Content

How to make a bee hive with your own hands

Once you've decided to become a beekeeper and bought a couple of families, it's time for new hives to be needed. Families grow and swarm and need to be moved into new houses. You can, of course, buy ready-made ones, but it is dangerous to buy used ones. It is not known what diseases can be bought with them, but they bite at new prices. There remains one thing - to make bee hives with your own hands according to the drawings. If you know all the manufacturing rules, then it is not difficult at all.

In this article, we will just talk about making hives with our own hands, the correct sizes and drawings for them. We will find out what a beehive lounger is and how to make it.

Materials needed to make a bee hive

In ancient times, beekeepers mined honey in the hollows of trees, then they began to hollow out logs for bees. With the development of beekeeping, they began to produce evidence for bees with their own hands of different designs, and the material for them is different.

Wood

The classic option for making bee hives. In such houses, bees feel in natural conditions, close to natural ones. The best wood species for making will be cedar, although linden and aspen are also possible. These hives breathe better, smell good and are dry.

Aspen and linden hives require additional insulation in winter. And these are expensive materials.

Some beekeepers make their own beehives from cheaper materials. These are pine, spruce, fir. But in such evidence, the bees are not comfortable. They collect moisture and resins, especially in new ones.... Coniferous smell. There is only one good thing in them, they are warm and require minimal insulation for the winter.

Plywood

Durable and environmentally friendly material. A house made of it must be covered with paints and insulated from the inside with expanded polystyrene, then it will be dry and warm in it. But plywood is afraid of moisture and requires constant and proper care.

Expanded polystyrene

A modern material used by beekeepers to make beehives. It has a low cost and does not require additional insulation in the winter.

Styrofoam

The most economical option. It is possible to use packaging from household appliances. The advantage of this material is its lightness even with filled frames. Excellent thermal insulation. The downside of this material is its fragility and constant color, so that it does not crumble from exposure to sunlight.

Polyurethane

Excellent thermal insulation properties. Does not rot, does not decompose. Fungus and bacteria do not develop in it. It does not allow moisture to pass through and it does not accumulate inside. Bees, mice and birds do not like to gnaw him.

Having carefully studied the characteristics of the material, you can start building the hive. Consider the options for the construction of wooden and foam houses.

Types and designs of hives

To keep bees, several types of hives are used, differing in design, volume, material and functionality. Providing bees with suitable housing means creating good conditions for life and work, and yourself with a good harvest of honey.

Bee houses are divided by design:

- collapsible;

- non-separable.

The latter, due to the difficulty in leaving, almost no one uses... All beekeepers use frame hives, where the number of frames can vary. A popular do-it-yourself hive is a 24-frame lounger. However, there are options for 16 and 20 frames.

In turn, frame hives are divided into:

- horizontal;

- vertical.

The horizontal or "lounger" consists of one body. Expansion goes sideways. It is easy to work with such evidence, to change the number of frames, but they have a drawback - they are cumbersome and heavy.

Vertical ones consist of several buildings. This form is lightweight and mobile.

Both forms use multiple sections. They are separated by partitions, which allows the volume to be changed in any direction.

You will also be interested to know:

- What to do with a bee sting.

- How to use royal jelly in cosmetology and medicine.

- How to use propolis tincture at home.

Popular designs

Dadanovsky

Used in almost all apiaries. Made of wood (cedar, spruce, pine, linden, aspen). Differs in simplicity and spaciousness. Consists of 12 frames and can be supplemented as the family grows, shops or buildings. In winter, bees are kept in the nesting compartment. With the onset of warmth and the increase in the family, they are supervised with buildings.

Alpine

Multi-hive hive. The creator is the French beekeeper Roger Delon. Made according to the hollow principle. That is, the natural living conditions of bees have been created and taken into account.

Compact design is convenient for confined spaces... It has no partitions or ventilation holes. Air flows naturally through the taphole.

Ruta

This DIY bee house intended for keeping bees in southern regions, because due to constant rearrangements of the buildings, hypothermia of the house occurs. Consists of 6 buildings with 10 frames.

Cassette

In connection with the increase in the incidence of bees among beekeepers, cassette hives have become popular. Such evidence have thin partitions, therefore, bees create a microclimate on their own.

Ukrainian lounger

Such a design of the hive in size is most suitable for beginners... They are easy to maintain. Easy to build, which will allow you to master the skills of beekeeping. Usually such hives are for 20 frames. The sides of the house are insulated, so the bees hibernate in them.

There are many designs of evidence, but let us dwell in more detail on the classic, lounger with a different number of frames and a multi-body, foldless. In this case, there are beehives sun beds for 16, 20 and 24 frames.

How to build a classic beehive step by step

Due to the simplicity of manufacture, the Dadanovsky hive is considered a classic option.

The classic beehive construction consists of:

- One or more buildings.

- One or two shops.

- Roof cover.

- The bottom of the hive.

- Ceiling.

- Roofs.

- Framework.

- Feeders.

- Plug-in boards.

Bee house instruction with drawings

Now let's talk about how to make a beehive with your own hands step by step. The sizes of the bee hive can be very different, but we will focus on one option. To do this, you will need:

- pick up the material (linden, pine, cedar, spruce, polystyrene, polyurethane, polystyrene), it must be dried;

- take boards 4 cm thick, go to the manufacture of the bottom and body;

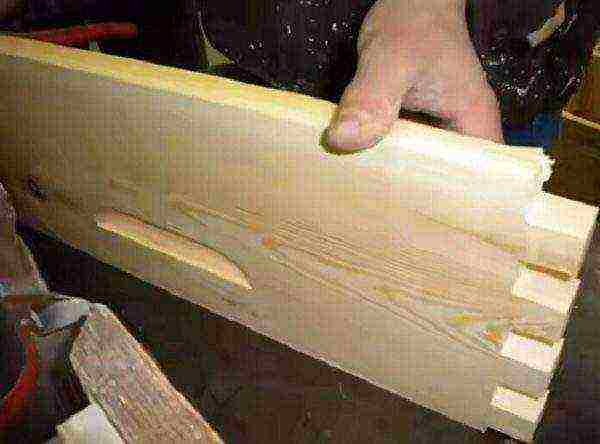

- make grooves in the boards to connect the walls of the body;

Beginning of assembling the hive.Preparing boards for the bee house. - make strips 18 * 4 mm;

- connect the boards into shields, for this we grease the grooves with PVA glue or liquid nails and press firmly against each other;

- you need to make five walls (one will be the bottom);

- connect the walls to each other;

- the lower body is assembled;

- paint the hive with acrylics and let dry;

- you need to drill the cells.

A 15mm thick board is required for the lid and sub-roof. Collect and cover with tin to prevent water ingress. Paint. Make ventilation holes 1.4 cm in diameter.

Dimensions:

- back and front shield (cm): width 53, height 32, thickness 4.

- side shield (cm): width 48, height 32, thickness 4.

- inner (cm): width 45, height 45, thickness 32.

In order to place the frames in the body, you need to make folds.

Dimensions 1.1 * 2 cm.

If there is a multi-body bee hive, then the dimensions will be different: 1 * 1.4 cm.

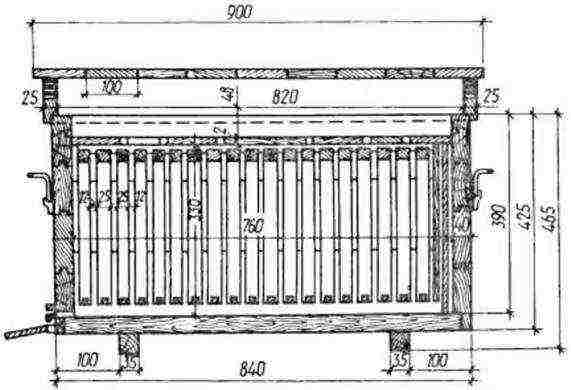

Drawing of 12 frame hive:

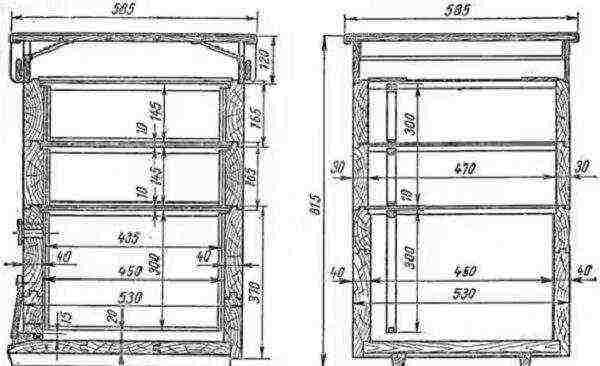

Drawing of 10 frame hive:

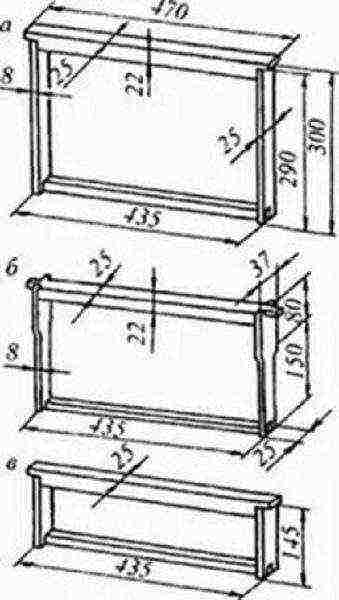

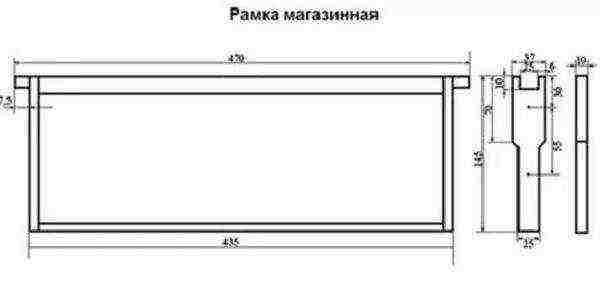

The frame in the nest is 43.5 * 30 cm;

Shop frame - 43.5 * 14.5 cm;

The distance from the walls of the case to the side strips is 0.07 cm;

Frame space - 2.5 cm;

Frame side width - 3.7 cm.

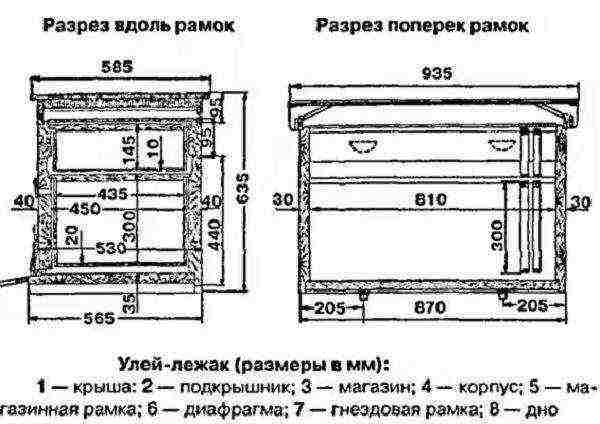

Beehive lounger for 16, 20 and 24 frames: drawings and dimensions

What tools and material will you need?

- Wood, plywood, polystyrene.

- Rulers, or tape measures.

- Squares;

- Hacksaws.

- Hammers.

- Drill, drill, self-tapping screws.

- Chisels.

- Glue.

- Carrying handles.

- Galvanized sheet metal for the roof.

- Frames in the amount of 24 pieces.

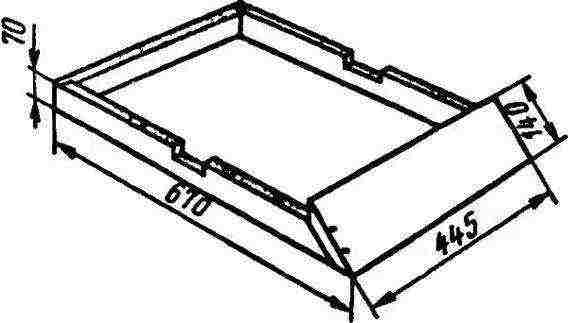

Hive dimensions:

- frames 30 * 43.5 cm;

- body (cm): length 87, width 56.5, height 63.5;

- roof length (cm): outside 93.5, inside 81;

- bottom thickness 3.5 cm;

- lower notch - 1.2 * 14 cm;

- the upper notch is 2.5 cm in diameter.

Instructions for making a beehive for 24 frames

- Cut out parts from the prepared material according to the drawings.

- Collect the bottom. Connect the two battens and the deck with soil and nails.

- Connect the side walls and attach to the bottom. Make a protrusion behind the bars 2 cm.

- Make grooves for frames on the front and rear walls. Size 1.8 * 1.1 cm.

- Cut the entrances from below.

- Attach a latch and an arrival board.

- Make a roof. Fasten the boards with nails into a thorn.

- Attach the opening hinges to the roof.

- Cover the roof with tin.

- Make a ventilation hole 20 * 0.03 cm on the rear side of the roof.

- On the front wall we drill a hole with a diameter of 2.5 cm.

- Cover them with a net.

- Strong legs to the bottom.

- Prolify and paint.

- Attach handles to make it easy to carry.

How to make evidence lounger for 20 and 16 frames

It is made according to the same principle with a difference in size.

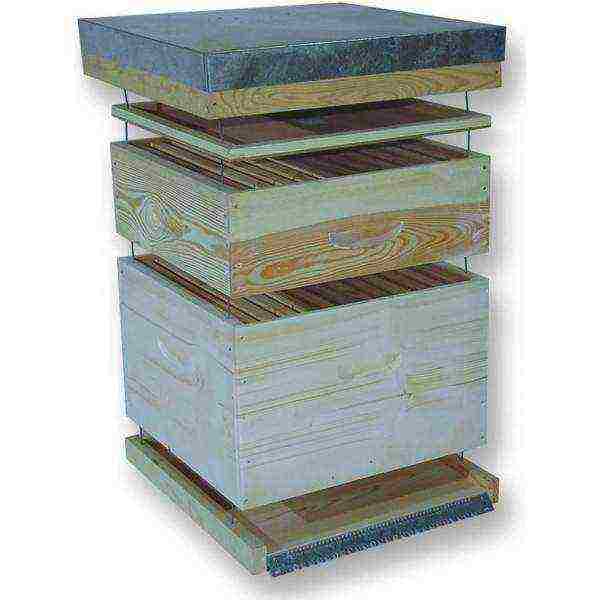

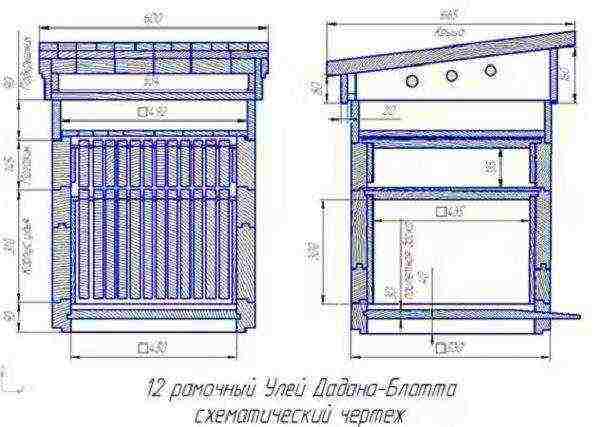

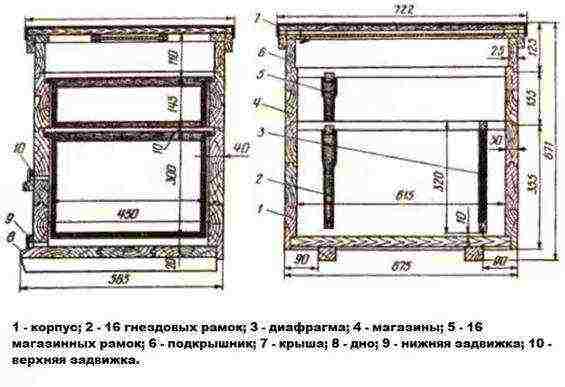

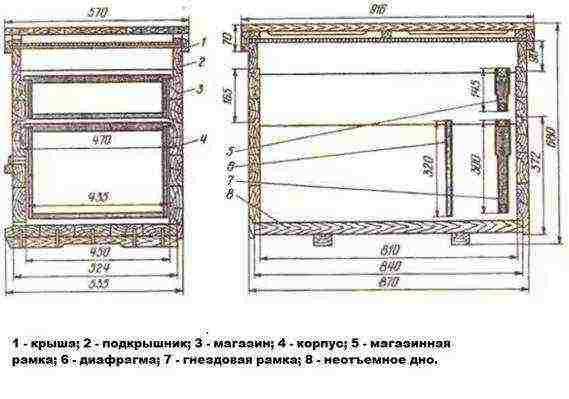

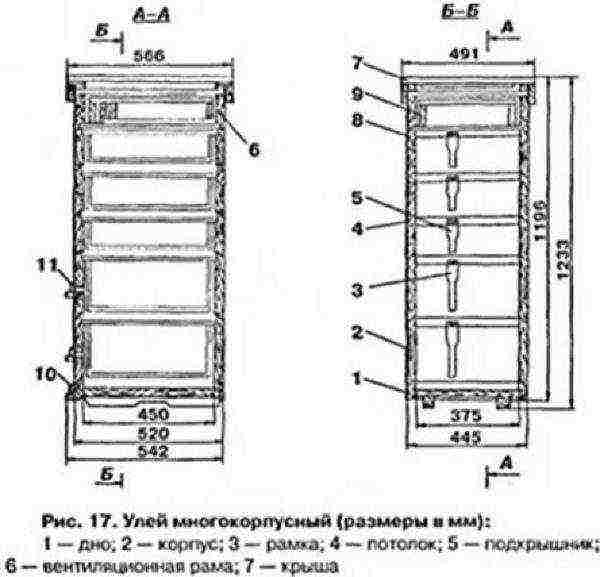

Multi-hull foldless hive: dimensions and drawings.

Over the years, this hive has not lost its popularity in use. Its user-friendly design allows it to be used anywhere. And it is simple to manufacture.

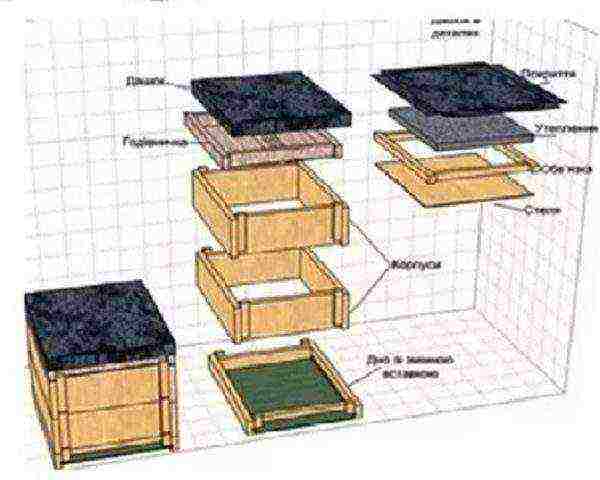

In order to build a hive correctly, you need to know what the structure consists of:

- Lid.

- Roof or ceiling.

- The shops.

- Housings.

- Bottom.

- Stand.

- Framework.

- Separating lattice.

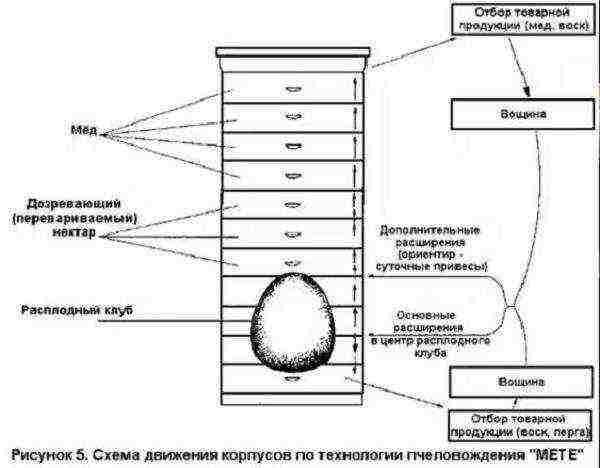

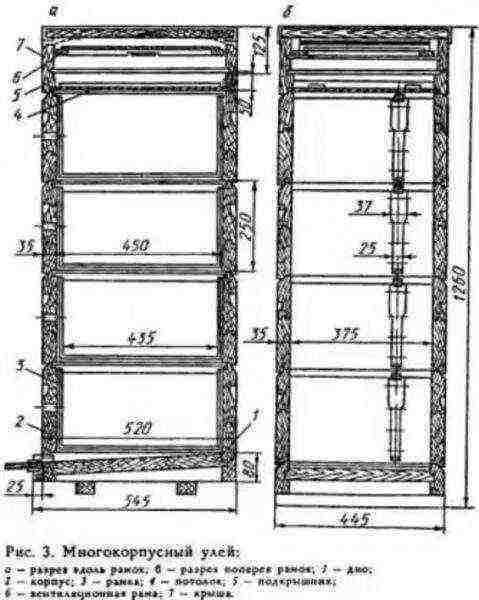

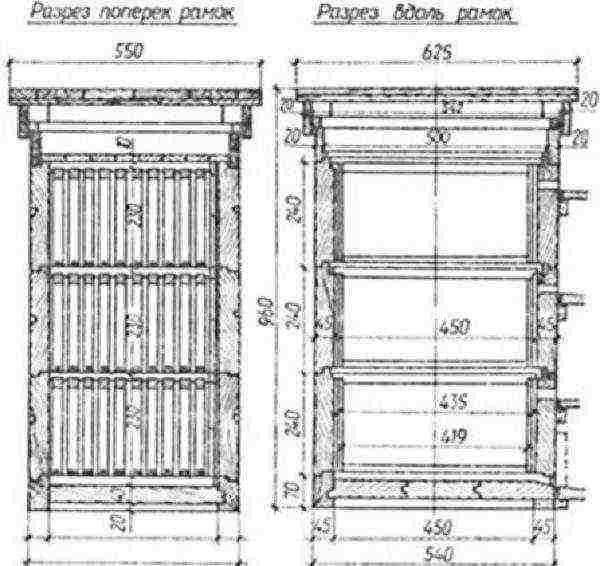

The case looks like a box. Its size from the inside (cm): 37.5 wide; length 45; height 24.

It includes 10 - 12 frames measuring 43.5 * 23 cm.

Reducing the size leads to inconvenience in working with frames. They cannot be reached when they are heavily propolised or swollen with moisture. Therefore, some increase the width of the body to 38 cm.

For the manufacture of cases, you need to take carefully dried boards. They should dry out within a year. When cutting out parts, the boards should be with a small margin (3-5 mm).The stock is left for further fitting of parts. For trimming, it is recommended to leave a gap of 1 cm.

Make folds on the front and back parts of the case to put frames on them. The sizes are 1.1 and 1.7 cm. This depth allows the upper body to be placed freely.

On the side walls, you need to attach handles or small recesses.

A 25 mm hole is drilled from the end of the hive under the roof for ventilation of the house.

Boxes with frames are tightly connected to each other. In this case, folds are not used. Such a constructive solution is more convenient to operate and easier to build.

You should also read about:

- The healing properties of propolis ointment.

- Secrets of treatment with tincture of wax moth and recipes for its preparation.

- How to determine the quality and naturalness of honey.

In housings with the use of folds during transportation or movement, the bees are most often hammered into the lower part and hide in the folded grooves, and subsequently die. Most often, the uterus dies in them and beekeepers abandoned such hives in favor of a foldless design.

For the manufacture of the roof, a plate with a thickness of 2 cm is taken. A shield is knocked off from it, which is covered with galvanized sheet metal.

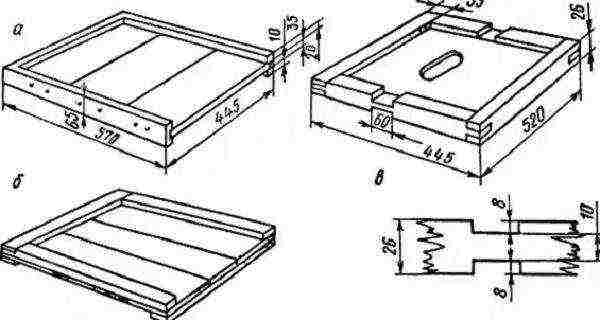

It is better to make the bottom removable, bilateral.

- three bars 57 * 6.5 * 3.5 cm - side;

- one 44.5 * 6.5 * 3. cm installed at the back.

Make grooves in them. Width 3.5 and depth 1 cm. Assemble the U-shaped structure. The grooves are intended for the installation of the floor plate.

It is necessary to provide for a protrusion of the front by 50 mm. It serves as an arrival board.

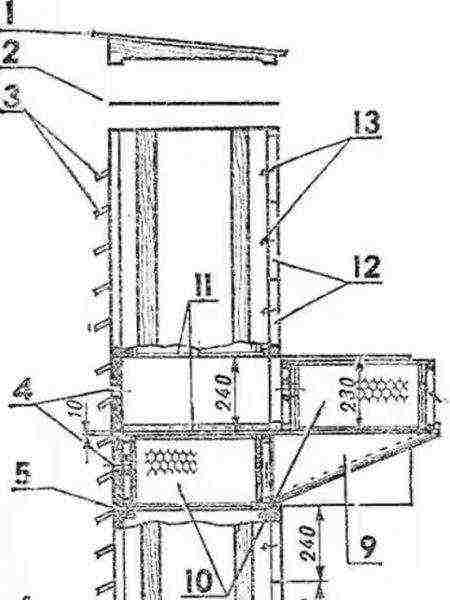

The roof cover (ceiling) is a solid flap, assembled from dies, measuring 52 * 44 cm. Around it is a rim made of slats. They are 3.5 cm wide and 1.5 cm thick. A hole is made in the center. It is needed for ventilation between the buildings or a feeder is placed on it.

The liner is placed on the body with the smooth side without a rim, which allows the bees to move freely. It can also serve as a dividing grid, in this case a mesh is stuffed onto the hole.

Stand.It is made of bars according to the size of the bottom. In the front part, a wide plate is nailed at an angle of 45 °. This will be the arrival board.

A 2.5 * 9 cm recess is cut out in the side bars. They are designed for convenience when you need to raise the hive or fix it when moving.

Dimensions of the dividing grid.Designed to isolate the temporary isolation of the uterus. For separating the brood body from the honey ones.

The size of the grille must match the size of the inner case. It is placed on the bars. Made from wire mesh.

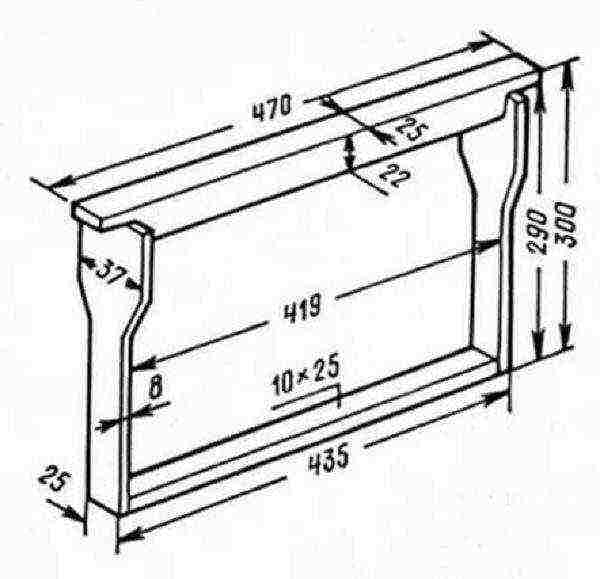

Frame sizes.Body and shop frames can also be made by hand. They must match the drawings.

Drawings of multi-hive hives.

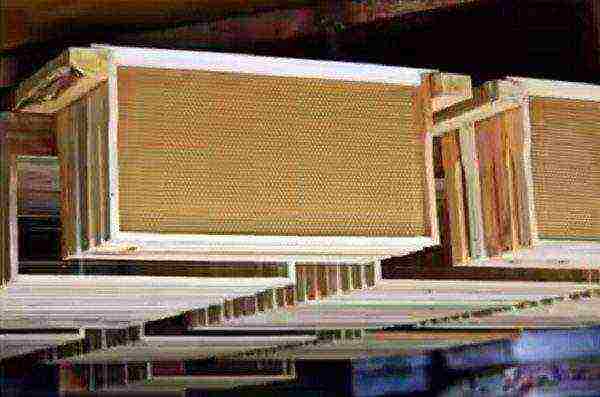

Frames in a beehive: sizes and descriptions of how to do it yourself

Frames are an important part of hives and most of the work is done with them. From constant use, they become unusable and need to be added. Therefore, the beekeeper should always have a large supply. To save money, it is better to make them yourself than to constantly purchase.

To make the frames, we will use the following tools:

- hammer;

- pliers;

- with an awl;

- boot nails;

- with a skein of thin wire.

Use natural materials for manufacturing. It is better if these are boards dried during the year. To make a frame, you should know what parts it consists of:

Upper bar.

Grooved or uniform.

Bottom bar.

Plain, grooved, or through.

Side bars.

They have holes for pulling the wire under the foundation.

The dimensions of the frames depend on the design of your hive. Standard sizes are:

- the width of the top and side boards is 2.5 cm;

- the height of the upper block is 2 cm;

- bottom width 1.5 - 2.5 cm;

- height 1 cm;

- external dimensions vary from the design of the hive, but usually 43.5 * 30 cm.

After we have chosen the material and decided on the dimensions, we proceed to the direct manufacture of the frame.

- Cut out details from dry boards according to the dimensions of the drawing.

- Connect all the parts using shoe nails.

- Drill 4 holes on the side strips and two double holes for attaching the wire. The distance between the holes must be equal.

- Stretch the wire. Start at the top hole and pull it out with a snake. Make sure that the wire does not cross anywhere. Fasten it securely so that heavy combs do not accidentally break off. As a result, you should have 4 lines.

On the frames prepared in this way, the foundation is fixed.

Now you know how to make your own bee hives with your own hands with drawings. Using the drawings and dimensions, you can easily build it yourself, thereby saving your budget and providing the bees with comfortable living conditions.