Content

- 1 Types of plywood

- 2 What types of plywood are

- 3 What is plywood

- 4 Views

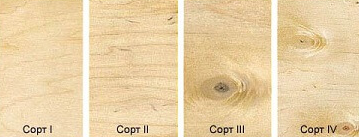

- 5 Classification by grade

- 6 Division by wood type

- 7 By destination

- 8 Dimensions and thickness

- 9 Manufacturing methods

- 10 There are 5 types of plywood in total:

- 11 5 grades of plywood

- 12 Plywood grade grades

- 13 Plywood grades fsf

- 14 Types of plywood

There is a generally accepted division of plywood into grades, on which the further quality of the work performed and individual operations depends. FK birch board is marked with grades 1, 2, 3 and 4. But the FSF material is distinguished by letter marking, which should be applied to the packaging. If the quality of the veneer on both sides of the processed sheet is the same, then only one designation is put. When the front side is different from the back, a different type of marking is applicable.

According to the quality of wood, the first grade is considered the best. It is used not only in construction, but also to create interior items, furniture, as well as some musical instruments. Plywood has become widespread in the automotive industry due to its strength and reliability. Various types of plywood with photos are presented in online stores and building materials catalogs.

Types of plywood

Plywood is a common building material made from wood veneers of all sizes and grades. There is a specific marking of the plywood sheet, which the master recognizes by the combination of letters and numbers on the packaging. This allows builders to immediately understand what kind of wood the building material is made of, what its quality is and where it is applicable.

Plywood is produced from several types of wood, but usually, when finishing work, builders use products from coniferous and birch species, marked with a material of the FSF type and grades of FC plywood. In addition to its cost, this material differs both in the means with which the wood sheets are impregnated and in the method of processing.

There are the following types of plywood:

- FC is a material for gluing the sheets of which carbamide glue is used, which gives strength to the product and ideal forms for interior wall upholstery;

- FSF - in the manufacture of this building material, an adhesive based on phenol-formaldehyde resin is used, which is able to withstand high humidity;

- FB - material that is impregnated with moisture-resistant bakelite varnish;

- BV - a plate, in the manufacture of which they use bakelite varnish and alcohol-insoluble substances;

- BS is a material used in aircraft construction due to its good impregnation with an alcohol-containing substance and bakelite varnish.

Each sheet in the factory is additionally amenable to processing. Grinding takes place on special equipment.

What types of plywood are

Each type of wood has its own characteristic differences:

- Grade 1 - there are no more than 3 defects on a sheet of wood, which include chips, knots and wormholes up to 6 mm in diameter. Noticeable cracks do not exceed 20 cm in length.

- Grade 2 - scratches and cracks on the plywood sheet should not exceed a length of 20 cm or 5% of the area. A small amount of glue leakage is possible (2% of the total sheet area).

- Grade 3 - the presence of 9 small defects is permissible, glue seepage in the amount of 5% over the entire treated area, the presence of gaps up to 2 mm.

- Grade 4 - the presence of many small defects and wormholes is permissible. This is a low-quality building material that is used for rough finishing.

The best view is the one that meets the requirements in a particular situation. And as for the letter marking, here, accordingly, the type of plywood sheet B will be of the highest quality, on the surface of which there should not be unnecessary holes and cracks, but there are intergrown knots. Wood marked C is the lowest quality and least expensive. It is used for those works where the density of raw materials does not matter.

Added: 24.06.2016 14:19:35

Very often in construction, renovation, exterior and interior decoration, a material is required that is equally strong and lightweight, inexpensive and resistant to environmental conditions. Plywood meets all these requirements. In this article, we will take a closer look at the types of plywood, its characteristics and the purpose of each type.

What is plywood

Familiar plywood

Familiar plywood

Plywood is a wood-laminated material with at least 3 layers. The layers are veneer or tree bark. When manufacturing, the veneer is placed in each layer perpendicular to the previous one, therefore, the density and strength increase, and the composition used for gluing the layers increases moisture resistance.

Views

Depending on the glue used

- FSF (phenol formaldehyde glue) - the highest level of moisture resistance. Due to the harmful substances in the resin, it is not recommended for living quarters and furniture production;

- FKM (melamine glue) - medium level of moisture resistance. It has a lower content of harmful substances, but also a lower resistance to moisture, therefore it can be used wherever there are no increased requirements for moisture resistance and toxicity level;

- FC (urea glue) - low level of moisture resistance. It does not contain harmful substances, therefore it can only be used in the interior decoration of residential premises, as well as kindergartens, rooms, furniture;

- FBA (albuminocasein glue) - non-waterproof plywood. It is environmentally friendly and can be used wherever increased resistance to moisture is not needed.

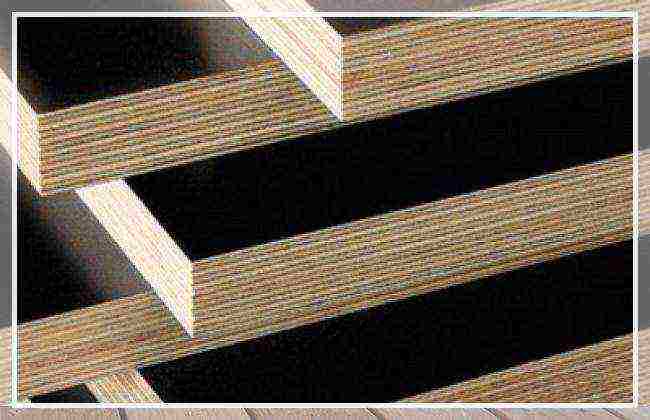

Bakelized plywood

Impregnation with bakelite varnish

Impregnation with bakelite varnish

Separately, it is necessary to highlight bakelized plywood (FB). It is impregnated with bakelite glue and has the highest level of moisture resistance and response to aggressive environmental conditions. Can be used: at high / low temperatures; from tropical to northern climates, with constant exposure to sea water, microorganisms, etc.

Because this building material is quite expensive, for the convenience of buyers, bakelite plywood is divided into several more subspecies: according to the composition of the resin, as well as according to the method of gluing, so that everyone can choose the desired brand and not overpay in vain:

- FBS (impregnation with alcohol-soluble glue), the main advantage is moisture resistance:

- FBS brand: all veneer layers are completely impregnated, the highest quality of the material;

- FBS-1 brand: the layers are not impregnated, but only coated, the quality is slightly lower;

- FBS-1A grade: only longitudinal layers are coated.

Waterproof material

Waterproof material

- FBV (impregnation with water-soluble glue), the main advantage is strength:

- FBV brand: only the outer layers are impregnated, and the inner ones are coated;

- FBV-1 brand: veneer is only coated.

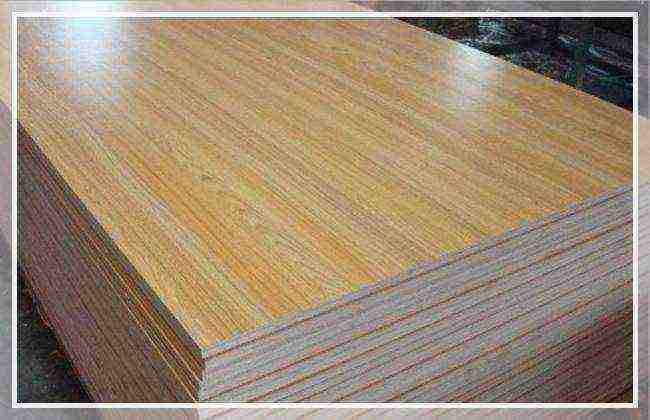

On the surface

Finished plywood

Finished plywood

Types of plywood for surface layer processing:

- Laminated. To enhance all the qualities of wood, the outer layers are covered with a special film for additional protection of the surface;

- Sanded on both sides (Ш2);

- Sanded on one side (Ш1);

- Unpolished (NSh).

The surface of the plywood is sanded in order to remove defects and make it more aesthetically pleasing.

Basically, sanded and laminated are used for finishing or decorative finishes, as well as for creating front parts of furniture.

Classification by grade

How to recognize the variety of fvnera

How to recognize the variety of fvnera

- Grade E (elite) - defects are not allowed, except for minor random changes in the structure of the wood;

- Grade 1 - the maximum length of warping or cracks should not exceed 20 mm;

- Grade 2 - cracks up to 200 mm, wood inserts, glue seepage up to 2% of the total sheet area are allowed;

- Grade 3 - up to 10 wormholes are allowed. per m2, with a diameter of each not more than 6 mm; the total number of the listed defects cannot be more than 9;

- Grade 4 is of extremely low quality. It may have the following defects: partially intergrown and fallen out knots - no limitation; wormholes up to 40 mm in diameter without limitation; defects of sheet edges up to 5 mm deep.

Application in construction

Application in construction

Thus, the grade of plywood depends on the presence of defects and their number on the surface of the wood veneer. At the same time, all types of plywood are used:

- Grade E and Grade 1: decorative finishes, interior and exterior finishing;

- Grade 2 and Grade 3: rough finishing or finishing, with additional application of varnishes and paints that mask defects;

- Grade 4: rarely - interior rough finish, mainly used for the manufacture of containers, packaging.

At the same time, the marking on the label can be, for example, the following: 3/4 or 4/4, this means that on the outside of the sheet the quality is of one grade, and on the inside - of another. Such products are very popular in the Russian market, because for the price, it is much more profitable.

Division by wood type

By the type of wood veneer, there are three types: birch, coniferous and combined. At the same time, they only look at the composition of the outer layers.

Birch

Hardwood

Hardwood

Birch is a deciduous type of construction plywood. Birch bark veneer is a very strong and dense material that has a homogeneous structure.

On the topic - what are the advantages of birch plywood over coniferous.

The density of such plywood is approximately 650 kg / m3, i.e. a sheet of such material is 20% stronger than a similar one from another type of wood, but, it does not contain natural resins at all, and it costs more.

It is mainly used where the unique properties of wood are required: strength and lightness. This is, first of all, large-scale and private construction, as well as car building, automotive industry, shipbuilding, packaging production.

Coniferous

Coniferous trees

Coniferous trees

Layers of such plywood are made from the bark of coniferous trees (in Russia, they are mainly made from spruce and pine). It is not as strong as birch, but it weighs 20% less, contains natural resins in the wood, which naturally protect against rotting and dampness, and also has a beautiful surface pattern, and is cheaper than deciduous.

Because The main advantages of this plywood are price, weight and a beautiful surface, then it is more used in private construction (roofing, partitions, floorings, external and internal finishing, etc.), as well as for creating decorative items and in design.

Combined

From various types of wood

From various types of wood

Composite plywood layers can consist of different types of wood, both coniferous and deciduous. In terms of quality characteristics, it is closer to birch, but it costs less. It is used both in construction and in furniture, packaging production, etc.

By destination

Also, plywood is very convenient to classify according to the methods of application, which we will consider below.

Korabelnaya

Application in shipbuilding

Application in shipbuilding

This type of birch plywood is also called "marine". Consists of the FB brand, i.e. it is impregnated with the most moisture-resistant bakelite glue under high pressure and temperature. Therefore, it can be successfully used in the construction and decoration of ships, boats, yachts and other floating facilities, as well as wherever a material is required that can withstand heavy loads and not deform from rotting during prolonged operation in constant humidity conditions: ports, docks, berths and other structures.

Furniture

Plywood furniture

Plywood furniture

Furniture plywood must meet certain requirements, especially for childcare facilities.This is, first of all, environmental safety (absence of substances harmful to humans), durability (furniture, during operation, usually has considerable loads) and a beautiful appearance. FK birch plywood meets all these requirements, since its strength is higher than that of coniferous, and it is impregnated with non-toxic urea glue. For the front sides of the furniture, it is better to use the first and second grade.

Construction

Construction plywood is mainly plywood of grades 3/4 and 4/4, which is used in internal hidden works: pre-finishing of floors, ceilings, walls; construction of interior partitions, flooring, podiums; leveling the "rough" floor, frame for a stretch ceiling, etc. Due to its lightness, strength, heat / noise insulation properties, ease of use, as well as low cost, it is used wherever there are no increased requirements for a beautiful appearance.

Aviation

Use in aircraft construction

Use in aircraft construction

This type of plywood is made from the FSF brand, impregnated with formaldehyde glue under special conditions, as a result, in terms of strength and moisture resistance, it is sometimes compared with steel, since, having a high density, it easily resists prolonged mechanical stress. Such qualities are required in order to apply it in the most critical industries: the construction of aircraft, helicopters, large and small ships; in the car building and automotive industry.

Formwork

Formwork plywood is used in the construction of a concrete foundation, therefore, it must have exceptional qualities in terms of strength, moisture resistance, resistance to adverse environments and various deformations (swelling, drying out, cracking, etc.).

We wrote about the main advantages in the article film faced plywood for formwork, with all the characteristics and strength indicators.

All the specified quality requirements are met only by FB film faced birch plywood with the maximum number of layers (thickness 18 mm for walls and 21 mm for floor). The process of lamination of sheets with a protective film greatly enhances the basic qualities of this building material: the density approaches almost 700 kg / m3, and the maximum strength is: along the fibers at least 55 MPa, across the fibers - at least 25 MPa. Due to these qualities, this material is durable and economical, i.e. after the construction of the foundation, the sheets can still be reused.

Decorative

Plywood for decoration

Plywood for decoration

Decorative plywood has the FC brand and is made from various types of wood, but, of course, from the elite or first grade, because it is the naturalness of the surface pattern that is appreciated. Also, to preserve the appearance and other valuable qualities of wood, it is either laminated or coated with a special varnish. Main application: exterior and interior finishing, decoration, interior design, furniture, DIY crafts, etc.

Transport

Car body coating

Car body coating

It is also called "automobile" - it is laminated or mesh-ribbed (if you need a minimum of sliding) FSF plywood. Such plywood is used for the manufacture of various parts of trucks: upholstery of the metal frame of vans, flooring, door upholstery, etc. Due to their strength and moisture resistance, such parts can be operated for a long time without fear of deformation or wear. Also, the advantages include ease of installation - almost all work can be done by hand and with little time.

Dimensions and thickness

If you have decided on the type, purpose and grade, then further parameters for choosing and buying plywood are the thickness and dimensions of the sheet, because the cost depends on it.

According to GOST standard sheet dimensions: 2440 x 1220 mm, but, at the same time, the most popular and convenient to use is: 1525 x 1525 mm.Sizes are also offered: 1500 x 3000, 1525 x 3050 - in various variations of length and width, as well as non-standard sizes (determined by a specific manufacturer).

Dimensions according to GOST

Dimensions according to GOST

The thickness of plywood from different manufacturers differs significantly within 3-30 mm, and depends on the raw materials used in the production and the number of layers in the product (from 3 to 21).

Manufacturing methods

The bark of trees is used to make plywood. The logs are pre-soaked in water and steamed. After that, the veneer is cut in several ways: planing, sawing and peeling. Peeling is considered the most efficient way, because the thickness of the cut bark is minimal and the wood raw material is used in an optimal way. This process takes place with the help of a rotating machine on which the tree trunk is clamped. In this case, the rotation occurs around the knife, cutting off the bark in a circle.

Further, the cut bark is sorted, depending on the defects present, according to quality grades, and processed in a special way to form sheets. After that, the sorted sheets are impregnated with glue and pressed. Moreover, each layer is perpendicular to the next, which provides special strength. The final part is surface treatment by lamination or sanding. After that, the finished product undergoes quality control, is marked and packaged.

So, we examined in detail the types of plywood by grades and types of wood, as well as the use of each type. Among such a variety of different brands, everyone can choose the option that is optimal in terms of price and quality. Summarizing all of the above, it is safe to say that if you need an easy-to-use, affordable, durable, lightweight, impervious to environmental conditions wood building material, then plywood is the best choice.

(

estimates, average:

out of 5)

Plywood is divided by grade in accordance with the requirements of GOST No. 3916.1–96. The grade of plywood is set according to the number of rejects on the plywood surface. This refers to the traces of knots, which are the most vulnerable places in any wood.

There are 5 types of plywood in total:

- E (Elite) grade of plywood: no visible defects or blemishes. A slight deviation in the structure of the wood, of a random nature, is allowed, except for dark eyes. Not allowed: partially intergrown, non-intergrown, falling out knots, holes from them, wormhole, healthy intergrown knots, slight brown streaks, etc. Such plywood can be varnished. Grade E plywood is used to make film faced plywood.

- 1st grade: plywood of the 1st grade has practically no defects, partially intergrown, non-intergrown, falling out knots, holes from them, a wormhole with a diameter of not more than 6 mm in the amount of 3 pieces are allowed. per 1 m², no more than 5 healthy intergrown knots per 1 m² with a diameter of up to 15 mm are also allowed. and slight brown streaks. Such plywood can be varnished. Grade I plywood is used for the production of film faced plywood.

- 2nd grade: in plywood of grade 2, partially accrete, non-accrete, falling out knots, holes from them, a wormhole with a diameter of not more than 6 mm are allowed in the amount of 6 pcs. per 1 m², no more than 10 healthy intergrown knots per 1 m² with a diameter of up to 25 mm are also allowed, repair of the sheet surface is allowed. Knots and open defects are sealed with veneer inserts. Such plywood is covered with various finishing materials and paints.

- Grade 3: in grade 3 of plywood, partially intergrown, non-intergrown, falling out knots, holes from them, a wormhole with a diameter of not more than 6 mm in the amount of 10 pieces are allowed. per 1 m² of sheet surface, healthy intergrown knots are also allowed without limiting the number. It is used for the manufacture of structures hidden from the external view, for the manufacture of containers and packaging.

- Grade 4: in grade 4 plywood, any manufacturing defects are allowed.Partially accreted, non-accrete, falling out knots, holes from them, a wormhole are allowed in unlimited quantities with a diameter of not more than 40 mm, only good gluing is guaranteed. It is used for the manufacture of durable containers and packaging.

Next comes non-high-quality plywood - illiquid stock (marriage).

Examples of plywood surfaces of different grades:

Sample of grade E plywood Sample of grade 1 plywood Sample of grade 2 plywood Sample of grade 3 plywood Sample of grade 4 plywood

Conclusion: The highest grade of plywood - E (elite) - is extremely rare and relatively expensive. The market is mainly represented by plywood of grades from 1 to 4. The 1st grade is the highest, the 4th is the lowest. The higher the grade of plywood, the better the surface quality.

Grade indication in plywood labeling

The grade is written after the size of the plywood in Roman or Arabic numerals. The sides of the sheet can be of the same grade, or they can be different.

Example of designation:

- "Plywood FC 1525 × 1525 × 9 mm, 4/4" - stands for: plywood FC - plywood brand FC, i.e. moisture resistant; 1525 × 1525 × 9 mm. - sheet size: length 1525mm, width 1525mm, thickness 9mm; 4/4 - grade 4/4, i.e. both sides of a leaf of the same grade (in this case - 4th grade)

- "Plywood FC 1525 × 1525 × 9 mm, 2/4, width 2" - The difference compared to the first option: 2/4 - grade 2/4, i.e. one side is 2nd grade 2, the other is 4th grade; shl. 2 - i.e. polished on both sides.

The main "popular" varieties: 1/2, 2/2, 2/3, 2/4, 3/4, 4/4.

Grade 4/4 is never sanded, while all other grades are all sanded on both sides.

We have all heard the word "plywood", but not everyone knows what it is. In this article, we will talk about what types of plywood are, what types and brands of this material are. It is very important in a wide variety of industries as a result of its high strength.

5 grades of plywood

Plywood is of five grades - E, I, II, III, IV. Before attributing plywood to one of the grades, experts assess the acceptable volume of material defects, processing flaws, as well as its appearance. The variety is expressed by two symbols, the first of which defines the class of the front layer, and the second - the back layer. For example, E / II or II / III.

E is an elite category in which there are no visible flaws or other damage. However, the timber may contain certain minor defects. The presence of knots falling out and holes made by them is completely unacceptable in this category. This type is often varnished. It is from it that the film faced plywood is produced.

I - this class of plywood is also almost flawless. But the presence of knots (falling out, partially accrete, not accrete) or punctures from them is permissible. There can be small wormholes, up to 6 mm in diameter, up to 3 pieces per sq. M. This plywood can also be laminated.

II - in this grade, knots and holes falling out may be present. The number of wormholes in one square meter is up to 6 pieces, and the number of healthy intergrown knots (diameter up to 25 mm) is 10 pieces. In this material, it is allowed to repair the plane of the sheet, during which knots and other imperfections are decorated with veneer inserts. Sheets of this plywood can be coated with paints and varnishes.

II - in this grade, knots and holes falling out may be present. The number of wormholes in one square meter is up to 6 pieces, and the number of healthy intergrown knots (diameter up to 25 mm) is 10 pieces. In this material, it is allowed to repair the plane of the sheet, during which knots and other imperfections are decorated with veneer inserts. Sheets of this plywood can be coated with paints and varnishes.

III - in this material dropping out knots and holes from them are permissible. There may be a wormhole with a diameter of up to 6 mm, with an amount of up to 10 pieces per square meter. In this material, there are healthy intergrown knots, in unlimited quantities. The scope is limited to the release of containers and packaging materials, as well as the creation of structures, without an external view.

IV - any manufacturing flaws are permissible in this plywood: knots, punctures from them, the number of wormholes up to 40 mm is not limited. This material is highly durable; it is used for packaging material.

The physical and mechanical properties of plywood are shown in the table

| Indicator name | Thickness, mm | Brand | The value of physical and mechanical parameters for plywood with internal layers of wood veneer | |||

| Birch | Alder, beech, maple, elm | Pine, larch, spruce, fir, cedar | Linden, aspen, poplar | |||

| 1. Moisture,% | 3-30 | FSF, FC | 5-10 | |||

| 2. Ultimate shear strength along the adhesive layer, MPa, not less: | ||||||

| after boiling in water for 1 hour | 3-30 | FSF | 1,5 | 1,2 | 1,0 | 0,6 |

| after soaking in water for 24 hours | 3-30 | FC | 1,5 | 1,0 | 1,0 | 0,6 |

| 3.static bending strength along the fibers of the outer layers, MPa, not less | FSF | 60 | 50 | 40 | 30 | |

| 9-30 | fc | 55 | 45 | 35 | 25 | |

| 4. Ultimate tensile strength along fibers, MPa, not less | FSF | 40,0 | ||||

| 3-6,5 | FC | 30,0 | ||||

| Note - Allowed birch plywood with a shear strength of 1.2 MPa adhesive layer in accordance with the terms of the agreement (contract) | ||||||

Plywood grade grades

For the production of veneered sheets, different adhesives are used. Possible plywood grades:

- FBA is non-moisture resistant. It is glued together with natural albuminocasein adhesives. It is environmentally friendly, but not often used due to its low moisture resistance

- FC - glued with urea glue. It is characterized by an average moisture resistance and is used for internal construction and interior work. It is used to produce packaging material

- FSF - glued with resin-phenol-formaldehyde glue. It is characterized by high moisture resistance, therefore it is used in outdoor construction work, roofing work.

Plywood grades fsf

Moisture-resistant plywood is marked as follows: B, BB, CP, C.

Grade B is characterized by a high surface quality. This quality allows for transparent and translucent processing, varnishing and toning with dyes. This class assumes the presence of healthy light knots up to 10 mm in diameter, and dark ones up to 6 mm. There should be no loose knots and holes from them. The coefficient of irregularity in the structure of the material does not exceed 10%.

BB grade can be treated with paint and translucent mixtures. The quality of the product can be improved by using veneer inserts. The presence of any size of healthy light knots is possible, and dark ones up to 20 mm. There can be closed cracks up to 200 mm long, and open cracks up to 2 mm wide. In total, the flaws should fluctuate within 25% of the plane of the sheet.

Specialists use the SR grade for veneering with matte and film coatings. The quality is slightly worse than the BB grade. There are healthy light knots, dark knots up to 1.5 mm. The size of the false nucleus, as well as the healthy hue change, does not exceed 50% of the leaf plane. Double veneer inserts glued on the edge are allowed.

The most budgetary is grade C. It is used if the construction of it plays a secondary role. There may be knots, intergrown and non-accrete, holes from fallen knots, up to 40 mm, open cracks up to 10 mm wide. The inner layers may contain a lack of veneer up to a width of 10 mm. Knots and cracks up to 60 mm can be covered. The leaf has a false core and brown spots, as well as grooves and grinding.

The grade of moisture-resistant plywood has its advantages, which include:

- operation in conditions of humidity above 80%

- increased strength

- ease of processing

- low price

- beautiful appearance.

Of the negative qualities are:

- high toxicity, due to the manufacturing technology using phenols in the adhesive material

- flammability (the components of the glue are highly flammable).

Types of plywood

The types of plywood differ in the type of raw material from which the sheet was made. It happens:

- deciduous (birch, lime, oak raw materials). Differs in increased strength, wear resistance and moisture resistance

- coniferous (pine, cedar, fir raw materials). It is lighter than deciduous and resistant to decay.

- combined (deciduous and coniferous raw materials alternate, and the outer layer is birch).

Plywood also differs in the type of surface machining. According to this criterion, they are distinguished: unpolished, polished on two or one side.

Birch plywood grades

Birch plywood is characterized by a very high strength and multi-layer structure.The material obtained from this tree can be called the most popular in industries where it is necessary to give a product high strength.

Birch plywood is:

- plywood FC (moisture resistant)

- plywood FSF (high moisture resistance)

- polished

- unpolished.

Plywood is produced by three main methods. The first method consists in cutting the raw material base into thin strips (5mm). In this case, valuable timber species is used. However, as a result of the high consumption of raw materials, plywood made by this method is almost never produced. The second method is to plan the veneer with a thickness of 3.5 mm. At the same time, a fairly high performance is noted. And the third method is the production of peeled plywood. It is produced from veneer with a thickness of 1.2 - 1.9 mm, obtained by peeling plywood logs. This method is the most popular.

Film faced plywood grades

Due to the fact that veneer in film faced plywood is covered with laminate, only the disadvantages of lamination are taken into account in determining the grade, as well as the flaws of the raw material present on the outside. The first grade is characterized by an ideal appearance. There should be no peeling of the film, roughness after repair, stains, bulges and holes, press marks, laminate swelling.

Allowed:

- traces of healthy knots

- light spots and stripes (up to a quarter of the surface)

- sticky film pieces up to 5 cm 2 cm

- paint drips up to 10 mm

- veneer deficiencies in the inner layer up to 10 mm and in depth up to 2 mm

- chips up to 5 mm.

Film faced plywood of the second grade may lack a film coating on an area of up to 1%. There may be overlays of film material, traces of flaws in the inner layers, light spots. Spots and small holes may be present on no more than 10% of the area.

Film faced plywood of the second grade may lack a film coating on an area of up to 1%. There may be overlays of film material, traces of flaws in the inner layers, light spots. Spots and small holes may be present on no more than 10% of the area.

Allowed:

- scratches up to 300 mm in length

- press plate prints, provided that the integrity of the film layer is preserved

- swelling of the laminate up to 100 mm

- the absence of veneer in the inner layers of plywood is allowed in length up to 25 mm

- chips up to size 20 x 5 mm

- roughness and abrasion.

Film faced plywood of the third grade may lack a film coating. There may be wood flaws, pieces of film adhering to the surface, light spots and streaks, as well as any flaws that were not resolved in the first and second classes.