cultivation.

- Feeding front - 2-2.5 cm per head (flute) or 40-70 broilers per round feeder.

- The drinking area is 10-12 heads per nipple. Vacuum drinkers (for the first days of chicks' life) - one per 50 heads, flute drinkers - 2 cm per head.

- Indoor air temperature: when day-old chicks are planted at a level of 32-34 ° C, then it decreases by about 0.2 ° C every day, by the 7th week of rearing it reaches 16-18 ° C.

- Humidity from 50 to 70%. The health of the bird's respiratory system and the temperature it perceives depends on the level of humidity. With high humidity in the hot season, the temperature is felt as higher; with low humidity, there is a large loss of fluid in the body.

- Light mode. Day-old chickens are given 23 hours of daylight hours, then from day 7, its duration is reduced to 16-20 hours, depending on the growth rate and feed consumption. In general, it is impossible to save feed on broilers - the more the bird eats, the faster it will grow. Therefore, the light regime should be aimed at stimulating the consumption of the compound feed by the bird.

When growing broilers in a cage, they often use the “meat removal” method - the males are slaughtered earlier, and the chickens are kept for another 5-7 days to gain live weight. Or, at the age of about 35 days, 20-25% of large birds are taken, and the rest is raised for another week. In this way, they free up space in the cell and prevent aggravation of food competition.

In addition, a heavy bird often "sits down" on its feet, which is associated with poor development of the musculoskeletal system (bones, ligaments) due to lack of movement. We wrote more about this here.

conclusions

Summing up, we can say that cage growing of broilers is beneficial both in industrial poultry farming and in subsidiary farming. The farmer determines the degree of mechanization of production based on the amount of labor, the total number of poultry raised for meat, and the year-round production.

When grown in the summer for their own needs (50-100 heads of poultry), you can get by with 2-4 simple homemade cages. And if it is planned to produce meat for sale (1000 heads of a one-time planting or more) and receive serious profits, then factory-made structures with a nipple water supply system, mechanized feed distribution and manure removal are selected.