Content

- 1 Selective grade

- 2 1 VARIETY

- 3 2 GRADE

- 4 3 GRADE

- 5 4 GRADE

- 6 What class to build a frame for a house

- 7 Peculiarities

- 8 Wood: grade 1

- 9 Wood: grade 2

- 10 Grades 3, 4, 5

- 11 Needles

- 12 Hardwood

- 13 Defects

- 14 How to choose

- 15 What you need to pay attention to

- 16 Properties of wood of various species

- 16.1 1. Pine

- 16.2 2. Spruce

- 16.3 3. Larch

- 16.4 4. Cedar

- 16.5 5. Yew

- 16.6 6. Oak

- 16.7 7. Ash

- 16.8 8. Beech

- 16.9 9. Hornbeam

- 16.10 10. Common birch

- 16.11 11. Maple

- 16.12 12. Alder

- 16.13 13. White acacia

- 16.14 14. Walnut

- 16.15 15. Linden

- 16.16 Choosing wood for furniture

- 16.17 Wood species for furniture

- 16.18 Wood furniture production

In the previous article, I touched on the type of wood, because sometimes the difference in price can reach two or three times. It turns out that wood has long been distinguished according to GOST, and there are five different types ...

CONTENTS OF THE ARTICLE

- Selective grade

- 1 VARIETY

- 2 GRADE

- 3 GRADE

- 4 GRADE

- What class to build a frame for a house from + VIDEO

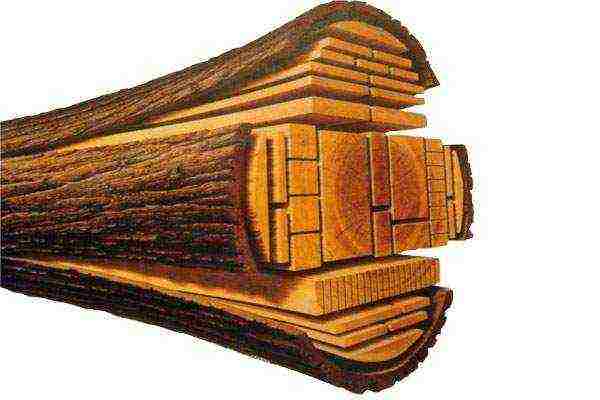

According to state standards, both boards and bars differ. GOST 2695-83 sets out the basic requirements for deciduous types of lumber, while GOST 8486-86 and GOST 24454-80 defines for coniferous materials.

The main requirements are moisture, deformation during drying, clear dimensions, as well as the presence of knots and other irregularities.

With a humidity of 20%, some size requirements are set, and with a higher or lower humidity, others. By the way, this indicator is described by GOST 6782.1 - 75

Evaluation of lumber occurs on the plane and the edge, the worst for the board. The bars are rated on the worst side.

Now let's go through the varieties:

Selective grade

The most expensive type of wood, may be called class "A", is 2 - 3 times more expensive than the first grade.

They are mainly used in shipbuilding and automobile construction. They can be used to make the "boards" of trucks, part of the cabins, in shipbuilding they are used to make deck boards, elements of cabins, sometimes yacht masts, etc.

Basic requirements - knots are permissible, but only large, or at a distance of 2 meters from each other. Rotten knots and rotten wood parts are not allowed. Cracks may be present, but they should not be more than 10%, and they should not be deep, mainly formed as a result of shrinkage. The inclination of the fibers is not more than 5% of the length. There should be no part of the root system in the wood. That is, the lumber must be clean without any flaws.

1 VARIETY

Or class "B". It is also used in industry, but is already used in wood production. The cost is cheaper, but the quality requirements are lower.

Basic:

- rotten, falling out knots, more than 10 mm, are not allowed.

- through cracks, the depth of which is more than 1 mm and the length of which is ¼ of the length of the lumber, are not allowed.

- there should be no elements of rotten wood, as well as elements of "dead" bark or overgrowing wounds.

- rottenness, elements that are gray, mold or inclusions of foreign parts are not allowed

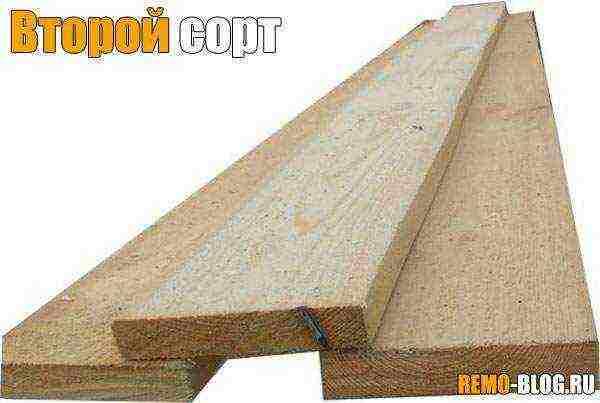

2 GRADE

Class "C". The requirements are no longer so strict, they can also be used in the production of furniture, however, in closed places, for example, the frame of upholstered furniture or beds.

Primary requirements:

- There should be no large knots larger than 20 mm that fall out or rot.

- Cracks with a depth of 1 mm and a length of 1/3 of the length of the lumber are not allowed.

- Rottenness, rotten places, parts affected by parasites are not accepted.

- Foreign bodies and mechanical damage are also unacceptable.

For this grade, some "defects" of wood are allowed, but only those that do not spoil the general characteristics and impressions.

3 GRADE

Class "D". In reality, this is a low level of wood. But it is also very cheap, it is mainly used in packaging production, usually boxes, boxes and the rest of the container.

Primary requirements:

- Large intergrown knots and end cracks are not allowed, to the full depth.

The rest of the flaws are almost all permissible, even rotting and damage to the wood layer and sharp slopes of the fibers.

Usually these are scraps from the first and second grades of sawn timber or really low-quality wood.

4 GRADE

Class "E".The lowest class, therefore, it is used for secondary production, for example, make temporary fences at construction sites, formwork for the foundation, pallets, scaffolding. Can be used for "temporary huts" or sheds.

As you understood, all the remaining imperfections are allowed here, all the scraps from the previous classes go here.

The price is the lowest, usually 5 - 7 times lower than the "select type".

It seems that there is a lot of information, but in reality the differences between even the "selected" class and the "first" are striking, they can be seen, what is said not with an armed eye. A selection bar or board, even without flaws - knots, etc., just an even "layer". The first grade may already have small knots and cracks.

What class to build a frame for a house

You can often hear such a question - guys, the frame should not be lower than the second class of wood (and preferably either "first" or "selected"). Moreover, it is necessary that he had additional treatment from decay and absorption of moisture, only then he can stand for a really long time. Also, the drying of the wood must be carried out correctly.

A small video of how to choose wood in Egypt, there are already 7 classes.

Here is such information, I think it was useful to you. Read our construction site.

The modern assortment of wood materials is characterized by an extensive selection, which is why it is often difficult to determine the quality. Despite the fact that the accompanying documentation displays basic information and characteristics, do not forget about the recommendations of professionals involved in the sale of timber. Before buying, you need to familiarize yourself with possible defects that have a direct impact on the cost and properties of the material, as well as with the processing methods and structural features that wood has. Varieties, breeds, and growing conditions are key aspects of the selection of quality material and the optimal option for its use.

Peculiarities

Lumber, like any other building material, is classified by grade. This parameter depends on the quality of wood processing and its characteristics. To determine the species, a special tool is required, so this is most often done by professionals. In any case, it is necessary to pay special attention to the appearance of the purchased product to determine the quality and purpose.

Wood: grade 1

The varieties are designated by numbers from one to five. The exception is the selected type of wood, GOST which has a stricter framework regarding the quality of this material. It is used in shipbuilding and does not have the slightest defect.

First-class workpieces may show signs of small cracks, knots and splits. At the same time, there should be no dark spots, traces of parasites, decay, fungus and mold. As an example, you can use an edged board - it should be dry, without dead particles, longitudinal through cracks and noticeable damage. There should be no core, roll, and the total inclination of the fibers can be within 5%. Such products are distinguished by the absence of flaws and an attractive appearance. They are used in finishing, exterior, interior work and in the construction of load-bearing elements.

Wood: grade 2

This material, unlike the first, can have a lot of flaws. It may have cracks with a length of no more than a third of the entire product. At the same time, the parameters of their width and depth remain at the same level. The presence of one large trail of parasites or several small ones is possible. The first and second types of wood have minimal differences, so the last option has become most common in outdoor work.

Grades 3, 4, 5

The third grade of lumber is intended for flooring, sheathing and carries light loads.Almost all types of defects can be present on it, including traces of wormholes, rot, dark spots and mildew. The presence of deep cracks with a length of no more than the entire length of the product is possible.

The fourth grade is used when cutting into small pieces, erecting elements under minimum load, as well as for the manufacture of containers and packaging. The main requirement of GOST is the integrity of the elements, while any defects in the surface and the entire structure may be present.

The fifth grade has the lowest quality. It is not intended for upholstery, furniture making or other work. It is used most often for lighting fireplaces and stoves.

All types have different costs and are used in certain areas of activity. Knowing the types of wood, you can not only choose the right material with the required characteristics, but also save your budget, since in some cases they can replace each other.

Needles

The wood has a resinous, tart odor and a sharper structure. The most widespread are cedar, fir and pine, they are used both in the production of various items and in the construction of houses and other objects. The leading place is occupied by pine, it can have a different shade, which does not depend on the quality of processing.

Among the advantages, it is worth noting lightness, strength, resistance to negative weathering and decay processes due to the high content of resins. It has a loose structure that provides high adhesion to paints and varnishes.

Spruce is in second place in popularity. It does not have such an extensive list of advantages as pine, it is more difficult to process due to its denser structure and many knots. Due to the minimal resin content, spruce products are moderately resistant to atmospheric precipitation and decay.

Coniferous wood varieties are classified in the same way as deciduous ones, their quality standards are determined by GOST 24454-80. It is worth noting that in addition to the numerical designation, you can often find markings in the form of letters from A to E. This must be taken into account when buying material in order not to make a mistake with the choice.

Hardwood

Products obtained from deciduous trees are distinguished by the greatest distribution and the minimum, almost imperceptible smell, which becomes noticeable only during processing and cutting. Hardwoods (such as oak, ash and birch) are indispensable in furniture and flooring. Each of them has its own characteristics. For example, oak has high strength characteristics and resistance to decay. The solid structure allows you to create the finest patterns on the surface, use it to create fasteners and curved elements.

Aspen, linden and alder are soft woods. This variety is common in construction and is produced in the form of profiles, lining, logs and beams. Softwood has a lower density than its wood counterpart and must be treated with special protective compounds to prevent decay.

Defects

Defects are traces of mechanical damage that occurred during processing and transportation. Fiber tilt often appears after separation from the longitudinal axis. Curvature is often present near the knots, which can be through, resulting in a deterioration in the quality of the material.

The quality of wood is affected not only by the species, but also by the growing conditions (temperature, humidity). Material of the same type, cut in different regions, may have slight differences in hardness. This parameter is measured on a special scale, the starting point for which is the hardness of the oak.

The strength of products reflects resistance to mechanical damage and varies depending on the presence of defects, moisture and breed. Tensile strength refers to the stress that leads to a breakdown in the integrity of the material.

How to choose

It is recommended that you inspect the materials yourself before purchasing. Remote ordering is possible only from reputable suppliers. Before heading to the warehouse, it is worth taking a plane with you, with which you can quickly clean up dirty areas to check the quality of layers and color.

Inspection for fibers, uneven layering, knots and cracks is of particular importance. Drying of wood affects the quality and the possibility of further use. With an illiterate execution, cracking, violation of geometry and resizing are possible.

What you need to pay attention to

Most suppliers have soft softwoods available - pine, fir, spruce and others. As a rule, this material is sold in the form of elements with standard dimensions. In this case, one or more surfaces can be processed. This must be taken into account, since after planing, the dimensions of the parts are reduced by a few millimeters, and the actual parameters will differ from the data indicated by the sellers.

Sorting of softwood is carried out according to the presence of minimal defects (small cracks, knots) and the uniformity of the layers. This classification is suitable for the selection of lining and other finishing materials. Furniture and joinery requires quality options with a flawless appearance. High strength is necessary in the formation of structures, materials suitable for this purpose are usually not available in the construction markets, as they are made to order.

Before buying, you need to make sure that you have certificates and product documentation. It is worth noting that not all types of wood must pass through mandatory certification, but most manufacturers try to arrange all the products they sell in due form.

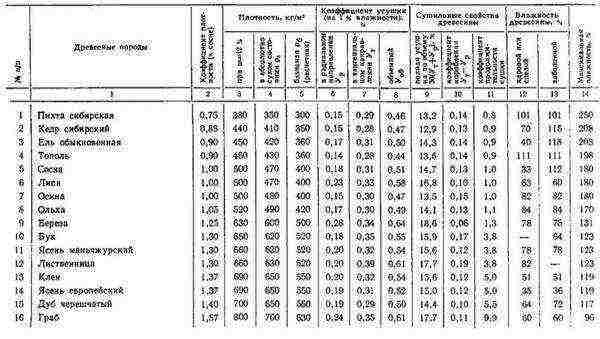

Properties of wood of various species

The main parameters by which commercial wood is selected for the production of furniture: strength, resistance to deformation, wear resistance. All these three qualities are combined into one indicator - the density of wood, that is, the ratio of the mass of a tree to its volume.

Types of wood depending on density:

A) Soft (up to 540 kg / m3) - spruce, pine, aspen, linden, fir, poplar, chestnut, alder, cedar;

B) Hard (550-740kg / m3) - larch, common birch, oak, elm, beech, sycamore, walnut, maple, apple, ash;

C) Very hard (from 750 kg / m3) - iron birch, mountain ash, white acacia, hornbeam, dogwood, boxwood, pistachio tree.

Consider the breeds most in demand in the furniture industry:

1. Pine

Wood color - brown, beige-yellow, white with light pink stains. The best material for making furniture is considered to be pine trees growing on hills with sandy soils or on dry hills. In such wood, the annual layers will be pronounced and narrow, close to each other. Pine grown in an area with high humidity will have a loose structure, and the blanks from it will have to be dried for a long time before being put into production. Pine wood is soft, easily scratched and damaged.

Pros:

- pliability in processing. Pine is easily planed along the grain, but with difficulty in the transverse direction. When sawing, the opposite is true - it is easy to cut across the log, but poorly along the length.

- easy to stick together;

- depending on the color and structure of the wood, pine is used both for the manufacture of furniture with subsequent varnishing, and for frames, and various structures with hardwood veneer facing;

- like all conifers, it has a pleasant smell, it releases phytocysts, which are considered medicinal.

2. Spruce

Spruce wood is softer than pine. In addition, the trunk contains a large number of knots, which make it difficult to process the wood for the manufacture of furniture panels. Compared to pine, spruce absorbs moisture better and begins to rot faster. Due to its low-expressive texture and low strength, spruce is most often used for mosaic decoration or in structures that do not experience significant stress during operation.

Pros:

- spruce wood is practically not subject to warping;

- perfectly sticks together.

Siberian fir is also used along with spruce - these two trees have similar characteristics.

3. Larch

The wood of this coniferous tree is prized for its unusual reddish-brown hue and high performance. From disadvantages of larch - a large amount of resins, which quickly destroys tools and causes difficulties in processing. If not properly dried, internal cracks form on larch wood.

Pros:

- high moisture resistance;

- excellent strength indicators (the best among conifers);

- slightly susceptible to warping;

- used for the manufacture of carved parts.

4. Cedar

The yellowish-white cedar wood is not distinguished by its high strength and density, therefore it does not withstand heavy loads.

Pros:

- resistance to decay and wormhole;

- suitable for carving;

- has a specific woody aroma.

5. Yew

Red-brown yew wood with light and dark veins has high strength, but also a large number of knots.

Pros:

- not exposed to a wormhole,

- easy to plan and grind,

- insensitive to atmospheric changes.

6. Oak

On the radial section of the oak trunk, large heart rays and light sapwood are clearly visible. Oak is the most widely used hardwood in solid wood furniture due to its excellent combination of strength and texture beauty. If the oak remains in water for a long time (several decades), its wood acquires a rare dark purple color with a green tint. Oak wood is difficult to polish, requires equipment with high hardening cutters.

Pros:

- despite the high viscosity of wood, it is processed quite well;

- bends easily;

- resistant to decay;

- lends itself well to methods of artificial aging.

7. Ash

The wood is similar in many qualities to oak, but lighter and does not have pronounced core rays. Ash trees must undergo antiseptic treatment, since in conditions of moisture, wood is quickly damaged by a wormhole. Poorly polished.

Pros:

- bends well after steaming;

- little cracking during drying;

- when discolored, it acquires an unusual shade of gray hair.

8. Beech

Beech wood is not inferior in strength to oak, but it is highly hygroscopic, therefore it is not recommended for the manufacture of furniture that will be used in high humidity conditions (bath, kitchen). Poorly polished.

Pros:

- high decorative qualities: beautiful texture both in radial and tangential section,

- quick to dry, does not crack;

- easy to handle: pricks, saws, cuts, bends;

- perfectly bleached and colored with the help of special solutions, - practically does not change the beautiful natural shade during varnishing.

9. Hornbeam

It has a solid, dense wood of a grayish-white color. It is often called a white beech, but the texture of the hornbeam is not so pronounced and often has an oblique structure, due to which the tree does not prick well.

Pros:

- after high-quality drying, the hornbeam becomes harder than oak;

- not subject to warpage;

- lends itself well to etching and finishing.

10. Common birch

Birch wood, despite its high density, is unstable against rotting, therefore it is used mainly for the manufacture of plywood, peeled veneer, chipboard. It dries for a long time and poorly, prone to a wormhole, cracks heavily, warps.

Pros:

- homogeneous structure and beautiful color of wood;

- bends well;

- in the production of solid wood furniture it is used as an imitation of valuable rocks (it is well colored when etched).

Separately, Karelian birch is distinguished, which has higher performance indicators, is known for its unusual texture and pink color of wood. It is expensive, therefore it is mainly used for veneering of solid wood furniture.

11. Maple

Despite the fact that dense maple wood rarely cracks, it is unstable against dampness. The most prized maple is bird's eye and sugar maple because of its characteristic beautiful structure.

Pros:

- easily pricks, well processed: cut, polished;

- has a homogeneous structure without pronounced fibers;

- when stained, it successfully imitates valuable breeds;

- maple wood does not have a pronounced core, therefore it is easily painted, varnished, stained.

12. Alder

Soft breed, no pronounced structure. Alder wood quickly darkens in air, therefore it is used mainly in a dyed form (like ebony or mahogany). Alder Feature: Wormhole exposed in dry locations, but resistant to rotting in wet conditions.

Pros:

- dries quickly

- easy to carpentry,

- well polished,

- warps slightly.

13. White acacia

The hardest hardwood, therefore, has a high frictional resistance, is distinguished by its elasticity. In dry form, it is difficult to process, therefore it is used mainly for cladding soft rocks.

Pros:

- perfectly polished;

- when exposed to air, the wood darkens, giving the texture a bright yellow-brown color and expressive texture.

14. Walnut

The older the tree, the more valuable and darker its wood. The most expensive variety is American Black Walnut.

Pros:

- a wide variety of shades;

- dense, but pliable wood;

- easily dyed due to the high content of tannins (from ebony tint to even white).

15. Linden

It is used in production for the manufacture of shaped turned elements. It contains little tannins, therefore it practically does not stain, but it lends itself well to staining (with the correct concentration of the solution, linden wood can be given the appearance of more valuable tree species). Needs antiseptic impregnation, as it is highly susceptible to a wormhole.

Pros:

- well withstands dampness,

- wood is durable and plastic,

- has a beautiful white and creamy shade.

As you can see, each wood has its own advantages and disadvantages, focusing on which you can choose a certain grade for the manufacture of solid wood furniture.

Furniture items made of wood bring a noble, eco-friendly and cozy touch to the overall interior. When choosing a type of wood for the production of furniture, experts take into account a wide range of factors: shade, texture, pattern and mechanical qualities of raw materials.

Choosing wood for furniture

When emphasizing the aesthetics of solid wood, it is often forgotten that it is very hard, porous and moisture resistant. As a result, a lot of troubles can arise when using the furniture.

If you decide to make some furniture yourself, you should know that hard and dense types of timber are characterized by excellent performance, but they are very difficult to process. Having opted for a solid "exotic" home craftsman is unlikely to be able to cope with high-quality sawing or grinding. This requires special equipment.However, the choice of inexpensive and easy-to-handle timber will not do anything good. From such raw materials "one-day furniture" is obtained, which after a few years takes on a shabby look. If you do not have special equipment, then you will most likely be able to create solid furniture for a summer residence, and for regular use it is better to give preference to pieces of furniture made by professionals. Special equipment allows you to smooth corners, make an even cut, chamfers and carry out high-quality finishing of surfaces. It is these processes that transform a solid wood product into an elite piece of furniture.

Timber are:

- soft: pine, alder, birch

- medium: oak, beech, cherry

- hard: merbau, maple, most of the exotic.

In addition to strength, it is worth paying attention to moisture resistance, because solid wood does not necessarily have to be moisture resistant. For example, a fairly hard beech behaves very moody in high humidity conditions, while a moisture-resistant teak, on the contrary, is rather soft. An interesting option is the thermowood, which has recently appeared on the market, which is made by processing timber with a very high temperature of 200 to 300 degrees. After that, the timber becomes very hard and at the same time moisture resistant.

Wood species for furniture

Performance is of course important, but design should not be forgotten either. Any master, first of all, must decide on the finishing type of furniture. To this end, you need to familiarize yourself with samples of timber, study the structure. If the master is interested in the texture of the future product, it is worth choosing oak, ash, walnut or brushed pine. Furniture items made from this timber do not need additional descriptions. It is immediately clear that this is a natural tree. If you need a smooth surface, for example, for a table, pay attention to birch, linden, maple, cherry, beech.

Naturally, furniture from hard grades is strong and durable, but furniture is also produced from softer grades. Each type of timber is characterized by its own, unique and inimitable qualities. Consider the types of wood from which furniture items are most often made in our country.

Walnut timber is a hard variety. This raw material is distinguished by a variety of shades. There are over a dozen types of walnut wood, but the most valuable is black walnut, which is used only for decoration and decoration of elite items. Walnut is hard and heavy, but interesting to work with because it is easy to work with. Carving on this raw material is very popular, because it almost never gets chipped.

Walnut timber is a hard variety. This raw material is distinguished by a variety of shades. There are over a dozen types of walnut wood, but the most valuable is black walnut, which is used only for decoration and decoration of elite items. Walnut is hard and heavy, but interesting to work with because it is easy to work with. Carving on this raw material is very popular, because it almost never gets chipped.

In general, birch is the most accessible raw material in our country, because birch groves are very widespread and logging is carried out throughout the country. Note that its mechanical properties are similar to beech. Birch timber is excellently glued, etched with dyes and polished, which is very important for choosing a color. With the help of wood stains, birch can be painted well. Veneer is often made from birch. Of the shortcomings, it is worth noting the rapid defeat by microorganisms. The structure of the Karelian birch is interesting - sometimes it looks like marble, or has unique patterns.

Oak furniture wood is characterized by hardness, durability and long service life. Shade from light yellow to yellowish brown. Sometimes there may be a green or gray tint. It is easy to paint, dry, varnish. It is not subject to destruction and warping, it is difficult to prick. Bending, gluing, grinding and drilling oak raw materials is quite simple. Oak carving is difficult, but the result exceeds all expectations. Oak is resistant to microorganisms and can be called one of the most demanded materials.

Beech timber is also distinguished by its durability and hardness.Moreover, they are quite plastic from pink-yellow to reddish-brown. Most often it is used as a solid wood, less often as a veneer. Curved beech wood furniture is very popular. Beech is easy to process, it can be dyed, bleached, polished, toned. The cost of such furniture is slightly lower than that of oak.

The unusually hard larch timber is very beneficial for human health, because biologically active compounds are deposited in them, including bioflavonoids, which eliminate free radicals. Phytoncides are released from such products, which prevent colds and viral diseases. The color range has about 12 shades, and is often used not only for the production of furniture, but also as a finishing material.

Pine timber is soft and light in color. Pine furniture is easy to scratch. Nevertheless, it is in demand in the production of cabinet furniture. Timber is resistant to microorganisms, moisture, temperature changes. Such furniture has a pleasant unobtrusive coniferous aroma.

Pine timber is soft and light in color. Pine furniture is easy to scratch. Nevertheless, it is in demand in the production of cabinet furniture. Timber is resistant to microorganisms, moisture, temperature changes. Such furniture has a pleasant unobtrusive coniferous aroma.

Raw materials from linden are white, they are durable and plastic very often carved objects are made from such raw materials. It is difficult to stain due to poor permeability. However, after staining, it easily acquires shades of valuable varieties. Linden is susceptible to infection by various pests, so it must be treated with protective compounds.

Cherry is used for the production of luxury furniture. After a while, such furniture becomes darker, looks great together with carvings and glass. It is processed simply - it is easy to bend, plan, varnish.

Maple furniture is a rarity. Maple timber is distinguished by its density, heavy weight, and durability. This wood is used as veneer in the processing of expensive types of furniture. The Canadian maple is the most beautiful. Its veneer has an unusual and memorable texture.

Furniture made of cedar wood is not often found in the home itself, but it is often found in buildings with high humidity, for example, in saunas. Cedar raw material has a low density, is characterized by increased resistance to moisture and is practically not affected by microorganisms.

Wood furniture production

What wood is better to buy furniture from - it is up to the buyer to decide. But in order to make the right choice, it is necessary to study the properties of the main varieties of timber, at least in general terms. It would be wrong to ask the question: what is the best wood for furniture? Each type of timber is good for certain products and conditions.

In the process of producing wooden furniture, craftsmen use ready-made furniture boards or edged solid boards. After sawing and drying, the forestry districts sell the boards to construction companies. Today the cost of one m3 of edged pine board is 6500-7500 rubles. Manufacturing solid wood furniture is quite expensive. This process requires very high quality materials. The raw materials used must necessarily correspond to the use of length and width. Such timber should be free from defects, because they reduce the life of furniture items.

In the process of producing wooden furniture, craftsmen use ready-made furniture boards or edged solid boards. After sawing and drying, the forestry districts sell the boards to construction companies. Today the cost of one m3 of edged pine board is 6500-7500 rubles. Manufacturing solid wood furniture is quite expensive. This process requires very high quality materials. The raw materials used must necessarily correspond to the use of length and width. Such timber should be free from defects, because they reduce the life of furniture items.

Massively furniture is made of glued furniture board. Its advantages include:

- it is an economical material

- after gluing the shield has increased strength

- glued raw materials almost do not change their size with fluctuations in temperature and humidity conditions

- this material has less internal stress

- the shield is less prone to warping

- glued panels can be made in absolutely any size.

Experts pay a lot of attention to the paint and varnish coating, which will act as a protector of wood from external factors. In addition, coatings increase the level of resistance to moisture, thereby increasing the life of the products.