The most budgetary, but high-quality grinder for home

Customer reviews and ratings play a significant role when choosing household appliances.

Sometimes the most expensive model of grinder with the most features has fewer positive reviews than its cheaper alternative.

Today, Bosch products please their customers with low-cost household electrical appliances and good quality.

If in this company there are practically no defective models, then this cannot be said about some domestic manufacturers of grinders.

Also, the products of the manufacturer Makita have proven themselves well in the market.

Video:

Further in the article, we will consider the technical characteristics of models from these well-known brands, how to choose a grinder, and also find out what kind of work the tools they produce are suitable for.

In the modern market of electrical tools, Bosch angle grinders, as well as Makita models, are in high demand.

The mentioned devices are operated with discs with a diameter of 125 mm, which allows them to be used in domestic conditions.

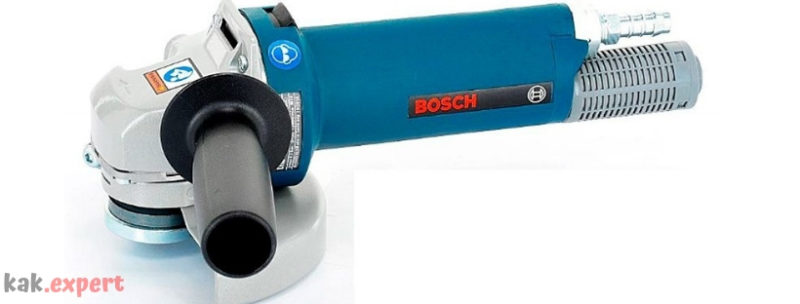

Bosch Angle Grinder

The Bosch GWS 850 CE model is equipped with an 850 W motor and a soft start button, which reduces the load on the network.

Professionals will not refuse to choose such a grinder, the more the device will seem convenient to use and inexperienced home craftsmen.

Despite the fact that the device belongs to the professional type, it is often purchased for domestic purposes.

At the same time, the speed of its rotation per minute can reach 11,000 revolutions. The weight of this angle grinder is 1.6 kg, which indicates its average power.

The device is equipped with a protective steel casing, which is installed in different positions, and has a narrowed body, so such a grinder can be safely operated in any hard-to-reach areas.

An intensive ventilation system will prevent the tool from overheating and prevent abrasive dust from settling.

Video:

Positive reviews from satisfied customers note the ideal ergonomics of the Bosch GWS 850 CE, - the machine is comfortable to hold in the hand.

The second degree of electrical protection ensures a safe working process. The machine is comfortable to use for right-handers and left-handers, since the handle can be installed on both sides of the device.

Depending on the place of sale, such a grinder can be bought for $ 60-90 with a three-year warranty.

Makita Angle Grinder

The Makita 9565 CVR grinder is much more expensive than the above-mentioned Bosch model, by about $ 150-180.

But if you want to buy really high-quality products with a 36-month warranty, some people prefer to overpay.

The presence of a drive with a SUPER-JOINT-SYSTEM clutch in the device prevents jerks and ensures a smooth start of the tool.

Consumers note that this model is well suited to work in all weather conditions, since the armature has a special coating, and the stator is well insulated.

Video:

The rotations in the angle grinder can be adjusted in two ways: by means of a special wheel located on the body of the grinder or by means of an electric force sensor.

Since the above tool has a high power, the weight of the machine is 2.4 kg. While low-power grinders will have a weight not exceeding 2 kg.

Angle grinder device, component parts

The design of angle grinders is distinguished by a relatively simple and technological design, which made it possible to establish their production at many enterprises.

The angle grinder consists of the following parts:

The body, which is made of reinforced polymers. Such materials are characterized by high strength, wear and environmental resistance. On the outer surface there is a button for turning on the tool with a lock. Some of the models have windows covered with hatches for replacing the drive brushes.

An electric motor powered by a household network or batteries. On angle grinders, drives are used that can provide high shaft speeds. To cool the windings and other parts, a fan is installed in the front part on the axle.

Single-stage bevel gear in a separate housing made mainly of magnesium or aluminum alloys. Consists of bevel gears, the shafts of which are mounted on ball or plain bearings. The interaction of parts with each other in the gearbox is provided by a housing filled with grease.

A spindle consisting of a shaft with a metric thread, a thick-walled washer and a nut for attaching a cut-off wheel or other equipment. On the gearbox housing, a button is usually provided on the opposite side, which fixes the shaft in motionlessness. This is necessary for dismantling and installing new equipment.

The removable handle is threaded and can be screwed into the gear housing in one of the selected positions. This is done for the convenience of holding the power tool in the process of performing various types of work.

Protective cover, covers part of the cutting wheel and does not allow the sheaf of sparks that is formed during work fly in all directions. The device protects the worker and the surrounding objects from wear and tear products of the tooling and material fragments formed during its processing.

The angle grinder is supplied to the consumer complete with a user's manual and a special wrench for attaching the equipment. The latter is a steel strip with two pins that match exactly with the holes in the fixing nut. In some cases, the manufacturer adds spare carbon brushes to the delivery set.

The principle of operation of angle grinders

The angle grinder is driven by an electric motor, which is turned on by pressing a latching button or switch. Power is supplied from the mains, as well as from a built-in or removable battery. Mostly the tool is equipped with collector motors, in which the stator winding has a large inductive resistance. This circumstance makes it possible to significantly reduce the operating currents.

While spinning, the shaft of the electric motor rotates the drive gear in the gearbox, which drives the driven gear, and thus transfers the force to the spindle. The body of the movement is made of magnesium or aluminum alloys to improve heat transfer. There are two types of gearing between gears: spur and helical (conical Glisson system). The second option is preferable because it provides greater reliability and helps to reduce noise.

On more expensive and more complex models, a trip clutch is used, which is installed between the motor and the gearbox. The main function of this unit is to prevent kickback when the disc suddenly stops due to jamming. This protects the operator from possible injury and the grinder components from damage. On such angle grinders, the spindle fixing button can be pressed until it stops completely.

The choice of a design scheme in which the plane of rotation of the cutting wheel or brush is parallel to the tool axis is explained quite simply. During the operation of the angle grinder, a significant torque arises, tending to divert the tool to the side. This effort is easily compensated by the operator, due to the optimal position of the arms along and perpendicular to the axis.

Purpose and scope of angle grinder

The term "grinder" for this construction tool appeared in the Soviet Union in the early 70s of the last century.This name was given to the angle grinders due to the place of origin; their manufacture was established at the Eltos-Bulgarka plant in Plovdiv. The angle grinder was designed by Ackermann + Schmitt (FLEX-Elektrowerkzeuge GmbH) in Steinheim an der Moore in 1954. The angle grinder quickly gained popularity among professionals, one of the main factors in the success of the tool was its versatility.

The use of special equipment allows using angle grinders to perform cutting and grinding operations of a wide range of various materials:

Ferrous and non-ferrous metals, as well as their alloys.

Natural and artificial stone.

Ceramic and silicate bricks.

Concrete and products from it.

All types of facing ceramic tiles.

Wood sanding.

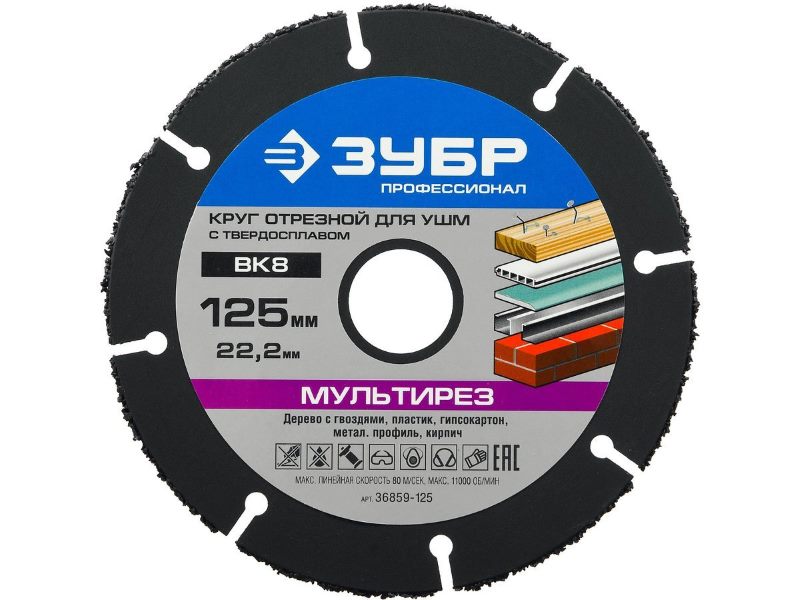

It is not recommended to use a grinder for cutting glass and wood, due to the high linear speed at the point of contact with the equipment, heating occurs and fire is possible. In recent years, circular saws for woodworking with soldered special high-melting alloys have been produced.

This accessory should be used very carefully and should not overheat. The above list of materials defines the main areas of application of angle grinders.

This power tool is widely used:

- In construction.

- At enterprises related to metalworking.

- In car body workshops.

A lot of angle grinders are in the hands of the population, the owners of households actively use them to perform household work. With its help, cutting and grinding of the above materials is carried out. This power tool, in particular, is used to process weld seams and descaling. The operation does not take much time and allows you to do without unnecessary shock loads on a fresh joint.

Security systems

In addition to these recommendations, how to choose an angle grinder, it is necessary to take into account the equipment of the grinder with safety mechanisms. The following options are important:

- number of handles for firm fixation;

- smooth start-up to prevent the wheel from jumping off at start-up and to minimize wear;

- protection against restarting after stopping;

- tool cooling system;

- inrush current regulator to reduce the load action on the network at start;

- protective clutch to prevent damage to the disc at the time of jamming;

- stopping mechanism at the moment of jamming;

- safety system to protect the engine from overheating.

Device and method of work

Considering the device of the grinder, we see that it consists of two power units - an electric motor and a gearbox. All angle grinders are equipped with a main rear handle and a second auxiliary handle, which can be rearranged on the body for different types of work.

To protect the operator from sparks of hot metal, the disc is covered with a steel casing, which on professional models has a device for quick rotation.

The installation of a cutting and grinding wheel in the spindle of the gearbox requires rigid fixation of the shaft. For this, a separate button is provided, by pressing which, we block the spindle and tighten the disc with a special wrench.

To attach the stripping devices on the shaft of the angle grinder there is a thread onto which nozzles with steel bristles are screwed.

The angle grinder is a fast and powerful tool. Therefore, cutting with a grinder requires strict adherence to the rules of safe work. The main ones are briefly described in the manufacturer's instructions, others can only be obtained with practical use.

In order not to expose yourself to unnecessary risks, be sure to wear durable gloves, special glasses or a mask when starting work. They will protect hands and eyes from hot metal particles that fly out from under the cutting and grinding wheel.

Answering the question, how to work with a grinder, note that the protective cover should not be removed under any circumstances. It may seem to you that it is more convenient to work without it.The cutting line can be seen better, and the circle can be supplied with a larger diameter. However, if the cut-off wheel is destroyed, the consequences of such "comfort" can be fatal.

Ideally, the workpiece should be firmly clamped in a vise. However, in practice, this is not always possible. However, do not try to hold the piece to be cut with one hand or pinch it with your feet. The angle grinder must be firmly held with both hands. In case of inaccurate contact with metal, sharp jerks occur, the tool can slip out of the hand and seriously injure the limbs.

You need to cut the metal without strong pressure, with the middle part of the circle, slowly drawing it along the cut line. When working, you need to ensure that the circle goes along the cut evenly, without bending. Otherwise, it may jam or break.

Before using a new cut-off wheel, it must be rotated in idle mode at maximum speed. This will insure you against the destruction of the defective product during operation.

When cutting a corner or channel, be sure to take into account the danger of the wheel jamming at the time of the end of the cut. Therefore, try to leave the end of the profile free and cut it from above.

It is better to cut the corner not in one pass, but in two, sequentially cutting each of its shelves.

Any break in work and replacement of the disc must be started by disconnecting the grinder from the network. Accidentally pressing a trigger button that is not protected by the self-locking device may turn on the tool.

When working, one should try to avoid getting the face and body into the plane of rotation of the disk, where an active ejection of hot particles of abrasive and metal occurs.

The cutting area must be free of flammable and flammable materials. Before picking up the angle grinder, look at your clothes. It should not have long sleeves or dangling parts that might wind around the shaft.

Even with minimal damage to the wheel (cutting edge stripping), throw it away without regret. Working with a broken circle is fraught with its complete destruction, which very rarely does without injury.

Choosing a grinder for home

You don't need an expensive professional tool for home use. However, you should not buy too cheap models, the resource of which is calculated in several hours.

Remember that a good grinder should have a soft starter that eliminates jerks. A lot of useful information about this tool can be found in user reviews. They objectively tell about the shortcomings and positive qualities of LMMs from different manufacturers and often give practical advice.

Please pay attention to the gear housing before purchasing. It must be made of steel or magnesium alloy

Aluminum and even more so plastic are signs of a low-grade tool. A useful option is to adjust the wheel rotation speed, and for powerful grinders - a blocking device when jammed.

Security is never overkill

Therefore, pay attention to angle grinders, which have protection against restarting

Another piece of advice on how to choose a grinder for your home is a mandatory test run of the tool and an ergonomics test. If the hand does not feel a strong vibration at idle speed, this indicates a high-quality assembly.

Reliable protection of the motor and bearings from dust is also very important. If the manufacturer has not thought about this, then the angle grinder will not work for a long time.

When deciding which grinder is better to buy, trust the products of well-known companies. Despite the higher cost, such a tool compares favorably with cheap models in controlled quality and well thought out design.

Useful video on the topic:

Es-TkW0Nflo

Examples of models of cordless grinders

Metabo W 18 LTX 150

Portable angle grinder Metabo W 18 LTX 150 has a small thickness for a comfortable grip during operation. Work is carried out from a Li-Ion battery 18 V with a capacity of 5.2 Ah. The weight of the grinder without the battery is about 2.8 kg.When delivered without a battery and charger, the Metabo W 18 LTX 150 will cost 12-13 tons.

The scope of delivery includes support flange, handle, dust filter, protective cover, quick-clamping nut. The grinder is equipped with protection against overheating and restarting. Smooth start-up and comfortable grip ensure comfortable operation.

Bosch GWS 18 V-Li Solo

This model of a well-known manufacturer is equipped with a brush motor and is designed to work with metal (cutting, cleaning, grinding). With speeds up to 10,000 rpm, metal is cut quickly and effortlessly.

AEG BEWS 18-125X-0

LBM AEG BEWS 18-125X-0 is designed for cutting metal profiles, angles, fittings and other metal products. In addition to cutting, the grinder can be used for grinding and cleaning metal surfaces using the appropriate equipment. Bulgarian AEG BEWS 18-125X-0 will cost 8 tons without a battery and charger.

Soft start is ensured by the functionlimiting the starting current. Among other things, it is worth noting the metal gearbox housing. As a result, heat dissipation during operation is improved. The anti-vibration handle reduces vibration to the hands of the person using the tool.

Ryobi R18AG-0

This inexpensive model of cordless angle grinder works with circles with a diameter of 115 mm. With the help of the Ryobi ONE + R18AG-0 5133001903 grinder, you can cut and grind metal, as well as process stone.

Diold AMSHU-24-01

LBM on the battery Diold AMSHU-24-01 operates from a nickel-cadmium battery with a voltage of 24 volts. Its capacity is 2 Ah. The model works with cutting and grinding wheels with a diameter of 115 mm.

Spindle diameter 14 mm. The electric motor spins it up to 7000 rpm. For quick and convenient replacement of discs, a spindle lock button is provided. The Diold AMShU-24-01 delivery set includes two batteries. In this configuration, the tool will cost the buyer 7─7.5 tons.

Encore AccuMaster AKM1825

Another inexpensive model. Cordless angle grinder Enkor AccuMaster AKM1825 is designed for cutting, cleaning and grinding metal structures. The small diameter of the body and the comfortable grip ensure comfortable working with the tool.

DEWALT DCG414N

The DEWALT DCG414N cordless grinder is based on a brushless electric motor. It can be used for a wide variety of cutting and grinding jobs. The brushless type of motor has high performance and long service life. The spindle speed reaches 9000 rpm.

The electric motor is resistant to overload, and the model also has a kickback protection system if the disc is jammed. LBM works with discs with a diameter of 125 mm. Weight without battery is 2.2 kg. The cost without a charger and a battery is about 17 tons.

The rechargeable battery is not included in the delivery set. The manufacturer recommends using the XR FLEXVOLT 54 V with a nominal voltage of 54 volts.

LBM Elitech MSHU 18BL is used for cutting and grinding steel materials, as well as stone.

FLEX ACCU 18.0-EC / 5.0 Set

Cordless angle grinder FLEX ACCU 18.0-EC / 5.0 Set is often used in small businesses and households. The tool can often be found in production and in various small workshops. The model is used for cutting and grinding metal products and stone, cleaning from paintwork materials and rust.

SAFUN CAG-18-115

LBM on the SAFUN CAG-18-115 battery has a brushless motor in its design. It provides high performance and long service life. The standard spindle lock allows quick wheel changes. Cutting and grinding wheels 115 mm are used here.

Among the advantages, the manufacturer notes the brushless motor, which has a long service life, as well as a high level of ergonomics and safety. A soft start is provided, which avoids jerking at the start. As a nice addition, there is battery charge indicator.

Verified brands and price range

To buy a reliable tool that will serve you for many years, you should consider only trusted manufacturers and do not skimp on the purchase. After analyzing the reviews of ordinary consumers and professional users, we have identified several of the most popular brands:

- STURM is a proven German-Chinese co-production company. One of the popular models, which is suitable for home and summer use, can be distinguished - AG9512P. The diameter of the working disk is 125 mm, while the machine produces a power of 1 kW with a number of revolutions from 4 to 11 thousand rpm. It has a comfortable weight - only 2.5 kg and a reasonable price - about 3800 rubles. equipped with such additional functions as speed control, soft start, anti-jamming protection. The handle can be adjusted in three different positions.

- Makita is a well-known brand for the production of hand tools. Manufactured in Japan, there are factories in China and Romania. An inexpensive but high quality model that is suitable for both home and professional use is the 9555 HN model. The diameter of the disc is also 125 mm, the power is slightly lower - 0.71 kW. The number of revolutions reaches 10 thousand rpm. This model is lighter at 1.9 kg, but is not equipped with any additional features. Its cost is about 3600 rubles.

- Metabo, Germany. For heavier construction work, which involve the processing of stone or concrete, the W 2000 model is suitable. It has a maximum working disc diameter of 230 mm, an impressive power of 2 kW and a weight of 5.8 kg. The number of revolutions is about 6.6 thousand rpm. Equipped with a function of protection against premature start. The price of this model is about 6900 rubles.

- DeWALT doesn't even need a description. Manufactured in the USA. Of the more powerful and professional models, a medium-sized model can be distinguished - D 28136. The disc diameter is 125 mm, the power reaches 1.5 kW, and the speed ranges from 2.8 to 10 thousand rpm. The tool weighs 2.6 kg. It is sold complete with a case, has the function of adjusting the speed, soft start and protection against intentional start. For a single use at home, it has a high price - 7800 rubles, but for professional use it is optimal.

- Sparky is a real Bulgarian made in Bulgaria, which is where the name comes from. Among the entire range, the M 850E will be the most suitable for home use, reliable and compact. Its weight is 2.4 kg, the diameter of the working circle is 125 mm. The machine has a power of 0.85 kW and a speed of revolutions from 3 to 10 thousand rpm. Equipped with speed control function and soft start. The price is about 3700 rubles.

- Among domestic manufacturers, one can single out the Energomash brand and its model UShM-9512P, which is suitable for working in an apartment or in the country. This model is not recommended for continuous operation for a long time, there is a risk of overheating. The tool weighs 2.5 kg, has a power of 0.85 kW and a rotation speed of 3-10 thousand rpm. The diameter of the disc is 125 mm, the price is in the region of 3700 rubles.

- "SPETS" is another worthy representative of domestic production. The BSHU-1050 model is distinguished by its low cost - only 2,100 thousand rubles and a good price / quality ratio. Suitable for small household chores. It has no additional functions. Working diameter 125 mm, power 1.1 kW. The number of revolutions is 11 thousand rpm. Machine weight - 2.3 kg.

Choosing such a necessary tool, you should not buy it in obscure places. It is better to go to a specialized store, be sure to check the operability on the spot, carefully inspect all the connections, clarify whether there is a guarantee, and what kind of product is included

Pay attention to the start button, or rather to its size. It should be large enough so that even with rough gloves you will not have difficulty turning on

How to choose the right grinder?

An unambiguous answer to the question: "which grinder is better?" does not exist. To choose the right one, you need to clearly understand what specific work it will be designed for. Consider the main parameters of the device that affect the choice of the grinder:

Disk

The disc, cutting or grinding, is the main working body of the tool. The diameters of the discs offered vary from 100 to 500 mm, the most common are the sizes 115, 125, 150 and 200 mm.

On the angle grinder, you can put working bodies of a smaller diameter, provided that the mounting hole is suitable and it will reach the part. Installing a disk larger than indicated in the device passport is unacceptable. This can cause pendants in the breakage of the angle grinder and cause serious injury.

Cutting disc for wood

The diameter of the disc determines the thickness of the material you can cut:

- construction and repair on your site, body repair, profile cutting up to 40 mm, cutting steel sheets - it is appropriate to choose a device with a small disc 115-125 mm;

- occasional cutting of a more massive profile up to 50 mm, two-inch pipes will require choosing a medium grinder with a 180-mm disc;

- continuous cutting of thick pipes and rolled products - it is reasonable to choose a professional grinder with 200-230 mm discs;

- for cutting massive building structures, rails, large pipes, it is better to choose with a gasoline drive, a 400mm disc.

The larger the diameter, the more massive and heavier the car, the more difficult it is to hold it in your hands for a long time.

Power

The drive power is divided into:

- household 300-900 watts;

- professional 1 - 5 kilowatts.

More power means faster cutting speed, larger maximum disc size, greater material thickness.

Grinder Dexter Power, 750 W

On the choice of capacity, experts agree on the following:

- for occasional use on the site, it is enough to choose a household appliance with a capacity of 400-700 watts;

- for long-term use, for example, in a procurement area of a small production, you will need to choose a device already 900-1500 watts;

- for use on construction sites, cutting reinforcement, cutting concrete, it is better to choose a device of 1.5-2.5 kilowatts.

More power means more weight as well as more energy consumption. If you cut thin corners with a powerful machine, most of the electricity will be wasted. With large volumes, this can amount to noticeable amounts.

Speed

A very important characteristic that determines the performance of a device. For different classes of devices it can be from 2,500 to 12,000 rpm, and the best grinders develop up to 15,000. Most models have an operating range of 3000-6000 rpm. For household models, this parameter is not adjustable. It is selected at the design stage.

Good professional grade grinders have speed control. This is very useful for extended use with different discs. Keeping a large grinder at full throttle is difficult.

Grinder Titan with speed control

For different applications, there are their optimal speeds:

- for household applications, it is quite enough to choose a grinder with a speed of up to 6000;

- in small industries related to cutting sheet blanks, cutting metal rolling, it is better to choose devices for 7000-12000 rpm;

- a car service for cleaning body parts before painting or welding will need to choose a grinder with a rotation speed of up to 15,000 rpm, this will save a lot of time on mass operations.

The best grinders are equipped with a smooth adjustment of the number of rotation speed, which allows you to accurately select the optimal rotation speed for each operation.

Number of handles

The number of handles indirectly indicates the class of the instrument and determines the convenience and safety of using the device.

A home grinder usually has one side handle.It can be rearranged to the left or right, depending on how it is more convenient to get to the working area. With the other hand, the operator holds the tool by the body. With low power, weight, dimensions, it is quite convenient.

Micro grinder

This grip is not suitable for powerful, heavy, oversized professional models. The body simply cannot be wrapped around with one hand. Therefore, for such models, two rubberized handles are provided. Their location depends on the purpose of the device. On the best models, the handles are also adjustable.

Varieties

Depending on the place of work, the intended tasks, the need for mobile movement over long distances around the working area, the availability of energy sources for the operation of angle grinders, and other factors, grinders are classified into several categories, each of which has its own subdivision - by functionality, power, size , diameter, etc.

For example, for work on a personal plot or in a garden, an electric grinder and a gasoline angle grinder may be suitable - it all depends on the area of the territory. If the garden is large, it is problematic and unsafe to constantly move the electric carrier around the site, and here a more effective solution would be to use a rechargeable or gasoline sander. For professional use, pneumatic powerful models are perfect.

Electrical

Both home low-power tools and professional angle grinders operate from 220 V. Tool mobility is limited by the length of the cable and carrying. Perfect for housework, in an apartment, in the country - it works with any type of disks, so there are no restrictions on functionality. The popular model is with Ø 115 mm or Ø 125.

|

|

Rechargeable

Rechargeable angle grinders for household and professional use differ from stationary electric models in the configuration of the case - it provides a recess for a lithium-ion battery with a voltage of 18 volts. Due to the low power, the grinder is usually not supplied with a handle for holding - it is held immediately by the body. Discs cannot be of a wide assortment due to power limitations - maximum Ø 150 mm. Most often, the choice of a 125 mm grinder is the most demanded.

|

|

Gasoline

A large body with a tank for fuel and internal combustion engines is a distinctive feature of all gasoline angle grinders. Large weight and dimensions forced the designers to make a heavy frame and an additional handle-holder. The gasoline sander works with large diameter wheels, has increased power, mobility and duration of work.

|

|

Pneumatic

The grinder on the pneumatic drive does not have its own motor, and the disk rotates from the application of pressure to the gearbox blades created by the air flow from an external compressor.This cutting tool can work without stopping any time until the disc is erased, since the angle grinder does not threaten overheating.

|

|