Content

- 1 What is lining

- 2 What lining is made of

- 3 Lining grades

- 4 Extra grade

- 5 First grade

- 6 Second grade

- 7 Third grade

- 8 Comparative table of lining by grades

- 9 Price differences between the varieties of lining

- 10

- 11 Types of varieties

- 12 Scope according to classification

- 13 Conclusion

- 14 # 1. What are the main advantages of wooden lining?

- 15 No. 2. What is the difference between ordinary lining and euro lining?

- 16 No. 3. What size lining is needed?

- 17 No. 4. Which wood is best?

- 18 No. 5. Which lining profile is better?

- 19 No. 6. What kind of lining is better to choose?

- 20 No. 7. Is it possible to distinguish low quality lining?

- 21 No. 8. Which manufacturers can you trust?

Lining is the perfect finish for any space. With its help, you can emphasize the natural beauty of the interior. The warmth of wood will make your home cozy. Wooden walls will emphasize the unity with nature. Someone says that these are relics of the past, but they are not.

Content:

- Views

- EXTRA

- Grade A

- Grade B

- Grade C

- Comparison

When choosing and buying this material, you need to pay attention to the class of the product. Choosing the right kind of lining will help you save money when decorating your premises.

So, if you want to use this material to decorate the utility room, then it is not at all necessary to buy an expensive one. In this case, it is advisable to take category B or C. It is impossible to answer which grade of lining is better, without having an idea of \ u200b \ u200bthe area of its application.

Views

The difference between varieties is primarily based on the presence or absence of external defects. All products are manufactured using the same technology. Separation occurs after sorting. Read more in the article - types of lining from A to Z.

In total, according to GOST, 4 types are distinguished:

- Premium or Extra (premium grade)

- Class A (1st grade);

- Class B (grade 2);

- Class C (grade 3).

Video - how you can be fooled when selling:

Lining of class "Extra" or "Premium"

This category has the highest price. On visual inspection, you will not notice any defects. Without a hitch - it's about her. Typically, these webs are produced by splicing.

This category has the highest price. On visual inspection, you will not notice any defects. Without a hitch - it's about her. Typically, these webs are produced by splicing.

If this method was not used, then it would cost fabulous money, since very few ideal boards are obtained from a single piece of wood. This material is smooth to the touch. You will not notice any knots or chips.

Manufacturers often vacuum pack it. This is done to reduce the risk of chipping and deformation during transportation. This type is considered elite. They are not ashamed to sheathe the rich interiors of a country house. Fasteners are usually sold in the kit. To you no need to adjust it during installation - it will fix perfectly.

When buying, do not trust the manufacturer's inscriptions. Check the category by personal inspection. If the seller refuses this request, it is better not to take it, as he knows about the trick. It also happens that perfect boards are placed on top in the package, and lower quality ones are hidden inside.

When mounting, use only special fasteners so as not to damage the material. Varnish is the perfect finish for this category. It will allow you to further reveal the beauty of the tree and emphasize its undeniable advantages.

Lining class A

It is in many ways similar to its more expensive brother. GOST determines the type of lining, therefore, comparing products from different manufacturers, you can see discrepancies in the quality of production.

Class A finishing material for some, sometimes better than the Premium category for other manufacturers. In this case, focus on the appearance of the product.

It is distinguished by a small number of defects... There are no “falling out” knots.If there are cracks, then they are not through and occupy an insignificant percentage of the total volume of the board. The core takes no more than 20%.

There should be no rot or blue on such a product. Black knots are also not allowed.

This type is used for front finishing work. Defects do not need to be shaded with paint. An excellent option for decorating it is varnish. It emphasizes the natural "shapes" of the product. Oils and wax will also work.

Premium and Class A are the grades of lining that are most suitable for finishing residential premises.

Class B

Manufacturers still use the name 2nd grade. This product contains visible and significant defects.

Manufacturers still use the name 2nd grade. This product contains visible and significant defects.

In this category, unevenness in the locking part (at the end) is permissible. Although this does not really interfere with installation.

Size of defects (chips, dents, gouges and cracks) should not exceed 3 cm by 60 cm running meter... On the finished product, you can find blueness (the value should not exceed 10%), resins, knots and core.

However, cracks should not be through and protrude into the butt end. Most of the defects are of a factory nature. Slight rot (no more than 10%) and wormholes (no more than 3 per linear meter) are possible.

In order to make the marriage less noticeable, special grouting and painting are used. The latter is preferable in dark tones.

This option is considered the most budgetary. It is available to a wide range of people.

Class C

This option is the lowest quality and, accordingly, the most affordable.

This option is the lowest quality and, accordingly, the most affordable.

Scope of application - rough work and utility rooms. Requires a large fit during installation and the difficulty of painting to tidy up the surface during finishing.

The percentage of defects on the surface is off the charts. They also include falling out black knots, through cracks, chips, remnants of the bark and core.

Some manufacturers classify frankly defective products in this category, although according to GOST this should not be. A rare specialist will agree to work with such material. During installation, great efforts will be expended to eliminate imperfections that make up most of the surface.

Comparative characteristics

Here are the varieties and description of the lining:

| Extra | BUT | IN | WITH | |

| Knots | Not allowed | Light knots are possible if they are healthy and do not fall out. No more than 1 per running meter | Healthy knots in any quantity. If dropped, then no more than 1.5 cm in diameter and no more than 1 per running meter | Unlimited |

| Cracks | Not allowed | Not end-to-end | Not end-to-end | Any |

| Core | If only in very small volumes (3-5%) | No more than 20% | Allowed | Allowed |

| Rot | Not allowed | Not allowed | No more than 10% of the total area | In any size |

| Wormhole | Not allowed | Not allowed | No more than 10% of the total area | Allowed |

| Resin pockets | Not allowed | Length no more than 5 cm | Allowed | Possible |

Lining cost

The price in different cities and from different manufacturers varies. Here is the average value for each category. The cost also depends on the wood used. The table shows the values for 1 square meter of a product with a length of 2-3 meters. Currency - rubles.

| Larch | Aspen | Pine | Linden | |

| Extra | 690 | 470 | 450 | 990 |

| BUT | 500 | 350 | 300 | 600 |

| IN | 350 | 300 | 230 | 500 |

| WITH | 200 | 180 | 180 | 300 |

Video - how to choose material:

Before buying a lining, decide on the room to be finished. With the Premium category, you can create royal mansions from an ordinary house, but will the price be affordable for you?

Whichever category you choose - wood trim will delight you with its warmth and comfort for many years.

The lining has long been one of the favorite finishing materials. Thanks to her, cozy, warm and original interiors are created.

What is lining

Lining is a long planed board. It has a groove and tongue for mounting. The material is environmentally friendly as it is made of wood.The characteristics are close to those of wood: durability, ease of installation, high-quality sound insulation.

Used lining for interior and exterior walls, ceiling. In addition, it can be used for the construction of terraces, gazebos, baths. Thanks to its good noise absorption, it is even used to sheathe walls in cinemas.

Currently, there are several types of lining:

- Ordinary (also called "euro lining") - has special grooves on its surface, which are necessary for ventilation.

- American - resembles a bar made of wood. This type is attached only in the horizontal direction. It is usually used for exterior decoration of buildings.

- Block house - imitates a round bar.

What lining is made of

The traditional material for the manufacture of lining is wood. Various species are used, both coniferous and deciduous.

Among conifers, the most common is pine. Spruce is also used, but much less often. This is due to the fact that the spruce has a loose structure.

All types of pine lining are suitable for indoor use and exterior wall cladding. But in some rooms (for example, a steam room in a bath), such material is not recommended. But the spruce lining is resistant to moisture and the appearance of mold, so it can be used in places where moisture may get in (baths, balconies, open terraces).

From deciduous, alder, ash, maple, aspen, linden are used. A little less often walnut and oak. as well as premium wood species can be purchased online on the website. The goods are delivered across the Russian Federation in shrink wrap. Elite species are made from larch. Linden and alder wood never heats up and does not burn the skin, regardless of the air temperature. Therefore, they are often used for wall cladding in steam rooms of baths and the construction of shelves there.

Recently, lining made from other materials (for example, plastic) has also been produced. Such a building material is conventionally called "clapboard" due to the presence of a "groove-comb" fastening system.

Lining grades

The lining is produced in accordance with the standards defined by GOST and TU (technical specifications). If GOST is common for all enterprises, then TU is developed by each manufacturer independently. That is why it is difficult to divide the lining into separate types. Each manufacturer may have their own.

The quality of the finished material depends on the quality of the selected raw materials. Therefore, the basis for dividing the lining into grades is chosen such characteristics as the presence of knots and resinous pockets, the blue of the raw material, existing cracks, etc. Depending on this, the following types of lining (or classes) are distinguished:

- Variety "extra" (also called "superior" or "premium").

- First grade (class A).

- Second grade (class B).

- Third grade (class C).

Products of various grades are manufactured using the same technology. Their division occurs after sorting, since the varieties of the lining differ only in the existing external defects.

Extra grade

Such a lining ("extra" grade) is distinguished by the complete absence of any defects. There are no knots, no cracks, no chips on it. Most often, this variety is made by splicing. This is due to the fact that it is very difficult to make perfect boards from a single piece of wood. Their number is very small. This variety is considered elite, it is used to decorate the interiors of wealthy country houses.

Accordingly, such a lining has the highest price - the highest grade. For its safety, manufacturers often pack it in a vacuum. Thus, they reduce the likelihood of damage (chips, deformations) on the product during transportation and storage. The kit usually includes special mounting hardware. The premium lining does not need to be adjusted, it will fit perfectly. During installation, you need to be careful not to damage the surface of the material, which is covered with a protective varnish.The lacquer coating further emphasizes the beauty of the wood.

When buying, you need to be careful. To avoid deception, visually inspect the material. Do not trust only the inscription on the label. There are times when there are perfect boards on top of the package, and lower quality on the bottom. Sellers who are confident in the quality of the material will not obstruct inspection.

First grade

In terms of its characteristics, the clapboard is comparable to the class A clapboard. Grade 1 from some producers is often better than the highest from others. This is due to discrepancies in the requirements of technical conditions during production. Therefore, in such situations, you need to focus on the appearance of the material.

The differences of the first grade of lining are in the absence of dropping knots and through cracks. Small and necessarily blind cracks occupy an insignificant part of the boards. The absence of blue, rot and blackheads is also characteristic.

The knots that are on the material must be light, healthy and not falling out. Their size does not exceed 1.5 centimeters in diameter. Loose knots should be healthy, intergrown and no more than 0.5 cm in diameter.

Cracks are allowed up to 9.5 cm long. They are necessarily not through, not plast, and go to the end of the board.

Defects in a product of this class do not need to be hidden. It is enough to treat the surface with decorative varnish (oil, wax), which will emphasize the natural lines of the wood.

Larch lining (grade 1, like the highest), is perfect for interior decoration of residential premises.

Second grade

Such a lining (grade 2) is characterized by the presence of visible defects. There are dents, cracks, chips. But their size does not exceed 5 cm per 1 linear meter of the board. On the surface of the product there is blue (up to 10% of the volume), knots, resin, core. At the ends, it is permissible not to do it, which does not interfere with the installation.

Knots do not exceed two centimeters in diameter, their number is up to one per running meter of material. If the knots are black, their diameter should not exceed 1.5 cm. Rotten and falling out knots are not allowed.

Reservoir cracks, extending into the end, with a length not exceeding a third of the entire length of the board, are acceptable. Through cracks - no more than 30 cm in length. The length of the seam through cracks is no more than 15 cm with a width of up to 1 mm.

Places with blue, coloring, pitching are allowed, one per board, if their size does not exceed 10x20 cm.

Most of the defects are formed during the manufacturing process. Existing cracks should not be through or extend to the end of the board. Rot up to 10% and a wormhole (up to 3 per linear meter) are possible. For this grade, any defects are permissible that will not interfere with the installation of the material.

The existing imperfections are usually hidden by grouting and painting in dark colors.

This class of lining is a budget option suitable for most of the population.

Third grade

For certain rough work and finishing of utility rooms, lining is also used. Grade 3 is the most suitable option. Low product quality explains the minimal cost.

During installation, the lining of this class must be adjusted and painted in order to hide serious surface defects. These can be knots falling out, through cracks, pith, remnants of bark, chips. Material defects take up most of the surface.

Comparative table of lining by grades

The distinctive characteristics, thanks to which the varieties of lining are distinguished, are most conveniently compared using a table.

|

Variety "Extra" |

1st grade |

2nd grade |

Grade 3 |

|

|

The presence of knots |

Unacceptable |

Up to 1 healthy, light-colored and captive knot per 1 running meter |

Healthy people are acceptable. No more than 1 drop (up to 1.5 cm in diameter) per 1 running meter |

Permissible |

|

Cracks |

Unacceptable |

Allowed (not through) |

Allowed (not through) |

Permissible |

|

Core |

3-5% |

Less than 20% |

Permissible |

Allowed |

|

Rot |

Unacceptable |

Unacceptable |

Less than 10% |

Permissible |

|

Resin pockets |

Unacceptable |

Less than 5 cm |

Permissible |

Permissible |

|

Wormhole |

Unacceptable |

Unacceptable |

Less than 10% |

Permissible |

Price differences between the varieties of lining

Differences in the quality of the material and the presence of defects lead to differences in the prices for the lining. Planks of the same type may differ in cost. This may be due to the way in which the material was dried. Conventionally dried board has natural moisture, it is heavier, but almost half the price. The material that has been dried in the chamber (it is lighter) is more expensive.

So, pine lining of class A, dried in a chamber, costs about 200-450 rubles per 1m2, and dried naturally - 130-300 rubles. Dry material from pine grades B and C will cost 180-350 and 140-250 rubles per 1m2, respectively.

The price for larch lining is approximately as follows (per square meter):

- The highest grade - 1200 rubles and above.

- First grade - 550-900 rubles.

- Second grade - 400-750 rubles.

- Third grade - 330-600 rubles.

The lining, regardless of the type, is a beautiful and environmentally friendly material that is easy to use in work. But when choosing the necessary material in the store, you should be careful. It is better to spend a little time checking the purchased products, whether they correspond to the declared grade. Otherwise, you might be wrong. This will affect the aesthetic features of the room, which will not look exactly as planned.

Lining is one of the most common cladding materials in modern construction. At the same time, metal or plastic is used for outdoor work, and natural wood is usually used inside. However, the properties of the natural material do not allow making identical products, which leads to the emergence of such a concept as the variety of lining.

They differ significantly in their technical characteristics and have their own tolerances and parameters.

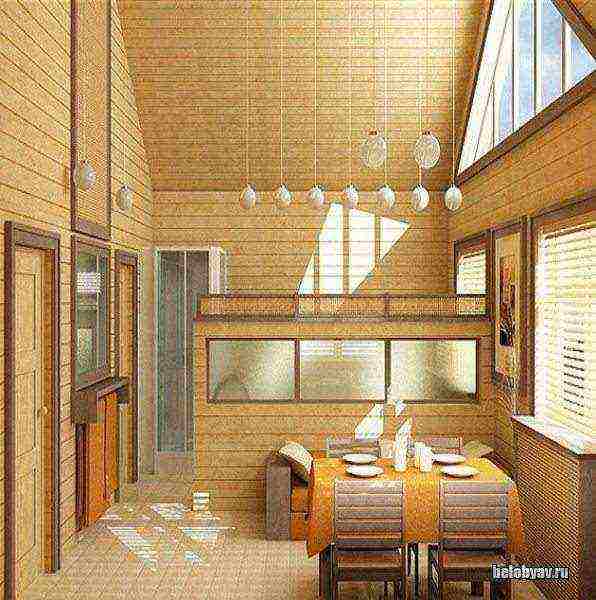

Dining room made of "Extra" class lining

Types of varieties

Currently, the classification of the lining is made in accordance with certain data, such as:

- knots;

- cracks;

- resin pockets;

- pitching;

- core;

- germination;

- color;

- rot;

- blue;

- wane;

- worm-hole;

- manufacturing defects.

Advice! It is necessary to be able to distinguish between different grades of this material in order to avoid deception and to choose a quality product for its real cost.

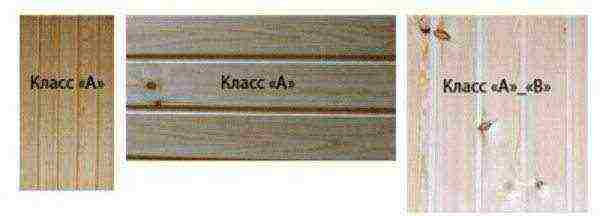

Lining of class "A"

These items must be completely free from manufacturing defect. The only thing that is permissible is surface roughness, but only in small quantities.

Also, grade A lining should not contain:

- wane;

- wormhole;

- blue;

- rot;

- germination.

The color of the material should not be more than ten percent of the total area. In this case, cracks and resin stones are allowed only insignificant and not through. The knots of the material should not fall out, and their diameter should not exceed 15 mm. Black knots can be present in this class of wood only if their diameter is not more than 7 mm.

Lining cutters and their use in interior decoration - read here.

Example of class "A"

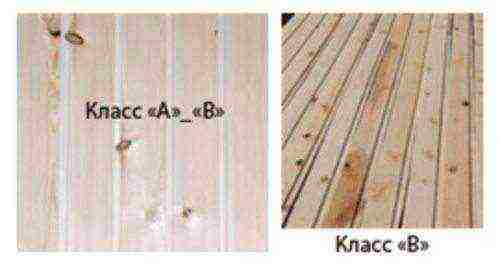

Lining of class "B"

Class B lining allows the presence of a significantly larger number of defects and damages. One of the most important differences of this type is the admissibility of unevenness at the end of the locking part. However, this should not interfere with the build.

Minor chips, cracks, cuts and dents are also allowed, but their size should not be more than 15 mm per 30 cm running meter.

Moreover, the depth of such defects for this class should be within 0.5 mm, and the finished product may contain:

- pitching;

- cores;

- coloring;

- germination (no more than 200 mm wide);

- blue (no more than 10%).

Also, the product may have sheet cracks, but without exit to the end and not through. Knots, however, such a lining can have different sizes, but only with their white color.Black and flowing species should not be more than 20 mm.

Example of class "B"

Lining class "C"

Lining of grade C is the cheapest and has a lot of quality tolerances and manufacturing defects.

It allows for the presence of:

- pitching;

- resin pockets;

- germinate;

- cores;

- coloring;

- blue;

- rot;

- wormholes;

- wane.

Also, this type of product can contain almost any type of manufacturing defect, but only if its size is not more than 15 of the total plane. In this case, knots can be present in such a lining without restrictions.

Example of class "C"

Lining of class "Extra"

This type of material is often called grade 1 lining, although in fact it can be attributed to the upper class or elite type... It completely lacks production defects and deformation of wood species. That is why this class is considered the best and has a rather high price.

Many manufacturers supply it in special vacuum packaging so that during transportation it does not deform due to interaction with the environment. Also, for this type of quality, special fastening clamps are provided, which are usually included in the delivery set.

Advice! Do not trust the inscriptions on the shop window; the quality of the material must be checked with your own hands.

Which is better - lining nails or nevertheless kleimers? Read here.

Scope according to classification

Each classification of lining by grades has its own conditional area of application and type of finishing.

- Extra class - used in critical areas of the building, which must have an impeccable appearance. Moreover, it is attached only to special clips so as not to spoil the appearance and is varnished. Elite types of wood are used for its manufacture, which have a beautiful structure and pattern. Many video tutorials on construction show examples of installing just such a lining, since it is very easy to work with it without being distracted by fitting.

Example of the Extra class

- Class "A" - also used on areas that are facial. Such a lining is not much different from "Extra", so it often competes with it. The fact is that different manufacturers treat the quality of their products in their own way. Looking at some of the photos, you can see that class “A” products from one manufacturer can be safely placed on a par with the “Extra” class of another manufacturer. The only difference is sometimes the price. Therefore, you should make a choice based on the appearance, and not on the characteristics indicated in the documents.

- Class "B" - can be called budget. When using it, you often have to use various putties and putties that would hide defects. That is why such a lining is purchased only when it is supposed to use dyes that could hide all corrections and knots. However, if you do the installation yourself, then you can take it to save money. In this case, you will have to use putties to match the wood, giving it a pleasant appearance and allowing you to use colored varnish.

- Class "C" - is considered the most recent in terms of its quality indicators. Below it there are already firewood. No professional builder would agree to work with him. This is due to the fact that his quality control of this material is carried out by rejection of class "B". Thus, among it you can often find products with significantly lower indicators than the instructions require. At the same time, defects in this material sometimes take a lot of time during assembly, since they require frequent revision or adjustment. Some unscrupulous manufacturers classify a specific marriage in this class. Therefore, it is necessary to be especially careful or completely exclude this class from work, regardless of such a parameter as price.

Sauna from the lining

Conclusion

Choosing high-quality clapboard made of expensive types of wood for work, you can turn the room into a real palace. This material is great for any premises, tolerates painting or varnishing well, has a stunning appearance and is installed in a short time. Moreover, it is one of the most environmentally friendly and has a pleasant smell.

Wooden lining will always be one of the most worthy and demanded materials for interior decoration.

Lining dimensions: centimeters do matter! Read here.

- # 1. What are the main advantages of wooden lining?

- No. 2. What is the difference between ordinary lining and euro lining?

- No. 3. What size lining is needed?

- No. 4. Which wood is best?

- No. 5. Which lining profile is better?

- No. 6. What kind of lining is better to choose?

- # 7. Is it possible to distinguish low quality lining?

- No. 8. Which manufacturers can you trust?

- LUNAWOOD

- "Astar"

- "Karelia"

- "Vyatka pine"

- PromMax

For cladding balconies, facades, arrangement of rooms and saunas, such decorative, practical and natural material as wooden lining is often used. It is a kind of board, the parameters and profile of which can differ significantly, as well as the color, which largely depends on the type of wood. Moreover, wooden lining is divided into several varieties, but even if there are markings on the packaging, you need to be able to choose the right material. So, how to choose the right wooden lining and what is important to pay attention to?

# 1. What are the main advantages of wooden lining?

All the basic properties of the material depend on the nuances of its manufacture. Wooden lining is produced from solid wood at wood processing enterprises. Lining is a 7-20 mm thick cut board with planed surfaces. The width of such material is 90-150 mm, the length can vary widely. Once upon a time, railway carriages were sheathed with thin long wooden planks with selected quarters, hence the name.

The raw material for the lining can be any kind of wood, and the main distinguishing property of the material is considered the presence of a groove and a ridge, thanks to which the installation is carried out. All this allows us to talk about numerous advantages of lining:

- excellent thermal and sound insulation properties;

- small coefficient of thermal expansion;

- due to the low weight, ease of transportation and installation is achieved, and there is no need to strengthen the foundation;

- due to the tongue-and-groove installation method, it is possible to assemble the skin without cracks;

- the appearance of the wooden lining is chic, it allows you to bring comfort to the interior or highlight the building when facing the facade;

- strength and durability;

- environmental friendliness, because the tree goes through a minimum of processing operations.

Among the cons you can only name a good ability to maintain combustion, but subject to fire safety rules, the material and your health are not in danger. A wooden lining is, of course, more expensive than its plastic counterpart, but it will also serve much longer, being resistant to physical stress.

No. 2. What is the difference between ordinary lining and euro lining?

On the construction market, you can find both ordinary wooden lining and material with the prefix "euro". The latter is significantly superior to conventional wall paneling in a number of performance indicators. So, the main differences are as follows:

- the size... The lining of the Soviet model is much thicker, and its thickness can reach 25 mm, the thickness of the Euro lining is 13, 16 or 19 mm. The maximum width of the Euro lining is 120 mm, the usual one - up to 150 mm;

- Castle... The protrusion of the lock in the euro lining is about 8-10 mm, which allows the elements to hold securely, even with strong changes in temperature and humidity. In an ordinary lining, the lock is often very tiny, so the lamellas diverge during operation;

- the presence of ventilation holes on the back of the Euro lining, which prevent the formation of cracks in case of temperature changes. There are no such grooves on a regular lining;

- humidity... The lining is forcibly dried until a moisture content of 10-15% is reached, thereby ensuring the absence of any deformations during transportation, installation and operation of the finished coating. The humidity of an ordinary lining reaches 20-25%, which negatively affects both the process of working with it and its behavior during operation;

- appearance... Since the Euro lining is made in accordance with strict European standards and on European equipment, the front side is always smooth. If there are knots on it, they are carefully processed. Manufacturers usually have several types of profiles. The elements of the lock fit exactly together. An ordinary lining rarely boasts such an ideal appearance and clarity of the execution of the lock connection, often its surface is rough and fleecy;

- euro lining is sorted into classes... Depending on the presence of defects on the wood itself and defects acquired during processing, as a rule, four classes are distinguished.

It is clear that when the euro-class lining appeared on the market, many builders began to use it. Nevertheless, ordinary lining can also be used and is sometimes used for external cladding, and in cases where the quality of the finished surface and its appearance are not so important, but the task of saving comes to the fore.

No. 3. What size lining is needed?

The first thing to decide on is lining length... You need to proceed from what kind of surface you will sheathe, and strive to generate a minimum of waste. It is clear that shorter slats are suitable for the balcony, and for cladding the facade or walls in the room, a lining with a sufficient length is needed. It will not be difficult to find the necessary material, since the lining is sold in 10 cm increments, ranging from 30 cm to 6 m. When carrying out calculations, it should also be borne in mind that often even the highest-quality material needs to be trimmed edges.

Width is chosen depending on the design idea, but it is worth considering the fact that a narrower lining will be more stable. The wider the material, the more prone to deformation it is. Recently, an interesting method has been often used - a combination of lining of different widths, due to which an original effect is achieved.

As for lining thickness, then first of all the conditions of further use of the material are taken into account. If the walls are sheathed indoors, then the lightest and thinnest clapboard with a thickness of 12.5 mm is quite suitable. Also material up to 16 mm thick can be used in these conditions. If we are talking about facing facades, when the lining also presses a thick layer of insulation, then it is better to choose a thicker material - it will be more durable, reliable and durable. A lining with a thickness of 18.5-22.5 mm is suitable.

When choosing, you may notice in the store the so-called spliced lengthwise wooden lining... Such material consists of several parts, which are carefully selected according to the pattern and color, but at the same time they can have different lengths. With the help of a microthorn connection, a special adhesive and high pressure, the individual elements are turned into a solid board. In terms of its main characteristics, such a material does not differ from a solid lining, and in some properties even surpasses it, because it turns out to be as stable as possible, and temperature and humidity have little effect on it. Technological features of production do not allow making such a lining with a thickness of less than 15 mm. In addition, some are afraid to use such a material in saunas and baths, as they are afraid of the influence of glue chemicals, which may begin to be released under the influence of high temperatures.

No. 4.Which wood is best?

In fact, any wood can be used for the manufacture of lining, but the properties of the lining will differ in many ways, as well as its price. The cheaper lining is not always worse, since the material should be chosen based on the conditions of its operation. As for the color of the wood, his choice is a purely subjective opinion.

All the lining that is present on the modern market can be divided into two main types:

- lining made of coniferous wood;

- lining made of hardwood.

Coniferous wood It is distinguished by a high content of resins and essential oils, due to which it resists the formation of fungi and withstands high humidity. This material has found a wide range of applications, excellent for external cladding, but completely unsuitable for saunas and baths. Under the influence of high temperatures, resin begins to stand out, and this process can continue for a long time. Not only does the material become sticky, it can also ignite spontaneously. Nevertheless, spruce and pine wood in the Nordic countries is used for the arrangement of saunas, but the material is de-resinated.

Most often, the following conifers are used for the manufacture of lining:

- Pine... It has a nice pattern, high strength, is inexpensive, but from time to time it must be varnished so that the material does not start to darken;

- spruce... The wood has excellent thermal insulation properties and a pleasant shade;

- larch... Very resistant to external influences, does not warp even with significant temperature fluctuations, is resistant to pests;

- cedar... Expensive wood with excellent performance properties, color from yellowish to coffee.

Hardwood less durable, but do not emit tar and heat poorly, which allows them to be used in baths and saunas. They require regular processing, otherwise, under the influence of external factors, they will change their color and deteriorate. Most popular hardwoods:

- oak... The most durable and durable, resistant to decay, dense, with a beautiful wood pattern, but such material also costs a lot;

- Linden... The wood has excellent soundproofing qualities and a delicate pleasant aroma; it is often used for decorating baths;

- ash... Due to its high hardness, such wood does not crack at all. Color - dark yellow;

- black alder has a pleasant light coffee color, resistant to moisture.

Separately, it should be noted that only wood with a low density is suitable for a bath, otherwise the material will be very hot, which can result in burns.

No. 5. Which lining profile is better?

Modern manufacturers produce lining with different cross-sectional profiles. In addition, the size and shape of the lock, the nature of the front and back surfaces, and some other parameters may differ. All this affects not only the external characteristics of the lining, but also the scope of its application.

Today, the most popular is lining with the following profiles:

- traditional euro lining with angular edges. After assembly, it forms visible seams due to the enlarged spike;

- lining softline differs in slightly rounded corners, it is recommended for use in saunas and baths;

- calm... Such a lining forms a barely noticeable seam, since there are no groove shelves near the spike. The corners can be either sharp or rounded. In the first case, it is possible to achieve the effect of a massive wall, so some manufacturers position such a lining as an imitation of a bar;

- loundhouse... In such a lining, the front side does not have a smooth surface - multiple patterns are created on it due to figured milling. The pattern can be of varying degrees of complexity, and such a lining becomes a real interior decoration. There is also a cheaper analogue - a lining with a carving effect.The pattern is applied to such material thanks to hot stamping;

- lining blockhouse and siding type imitate log and siding, respectively;

- double-sided lining - quite an interesting and not yet very common solution. The spike and groove are exactly in the middle, and both sides receive the same treatment, so during installation, the specialist can choose which color and pattern is best. The only drawback is the lack of ventilation holes, so this material is not very suitable for baths.

No. 6. What kind of lining is better to choose?

To determine the type of lining, it is customary to use the European standard such as DIN, but some manufacturers use different GOSTs and TUs developed with their own hands, so it is so easy to make a mistake when buying and it is so important to look not only at the marking, but also at the quality of the material itself.

The type of lining is determined after manufacturing, since materials of different grades are produced on the same equipment using the same technology. Later, the lining is sorted depending on the presence of knots, blue spots, cracks, unevenness and resin pockets. As a rule, there are four classes of lining:

- extra or premium... This is an ideal lining without knots and cracks, and uneven, blue or roughness is allowed only on the back side;

- class A. There may be knots no more than 1 cm in diameter (no more than one per running meter), blind small cracks, which are often filled by the manufacturer, and other minor defects can only be on the back side;

- class B... The diameter of the knots can reach a third of the width of the lamella, their number is not limited. Opened pockets, small through cracks may also be present;

- class C... This, roughly speaking, is the rest of the lining, with a large number of defects, cracks, knots, with blue spots and unevenness on the front surface.

As for the scope of use, only class C lining is not allowed for finishing. The material of other classes has almost the same operational properties, and the choice depends only on personal preferences. Not everyone likes extra class lining, as it looks faceless and boring.

No. 7. Is it possible to distinguish low quality lining?

You should not always blindly trust the class indicated on the package - it is better to examine the material with your own eyes... Pay attention, first of all, to the packaging. It is undesirable to use stretch film, since such storage negatively affects the humidity of the lining. Of course, it is better to inspect the goods before buying, but if the material is packed in film, then it will not work to examine it, and it is unlikely that they will be allowed to open the packaging. The only way out is to buy one or two packages and check the quality. If, with the clapboard, everything is fine, then the already purchased products will come in handy, and if not, then you will insure yourself against larger financial losses.

The geometry of the product should not be violated - the lining of the lining should be even. Even a small arc indicates that the material was stored incorrectly, and if such a board can be mounted, it is unlikely that it will last long, and with a high probability it will soon come out of the castle. You also need to inspect the castle. It should not have knots and cracks, but it is better to take a kleimer with you and check the reliability of the future connection. At specialized points there should be a tool that measures the moisture content of the lining, so you should not give up the opportunity to check the real indicator. It should not exceed 15%.

No. 8. Which manufacturers can you trust?

Of course, the name and reputation of the manufacturer plays a significant role in the choice. Large companies will not risk their name and produce low-quality products. It is worth noting that today there are a lot of domestic companies on the market that produce lining of excellent quality.There are imported products, but only in small quantities, so we will not divide manufacturers into foreign and domestic ones, but we will give a general list of the best.

LUNAWOOD

A young Finnish company founded in 2002. Today it is the world leader in the production of thermowood, develops its own innovative methods, is constantly improving. Wood that has been treated with high temperature and steam loses nutrients, becomes resistant to any weather conditions, deformation and decay. The company mainly uses pine wood, and the products are widely represented on the domestic market.

"Astar"

Domestic company operating since 2004. For the production of various wood products, it uses European equipment, which, together with the professionalism of its employees, makes it possible to produce products that meet European standards. The assortment of the company includes euro lining of different grades and with different parameters - from extra class to class C, with a length of 1.8 to 3.6 m.

"Karelia"

The company was founded in 2004, and at that time carried out work on the construction of objects made of wood. Since it was not so easy to find high-quality material on the market, it was decided to create our own production. Today it is equipped with the most modern equipment, high-quality raw materials are used here, and constant quality control is carried out. The lining is produced from different breeds, with different profiles and parameters, so it will not be difficult to find the right material.

"Vyatskaya pine"

Completely waste-free production, founded in 1999. Equipped with Italian and German equipment, it has repeatedly received prestigious awards. The assortment is constantly increasing here, and the production of lining plays a key role. It is made of pine wood, and the manufacturer offers lining with different types of profiles and parameters.

PromMax

One of the leaders among domestic producers of sawn timber. Among the advantages of the company is a huge assortment, reasonable prices, modern equipment and the opportunity to personally inspect products for their compliance with the declared class. The company offers eurolining made of pine and spruce, as well as from aspen, which is perfect for arranging baths and saunas.