Content

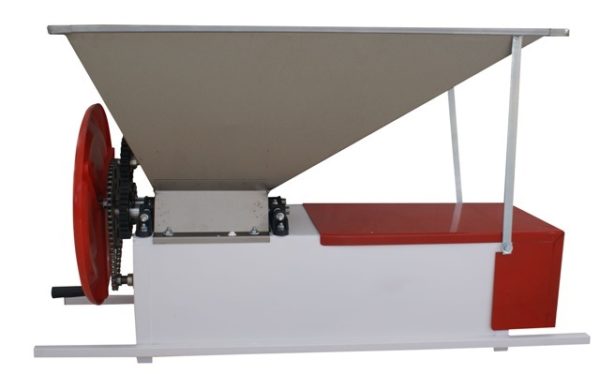

What are the crushers or crushers for grapes

Any horticulturist who grows grapes for wine making is familiar with a tool such as a grinder. There are several variations of the mechanism, and they will be discussed in this article.

Why do you need a grape crusher

The crusher is a device with a simple mechanism. The most primitive construction consists of the following elements:

- bunker for loading berries;

- the container into which the cake is collected;

- crushing rollers;

- a frame that holds all the nodes;

- a handle that drives the shafts;

- gear systems.

The tool is used by private winemakers and industrialists to process grapes for juice.

The principle of operation is based on filling the bunker with berries and setting the working shafts in motion, which, under the force of squeezing, press the skin and pulp, separating the juice. The processed product goes into the mash compartment. The drive that makes the crushing elements move is mechanical and electrical.

A design feature is considered to be a gap that is specially left between the working shafts. This allows you to squeeze the grapes without crushing the seeds. Damaged seeds negatively affect the taste of the juice, subsequently imparting bitterness to the wine.

Types of crushers

There are several types of construction of grape crumbs, each of which has a number of advantages.... Winemakers choose the mechanism taking into account the volume of processing and the required productivity.

In addition, equipping the equipment with a comb separator has a direct impact on the taste of the drink, because the seeds can both add exquisite astringency and make the wine intolerably bitter. The technology for processing grapes of red and even varieties allows for the presence of seeds, while in the manufacture of white wines, the procedure for filtering the juice is necessary.

With comb separator

Structurally, the crushers differ in several ways, but the main one is the presence or absence of a comb separator.... The importance of this element in the equipment is due to the squeezing process, in which tannins and bitterness from the stem get into the juice.

Without comb separator

Structurally, crushers with and without a comb separator do not differ significantly, except that there are no ridges and the function of separating the berries from the brush. The process of processing grapes is carried out more slowly due to the fact that the raw material requires preliminary preparation - the separation of the grapes from the stem part.

Roller crushers-comb separators

Such units prepare high-quality must for wine., and the pressing process itself is similar to the production technology.The principle of operation of the grinder is based on the extraction of berries by rollers, followed by filtration of the juice with a comb separator.

The parameters of the gap between the two rotating shafts are adjusted depending on the used grape variety (the seed size is considered as a guideline). The surface of the main structural element - shafts, can be of several options:

- smooth;

- corrugated;

- 4, 6, 8-bladed.

Most factory-assembled crushers have shaped rolls.

Centrifugal impact crushers

Crushers of this type are designed in horizontal and vertical versions. The principle of operation of the mechanism is based on the impact of the impact force of the rotor rotating at a speed of 300-500 rpm. The equipment is equipped with a comb separator, which maximally cleans the juice from the cake.

Mechanical and electrical crushers

The working principle of mechanical and electric crushers is the same, only in the first case, the functioning of the system is carried out manually, and in the second - with the help of an electric drive. A feature of the equipment is the presence of a comb separator, which is a kind of cylinder with a horizontal arrangement. The design of the cylinder also includes a shaft and helical blades, which help to separate the berries from the ridges during the pressing process.

How to make a hand crusher with your own hands

There is no need to purchase factory-assembled equipment to process crops from your personal plot... It is not difficult to build it with your own hands. But first you need to decide on the type of construction and the required materials. A simple crusher will require a small number of parts, most of which can be replaced with improvised means.

Assembly steps of a simple design for squeezing grape juice

- Draw unit drawing or use ready-made as a basis.

- Collect a hopper for loading raw materials. The structural element is similar in shape to a truncated inverted pyramid. It is better to choose a hard wood (for example, oak) as a material for its manufacture. The use of plastic and stainless steel is also allowed.

- A shaft with blades (4-6 pcs.) Is installed at the bottom of the hopper. To make it, you need to take a pipe (diameter 30-40 mm) and plates (length 15-20 cm, width 8-10 cm) made of stainless steel. Weld the blades to the pipe in a staggered manner (alternating the sides of the connection of the parts every time).

- Install the shaft into the holes on the hopperlocated at the bottom of it.

- Fix the net at the bottom of the hopper. Its diameter should correspond to the parameters of the processed berries. You can cut several parts from metal meshes with different cells at once and change them taking into account the used grape variety.

- The shaft is driven by a handle. To do this, you need to bend the rod (at least 10-12 mm), giving it a zigzag shape. One side of the handle is fixed to the shaft.

- The frame is considered the basis of the design. It needs to be knocked down from wooden blanks according to parameters slightly exceeding the dimensions of the lower part of the bunker. The height must be at least 15 cm.

- 2 shafts are fixed to the frame with a gap of 2-3 mm. From the outside of the frame, install the gears on the shafts.

- Install the handle on one of the roller axes.

This design has 2 handles that drive the comb separator and juice rollers. It is not difficult to improve the equipment by combining both mechanisms into a single manual or electric control (installation of an electric drive).

Purchase a ready-made grape crusher or assemble a simple device with your own hands - it's up to everyone to decide. But in any case, it is interesting to improve the existing model for certain conditions to facilitate the process of squeezing juice. With an innovative idea, you can subsequently share it with like-minded people on the network.