1 Functions of engine oil

Each technique, including walk-behind tractors, comes with a passport and instructions for sale. Manufacturers always recommend in the instructions those types of oil that will allow the technique to last a long time and not break.

You need to know that during the operation of the walk-behind tractor, engine oil performs 4 functions at once:

- cooling;

- grease;

- cleaning;

- seal.

A wide selection of oils for the walk-behind tractor

When the air-cooled walk-behind tractor engine is running, the lubricant burns and remains on the hot cylinder, after which a smoky exhaust is formed. The deposition of resinous substances dramatically affects the contamination of some parts and their lubrication becomes more difficult.

It is recommended to use antioxidant agents with oil, which clean the engine from dirty deposits. Correctly selected oil for a walk-behind tractor according to the SAE classification is a guarantee of the durability of the equipment.

For example, when using grease of the SAE 10W30 type at a temperature of 5 ° C and higher, its consumption will be much higher and there will be a high probability of engine breakdown. It is undesirable to pour summer lubricants at air temperatures below 5 ° C. Such use results in difficult starting of the engine and damage to the cylinder bore.

1.1 Classification of oil grades by viscosity

The viscosity grade of engine oil grades is generally classified according to SAE (Society of Automotive Engineers).

High quality flushing oil MPA - 2

Namely:

- Summer grades - oils belonging to this category are used in summer, have a high viscosity and do not have a letter designation. These include: SAE 20, 30, 40, 50, 60.

- Winter grades - these oils are used in winter and have a low viscosity. The letter designation of this variety is W (Winter). These include: SAE 0W, 5W, 10W, 15W, 20W, 25W.

- All-season varieties are the most popular at the present time, as they are used both in summer and winter. They are designated by a double combination: 5W-30, 10W-40.

In addition to seasonal differences in lubricants, they are divided in composition into two types:

- mineral;

- synthetic;

- semi-synthetic.

| Differences in chemical and physical characteristics of oils of different types for 4-stroke engines | |||

| Indicators | Mineral | Semi-synthetic | Synthetic |

| Viscosity index | 90-100 | 115-125 | 130-160 |

| Alkaline number, mg | 5,5-10 | 5, -10 | 5,5-10 |

| Pour point, ° С | -15 | -30 | -40 |

All oils are also divided into lubricants for both 2-stroke and 4-stroke engines. Usually, 4-stroke air-cooled engines are installed on motoblocks. Such engines only need to be filled with 4-stroke oil.

Checking the oil level with the dipstick in the oil filler hole

An air-cooled engine runs more heat than a water-cooled engine under the same operating conditions. Therefore, the filling liquid must have low volatility and high thermal-oxidative stability. Also, modern oils must be environmentally friendly, i.e. the amount of smoke and toxicity of exhaust gases is controlled.

Since waste is often simply burned in boilers or steam generators, it should not contain components that form toxic compounds when burned. In a motor-cultivator that runs on gasoline and does not have instructions, it is better to pour 4-stroke oil of the 5W30 or SAE30 brand.

In winter, winter or gear oil, such as 0W40, is preferable. But this quality comes at a price. It is not worth saving on this, because high-quality oil affects less engine wear and its durability.

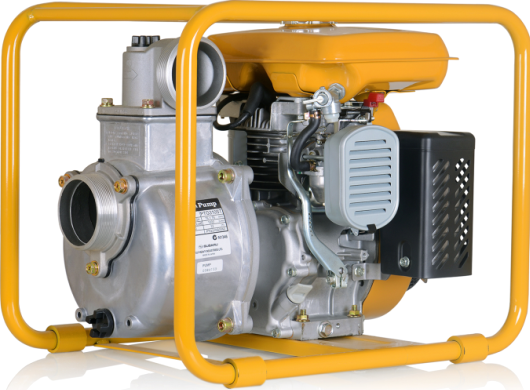

Fuel consumption during operation of a motor pump per hour

Fuel consumption is an important indicator of any technical device. It depends on the following specifications:

- type of engine;

- pump performance;

- suction depth and lift height;

- diameters of nozzles;

- the head created by the liquid at the outlet.

There are units on the market for professionals and for household use. The former consume more fuel - on average, up to 3 liters per hour. The consumption of gasoline per hour for household pumps does not exceed one liter.

The operating time of the unit at one filling is also important. Refueling will result in interruptions and the pump engine must cool down before refueling. Of course, this does not matter for summer residents, but for professionals every minute is important. In theory, the time of continuous operation can be easily calculated by dividing the capacity of the fuel tank by the standard fuel consumption. The consumption of the motor pump, in general, allows the operation of about two hours. But in fact, it still depends on the set power, which is regulated by the operating operator, fuel quality, weather conditions and a number of other factors.

Gasoline motor pumps will facilitate many jobs, and in some cases they are irreplaceable. Therefore, they should be purchased, the costs incurred will certainly pay off.

Safety precautions when working on a loader crane.

For how long are the overalls issued?

Quanto costa

In the public sector, low-power two-stroke gasoline motor pumps are out of competition. Their advantage is the low price and easy engine repair - the "two-stroke" is simpler than the "four-stroke".

The disadvantage is that these pumps are more difficult to handle. In addition, the resource and power of such motor pumps are usually lower, and the fuel consumption and environmental cleanliness of the exhaust are lower.

Four-stroke motor pumps are more powerful, but they also cost more. In powerful motor pumps for contaminated water, four-stroke engines are most often used.

The most powerful motor pumps are diesel ones. In addition, due to the greater strength of the materials, they have a higher engine resource. The only drawback of diesel motor pumps is the high price of both the pump itself and its spare parts. But this is sufficiently compensated by the high reliability and low fuel consumption.

Application area

Motor pumps have been used for many decades in various areas of human life. Among the most significant are the following:

- agricultural irrigation;

- extinguishing fires;

- water supply for private houses;

- erosion of the soil surface;

- moving large volumes of water between containers;

- drainage pumping;

- autonomous water supply in emergency situations;

- pumping out water from the emergency water supply system;

- construction work;

- elimination of emergency situations;

- elimination of accidents on the railway;

- filling of pools and reservoirs;

- drainage of wetlands;

- pumping of oil products;

- movement of chemical fluids and faeces;

- cleaning of cesspools.

For the implementation of measures for the irrigation of the personal plot, experts recommend using several types of motor pumps.

- Gasoline engines 2-stroke and 4-stroke. Advantages - low price range. Disadvantages - poor performance.

- Diesel engines. Disadvantages - high cost, presence of noise vibrations. Advantages - high power level, the ability to use inexpensive fuel, versatility.

- Gas engines. Advantages - a long period of operation, the ability to use gas or electricity, the absence of soot. Disadvantages - high price range, the need to fill gas cylinders.

The dirty water device has a wide range of applications and can be used for the following tasks:

- draining basements and cellars;

- elimination of accidents in the public sector;

- filling of artificial reservoirs;

- filling of pools of different sizes.

The dirty water tiller is capable of lifting water from a depth of more than 75 m, which contains large particles of sand and gravel. The maximum size of the inlet section is 10 mm. This device has a number of features that significantly increase its service life:

- the material for the manufacture of the main parts is cast iron;

- the use of anti-corrosion agents;

- the presence of water cooling of the engine;

- top placement of valves;

- the presence of smooth corners on the transport frame;

- automatic supply of lubricants;

- the ability to work at low speeds;

- the presence of an iron square frame;

- mobility;

- small size.

Popular manufacturers and estimated prices

The price that one has to pay for autonomy is a complex device, expensive repairs and maintenance. The electric motor does not need high-quality fuel, adjustment of injection and ignition, air and oil filters. On the contrary, all these components are of great importance for the performance of a motor pump. Therefore, when buying a stand-alone pump, you need to focus on products that have passed the test of time and have earned positive feedback from the owners.

Honda WB20X

Honda WB20X

Having bought a motor pump from the Japanese corporation Honda, Hitachi, Koshin or Subaru, you can be sure that it will work out its resource without serious breakdowns and expensive repairs. However, the cost of such equipment is quite high and is (for fire-fighting motor pumps) from 18,000 rubles. Average prices for Japanese-made pumps designed for pumping dirty water start at 40 thousand rubles.

ROBIN-SUBARU PTG310ST for dirty water

ROBIN-SUBARU PTG310ST for dirty water

A brand is an important but not the only choice aid. Some manufacturers, such as Fubag and DDE, are compromising on price. They put reliable Honda engines on their models, and make the rest of the units themselves. As a result, the consumer receives good quality at reasonable prices (from 9,000 rubles for pumps for clean water and from 20,000 rubles for mud).

FUBAG PTH 600

FUBAG PTH 600

Popular budget model CHAMPION GP26-II

Popular budget model CHAMPION GP26-II

Reviews of motor pumps of domestic and Chinese production are contradictory. Some owners are happy with the purchase and claim that the quality of the pump matches its price. Others, on the contrary, complain about the low reliability of these installations, the high cost of repairs and the lack of spare parts.

Huter MP 50

Huter MP 50

The motor pumps of the German brand Huter, assembled in China, have proven themselves quite well. They are quite reliable and inexpensive. Prices for installations for pumping clean water start at 8,000 rubles. For a mud pump of this manufacturer, you will have to pay from 23,000 rubles.

Types of fuel used

Motor pumps are equipped with engines that use different types of fuel. Depending on this principle, such models are distinguished:

- diesel motor pump;

- gasoline;

- gas.

In gasoline and gas units, an engine with approximately the same design is installed. In some cases, the owners of country houses adapt a gasoline appliance for another fuel - gas. However, in this case, additional installation of the gear-type module is required.

Read here: Best Gasoline Snow Throwers - Ranking of the Best Models of 2020. Assessing the quality of inexpensive homemade devices

When it is planned to organize irrigation on the site, then a gasoline motor pump with a two-stroke engine is more expedient. Equipment equipped with gas or electric motors is quite expensive. It is also not very effective.

The most famous brands of oil Sae 30

- • Russian brand CARVER Sae30, known as a mineral summer oil with dispersant, antioxidant, anticorrosive additives. This is an excellent lubrication option for keeping the engine in top working condition for a long time.

- • Mineral grease Motul Garden 4T Sae30 also has a number of advantages, it has good resistance to temperature, resistant to foaming. It can be successfully combined with various types of fuel.

- • Swedish oil product Husqvarna Sae30 also has a lot of fans, has a number of advantages, such as durability, anti-carbon properties, stability and efficiency.

- • American mineral grease Patriot Supreme HD Sae30, has proven itself well under heavy and increased loads. For owners of motoblocks, mini-tractors, mowers, this is an ideal lubrication option.

- • Premium Bison 10W-30 - produced for all-season use. It is a Russian brand used for diesel units and gasoline engines. It has high resistance to oxidative processes, it is used in the temperature range from -25 to +50 degrees.

- • G-MOTION 4T 10W-30 German fluid for lubricating four-stroke engines. Has high thermal oxidative protection, reduces wear of engine elements. Especially in demand on walk-behind tractors, cultivators, snow blowers.

In addition to the excellent performance of the working base, the oils have a high level of extreme pressure performance. They manifest themselves at a height, both in an aggressive environment and during overloads. Due to the reduced level of wear and the protective layer, light equipment is used for a long time. At the same time, energy consumption is greatly reduced, and this is undoubtedly in favor of the owner of the power unit.

Operation and causes of engine breakdown

Most often, two-stroke motors are found in motor vehicles, boat engines, lawn mowers, chain saws and other devices where a light and reliable engine is required. Nevertheless, even such a simple design engine can fail due to violation of the operating rules.

Poor quality of gasoline. Poor fuel often leads to knocking. This is most often noticeable at low revs with podgazovki. The resulting shock loads lead to breakage of the piston baffles, excessive loads on the crankshaft bearings. Detonation can occur due to engine overheating, piston carbon deposits and a lean mixture.

Poor quality of parts from which the motor is assembled. This is especially true for Chinese manufacturers, who often allow defects in the production of components. This leads to early failure of the piston, crankshaft, cylinder and other parts, and then overhaul. A simple compression measurement usually helps to assess the piston condition.

Low quality engine oil

Fuel-oil mixture for two-stroke engines is very important. It will depend on its quality how smoothly the engine works, the cleanliness of the exhaust, the absence of overheating and unnecessary noise.

Bad oil leads to the formation of a layer of carbon deposits on the piston, in the main and connecting rod bearings, to scuffing on the cylinder walls and the piston skirt, the passage section of the muffler decreases due to carbon deposits. Oils for two-stroke engines should be used synthetic or semi-synthetic, the use of mineral water is undesirable.

Overheating on an air-cooled two-stroke engine is not uncommon. This is caused by prolonged operation with a fully open throttle, or a malfunction of the cooling system. Overheating can be short-term, when there is a loss of power and maximum speed, after reducing the load and cooling the engine, everything returns to normal. A wedge occurs due to very strong overheating, when the thermal gap between the piston and the cylinder is reduced so much that the friction forces tightly grab them together. After it, repair of the CPG is required.

Carburetor not tuned. The fuel mixture is too lean or too rich. Driving on an over-rich mixture is fraught with high fuel consumption, loss of power and sludge formation. A lean mixture can cause knocking and a decrease in maximum engine power.

Yet, due to the toxicity of the exhaust, two-stroke engines are gradually being replaced by modern four-stroke engines. They continue to be used only where high power density is required with minimal weight and simplicity of design - motor vehicles, chainsaws and trimmers, aircraft models and much more.

Varieties and specifications

Manufacturers divide all products of this group of goods into 3 classes according to the method of movement.

- First (portable). Lightweight models with manual starter and low oil consumption;

- Second (mobile). Models weighing less than 110 kg. These devices are the most popular and highly mobile.

- The third (stationary) - professional devices, the mass of which exceeds 120 kg, the pumping volume is in the range of 500-1000 liters per minute. The devices are used in industrial enterprises, have a powerful diesel engine and improved technical parameters.

There are several types of motor pumps:

- gasoline with a 2-stroke internal combustion engine;

- gasoline with a 4-stroke internal combustion engine;

- diesel;

- electrical;

- with gas power plants.

There are several types of pumps, which differ in the level of purification of the pumped liquid.

- For dirty water. They are used for pumping water with sand and gravel, the diameter of which does not exceed 30 mm. Scope - construction and emergency response.

- For lightly contaminated water. They are used to work with water in which there are solid and fibrous particles no more than 0.1 cm in size. Scope of application - removal of water from flooded basements and drained reservoirs, for the performance of work by public utilities.

- For clean water. They have special filters with small cells. The field of application is filling of pools and irrigation of agricultural crops.

- For chemicals and liquid fertilizers.

In floating diaphragm trailed motor pumps, the minimum capacity is 600 liters per minute. The main task of the device is to eliminate accidents and solve complex problems in hard-to-reach places. The period of operation at maximum load is 1 hour. The diaphragm device is used to transport viscous liquids and has a special principle of operation, which consists in lowering and increasing pressure due to the movement of the diaphragm and the blocking valve.

What kind of oil to fill?

A walk-behind tractor, like any other technical device, needs careful use and constant care. Oil plays a huge role in this process, which ensures stable operation of the power plant. However, it is necessary to figure out what kind of oil can be poured into a particular engine, since the durability of the unit depends on this.

Of course, the most correct option will be the one indicated in the instructions for use. It is necessary to carefully read the document and strictly follow it. If this information is not specified, you can use the classification of the American Petroleum Institute.

- API CJ-4 oil will be an excellent solution for devices with high power. We are talking about power units that produce 10-12 horsepower. Such installations are subjected to enormous loads on a regular basis. This type of oil fully complies with the regulations on particulate matter emissions.

- CH-4 can only be used in four-stroke power plants that run on diesel fuel. The main advantage of this oil is its minimal sensitivity to fuel quality.

- CF-2 oil will be an excellent option for motoblocks that differ in two-stroke power units. The product contains special additives that provide reliable protection of the power plant against wear and have a positive effect on durability.

Sometimes situations may arise when the work of the walk-behind tractor is not as smooth as we would like. There are several main reasons for this problem.

- Poor PCV performance, causing oil to flow back into the powertrain. To solve this problem, you need to replace the PCV valve.

- Mechanical malfunction of the diesel engine, which causes too much oil consumption.In this case, it is necessary to check the compression.

- Old valve seals that allow oil to enter the engine. These parts should be checked regularly and replaced if worn.

As is clear from the above, diesel power units are considered the ideal solution for motoblocks. They are characterized by a low level of fuel consumption, which is especially important when the equipment is used regularly

When choosing, be sure to pay attention to the power of the installation, the type of oil to be filled, and other technical parameters.

For more information on popular models of diesel engines for a walk-behind tractor, see the video below.

Let’s block ads! (Why?)

In what cases is a motor pump for dirty water necessary, features of its application

Unlike a device such as a pumping station, a gasoline motor pump does not require special knowledge for operation, but it is used for the following purposes:

- Providing water to a country house or summer cottage;

- Irrigation system equipment, moreover, not only the backyard territory, but also agricultural fields;

- Drainage of ponds, ditches, construction sites;

- Extinguishing fires;

- Pumping water and other liquids, carrying out drainage works.

Thanks to the gasoline engine, and, therefore, independence from the mains, such a motor pump has a high autonomy of use and is much safer in operation.

- When using the equipment, you should take into account the features of its functioning:

- Avoid dry running - overheating will lead to breakage;

- Control the presence of oil and the condition of the filter - this will ensure long-term engine operation;

- Put the device away for storage only after draining gasoline from it;

- Follow the instructions clearly when starting the motor pump;

- Watch out for kinks;

- Avoid prolonged use of the pump for pumping hot water, despite the fact that the instructions indicate the upper threshold of +90 C.

Fire pumps, with increased outlet pressure

The term "fire" in the name of the pump should not be misleading. Using this name, manufacturers emphasize the increased pressure at the outlet of such household pumps.

Pumps of this design are used to supply water to consumers at a distance of hundreds of meters.

The height to which such a pump can pump water reaches 60 m, so they can be successfully used for fire extinguishing.

The performance of these pumps significantly exceeds this characteristic of low-pressure pumps and amounts to 400-600 l / min.

In the presence of a large suburban area or its location at a considerable distance from water sources, a high-pressure pump will be the best option, given that its weight and dimensions are not much higher than that of typical autonomous pumps.

Best lists

We will not dwell on the overall rating and make another small list in which we will consider one motor pump in the following categories:

- for pumping clean water;

- fire department;

- mud.

For pumping clean water

The HYUNDAI HY 81 is ideal for draining swimming pools, ponds, wells, garden irrigation or medium-height watering. Equipped with a professional performance motor. Light weight and compactness make it quite mobile for transportation. When pumping, the presence of solid particles up to 5-6 mm in diameter is allowed in the water.

| Overall dimension | 530x425x435 mm |

| The weight | 27 kg |

| Performance | 1000 l / min |

| Height of water column | 28 m |

| Suction depth | 8 m |

| Inlet pipe diameter | 80 mm |

| Engine volume | 212 cc |

| Fuel tank capacity | 3.6 l |

Cost: 13,500 rubles.

motor pump HYUNDAI HY 81

Fire department

Konner & Sohnen KS 50 HP high-pressure gasoline motor pump with the ability to supply water in three directions at once. The casing is made of high-strength aluminum that does not corrode and is protected by a metal tubular (pipe diameter 32 mm) frame from external damage.A high-quality and powerful engine guarantees high performance and low fuel consumption.

| Water column height | 70 mm |

| Motor | 210 cc |

| Tank capacity | 3.6 l |

| Discharge valve diameter | 40/40/50 |

| Productivity | 500 l / min |

| The weight | 28 kg |

Price: 19,000 - 20,000 rubles.

motor pump Konner & Sohnen KS 50 HP

Mud

Koshin KTH-100X is a very powerful device for highly contaminated water, perfect for use in municipal services. The HONDA GX340 gasoline engine is characterized by high performance, reliability and low noise level. A strainer protects the pump from penetration of solid particles with a diameter of more than 27 mm. The pump is supplied with a filter, two hose connections, clamps (3 pcs.) And a spark plug wrench.

| Weight | 85 Kg |

| Dimensions (edit) | 780x570x652 mm |

| Outlet diameter | 100 mm |

| Engine volume | 337 cc |

| Lifting height | 25 m |

| Power | 7100 Wt |

| Productivity | 1600 l / min |

Estimated cost: 142,000 - 143,000 rubles.

motor pump Koshin KTH-100X

What to look for when choosing

With all the variety of devices of this type on the market, it is rather difficult to make a choice, in this case, the main thing is to initially decide what exactly you are purchasing this equipment for and how much money you have to buy

Further, we are already paying attention to the technical characteristics, namely:

- Water delivery head or head. Quite an important criterion, especially in the construction or fire field, if you choose to water the garden, then 20 m is quite enough.

- Performance shows the speed of pumping liquids, and accordingly, the higher it is, the faster the pump will cope with the task.

- Perhaps you will not always pump absolutely clean water, so consider an option with a filter from large solid objects.

- The compactness of the device will be required during transportation if you water a dacha or a vegetable garden, and there is nowhere to store the pump right on the spot or it is dangerous.

These simple rules will help you in the process of selecting the necessary equipment.

What it is?

A motor pump is a surface-type transportable pump, which is widely used in all areas of human activity. The most important technical parameters are performance for 1 minute, lift height, suction depth, hole size, motor power. This device consists of two parts that constantly interact with each other:

- surface self-priming pump;

- mechanical internal combustion engine.

The surface apparatus belongs to the type of dynamic vane devices. The hydraulic machine and the crankshaft of the engine with impeller blades are reliably connected to each other or manufactured as a single piece. The liquid is set in motion by the impeller blades. Some models have multiple wheel stages. The movement of the wheels creates centrifugal force and different levels of pressure inside and out of the device.

To form the suction area, the designers placed curved blades on the moving disk, which are directed in the opposite direction relative to the movement of the wheel. The pressure difference inside the device and at the outlet facilitates the movement of the liquid, which moves from the inlet to the center of the installation and is poured out through the outlet. To increase productivity, experts recommend installing a motor pump at the level of water intake, which will significantly reduce its resistance.