Content

8 types of do-it-yourself chicken feeders

Feeding poultry in terms of labor and money costs comes first in the breeding process. In this regard, the selection of ready-made feeders must be approached competently.

You can save on money if you do it yourself. In addition to the material incentive, you will receive moral and aesthetic pleasure, seeing how chickens eat from hand-made feeders.

Requirements

There are certain requirements for their manufacture:

- Strength: they must be made of a material that keeps a certain shape, little or no deformation;

- Convenience in operation: it is convenient to clean, you can easily fill it with food, and it is convenient for the bird to eat from it;

- The number of units should ensure the fulfillment of its task - feed all livestock (if you put one small feeder for 50-100 heads, you can only imagine what will happen in the chicken coop);

- A feeder made of a specific material should be used for a certain type of feed;

- She must be sustainable (do not topple over or fall on its side from direct contact with the bird);

- Rational use (manufactured in such a way as to make it impossible for droppings to enter it and to minimize the ingress of debris).

- Manufactured not harmful for supplying materials.

Types of homemade chicken feeders

All feeders are classified according to the following criteria:

Depending on the feeding method:

- bunker;

- grooved.

Depending on the material from which they are made:

- wooden;

- solid metal;

- plastic;

- from metal mesh or rods:

- combined.

From a plastic bottle

This model of the feeder is considered the easiest to manufacture. It is easier to put only a bowl of food in the chicken coop.

The manufacturing technique is as follows:

In 1.5 liter bottles, the bottom is cut off (food is poured through it) and, closer to the neck, we make holes along the perimeter so that grain is poured through it.

The bottom is also cut off from 2-liter bottles, but the sides are left at a height of 10 cm (they cover the bottles in which the food is located, against rain, other moisture and foreign bodies). 5-liter bottles are cut in such a way that the distance from the cut line to the bottom is no more than 15 cm.

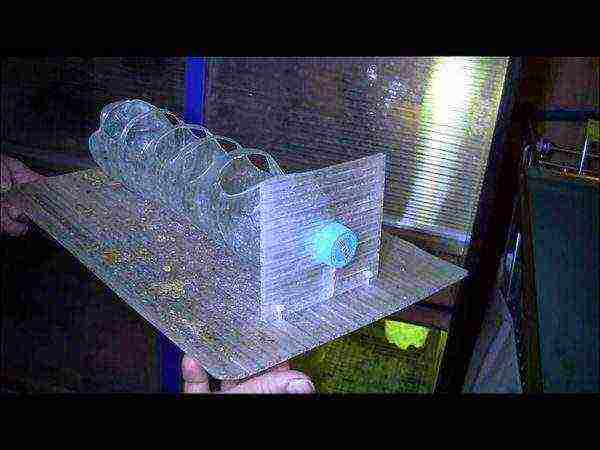

In the center of the cut containers, a hole is made along the diameter of the neck of 1.5 liters. bottles. In a 50x30 plywood sheet, we also make holes in a diameter of 1.5 liters. bottles. It remains for us to lower a 1.5 liter bottle in a container of a larger diameter so that the neck goes through 2 holes and comes out from the bottom of the piece of plywood.

Then, from the bottom, it twists the lid. In 1.5 liters. The feeder is ready.

From a 5 liter plastic bottle

The feeder is made in different ways.The easiest one is to cut holes of small diameter along the bottom perimeter, sufficient for pouring out grain, another type of dry food; you can pour grain into the bottle itself through a watering can inserted into the neck. We substitute any vessel below.

In the process of eating, the grain will fall through the holes. into a substituted vessel. It can be made in another way: in the same container we cut out small squares around the perimeter of such a size that the chicken can freely stick its head inside and peck the grain. With this option, you do not even need a vessel as a pallet.

But if you need to tighten the structure, make it more massive, we screw a piece of plywood to the bottom of the bottle. This prevents the bottle from tipping over if the feed is running low.

How to make a bunker bird feeder

The above methods of making feeders from plastic containers are also a kind of bunker feeders, but without a feed adjustment mechanism.

An improved version of the hopper feeder is done in this way:

Plywood is cut into several pieces:

- the front of the hopper - 40x50 cm;

- rear end - 40x40 cm;

- 2 side walls tapered to connect the front and rear walls;

- upward-opening lid slightly larger than the top of the hopper.

A slot is left at the bottom of the hopper for spilling feed into the tray for birds to eat. As the chickens consume the feed, the feed level in the hopper drops. It is easy to fill it up.

To do this, open the lid and add the required amount. It will be improved by making a grain feed adjustment mechanism at the bottom. The principle of its operation is to reduce the size of the slot (slot) or increase it depending on the structure of the feed. This type of feeder is attached both indoors and outdoors.

Automatic feeder and drinker from a sewer pipe

It can be made from a plastic PVC sewer pipe. Better if you take the average diameter - 15 centimeters. In addition, for the arrangement, you will need two plugs and a tee. We choose the length that is necessary. Two pieces of 20 and 10 centimeters are cut from the pipe.

Then the longest and 20-centimeter sections of the pipe are connected with a tee, and the plugs are installed at the ends. A 10-centimeter piece of pipe is connected to the branch of the tee - this will be a feed tray.

Pour food into this structure (or water in the case of an autodrinker) and fix it on the wall of the hen house with the long side to the top.

Some suggest the following option for a homemade construction from scrap materials: In the lower part of the pipe, holes are drilled on both sides, expanding them to a diameter of 70 millimeters, so that the birds have free access to food. A plug is put on one side of the pipe, and the second section is connected with a knee at a right angle. Feed is poured into it and a second plug is placed. You can also make an automatic drinker.

In our opinion, such a feeder has a very big drawback: the food will not be able to move along the pipe itself as the bird eats it, but will collect near the first hole, since there is no slope. The ideal angle of inclination in this case is difficult to make, since the coefficient of friction for each feed is different.

Wood option

One option for making a wooden feeder was described above (bunker feeder). You can make another variety. To do this, you need boards or slats made of wood.

We take any length. Let it be 1.5 meters. For the side walls, we prepare 2 blanks measuring 150cm x 10cm, and 2 blanks measuring 20cm x 15cm. We put together all this as shown in the figure.To give strength to the structure and prevent birds from entering the feeder, a wide rail is nailed from above.

Instead of a rail, you can take any handle from the inventory, for example, a shovel. Attach on both sides in such a way that it easily rotates around its axis. This is to make it difficult for the chickens to sit on the feeder and keep their balance.

It should be noted: it is advisable to use a wooden feeder in covered rooms to avoid getting wet and damage to the material. It is not suitable for wet feed as it makes it difficult for the breeder to clean it.

From metal mesh or rods

This version of the feeder is useful for greenery, because otherwise the chickens will drag the grass throughout the entire poultry house. The feeder is in one place. To construct it, you just need to bend the small diameter welded metal mesh into a ring and attach the ends to each other.

This feeder has no bottom. But for strength, it is nailed to a wooden, plywood or any other plane.corresponding to the diameter of the ring. Cover the top with something. This design makes it easy to throw away all the wilted contents and put in fresh green mass. Naturally, it is not suitable for bulk feed, since it has a large cellular structure.

DIY homemade chicken feeders

Chickens need to eat especially well in the first days of life. If their number is small, the problem with feed containers is easy to solve. For this, one feeder is installed. But if their livestock is more than a hundred, then very soon they will grow up and in order to provide normal access to feed, it is necessary to install several feeders or one large one.

Bunker option from scrap materials

The simplest chicken feeder can be made from a regular plastic bottle. The essence of the design is to cut out several windows in one row so that the chicken can stick its head in and peck at the food. On the side of the cut-out windows at an angle of 90 degrees, cut out one or two smaller holes to fit the neck of the bottle.

Insert the cut bottle, as shown in the figure, into the hole. It turned out to be a kind of watering can through which the food is poured.

Another version of the hopper feeder can be offered for chickens.

To do this, from any lightweight solid material (for example, the thinnest extruded foam), we cut out a circle in which we make holes along the contour, so that the chickens can peck the food.

In the middle we cut a hole along the diameter of the bottle or can in which we fill it. We substitute any dish under the bottom (you can use a plastic bowl). From an inverted jar, the grain is poured into a bowl as it is eaten. The diameter of the circle should be slightly larger than the diameter of the bowl.

If we take a glass jar as a bunker, then this design option has one significant drawback - in order to fill it, you need to turn the jar over and fill it with compound feed. Then put on a foam circle, a bowl, and only then turn it over and put it on the floor.

This design is only suitable for raising chickens.because a grown young or an adult bird will overturn the jar and it may break.

Automatic feeding for chicks

As a matter of fact, the auto feeder is made in such a way that from the filled hopper (it does not matter what it will be and what it is made of: from a plastic bottle, glass, wooden, etc.) as the bird eats grain, it spills out into a container under the hopper (bowl , cell other).

Almost all of the above types of feeders are built on a bunker basis. This is the auto feeder.That is, having filled the grain into the bunker once, for example, in the morning, the owner does not worry that he needs to feed the bird in 3, 6 or 24 hours. When it is empty, the bunker is again filled with feed.

All that is needed for his equipment is a bowl or disposable plastic utensils., depending on the size of the hopper itself (it can be a 20-liter bucket, or it can be an ice cream bucket).

In the bottom along the perimeter we cut small holes so that the food can be poured into the bowl when it is eaten. From above, this design is covered with a lid.

It can be made more mobile by attaching a handle to the structure.

As you can see, there are a lot of techniques for making feeders. We stop our choice based on the specific situation: the number of bird heads, its age, conditions of detention, the availability of certain materials in the household, for what purposes it is grown (for example, if these are broilers, then a bunker feeder (it is also an auto feeder) is simply irreplaceable , since broilers need to constantly feed, and from time to time during the day it is quite troublesome to add feed to the bird).

In addition, the material of the feeder itself also depends on the composition of the feed. For example, for a damp mash, an open-type metal or plastic feeder is better suited. It is easier to clean. For bulk feed, hopper feeders are ideal. They keep the food inside dry and clean.